“Unrivaled Reliability with SourcifyChina’s Best CNC Plasma Cutter: Top Choice for Precision Manufacturing”

Discover the unmatched dependable performance of SourcifyChina’s best CNC plasma cutter, designed for precision and reliability. Ideal for industries demanding excellence, this cutting-edge machinery ensures superior quality and efficiency in every cut. Choose reliability, choose SourcifyChina.

Why Choose SourcifyChina Factory for Buying the Best CNC Plasma Cutter from China?

SourcifyChina Factory offers high-quality CNC plasma cutters, ensuring precision and efficiency in every cut. Their advanced technology and rigorous quality control make them a trusted choice for buyers seeking reliable machinery.

The factory provides competitive pricing without compromising on quality. This balance of affordability and excellence makes SourcifyChina a top contender in the CNC plasma cutter market, especially for cost-conscious buyers.

SourcifyChina emphasizes exceptional customer service, offering comprehensive support from pre-purchase consultations to post-purchase technical assistance. This commitment ensures a smooth purchasing experience and ongoing satisfaction.

Their CNC plasma cutters are designed with user-friendly features and durability in mind, catering to various industrial needs. Buyers can trust in the longevity and performance of their equipment.

Choosing SourcifyChina Factory means benefiting from their extensive industry experience and expertise. Their knowledgeable team ensures you receive the best product recommendations tailored to your specific requirements.

In conclusion, SourcifyChina Factory stands out for its high-quality products, competitive pricing, exceptional customer service, user-friendly designs, and industry expertise. These attributes make it the ideal choice for purchasing CNC plasma cutters from China.

When seeking the best CNC plasma cutter, factors such as cutting precision, power, and versatility are pivotal. High-quality machines often feature robust construction, intuitive controls, and advanced software compatibility.

– Hypertherm Powermax45 XP: Renowned for its versatility and precision, suitable for both light and heavy-duty cutting.

– Miller Spectrum 625 X-TREME: Compact yet powerful machine, ideal for professionals needing portability and power.

– Lincoln Electric Tomahawk 1000: Offers top-tier cutting performance with user-friendly features and excellent customer support.

– Lotos LTP5000D: Budget-friendly option providing solid performance for hobbyists and small shops.

– Razorweld Razorcut45: Known for its reliability and consistent performance, making it a great mid-range option.

– Eastwood Versa-Cut 60: A robust choice for demanding jobs, known for its ease of use and powerful cutting capabilities.

– Everlast PowerPlasma 62i: Ideal for a range of applications, this model combines power and precision with user-friendly interfaces.

– Hobart AirForce 27i: Integrates portability with efficiency, perfect for DIY enthusiasts and smaller projects.

– PrimeWeld CUT60: Offers professional-level performance at an affordable price, known for its efficiency and ease of use.

Choose a CNC plasma cutter based on specific needs, considering factors like cutting thickness, material compatibility, and budget. Advanced features like automatic torch height control, pilot arc starting, and CNC software integration can significantly influence performance and user experience.

A CNC plasma cutter is a versatile tool widely used in industries for precise cutting of metals. It’s ideal for applications requiring speed, accuracy, and efficiency. Here are some of its key applications:

– Metal Fabrication: Used in creating metal components for machinery and structures.

– Automotive Industry: Cutting car parts and chassis with precision.

– Construction: Fabricating steel beams and other structural elements.

– Art and Design: Crafting intricate metal art pieces and custom designs.

– Repair and Maintenance: Cutting and shaping replacement parts on-site.

– Shipbuilding: Creating large metal sections for ships and submarines.

– Manufacturing: High-speed cutting for mass production of metal parts.

– Agriculture: Producing durable farming equipment components.

– Aerospace: Cutting lightweight yet strong materials for aircraft construction.

– Prototyping: Quickly creating prototypes of metal parts for testing and development.

These applications highlight the versatility and essential nature of CNC plasma cutters in various industries.

