Reliable SourcifyChina Factory Offers High-Quality Automatic Tool Changer CNC Machines

SourcifyChina’s factory is renowned for its reliable automatic tool changer CNC machines, ensuring top-tier performance and efficiency for various industrial applications. Their commitment to quality and innovation sets them apart in the competitive CNC machinery market.

SourcifyChina is a renowned factory specializing in automatic tool changer CNCs, offering top-quality products at competitive prices. With advanced manufacturing capabilities, SourcifyChina ensures high precision and reliability in every machine, making it a preferred choice for buyers worldwide.

The factory’s commitment to innovation guarantees that customers receive cutting-edge technology that enhances productivity and efficiency. SourcifyChina’s CNC machines are designed to meet diverse industry standards, providing versatile solutions for various manufacturing needs.

Customer satisfaction is at the heart of SourcifyChina’s operations. Their dedicated support team provides comprehensive after-sales service, ensuring that any issues are promptly addressed and resolved. This focus on customer service builds trust and loyalty among buyers.

Additionally, SourcifyChina maintains strict quality control processes throughout the production lifecycle. From material selection to final assembly, each step is meticulously monitored to maintain the highest standards of quality. This attention to detail assures buyers of the machines’ durability and longevity.

Choosing SourcifyChina means partnering with a factory that values transparency and accountability. They provide clear communication and regular updates throughout the purchasing process, ensuring that buyers are always informed and confident in their investment.

In summary, SourcifyChina stands out as a reliable supplier of automatic tool changer CNCs from China due to its high-quality products, innovative technology, excellent customer service, stringent quality control, and transparent operations. Buyers can trust that they are making a sound investment in a product that will meet their needs and exceed their expectations.

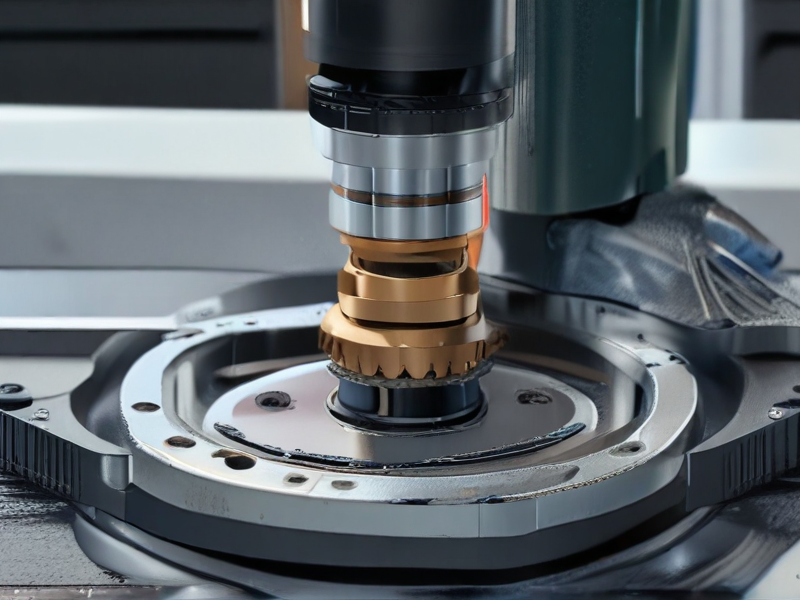

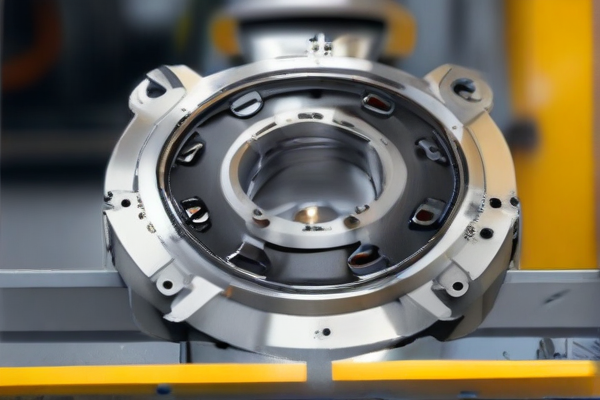

Automatic tool changers (ATCs) in CNC machines enhance productivity by enabling seamless tool switching during machining processes. They vary in types, including carousel and chain types, offering different capacities and switching mechanisms to suit diverse manufacturing needs.

