Technology and Applications of print metal 3d

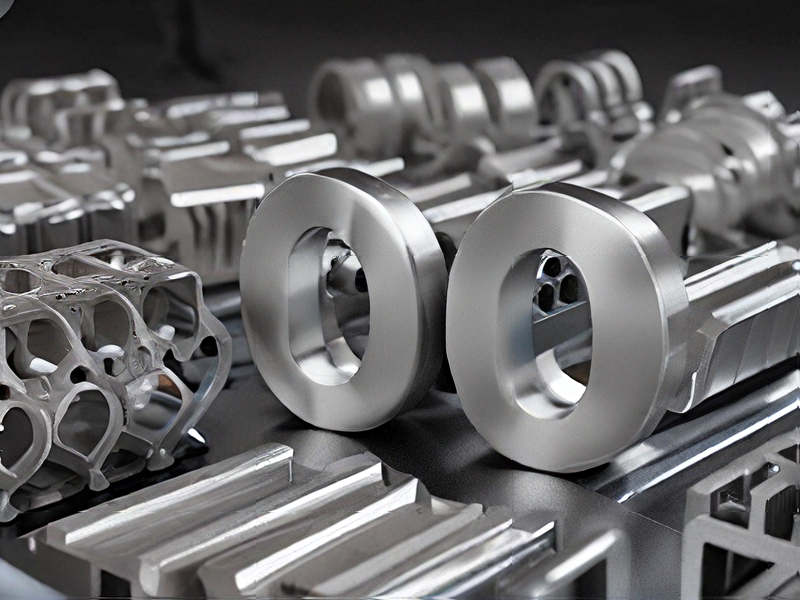

Metal 3D printing, often referred to as additive manufacturing, utilizes advanced techniques to create complex metal parts layer by layer. The primary technologies include Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Binder Jetting.

DMLS and SLM utilize high-powered lasers to fuse metal powders into solid structures. These methods are ideal for producing intricate geometries that traditional manufacturing techniques struggle to achieve, such as lattice structures and complex internal channels, making them highly suitable for the aerospace, automotive, and medical sectors.

Binder Jetting, on the other hand, involves depositing a liquid binder onto layers of metal powder, which are later sintered to create a solid part. This method offers a faster and more cost-effective approach, especially for producing larger components.

The applications of metal 3D printing are vast. In aerospace, it enables the production of lightweight components that enhance fuel efficiency. In the medical field, it facilitates the creation of custom implants tailored to individual patients, improving surgical outcomes. The automotive industry benefits from rapid prototyping, allowing for quicker iterations in design and reduced time-to-market for new models.

Beyond industrial applications, metal 3D printing is also paving the way for innovations in sustainable manufacturing, as it reduces material waste and allows for localized production, minimizing logistics costs.

As the technology continues to evolve, advances in software, materials, and post-processing techniques are likely to expand its capabilities, making metal 3D printing an integral part of the future manufacturing landscape.

Quality Testing Methods for print metal 3d and how to control quality

Quality testing of printed metal components in 3D printing is essential to ensure structural integrity, functionality, and overall performance. Here are some effective methods for quality testing and quality control strategies:

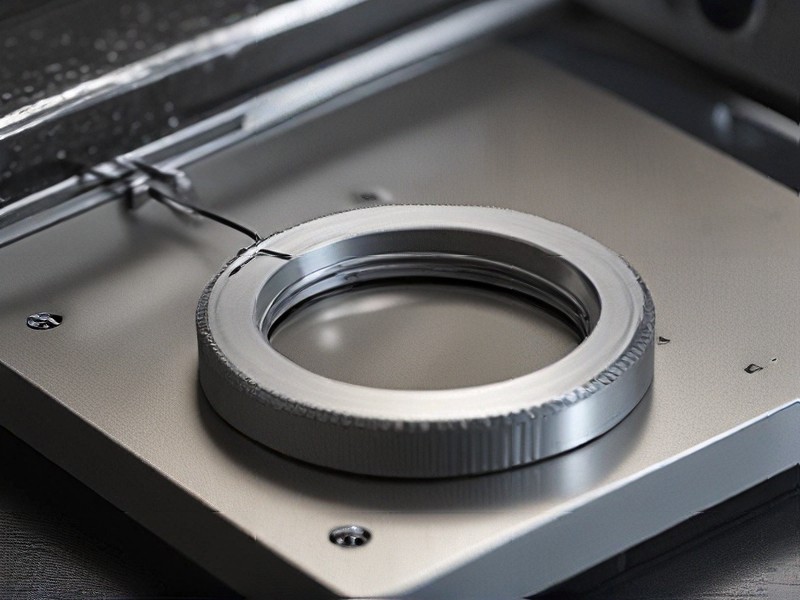

1. Visual Inspection:

– Conduct a thorough visual examination to identify surface defects, including layer misalignment, warping, or excessive roughness. This initial step can highlight obvious issues before more rigorous testing.