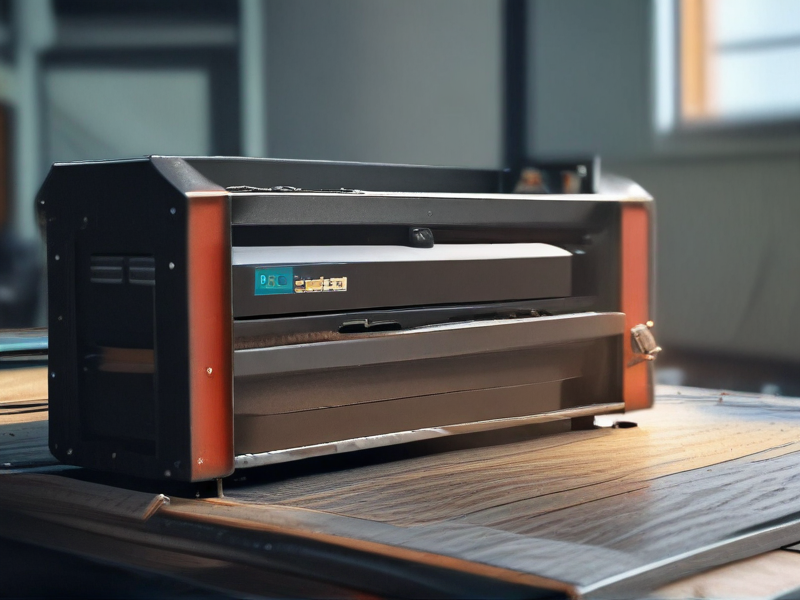

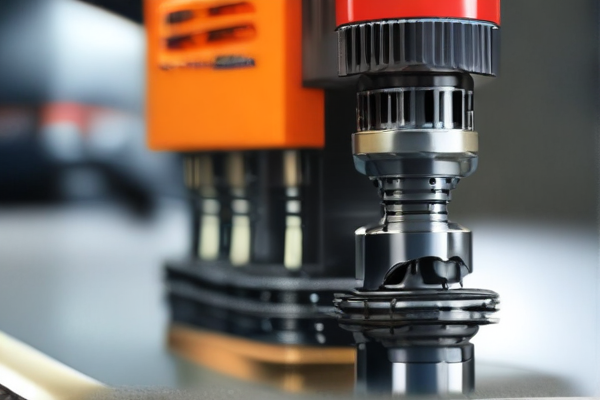

The SourcifyChina best CNC plasma cutter is crafted with high-grade stainless steel, ensuring durability and resistance to corrosion. This material choice provides the cutter with a robust frame, ideal for heavy-duty operations.

Precision components within the machine are made from hardened steel. This selection enhances the accuracy of cuts, contributing to the device’s superior performance and long-lasting functionality.

The cutting bed is constructed from reinforced aluminum. This lightweight yet sturdy material supports the workpiece effectively, minimizing vibrations and ensuring smooth, precise cuts.

To enhance user experience, ergonomic controls and housing are designed with high-quality polymers. These materials offer durability while maintaining comfort and ease of use during extended operation sessions.

SourcifyChina employs a rigorous quality control process for its CNC plasma cutters to ensure exceptional performance. Each cutter undergoes precise calibration and testing to meet strict industry standards, ensuring accurate and consistent cuts.

The manufacturing process includes sourcing high-quality materials and components, followed by meticulous assembly by skilled technicians. This attention to detail guarantees the longevity and reliability of the CNC plasma cutters.

Advanced inspection techniques are used at each production stage to detect and address any potential defects early. This proactive approach minimizes downtime and enhances overall product quality.

Before shipment, every CNC plasma cutter undergoes a final comprehensive testing phase. This step ensures each unit functions optimally and meets the performance expectations set by SourcifyChina.

Customer feedback is continuously integrated into the manufacturing process, fostering ongoing improvements and innovation. This commitment to quality and excellence distinguishes SourcifyChina’s CNC plasma cutters in the competitive market.

