Technology and Applications of wolfram metal

Wolfram metal, also known as tungsten, is a dense, strong, and highly resistant metal with remarkable properties, making it invaluable in various technological applications. With a melting point of 3,422°C (6,192°F), tungsten maintains stability under extreme temperatures, which is crucial for industries requiring high-performance materials.

Applications:

1. Lighting: Tungsten is famously used in incandescent light bulbs. Its high melting point allows it to be used as a filament that produces light when heated.

2. Electronics: In electronics manufacturing, tungsten’s conductivity and ability to withstand high temperatures make it ideal for contacts, electrodes, and wiring in devices such as semiconductors.

3. Aerospace: Tungsten’s high density contributes to counterweights and ballast in aircraft and spacecraft, enhancing stability without compromising structural integrity.

4. Military and Defense: Its high density and hardness make tungsten suitable for armor-piercing projectiles and other military applications.

5. Medical: Tungsten’s properties are utilized in radiation shielding and protective equipment in medical imaging, where it safeguards patients and staff from harmful x-rays.

6. Jewelry: Tungsten carbide, a compound formed with carbon, is popular in the jewelry industry due to its scratch resistance and durability, making it ideal for wedding bands and fashion accessories.

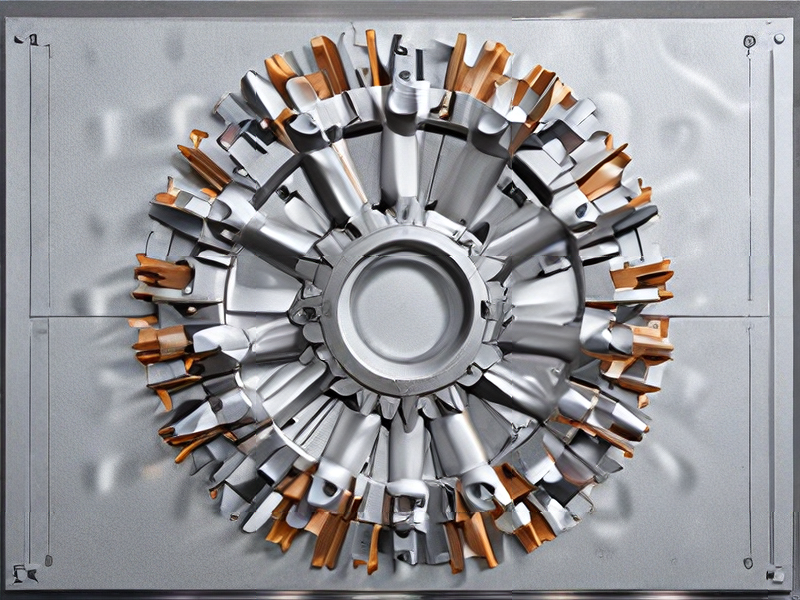

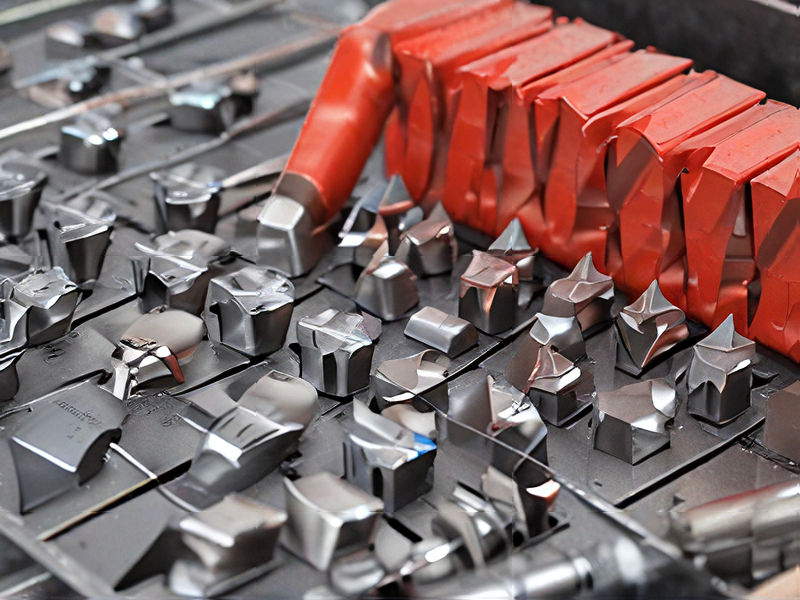

7. Industrial Tools: Tungsten is integral in manufacturing cutting tools, as it’s hard enough to withstand wear and tear in drilling, milling, and grinding processes.

In summary, wolfram metal’s combination of high melting point, density, and strength positions it as an essential material across diverse industries, underscoring its significance in modern technology.