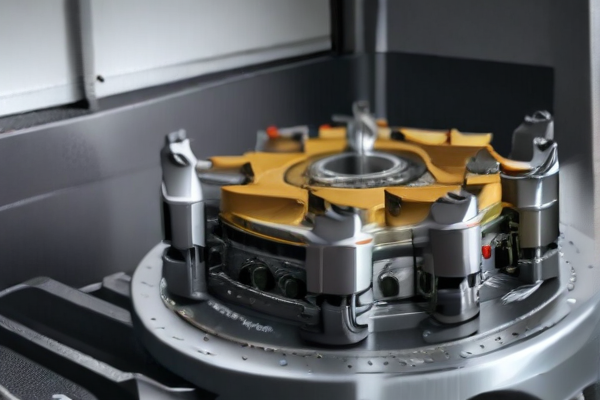

– Carousel ATCs: Circular arrangement, typically up to 24 tools.

– Chain ATCs: Linear or circular, higher capacity (up to 200 tools).

– Turret ATCs: Mounted on the spindle, faster tool changes.

– Random Access ATCs: Direct access to any tool, minimizing tool change time.

– Tool Magazines: Larger capacity, supporting various ATC types.

– Dual-arm ATCs: Two arms for simultaneous tool exchanges, enhancing speed.

– Side-mount ATCs: Attached to the machine side, saving space.

– Fixed Pot ATCs: Each tool has a fixed position, reducing retrieval time.

Each type caters to different operational needs, balancing speed, capacity, and complexity. Selecting the right ATC involves considering factors such as the type of machining, production volume, and specific machine compatibility.

An automatic tool changer (ATC) in CNC machines enhances efficiency by swiftly switching tools during machining, reducing downtime and increasing productivity. ATCs are essential in high-volume production, complex part manufacturing, and automation integration.

– High-Volume Production: Minimize manual intervention and downtime.

– Complex Part Manufacturing: Efficiently manage multiple tool changes for intricate designs.

– Automation Integration: Seamless integration into automated production lines.

– Precision and Consistency: Maintain high accuracy and uniformity across production runs.

– Versatility: Easily adapt to various machining operations without manual tool changes.

– Reduced Labor Costs: Lower the need for skilled labor to manage tool changes.

– Improved Workflow: Streamline processes and reduce bottlenecks.

– Maintenance and Reliability: Enhanced machine longevity with reduced wear from frequent manual tool handling.

– Customizability: Configure ATCs for specific production needs and tool requirements.

– Safety: Reduce operator risk by automating tool changes.