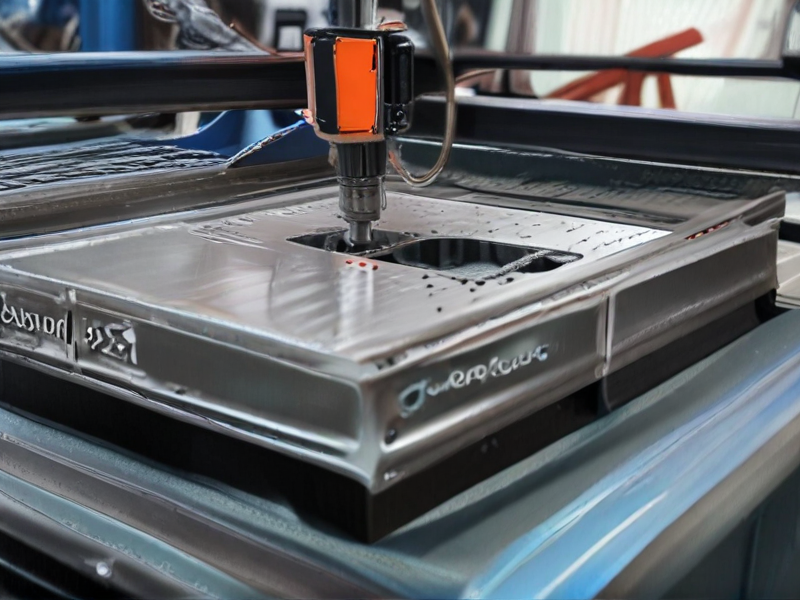

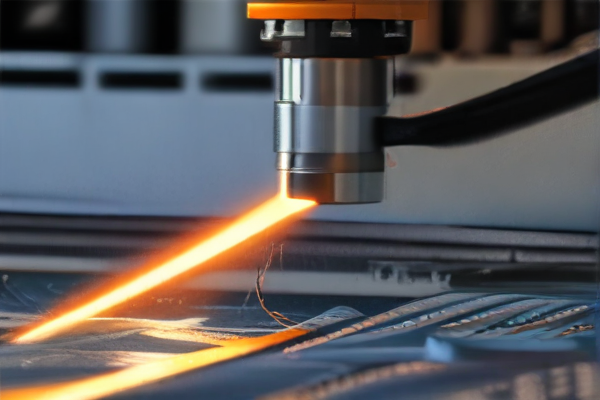

The SourcifyChina best CNC plasma cutter offers unparalleled precision thanks to its advanced computer numerical control (CNC) systems. This ensures detailed and accurate cuts, minimizing waste and maximizing efficiency.

Equipped with state-of-the-art plasma technology, it can cut through various metals such as steel, aluminum, and copper with remarkable speed. This versatility makes it a valuable asset for diverse industrial applications.

The machine also features an intuitive user interface, facilitating ease of operation for both seasoned professionals and novices. This user-friendly design minimizes training time and enhances productivity across different skill levels.

Durability and reliability are cornerstones of the SourcifyChina CNC plasma cutter. Constructed with high-quality materials, it’s built to withstand the rigors of industrial use, providing long-term operational stability and reduced maintenance costs.

Safety is a top priority, as evidenced by its comprehensive safety features. These include emergency stop buttons, protective shields, and automated monitoring systems to ensure a secure working environment.

To top it off, the cutter supports integration with various software platforms. This compatibility allows for seamless transitions from design to execution, enabling customized cutting projects with high precision and consistency.

In summary, the SourcifyChina best CNC plasma cutter combines precision, versatility, user-friendliness, durability, safety, and software integration to deliver unparalleled cutting performance. These capabilities make it a top choice for professionals seeking efficiency and accuracy in their metalworking projects.