Quality Testing Methods for wolfram metal and how to control quality

Quality testing of tungsten (commonly referred to as wolfram) involves several methods to ensure its purity and mechanical properties, essential for its applications in industries such as aerospace, electronics, and manufacturing.

1. Chemical Analysis: To verify the purity of tungsten, techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or X-Ray Fluorescence (XRF) are employed. These methods determine the presence of impurities and ensure that the tungsten meets required specifications.

2. Mechanical Testing: Tensile strength, hardness, and ductility tests assess the mechanical properties of tungsten. A tensile test measures the material’s resistance to tension, while hardness tests (e.g., Rockwell or Vickers) evaluate its resistance to deformation.

3. Microstructural Analysis: Optical microscopy or Scanning Electron Microscopy (SEM) examines the grain structure and defects within the tungsten. This reveals insights into the manufacturing process and can indicate potential weaknesses.

4. Dimensional Inspection: Using tools like calipers and micrometers ensures that tungsten components meet precise dimensional tolerances required for their intended applications.

5. Non-destructive Testing (NDT): Techniques such as ultrasonic testing or eddy current testing identify internal flaws without compromising the material’s integrity.

Quality Control Strategies:

– Standards Compliance: Adhering to international standards such as ASTM or ISO ensures consistency in quality.

– Regular Audits: Conducting internal and external quality audits helps identify areas for improvement.

– Supplier Evaluation: Assessing raw material suppliers based on their quality certifications can prevent substandard materials from entering the production process.

– Employee Training: Continuous training for staff on quality management and testing methods fosters a culture of quality awareness.

Through systematic testing and rigorous quality control measures, manufacturers can ensure the reliable performance of tungsten in its various applications.

Tips for Procurement and Considerations when Purchasing from wolfram metal

When procuring materials from Wolfram Metal, it’s essential to consider several factors to ensure a successful purchase:

1. Quality Standards: Verify that the products meet industry standards and specifications. Request certifications and quality assurance documents to ensure reliability.

2. Supplier Reputation: Research Wolfram Metal’s reputation in the market. Look for reviews, testimonials, and case studies to gauge customer satisfaction and service reliability.

3. Pricing: Compare prices with other suppliers to ensure competitive rates. However, remember to balance cost with quality—cheapest isn’t always the best.

4. Material Specifications: Clearly define the material requirements, including purity levels, size, and applications. This will help avoid misunderstandings and ensure that you receive the exact products needed.

5. Lead Times and Availability: Assess the delivery timelines and stock availability. Reliable suppliers should provide clear information about their lead times to prevent disruptions in your supply chain.

6. Support and Communication: Evaluate the responsiveness and communication style of the supplier. Good customer service can facilitate smoother transactions and address any issues promptly.

7. Payment Terms: Understand the payment options and terms available. Flexible payment terms can assist with cash flow management.

8. Sustainability Practices: Investigate whether Wolfram Metal employs sustainable sourcing and manufacturing practices. This can be important for corporate social responsibility (CSR) initiatives.

9. Post-Purchase Support: Inquire about post-purchase services such as warranties, returns, and support options. This is crucial for addressing any future concerns regarding product quality.

Considering these factors can lead to a more informed procurement process and successful partnership with Wolfram Metal.

FAQs on Sourcing and Manufacturing from wolfram metal in China

FAQs on Sourcing and Manufacturing from Wolfram Metal in China

Q1: What is Wolfram Metal?

A1: Wolfram Metal refers to tungsten, a high-density metal used in various industries, including aerospace, electronics, and manufacturing. China is the largest producer of tungsten, accounting for a significant share of global supply.

Q2: Why source tungsten from China?

A2: Sourcing tungsten from China offers competitive pricing, abundant supply, and advanced manufacturing capabilities. Chinese suppliers often provide a wide range of tungsten products, such as rods, sheets, and custom components.

Q3: How do I select a reliable supplier?

A3: Research potential suppliers through trade platforms, seek recommendations, and verify credentials. It’s essential to review their production capacity, quality certifications (like ISO), and customer reviews.

Q4: What are the key considerations in the manufacturing process?

A4: Key considerations include material quality, manufacturing techniques, cost efficiency, compliance with international standards, and lead times for production and delivery.

Q5: What are common challenges in sourcing tungsten?

A5: Challenges may include fluctuating market prices, quality control issues, and communication barriers. Establishing clear specifications and maintaining open communication with suppliers can mitigate these risks.

Q6: Are there legal or regulatory considerations?

A6: Yes, ensure compliance with international trade regulations, including customs duties and import/export restrictions. Familiarize yourself with China’s labor laws and environmental standards if applicable.

Q7: What are the payment and shipment options?

A7: Common payment methods include bank transfers and letters of credit. For shipping, air freight is faster but more expensive, while sea freight is cost-effective for bulk orders.

By addressing these FAQs, businesses can facilitate effective sourcing and manufacturing processes for tungsten products in China.