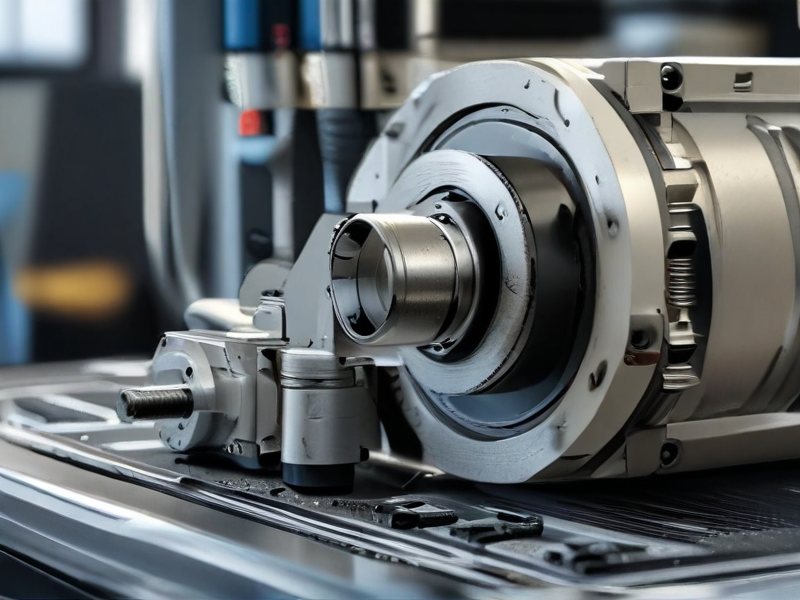

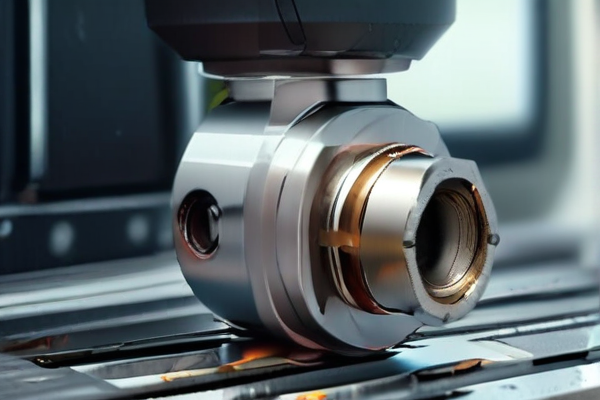

The “SourcifyChina Automatic Tool Changer CNC” is primarily constructed using high-grade steel for its structural components, ensuring durability and long-term reliability. This material choice enhances the machine’s ability to withstand rigorous industrial operations.

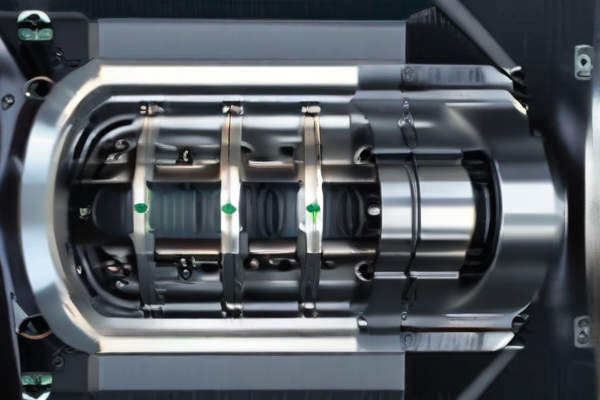

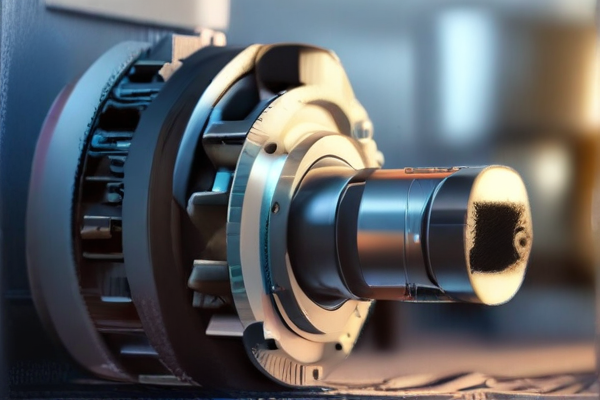

The tool changer’s spindle is often made from hardened steel, providing the necessary strength to handle high-speed machining tasks. Its precision is maintained through advanced manufacturing techniques, assisting in delivering consistent results.

The housing and various external fixtures are usually crafted from aluminum alloys. These alloys are lightweight yet strong, offering corrosion resistance and contributing to the overall efficiency and performance of the CNC machine.

Plastic and composite materials are utilized for non-critical components and covers. These materials help in noise dampening and aesthetics without compromising the machine’s structural integrity or operational efficiency.

Electrical components and wiring harnesses are typically made from high-quality copper and insulated materials. These ensure efficient power distribution and data transfer, vital for the machine’s automated and precise functions.

All these materials are selected to complement each other, resulting in a robust and efficient CNC machine. This combination allows the “SourcifyChina Automatic Tool Changer CNC” to meet a wide range of industrial requirements, offering both precision and longevity.

SourcifyChina ensures the high quality of its automatic tool changer CNC machines through rigorous quality control processes. Each machine undergoes several inspection stages, from initial material selection to final product testing, to guarantee durability and precision.

During material selection, SourcifyChina partners with ISO-certified suppliers to acquire high-grade metals and electronic components. Every batch of raw materials is tested for compliance with industry standards, ensuring each part meets the company’s stringent specifications.