A top-of-the-line CNC plasma cutter offers precision, versatility, and efficiency, making it an invaluable tool in metal fabrication industries. These advanced machines provide numerous benefits.

– High Precision and Accuracy: CNC plasma cutters deliver exact cuts, reducing material waste and ensuring consistent quality in production.

– Versatility: Suitable for various metals including steel, aluminum, and copper, allowing for a broad range of applications.

– Increased Productivity: Automated controls and quick cutting speeds result in faster project completion.

– Cost Efficiency: Reduces labor costs and material waste, enhancing overall operational cost savings.

– Ease of Use: User-friendly interfaces and minimal training requirements make these machines accessible to operators.

– Consistency: Ensures repeatable results, crucial for large-scale manufacturing projects.

– Safety: Advanced safety features and reduced manual handling lower the risk of workplace accidents.

– Customization: Capable of handling complex designs and intricate patterns efficiently.

– Durability: High-quality machines have long lifespans and require minimal maintenance.

Thus, the best CNC plasma cutters are investments that provide robust returns in precision, productivity, and cost savings.

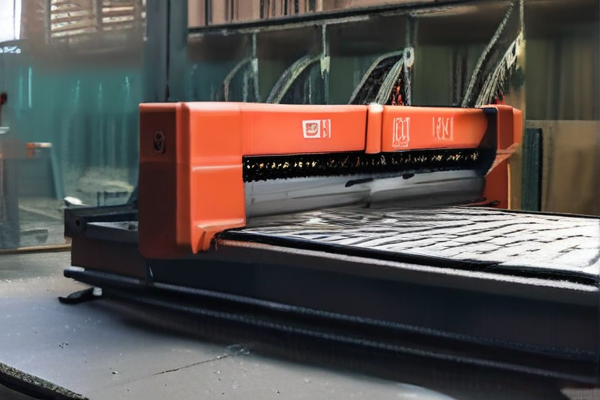

A top-tier CNC plasma cutter stands out for its precision, efficiency, and versatility, making it an indispensable tool for fabricators and manufacturers.

– Precision Cutting: High-definition plasma systems achieve sharp and accurate cuts on various metals.

– Versatility: Capable of cutting various materials including steel, aluminum, and brass.

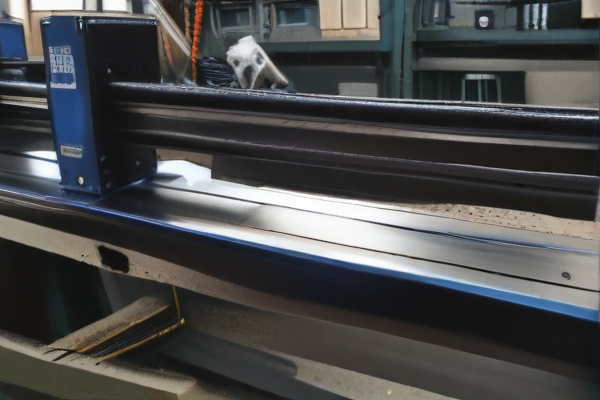

– Durable Construction: Built with high-quality materials to withstand heavy-duty usage.

– User-Friendly Interface: Intuitive software and control panels for easy operation.

– High Cutting Speed: Efficiently cuts through thick materials at rapid speeds.

– Consistent Performance: Delivers reliable results with minimal maintenance.

– Safety Features: Equipped with safety mechanisms like automatic shut-off and protective covers.

– Cost-Efficiency: Low operational costs and extended machine life.

– Automated Capabilities: Supports automated cutting processes for enhanced productivity.

– Portability: Some models are designed to be portable for easy transportation and onsite work.

– Advanced Technology: Incorporates features like torch height control and nesting software for optimized cutting paths.

– Strong Support and Service: Comes with robust customer support and readily available repair services to minimize downtime.

Investing in a high-quality CNC plasma cutter ensures superior cut quality, operational efficiency, and long-term reliability, streamlining manufacturing processes and enhancing overall productivity.