2. Dimensional Inspection:

– Use coordinate measuring machines (CMM) or laser scanning to ensure that the printed components meet specified tolerances. Verification of dimensions is crucial for parts that fit with other assemblies.

3. Non-Destructive Testing (NDT):

– Employ techniques such as ultrasonic testing, X-ray computed tomography (CT), or magnetic particle inspection to detect internal flaws without damaging the component. These methods can help identify voids, inclusions, or anomalies.

4. Mechanical Testing:

– Perform tensile, fatigue, and hardness tests to assess the material properties of the printed parts. These tests ensure that the components can withstand operational stresses and strains.

5. Microstructural Analysis:

– Use metallography to examine the microstructure of printed parts. Scanning electron microscopy (SEM) can reveal grain structures and phase distributions, highlighting how printing parameters affect material properties.

6. Process Control:

– Implement a robust quality management system that involves regular calibration of equipment, standardized procedure documentation, and monitoring of production parameters (e.g., temperature, speed).

7. Feedback Loop:

– Establish a system for collecting feedback from end-users to identify any performance issues in the field, which can inform future design iterations and process improvements.

By combining these methods, manufacturers can effectively control the quality of printed metal parts, ensuring they meet performance and safety standards.

Tips for Procurement and Considerations when Purchasing from print metal 3d

When procuring metal 3D printing services, consider the following tips and factors to ensure a successful purchase:

1. Supplier Credentials: Research the supplier’s experience, certifications, and expertise in metal 3D printing. Look for ISO certifications and industry-recognized standards that validate their quality.

2. Material Selection: Understand the range of metals offered, including titanium, stainless steel, aluminum, and more. Choose materials based on the application requirements, such as strength, weight, and corrosion resistance.

3. Technology: Different 3D printing technologies (e.g., DMLS, SLM) have varying capabilities and tolerances. Ensure the supplier’s technology aligns with your project needs.

4. Design for Additive Manufacturing (DfAM): Collaborate with the supplier on design optimization to maximize the advantages of 3D printing. Consider issues like support structures and geometric complexity.

5. Prototyping Options: Determine if the supplier offers rapid prototyping to test design integrity before full-scale production. This can mitigate risks and adjust designs early on.

6. Post-Processing Services: Inquire about available post-processing options like heat treatment, finishing, or machining. These can significantly affect performance and appearance.

7. Cost Transparency: Request detailed quotes that outline all costs, including setup, production, and post-processing. Be wary of hidden fees that might arise later in the process.

8. Lead Times: Discuss production timelines to ensure they align with your project schedule. Understand potential delays and how they can impact your deadlines.

9. Quality Control: Ask about the quality assurance processes in place. Ensure that the supplier performs thorough inspections and testing to guarantee product reliability.

10. Customer Support: Evaluate the level of support available. Responsive communication can be crucial in resolving issues during production.

By following these considerations, you can make informed decisions that lead to successful procurement experiences in metal 3D printing.

FAQs on Sourcing and Manufacturing from print metal 3d in China

FAQs on Sourcing and Manufacturing 3D Printed Metal Parts in China

1. What is Metal 3D Printing?

Metal 3D printing, also known as additive manufacturing, involves using a 3D printer to produce metal parts layer by layer from a digital model.

2. Why Source from China?

China offers competitive pricing, advanced manufacturing technology, and a vast network of specialized suppliers. This can lead to cost-effective production and quick turnaround times.

3. What materials are available for metal 3D printing?

Common materials include stainless steel, titanium, aluminum, and nickel-based alloys. Specific suppliers may offer unique materials tailored to particular applications.

4. What should I consider when selecting a supplier?

Evaluate their experience, certifications (ISO, ASTM), production capacity, quality control processes, and customer reviews. Request samples to assess quality.

5. What are typical lead times?

Lead times can vary based on complexity and volume, but generally range from a few weeks to a couple of months. Always confirm timelines before placing an order.

6. How is quality ensured?

Suppliers often employ strict quality assurance measures, including tests for material properties, dimensional accuracy, and surface finishes. Ask for quality assurance documentation.

7. What is the cost structure?

Costs vary based on material, part complexity, and volume. Expect additional fees for post-processing and finishing services.

8. How do I communicate my design specifications?

Provide clear, detailed CAD files and specifications. Using industry-standard formats like STL or OBJ can ensure better communication.

9. What are the shipping options?

Shipping options include air freight for faster delivery and sea freight for cost-effectiveness. Be mindful of customs regulations and tariffs.

10. How to handle intellectual property (IP) concerns?

Always utilize non-disclosure agreements (NDAs) and carefully vet suppliers to protect your designs and proprietary information.