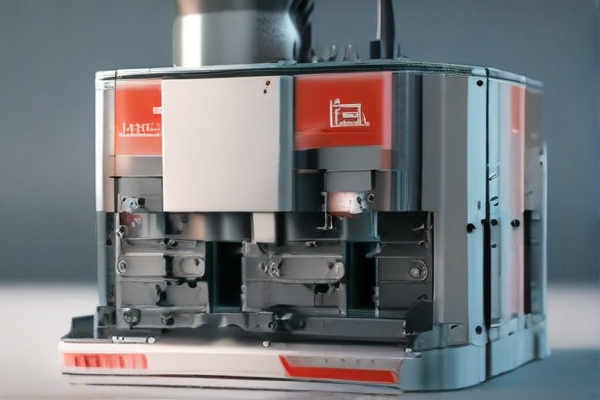

In the assembly phase, skilled technicians, equipped with advanced tools, meticulously construct each CNC machine. All components are assembled under strict protocols to maintain structural integrity and accurate functionality.

After assembly, each machine is subjected to performance tests under real operational conditions. High-precision sensors and diagnostic tools assess critical factors such as spindle speed, tool change accuracy, and overall system reliability against predefined benchmarks.

Quality control doesn’t end at performance testing. SourcifyChina ensures long-term reliability by implementing stress tests that mimic prolonged usage. Engineers review data from these tests to identify potential flaws, leading to adjustments and improvements as needed.

Finally, each CNC machine undergoes a comprehensive final inspection before shipment. This includes a thorough verification of mechanical and electronic systems, ensuring every product meets the company’s high-quality standards.

Through these meticulous quality control measures, SourcifyChina maintains its reputation for manufacturing reliable, high-performance automatic tool changer CNC machines, offering customers confidence and satisfaction with each purchase.

The SourcifyChina automatic tool changer CNC machine is a versatile and efficient piece of equipment designed for high-precision machining tasks. It boasts a rapid tool change capability, minimizing downtime and increasing productivity.

Equipped with advanced servo motors, the machine ensures precise and consistent performance, making it suitable for intricate and complex designs. Its robust construction provides stability, allowing for high-speed operations without compromising accuracy.

The user-friendly interface of the SourcifyChina CNC machine simplifies programming and operation, making it accessible even to operators with limited experience. It supports various programming languages, enhancing its versatility across different machining applications.

Furthermore, the automatic tool changer can accommodate a wide range of tool sizes and types, catering to diverse machining needs. This flexibility allows manufacturers to handle multiple processes within a single setup, streamlining workflows.

Overall, the SourcifyChina automatic tool changer CNC machine is a reliable and efficient solution for modern manufacturing, offering high precision, versatility, and ease of use. Its advanced features ensure that it can meet the demands of various industries, from aerospace to automotive, with superior performance and productivity.

An automatic tool changer (ATC) in CNC machines enhances efficiency and precision, making them invaluable for complex manufacturing tasks. Here are some benefits of using ATC in CNC machines:

– Increased Productivity: ATCs significantly reduce the downtime associated with manual tool changes, allowing for continuous operation and higher throughput.

– Enhanced Precision: Consistent tool changes ensure accurate machining, reducing the risk of human error.

– Cost Efficiency: Minimizes labor costs and tool wear by optimizing the tool change process.

– Versatility: Enables the machine to perform multiple tasks without manual intervention, increasing the range of operations.

– Improved Safety: Reduces the need for operator interaction with the machine, lowering the risk of accidents.

– Reduced Setup Time: Speeds up the preparation for different machining tasks, enabling quicker transitions between jobs.

– Consistent Quality: Maintains consistent quality of the finished product by ensuring the correct tool is always used.

– Integration with Automation: Can be easily integrated into automated production lines, enhancing overall manufacturing efficiency.

– Inventory Management: Helps in better tool management and inventory control, ensuring the right tools are always available.

– User-Friendly: Modern ATCs often come with user-friendly interfaces, making them easier to operate and maintain.

Overall, ATCs are a crucial component in modern CNC machining, driving improvements in productivity, precision, and operational efficiency.

An automatic tool changer (ATC) in CNC machines enhances productivity and efficiency by swiftly swapping tools during machining processes.

– Increased Efficiency: Reduces downtime by quickly changing tools without manual intervention.

– Tool Storage: Houses multiple tools in a magazine, ready for automatic selection.

– Precision: Ensures accurate tool positioning and alignment.

– Flexibility: Accommodates various tool sizes and types for diverse machining tasks.

– Reduced Manual Labor: Minimizes operator involvement in tool changes, enhancing safety.