SourcifyChina’s best CNC plasma cutter offers unparalleled precision for custom products and projects. With advanced technology, it ensures accurate cuts for a variety of materials, enhancing the quality and efficiency of production processes.

Their CNC plasma cutter supports intricate designs, making it ideal for custom metalwork, signage, and artistic projects. Businesses and craftsmen benefit from its reliability and versatility, tailoring each piece to specific needs.

SourcifyChina’s commitment to innovation is evident in their CNC plasma cutter, which is designed to handle both small-scale and large-scale production with ease. Its robust construction and user-friendly interface simplify complex tasks.

For bespoke projects requiring high precision, SourcifyChina’s CNC plasma cutter is a top choice. It integrates seamlessly into existing workflows, boosting productivity and ensuring consistent results for every custom creation.

SourcifyChina is a prominent supplier specializing in CNC plasma cutters, renowned for their cutting-edge technology and high precision. Catering to industries ranging from automotive to metal fabrication, SourcifyChina offers state-of-the-art CNC plasma cutting systems known for their robustness, efficiency, and advanced automation features. Their machines stand out due to their high-speed cutting capabilities and exceptional accuracy, which is essential for producing intricate designs and complex shapes. Committed to quality and innovation, SourcifyChina integrates user-friendly interfaces and advanced control software, ensuring seamless operation and minimal downtime. The company’s comprehensive support services, including installation, training, and maintenance, underscore their dedication to customer satisfaction, making them a trusted partner for businesses seeking reliable and efficient CNC plasma cutting solutions.

In the aerospace and defense sectors, the best CNC plasma cutters are indispensable tools for manufacturing and maintaining high-performance components. These advanced cutters offer unparalleled precision and speed, crucial for fabricating intricate parts from materials such as aluminum, titanium, and high-strength steel. The ability to consistently produce parts with tight tolerances enhances the structural integrity and performance of aircraft and defense systems. Additionally, CNC plasma cutters streamline production processes, reducing lead times and costs, which is vital for meeting the rigorous demands and deadlines associated with military and aerospace projects.

Marine applications similarly benefit from the capabilities of the best CNC plasma cutters. Shipbuilding and repair require the cutting of large, thick metal sheets used in hulls, decks, and other structural components. The accuracy and efficiency of CNC plasma cutters ensure that these cuts are precise, reducing waste and the need for additional finishing work. In an industry where corrosion resistance and durability are paramount, the ability to quickly and accurately process materials like stainless steel and aluminum alloys is crucial. The robust performance of CNC plasma cutters not only improves the quality and longevity of marine vessels but also significantly enhances overall operational efficiency.

In the automotive industry, the best CNC plasma cutters are indispensable tools for precision and efficiency. These machines are used to fabricate a wide range of components, including body panels, chassis parts, and custom exhaust systems. Their ability to cut through thick metals with high accuracy reduces material waste and enhances production speed, making them ideal for both high-volume manufacturing and custom car modifications. The precision of CNC plasma cutters ensures that each part meets stringent quality standards, essential for maintaining safety and performance in vehicles. Additionally, the versatility of these cutters allows automotive manufacturers to easily adapt to design changes and produce complex shapes that are crucial for modern vehicle aesthetics and aerodynamics.

In the electronics industry, CNC plasma cutters play a critical role in the creation of enclosures, brackets, and intricate components for various devices. These machines can precisely cut thin metals and conductive materials used in electronic assemblies, ensuring clean edges and accurate dimensions. This precision is vital for fitting components into tight spaces and ensuring proper alignment in electronic products. Moreover, CNC plasma cutters facilitate rapid prototyping and small-scale production runs, which are common in the electronics sector due to the fast-paced nature of technological advancements. By employing these cutters, electronics manufacturers can quickly iterate designs and bring new products to market efficiently, maintaining a competitive edge in the industry.

