Technology and Applications of metal engraver laser

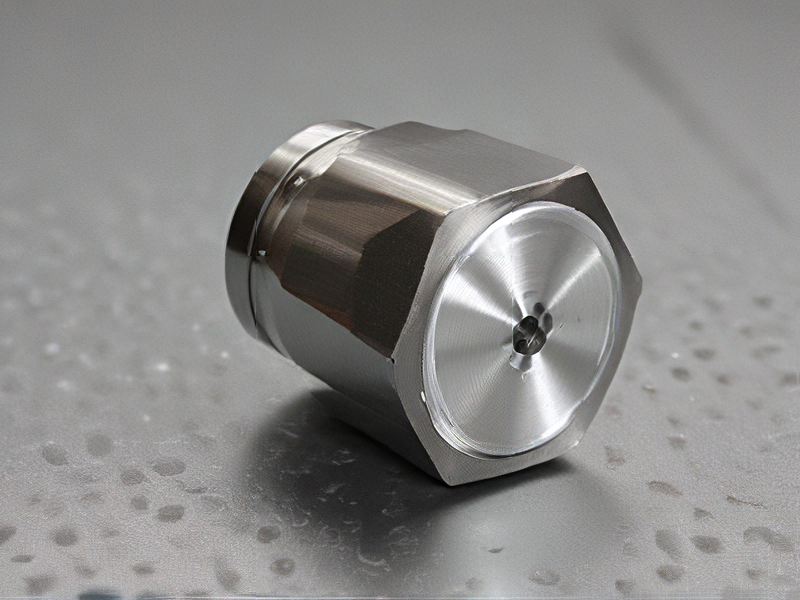

Metal engraver lasers are advanced tools used for marking, engraving, and cutting metal surfaces with high precision and efficiency. The primary technology behind these devices is the use of laser beams, which are highly focused light sources that can be directed to create detailed patterns or cuts on metal.

Technology

Laser Types:

1. Fiber Lasers: Utilize optical fibers doped with rare-earth elements, providing high power and efficiency. They are ideal for deep engraving and high-speed marking.

2. CO2 Lasers: Use a gas mixture to produce a laser beam, suitable for marking but less effective for deep engraving on metals.

3. Nd:YAG Lasers: Employ a solid-state crystal to generate the laser, known for their versatility and precision in metal engraving.

Operating Mechanism:

– The laser beam is directed onto the metal surface using a system of mirrors or fiber optics.

– The focused beam heats and vaporizes the metal, creating an engraving or cut.

– Advanced systems can adjust the laser’s intensity, speed, and focus to achieve different depths and textures.

Applications

Industrial Use:

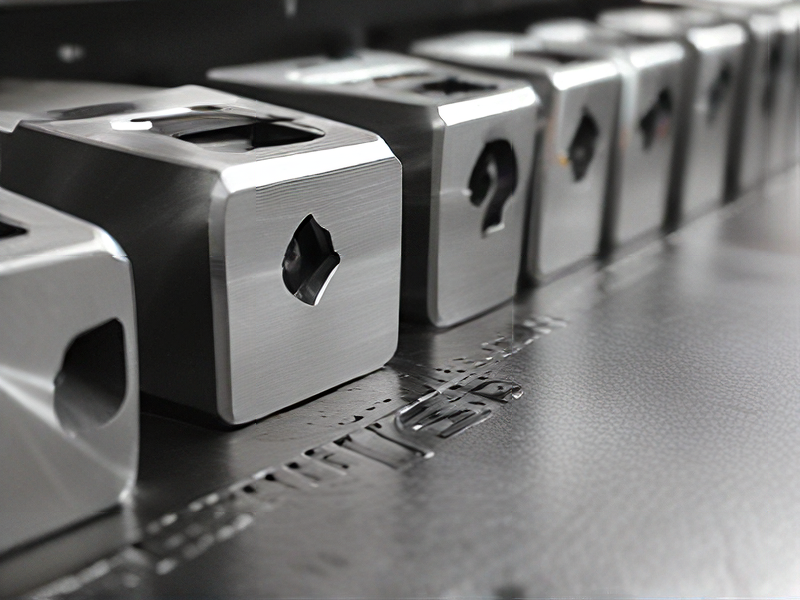

– Manufacturing: Engraving serial numbers, barcodes, and logos on products for traceability and branding.

– Aerospace: Marking parts with detailed specifications and serial numbers to ensure quality and compliance.

Jewelry and Art:

– Creating intricate designs on rings, bracelets, and other metal artworks.

– Personalizing items with names, dates, and custom patterns.

Electronics:

– Marking components with identification codes, improving traceability and quality control.

Medical Devices:

– Engraving surgical instruments and implants with unique identifiers for tracking and sterilization purposes.

Automotive:

– Engraving VIN numbers and part codes for identification and anti-counterfeiting.

Advantages

– Precision: Can achieve extremely fine details, making them suitable for intricate designs.

– Durability: Engravings are permanent and resistant to wear and environmental factors.

– Speed: High-speed processing reduces production time and costs.

– Flexibility: Suitable for a wide range of metals and applications.

Laser metal engravers have revolutionized industries by offering unparalleled precision, efficiency, and versatility, making them indispensable in modern manufacturing and design processes.

Quality Testing Methods for metal engraver laser and how to control quality

Quality testing methods for metal engraver lasers are crucial to ensure precise and consistent results. Here are key methods and control strategies:

Quality Testing Methods:

1. Visual Inspection:

– Purpose: Identify surface defects such as burrs, scratches, or uneven engraving.