– Consistency: Maintains consistent tool changes for uniform production quality.

– Enhanced Productivity: Speeds up production cycles, increasing throughput.

– Error Reduction: Lowers the risk of human errors in tool handling.

– Versatility: Suitable for complex machining operations requiring multiple tools.

– Integration: Easily integrates with CNC machine controls for seamless operation.

SourcifyChina specializes in custom automatic tool changers for CNC machines, offering innovative solutions tailored to specific client needs. Their products enhance efficiency and precision in manufacturing processes.

Each custom tool changer is designed to integrate seamlessly with various CNC systems, ensuring minimal downtime and maximum productivity. SourcifyChina prioritizes reliability and durability in their designs.

Their team of experts works closely with clients to understand their unique requirements, developing bespoke solutions that cater to a wide range of industries. This collaborative approach ensures optimal performance and satisfaction.

In addition to product development, SourcifyChina provides comprehensive support and maintenance services, ensuring long-term operational success for their clients. Their commitment to excellence and customer satisfaction sets them apart in the industry.

SourcifyChina is a pioneering company specializing in the development and innovation of automatic tool changers for CNC machines. Renowned for their commitment to precision engineering and advanced manufacturing technologies, SourcifyChina has emerged as a trusted name within the global CNC sector. Their state-of-the-art automatic tool changers are designed to optimize productivity and efficiency, reducing downtime and increasing the versatility of CNC machines in various industrial applications. By focusing on robust quality control and rigorous testing protocols, SourcifyChina ensures that each product meets stringent international standards, catering to a diverse clientele ranging from small manufacturing units to large-scale production facilities. With a relentless emphasis on customer satisfaction and continuous improvement, SourcifyChina remains at the forefront of innovation, continually adapting to the evolving demands of the CNC automation industry.

The application of Automatic Tool Changer (ATC) CNC (Computer Numerical Control) systems in the aerospace, defense, and marine industries revolutionizes manufacturing efficiency and precision. In aerospace and defense sectors, stringent requirements for accuracy and material durability necessitate advanced machining techniques that ATC-equipped CNC machines provide. These systems facilitate the rapid swapping of diverse cutting tools, enabling complex geometries and materials, such as titanium and composites, to be machined with high precision and minimal downtime. The automation and versatility afforded by ATC CNCs significantly reduce cycle times and operational costs, enhancing the production of aircraft components, missile parts, and satellite structures, thereby meeting stringent regulatory and performance standards.

In the marine industry, ATC CNC machines contribute to the effective fabrication of intricate and large-scale components, such as propellers, engine parts, and hull sections. The ability to automate tool changes ensures consistent quality and precision, which is crucial for maintaining the structural integrity and performance of marine vessels under harsh marine environments. The transition from manual to automated processes also significantly minimizes human error and aligns with stringent industry standards, thereby improving both the safety and reliability of marine equipment. Ultimately, the integration of ATC CNC technology into the aerospace, defense, and marine manufacturing ecosystems leads to enhancements in product quality, production efficiency, and operational scalability, positioning these industries at the forefront of technological advancement.

In the automotive industry, the application of automatic tool changer CNC (Computer Numerical Control) machines significantly enhances manufacturing efficiency and precision. These machines facilitate the seamless transition between different tools without manual intervention, thus accelerating production cycles and reducing downtime. For instance, in the fabrication of complex automotive components like engine blocks, transmission parts, and intricate body panels, automatic tool changers ensure that multiple machining operations—such as drilling, milling, and tapping—are executed with high accuracy and speed. This automation not only improves the consistency and quality of the parts produced but also supports the high-volume production demands of the automotive sector, ultimately contributing to cost savings and increased productivity.

In the electronics industry, automatic tool changer CNC machines play a crucial role in the precise manufacturing of various electronic components and devices. These machines are essential for the production of circuit boards, connectors, and housings, where they enable rapid and accurate tool changes necessary for intricate milling, drilling, and engraving tasks. The ability to swiftly switch between different tools allows for the creation of complex geometries and fine features required in modern electronic devices. Moreover, the automation provided by CNC with automatic tool changers reduces the risk of human error, enhances repeatability, and ensures high-quality outputs, which are critical for the reliability and performance of electronic products. This technology supports the ever-evolving demand for miniaturization and the integration of multiple functions within compact electronic assemblies.