The “best CNC plasma cutter” revolutionizes the construction industry by providing precision and efficiency in cutting various metals. Its ability to produce clean, accurate cuts on steel, aluminum, and other metals makes it indispensable for fabricating structural components, creating detailed metal frameworks, and crafting custom architectural elements. The automation and precision offered by CNC (Computer Numerical Control) technology reduce manual labor and minimize material wastage, ensuring cost-effectiveness and high-quality outcomes. With advancements in software and hardware integration, these plasma cutters can execute complex designs and patterns with ease, enhancing the overall productivity and capability of construction projects.

In the energy sector, CNC plasma cutters play a crucial role in the manufacturing and maintenance of equipment and infrastructure. They are essential for cutting parts used in power plants, pipelines, and renewable energy installations like wind turbines and solar panel mounts. The high precision and speed of these cutters enable the production of intricate components required for efficient energy systems, ensuring tight tolerances and reliable performance. Additionally, CNC plasma cutters are valuable in repair and retrofitting operations, allowing for quick and accurate modifications to existing systems, which is vital for maintaining operational efficiency and extending the lifespan of energy infrastructure. This technology not only enhances production quality but also supports sustainable practices by optimizing material usage and reducing waste.

In the industrial equipment sector, the application of best CNC (Computer Numerical Control) plasma cutters significantly enhances precision, efficiency, and versatility in metal fabrication processes. These advanced machines leverage high-powered plasma jets to cut through various types of metals, such as steel, aluminum, and copper, with remarkable accuracy. Industries like automotive, aerospace, and construction extensively use CNC plasma cutters to streamline production processes, reduce material waste, and produce complex metal parts with tight tolerances. The precision and speed of CNC plasma cutters also enable manufacturers to handle large-scale production runs and custom designs effectively, thereby improving overall productivity and operational costs.

Beyond basic cutting, the best CNC plasma cutters integrate advanced features such as automated height control, multi-axis capabilities, and nesting software, which optimize material usage and further enhance operational efficiency. These features allow for intricate cuts and detailed patterns that are difficult to achieve with traditional cutting methods. In heavy industries, where downtime can be costly, the reliability and minimal maintenance requirements of high-quality CNC plasma cutters ensure consistent performance and reduce the likelihood of production delays. As a result, the adoption of these advanced plasma cutting technologies is pivotal in maintaining competitive advantage and operational excellence in the industrial equipment industry.

CNC plasma cutters have revolutionized the production of medical devices by offering unparalleled precision and efficiency. These advanced cutting machines are equipped with computer numerical control (CNC) systems, enabling them to make intricate and precise cuts in various materials, including metals and plastics commonly used in medical device manufacturing. The ability to produce complex shapes and detailed components with minimal human intervention ensures high levels of consistency and quality, which are crucial in the medical field. For instance, CNC plasma cutters can be used to create parts for surgical instruments, prosthetics, and implantable devices, all of which require exacting standards to ensure patient safety and effective performance.

In addition to precision, CNC plasma cutters provide significant time and cost savings for medical device manufacturers. The automation and speed of these machines reduce production time, allowing for quicker turnaround from design to finished product. This efficiency is particularly important in the fast-paced medical industry, where innovation and rapid response to market demands are critical. Furthermore, CNC plasma cutters minimize material waste through their precise cutting capabilities, which not only conserves resources but also reduces costs associated with excess material usage. This combination of precision, efficiency, and cost-effectiveness makes CNC plasma cutters an indispensable tool in the medical device manufacturing process, helping to advance the development of cutting-edge medical technologies.

The best CNC plasma cutters have revolutionized machining and manufacturing by providing precise, efficient, and versatile metal cutting capabilities. In machining, these cutters use high-velocity ionized gas to melt and cut through various metals with exceptional accuracy. This technology enables the production of complex geometries and intricate details that would be challenging to achieve with traditional methods. CNC plasma cutters are particularly valuable for creating custom parts, prototypes, and low to medium-volume production runs. Their ability to cut through thick metals, such as steel and aluminum, without significant thermal distortion enhances their appeal in industries where precision and material integrity are crucial.

