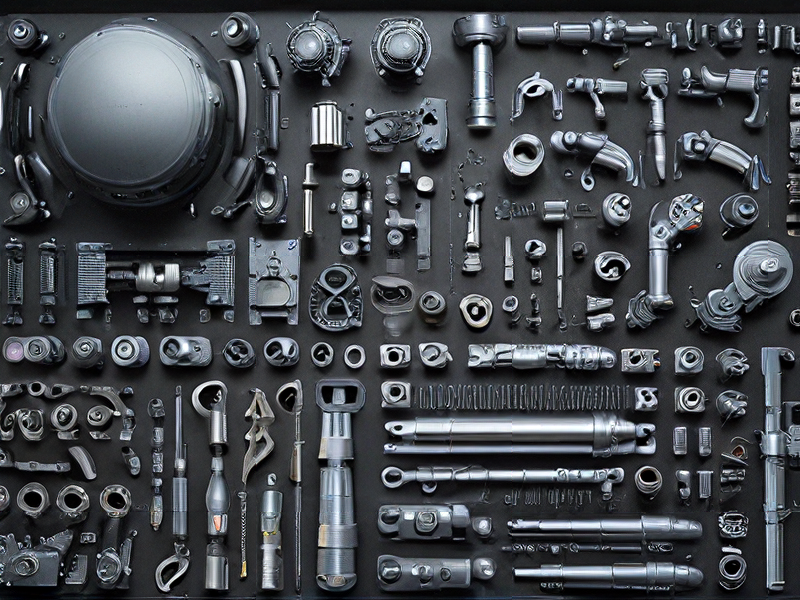

Technology and Applications of machines and tools

Machines and tools, powered by technology, have revolutionized countless aspects of our lives.

From simple hand tools to complex robots, these inventions have increased efficiency, productivity, and our ability to accomplish tasks.

In manufacturing, automated machinery produces goods at scale and with precision, while in healthcare, advanced medical devices enable precise diagnosis and treatment.

Communication technologies like smartphones and the internet connect people globally, facilitating instant information sharing and collaboration.

Transportation systems, including cars, airplanes, and trains, rely on sophisticated engineering to move people and goods efficiently.

Furthermore, tools like computers and software have transformed every sector, from education and research to finance and entertainment.

As technology advances, we can expect even more innovative applications of machines and tools, further shaping our world and pushing the boundaries of human potential.

Quality Testing Methods for machines and tools and how to control quality

Quality testing of machines and tools is crucial to ensure they meet performance and safety standards.

Here are some common methods:

* Functional Testing: Verifies if the machine performs its intended functions correctly. This involves simulating real-world usage scenarios and checking for errors or deviations.

* Performance Testing: Measures the machine’s speed, efficiency, and resource utilization under various loads. This helps identify bottlenecks and optimize performance.

* Reliability Testing: Evaluates the machine’s ability to operate consistently and withstand stress over time. It involves subjecting the machine to extreme conditions and monitoring its performance.

* Durability Testing: Assesses the machine’s resistance to wear and tear, impacts, and other environmental factors. This ensures the machine can withstand prolonged use.

* Safety Testing: Verifies that the machine meets safety standards and protects users from harm. This includes testing for potential hazards, including electrical shock, mechanical entanglement, and noise levels.

Controlling quality involves a combination of:

* Design for Quality: Incorporating quality considerations into the design phase to minimize potential defects.

* Process Control: Implementing standardized procedures and monitoring processes throughout the manufacturing and assembly stages.

* Inspection and Testing: Conducting rigorous inspections and tests at various stages of production to identify and rectify defects.

* Feedback Mechanisms: Gathering feedback from users and incorporating it into future designs and improvements.

Tips for Procurement and Considerations when Purchasing from machines and tools

Purchasing machines and tools requires careful planning and consideration.

Procurement Tips:

* Define Needs: Clearly outline the specific tasks the equipment will perform and the required features.

* Research Options: Explore various manufacturers and models, comparing specifications, capabilities, and prices.

* Seek Expert Advice: Consult with industry professionals or experienced users to gain insights and recommendations.

* Request Quotes: Obtain detailed quotes from multiple suppliers, including delivery costs and warranty information.

* Evaluate Financing Options: Explore financing options if necessary, considering interest rates and payment terms.

Key Considerations:

* Quality and Durability: Prioritize machines and tools known for their reliability and longevity.

* Safety Features: Ensure the equipment meets relevant safety standards and incorporates appropriate safety features.

* Maintenance Requirements: Factor in the cost and frequency of maintenance, spare parts availability, and technical support.

* Energy Efficiency: Consider the energy consumption of the equipment and its potential impact on operating costs.

* Scalability: If your needs may change in the future, choose equipment that is scalable or adaptable to future growth.

Careful planning and due diligence will help you make informed purchasing decisions and acquire machines and tools that meet your specific requirements.

FAQs on Sourcing and Manufacturing from machines and tools in China

## FAQs on Sourcing & Manufacturing in China:

1. Where do I start sourcing from China?

– Online Platforms: Alibaba, Global Sources, Made-in-China connect you with manufacturers.

– Trade Shows: Exhibitors showcase their products, allowing direct interaction.

– Trade Agents: They act as intermediaries, sourcing and managing production.

2. What are the key manufacturing hubs in China?

– East China: Guangdong, Zhejiang (electronics, textiles, manufacturing)

– North China: Beijing, Tianjin (automotive, machinery)

– Central China: Jiangsu, Hunan (heavy industry, chemicals)

3. What manufacturing processes are common in China?

– Contract Manufacturing: You provide designs, they produce.

– OEM/ODM: Original Equipment Manufacturing/Design Manufacturing – customized production.

– CNC Machining, 3D Printing, Injection Molding:

Common for precision parts and rapid prototyping.

4. What are the payment terms?

– Letter of Credit (LC): Secure for buyers, higher fees.

– T/T (Wire Transfer): Common, payment in installments.

– PayPal: Convenient but limited for large orders.

5. What are the challenges?

– Language barrier: Use translation tools and cultural understanding.

– Quality control: Thorough inspections and audits are essential.

– Logistics: Freight can be complex, consider insurance.

Remember to conduct thorough due diligence, research potential suppliers, and ensure clear communication throughout the process.