The construction industry is increasingly incorporating advanced automation technologies to enhance efficiency and precision in various tasks. One such technology is the automatic tool changer CNC (Computer Numerical Control) system. This technology allows for swift and seamless switching between different tools, drastically reducing downtime and enabling more consistent and accurate work. For example, in large-scale construction projects, CNC machinery equipped with an automatic tool changer can effortlessly switch between drilling, cutting, and milling tools. This not only accelerates the pace of construction but also minimizes human error, leading to higher-quality outcomes. Additionally, the automation of these processes allows for more complex designs to be realized with greater ease, thus pushing the boundaries of architectural creativity.

In the realm of energy applications, automatic tool changer CNC systems are revolutionizing the production and maintenance of energy infrastructure. Renewable energy sectors, such as wind and solar power, benefit enormously from these advanced systems. For instance, the production of wind turbine components requires precise machining of large-scale parts, which is effectively managed by CNC machines equipped with automatic tool changers. These systems can efficiently switch between diverse tools to perform functions ranging from cutting and shaping to drilling and finishing, ensuring optimal functionality and durability of the components. In solar panel manufacturing, similar benefits are realized as CNC machinery ensures high precision and reliability in producing the intricate parts required. The resultant increase in production speed and reduction in error rates translate into lower costs and improved scalability, which are critical for meeting growing global energy demands.

The industrial equipment industry has witnessed significant advancements with the integration of automatic tool changer CNC (Computer Numerical Control) systems, revolutionizing the capabilities and efficiencies of modern manufacturing. An automatic tool changer (ATC) allows CNC machines to perform various operations without the need for manual intervention to change tools, significantly reducing downtime and increasing productivity. In a typical production setting, an ATC-equipped CNC machine can seamlessly switch between drilling, milling, and cutting tools, executing complex machining processes with precision and speed. This automation not only accelerates the manufacturing cycle but also enhances repeatability and accuracy, leading to higher quality end products and reduced waste.

Further, the implementation of CNC with automatic tool changers in the industrial equipment sector has driven cost efficiency and scalability in production. These systems enable manufacturers to handle large volume orders and customizations with minimal setup times, catering to diverse market needs swiftly. For instance, in the aerospace and automotive industries, where component precision and quality are paramount, ATC-equipped CNC machines ensure every piece meets stringent specifications consistently. Additionally, the ability to quickly adapt and change tools allows for greater flexibility in production lines, accommodating rapid shifts in product design or material specifications. This adaptability is crucial in today’s fast-paced market environment, where consumer demands and technological advancements necessitate agile and resilient manufacturing processes. With continuous improvements in robotic and automation technologies, the future of the industrial equipment industry looks poised to achieve even greater heights of efficiency and innovation through advanced ATC-integrated CNC solutions.

The integration of automatic tool changers (ATCs) in CNC (Computer Numerical Control) machining has revolutionized the production of medical devices, significantly enhancing both efficiency and precision. One major application in the medical field is the manufacturing of intricate components for surgical instruments and implants. These devices require complex geometries and tight tolerances, which can be seamlessly achieved with CNC machines equipped with ATCs. By automatically switching between various cutting tools, drilling instruments, and milling heads, these CNC machines can produce highly detailed parts without manual intervention. This results in a substantial reduction of human errors, consistent quality, and faster production rates, critical in meeting the high standards and demands of the medical industry.

Another significant application of ATC-equipped CNC machines is in the production of personalized medical devices, such as prosthetics and dental implants. The ability to rapidly change tools allows for the customization of each piece to match the specific requirements of individual patients. Advanced CNC machines can quickly alternate between tools for milling, grinding, and polishing, ensuring that each prosthetic or implant not only meets the exact specifications but also possesses the necessary surface finish to be biocompatible and comfortable for the patient. This level of customization and precision achievable with ATC technology is paramount in advancing patient-specific solutions, thereby improving overall treatment outcomes and patient satisfaction in the medical field.

Automatic Tool Changer (ATC) CNC machines have revolutionized machining and manufacturing by significantly enhancing productivity and efficiency. In a conventional setup, manually changing tools can be time-consuming and labor-intensive, leading to increased downtime and reduced output. ATC CNC machines streamline this process by automatically switching tools as needed during a machining cycle. This automation enables continuous production runs and minimizes interruptions, allowing for more complex and precise machining tasks to be completed in less time. Consequently, manufacturers can achieve higher levels of accuracy and repeatability in their operations, which is crucial for producing high-quality components with tight tolerances. The enhanced speed and precision also reduce the likelihood of human error, contributing to safer and more reliable manufacturing processes.