In manufacturing, the adoption of high-quality CNC plasma cutters enhances productivity and reduces operational costs. These cutters streamline the fabrication process by integrating with computer-aided design (CAD) software, allowing for automated, repeatable, and error-free cutting operations. This automation minimizes manual labor and reduces waste, leading to more efficient use of materials and lower production costs. Furthermore, CNC plasma cutters are versatile tools that can be employed in various sectors, including automotive, aerospace, construction, and metalworking. Their capability to produce consistent, high-quality cuts with minimal setup time makes them indispensable in modern manufacturing environments, where speed and precision are paramount.

Sure! Here are some frequently asked questions (FAQ) regarding manufacturing the best CNC plasma cutter quality work from SourcifyChina factory:

1. What sets SourcifyChina apart in CNC plasma cutter manufacturing?

SourcifyChina is renowned for its cutting-edge technology, skilled craftsmanship, and stringent quality control processes. Our extensive experience ensures high precision, durability, and performance in every CNC plasma cutter we produce.

2. What materials can SourcifyChina’s CNC plasma cutters handle?

Our CNC plasma cutters are designed to handle a variety of metals including mild steel, stainless steel, aluminum, brass, and copper. This versatility makes them suitable for a wide range of industrial applications.

3. How does SourcifyChina ensure quality in its CNC plasma cutters?

We adhere to international quality standards such as ISO and CE. Each cutter undergoes rigorous testing, including precision cuts, durability checks, and performance evaluations, to guarantee optimal functionality and longevity.

4. Are custom specifications available for CNC plasma cutters?

Yes, SourcifyChina offers customization options to meet specific needs. You can request tailor-made specifications like cutting speed, thickness, size, and additional features to suit your particular requirements.

5. What after-sales support does SourcifyChina provide for CNC plasma cutters?

We provide comprehensive after-sales support including installation assistance, technical troubleshooting, and maintenance services. Our dedicated support team ensures your CNC plasma cutter operates seamlessly.

6. What is the typical lead time for manufacturing and delivery?

Lead times vary depending on the complexity of the order but generally range from 4 to 8 weeks. We prioritize timely delivery without compromising on quality.

7. How cost-effective are SourcifyChina’s CNC plasma cutters?

Our CNC plasma cutters offer excellent value for money. Competitive pricing combined with high-quality materials and cutting-edge technology ensure cost-effective solutions for our clients.

8. Can I request a demo or sample product?

Yes, we offer demo sessions and sample products upon request. This allows you to evaluate our CNC plasma cutters’ performance and quality before making a purchase decision.

When considering the best CNC plasma cutter manufacturing from SourcifyChina factory, several key tips can guide your decision:

1. Assess Quality Standards: Ensure the factory adheres to strict quality control measures. Check for certifications like ISO 9001, which indicate a commitment to quality.

2. Evaluate Technical Specifications: Match the plasma cutter’s specifications to your needs. Consider factors like cutting speed, thickness capacity, and precision.

3. Check for Advanced Features: Look for advanced features such as automatic height adjustment, user-friendly control interfaces, and robust software integration.

4. Examine Durability and Materials: The build quality of the machine is crucial. High-grade steel and durable components will ensure longevity and reliability.

5. Customer Support and Warranty: Reliable after-sales support and a comprehensive warranty can save time and money in the long run. Ensure the factory provides these services.

6. Energy Efficiency: Consider energy-efficient models that reduce operational costs. Inquire about the power consumption of the machines.

7. Customization Options: SourcifyChina offers customization to meet specific requirements. Discuss your unique needs to see if they can tailor a solution for you.

8. Factory Reputation: Research the factory’s reputation through reviews and testimonials. Positive feedback from other customers can provide confidence in your choice.

9. Trial and Testing: If possible, request a demo or trial period to test the machine’s performance before committing to a purchase.

10. Pricing and Financing: Compare pricing with other manufacturers to ensure competitive rates. Also, check if financing options are available to ease the purchasing process.

By focusing on these aspects, you can make an informed decision and select a high-quality CNC plasma cutter from SourcifyChina factory that meets your production needs efficiently.

1. What makes SourcifyChina Factory’s CNC plasma cutters the best choice?

SourcifyChina Factory offers state-of-the-art CNC plasma cutters that are renowned for their precision, durability, and advanced technology. Their machines are equipped with features that ensure high performance and efficiency, making them a preferred choice for various industrial applications.

2. How do I determine which CNC plasma cutter is right for my needs?

Consider factors such as the material type, thickness, cutting speed, and required precision. SourcifyChina Factory provides detailed product specifications and expert advice to help you choose the best model for your specific requirements.

3. What is the average lead time for ordering a CNC plasma cutter from SourcifyChina?

The lead time varies depending on the model and order quantity. Typically, it ranges from 2 to 6 weeks. SourcifyChina Factory ensures timely delivery by maintaining a streamlined production and shipping process.

4. Are there any customization options available for CNC plasma cutters?

Yes, SourcifyChina Factory offers customization options to meet specific industrial needs. You can request modifications in terms of size, power, and additional features to tailor the machine to your exact requirements.

5. What kind of after-sales support does SourcifyChina provide?

SourcifyChina Factory provides comprehensive after-sales support, including installation assistance, training, maintenance, and troubleshooting services. They ensure that customers receive continuous support throughout the lifespan of the machine.

6. How can I place an order with SourcifyChina Factory?

You can place an order by contacting their sales team through their website, email, or phone. They will guide you through the ordering process, including product selection, customization options, and payment terms.

7. What are the payment options available?

SourcifyChina Factory accepts various payment methods, including bank transfers, credit cards, and letters of credit. They provide flexible payment terms to accommodate different customer needs.

8. Is there a warranty on CNC plasma cutters from SourcifyChina?

Yes, all CNC plasma cutters from SourcifyChina Factory come with a warranty that covers parts and labor for a specified period. This warranty ensures that you are protected against manufacturing defects and operational issues.

Sourcing the best CNC plasma cutter from a SourcifyChina factory requires a strategic approach to ensure quality and reliability. Here are key tips to guide you:

1. Research Reputable Manufacturers:

– Use platforms like Alibaba, Made-in-China, and Global Sources to identify top-rated CNC plasma cutter manufacturers. Check their ratings, reviews, and product certifications.

2. Verify Certifications and Standards:

– Ensure the factory complies with international standards (e.g., ISO 9001). Look for certifications such as CE, RoHS, and other relevant safety and quality standards.

3. Assess Manufacturing Capabilities:

– Evaluate the factory’s production capacity, technology, and equipment. A tour (virtual or physical) of the factory can provide insights into their capabilities and quality control processes.

4. Request Samples:

– Before placing a large order, request samples to evaluate the quality, performance, and durability of the CNC plasma cutters.

5. Check Customer References:

– Ask for references from previous customers, especially those in similar industries. Contact these references to gauge their satisfaction with the product and service.

6. Negotiate Terms and Pricing:

– Clearly outline your requirements and negotiate favorable terms. Ensure the contract includes details on pricing, lead times, payment terms, and warranties.

7. Quality Control and Inspection:

– Implement strict quality control measures. Hire a third-party inspection company to verify the quality of the products before shipment.

8. Understand Import Regulations:

– Familiarize yourself with the import regulations and duties of your country to avoid any legal or logistical issues.

9. After-Sales Support:

– Ensure the factory offers reliable after-sales support and spare parts availability. This is crucial for maintenance and long-term operation.

By following these steps, you can effectively source high-quality CNC plasma cutters from a SourcifyChina factory, ensuring a good balance between cost, quality, and reliability.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.