The applications of ATC CNC machines extend across various industries, from aerospace and automotive to electronics and medical devices. In the aerospace industry, where components often require intricate geometries and stringent quality standards, ATCs facilitate the efficient production of complex parts, thereby supporting the industry’s need for lightweight and robust materials. Similarly, in the automotive sector, ATC CNC machines are used to produce a wide array of components, from engine parts to intricate body structures, ensuring consistency and durability. In electronics, where miniaturization and precision are paramount, ATCs allow for the rapid and accurate machining of tiny components. In medical manufacturing, the ability to seamlessly switch between different tools enables the precise machining of surgical instruments and implants, meeting the high regulatory standards of the healthcare industry. Overall, the integration of ATC CNC machines into manufacturing processes empowers industries to meet growing demands for quality and efficiency.

Sure, here are some frequently asked questions (FAQ) with answers regarding manufacturing “automatic tool changer CNC quality work from SourcifyChina factory”:

1. What is an automatic tool changer (ATC) in CNC machines?

An automatic tool changer (ATC) is a device that allows a CNC machine to change tools automatically without requiring manual intervention. It enhances the machine’s efficiency and flexibility by enabling it to switch between different tools for various operations, such as cutting, drilling, or milling.

2. How does SourcifyChina ensure the quality of their CNC machines?

SourcifyChina ensures quality through rigorous testing and quality control processes. They use high-grade materials, advanced manufacturing techniques, and comprehensive inspection protocols to meet international standards. Their QC team inspects each machine for precision, durability, and performance before shipping.

3. What industries can benefit from automatic tool changer CNC machines?

Industries such as automotive, aerospace, electronics, mold-making, and metal fabrication can greatly benefit from automatic tool changer CNC machines. These machines enable high efficiency, precision, and consistency crucial for complex manufacturing processes.

4. How does an ATC improve production efficiency?

An ATC improves production efficiency by reducing tool change time, minimizing operator intervention, and allowing for continuous operation. This leads to faster production cycles, reduced downtime, and increased overall productivity.

5. Can SourcifyChina customize CNC machines with specific ATC configurations?

Yes, SourcifyChina offers customization options for CNC machines, including specific ATC configurations. They work closely with clients to understand their requirements and provide tailored solutions that meet their unique production needs.

6. What support services does SourcifyChina provide post-purchase?

SourcifyChina provides comprehensive post-purchase support, including installation assistance, operator training, machine maintenance, and technical support. They have a dedicated customer service team to address any issues promptly and effectively.

7. Are SourcifyChina’s machines compatible with international software and standards?

Yes, SourcifyChina’s CNC machines are compatible with major international software and adhere to global standards. This ensures seamless integration into existing manufacturing setups and supports various CAD/CAM software platforms.

8. What is the lead time for ordering a CNC machine with an ATC from SourcifyChina?

When considering SourcifyChina factory for automatic tool changers (ATCs) in CNC manufacturing, there are several key factors to keep in mind to ensure optimal utilization and efficiency:

1. Assess Requirements: Identify the specific requirements of your CNC operations. Determine the type and number of tools needed, change frequency, and machining complexity.

2. Quality and Compatibility: Ensure the ATC systems from SourcifyChina are compatible with your existing CNC machines. Look for high-quality materials and robust construction to withstand rigorous use.

3. Precision and Speed: Evaluate the accuracy and speed of the ATC. Faster tool changing can significantly reduce downtime and increase productivity.

4. Customization Options: SourcifyChina often offers customization. Tailor the tool changer to your specific needs. Discuss with their engineers to get modifications that suit your manufacturing processes.

5. Ease of Integration: Check how easily the ATC can be integrated into your current system. Seamless integration minimizes disruptions and enhances workflow efficiency.

6. Support and Training: Ensure that SourcifyChina provides adequate support and training for your staff. Proper operation and maintenance knowledge can prevent costly downtimes.

7. Durability and Maintenance: Investigate the durability and maintenance requirements. Reliable ATC systems with low maintenance needs contribute to long-term savings.

8. Cost vs. Value: While cost is a factor, focus on the value offered. A cheaper ATC might incur higher long-term costs due to frequent repairs or downtimes.

9. Client Reviews: Look for reviews and testimonials from other clients. Positive feedback on SourcifyChina’s ATCs can provide assurance of quality and performance.

10. After-Sales Service: Good after-sales service is crucial. Ensure SourcifyChina offers robust after-sales support, including spare parts availability and technical assistance.

By keeping these tips in mind, you’ll be better equipped to leverage automatic tool changers from SourcifyChina factory effectively in your CNC manufacturing processes.

Sure, here are some frequently asked questions (FAQ) about sourcing Automatic Tool Changer (ATC) CNC machines from the SourcifyChina factory, with answers provided.

1. What types of Automatic Tool Changer CNC machines does SourcifyChina offer?

SourcifyChina offers a variety of ATC CNC machines, including milling machines, lathes, and routers, tailored for different machining needs. Each machine is designed with precision and efficiency in mind.

2. Can I customize the CNC machine specifications to match my requirements?

Yes, SourcifyChina provides customization options for CNC machines to cater to specific industry needs. You can adjust specifications such as spindle power, tool capacity, and control systems.

3. What is the lead time for an order of ATC CNC machines?

The lead time generally ranges from 4 to 8 weeks, depending on order size and customization requirements. SourcifyChina will provide a more accurate timeline upon order confirmation.

4. How do I place an order with SourcifyChina?

To place an order, you can visit their official website, fill out the inquiry form, or contact their sales team directly via email or phone. Detailed guidance will be provided by their sales representatives.

5. What are the payment terms for purchasing from SourcifyChina?

SourcifyChina typically accepts payments through bank transfers (T/T), Letters of Credit (L/C), and other secure payment methods. Detailed payment terms are discussed during the order process.

6. Is there a warranty or after-sales service provided?

Yes, SourcifyChina offers a standard warranty period for their ATC CNC machines, usually one year. They also provide after-sales support, including technical assistance and spare parts supply.

7. How does SourcifyChina ensure the quality of their CNC machines?

SourcifyChina adheres to strict quality control processes, including in-house testing, inspections, and certifications to ensure every machine meets international standards before shipment.

8. Can I visit the factory before making a purchase?

Yes, factory visits are encouraged. You can schedule a visit to SourcifyChina’s manufacturing facility to inspect the machinery and meet the team. Pre-arrangement with the sales team is required.

9. Do they provide training for machine operation and maintenance?

Absolutely, SourcifyChina offers training sessions for customers either at their facility or remotely. Training covers machine operation, routine maintenance, and troubleshooting.

Sourcing an automatic tool changer (ATC) CNC machine from a factory like SourcifyChina can be a challenging task, but with the right approach, you can ensure a smooth experience. Here are some tips:

1. Define Your Requirements: Clearly specify what you need in terms of machine specifications, such as type of CNC, number of tool slots, accuracy, and size.

2. Research Factories: Use platforms like Alibaba, Made-in-China, and Global Sources to find factories that specialize in CNC machines. Look for SourcifyChina factory listings and reviews.

3. Request Quotes and Information: Contact multiple suppliers, including SourcifyChina, requesting detailed quotations, product catalogs, and lead times. Be specific about your requirements.

4. Verify the Supplier: Check the legitimacy of the factory. Look for business licenses, certifications (like ISO 9001), and customer reviews. You can also request references.

5. Sample Orders: If possible, order a sample unit to assess the quality and confirm it meets your standards before committing to a larger order.

6. Negotiate Terms: Discuss pricing, payment terms, and shipment details. Make sure you understand the warranty, after-sales service, and return policies.

7. Request Detailed Documentation: Ensure that all the technical specifications, configurations, user manuals, and maintenance guides are provided.

8. Factory Visit: If feasible, arrange for a visit to the SourcifyChina factory to inspect their manufacturing process, quality control, and facilities.

9. Sign a Contract: Clearly outline all terms, conditions, and specifications in a formal contract to protect both parties.

10. Arrange Logistics: Coordinate with the supplier for shipping arrangements. Consider insurance and customs clearance to avoid complications.

Following these steps diligently will help you source an ATC CNC machine efficiently from SourcifyChina or any other reputable factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.