– Tools: Magnifying glasses or microscopes.

2. Dimensional Measurement:

– Purpose: Verify the accuracy of engraved dimensions.

– Tools: Calipers, micrometers, and coordinate measuring machines (CMM).

3. Surface Roughness Testing:

– Purpose: Assess the smoothness of engraved surfaces.

– Tools: Profilometers to measure surface texture and roughness.

4. Material Composition Analysis:

– Purpose: Ensure the laser is compatible with the metal being engraved.

– Tools: X-ray fluorescence (XRF) analyzers.

5. Depth Measurement:

– Purpose: Confirm the engraving depth meets specifications.

– Tools: Depth gauges or 3D laser scanners.

6. Laser Power and Stability Testing:

– Purpose: Ensure the laser operates at the correct power level.

– Tools: Laser power meters and stability analyzers.

Quality Control Strategies:

1. Calibration and Maintenance:

– Regularly calibrate the laser engraver to maintain precision.

– Perform routine maintenance to avoid mechanical failures.

2. Standard Operating Procedures (SOPs):

– Develop and follow SOPs for operating the laser engraver.

– Include specific settings for different metals and engraving types.

3. Training and Certification:

– Train operators thoroughly on equipment use and quality standards.

– Certify operators to ensure they understand and can implement quality control measures.

4. Sample Testing:

– Conduct sample tests before full-scale production runs.

– Adjust settings based on sample test results to optimize quality.

5. Automated Quality Control Systems:

– Integrate automated inspection systems for real-time monitoring.

– Use sensors and cameras to detect defects immediately during the engraving process.

By implementing these testing methods and quality control strategies, manufacturers can ensure the high quality and precision of metal engraver laser outputs.

Tips for Procurement and Considerations when Purchasing from metal engraver laser

When procuring from a metal engraver using a laser, consider the following tips:

1. Quality and Precision:

– Ensure the engraver uses high-quality lasers that offer precision and consistency.

– Request samples to evaluate the quality of engraving and detail.

2. Materials Compatibility:

– Confirm that the laser engraver can handle the specific types of metals you need (e.g., stainless steel, aluminum, brass).

– Understand the engraver’s capability in terms of thickness and type of metal.

3. Experience and Expertise:

– Choose suppliers with a proven track record in metal engraving.

– Check customer reviews, portfolios, and ask for references.

4. Technology and Equipment:

– Verify that the engraver uses modern, well-maintained equipment.

– Advanced technology ensures better accuracy and faster turnaround times.

5. Customization and Design Support:

– Ensure the supplier can handle custom designs and offers support in the design phase.

– Look for services that provide detailed previews or prototypes before full production.

6. Turnaround Time:

– Discuss lead times and ensure they align with your project deadlines.

– Confirm the supplier’s capacity to handle bulk orders if necessary.

7. Cost and Pricing Structure:

– Obtain detailed quotes and understand the pricing structure, including any additional costs (e.g., setup fees, material costs).

– Compare quotes from multiple suppliers to ensure competitive pricing.

8. After-Sales Support:

– Check for warranties or guarantees on the work performed.

– Ensure the supplier offers support for any issues post-purchase.

9. Compliance and Certification:

– Verify that the engraver complies with industry standards and has necessary certifications.

– Ensure the engraver follows environmental and safety regulations.

10. Communication and Customer Service:

– Good communication is key for a smooth procurement process.

– Choose a supplier with responsive and helpful customer service.

By considering these factors, you can ensure a successful procurement process with a metal engraver using laser technology.

FAQs on Sourcing and Manufacturing from metal engraver laser in China

FAQs on Sourcing and Manufacturing from Metal Engraver Laser in China

1. Why source metal engraver lasers from China?

China offers a competitive advantage in manufacturing metal engraver lasers due to its advanced technology, large-scale production capabilities, and cost efficiency. This results in lower prices and a variety of options without compromising on quality.

2. How do I ensure the quality of metal engraver lasers from Chinese manufacturers?

To ensure quality, research reputable manufacturers, request product samples, and verify certifications (e.g., ISO, CE). Utilize third-party inspection services to check product standards and factory conditions.

3. What are the common types of metal engraver lasers available?

Common types include fiber lasers, CO2 lasers, and diode lasers. Fiber lasers are typically preferred for metal engraving due to their precision and efficiency.

4. What is the typical lead time for manufacturing and shipping?

Lead times vary but generally range from 2 to 6 weeks for manufacturing. Shipping can take an additional 1 to 4 weeks, depending on the shipping method and destination.

5. What are the payment terms and methods commonly accepted?

Common payment terms include a 30% deposit upfront and the remaining 70% upon completion or before shipment. Payment methods often accepted are T/T (bank transfer), L/C (letter of credit), PayPal, and sometimes credit cards.

6. How can I handle shipping and customs clearance?

Many manufacturers offer shipping services. Alternatively, you can use freight forwarders who handle logistics and customs clearance. Ensure all necessary documentation (e.g., commercial invoice, packing list, bill of lading) is prepared to avoid delays.

7. What after-sales support can I expect?

Reputable manufacturers provide warranties, technical support, and spare parts. Confirm the terms of after-sales services before purchasing to ensure comprehensive support.

8. Are there any risks involved in sourcing from China?

Risks include quality issues, communication barriers, and potential delays. Mitigate these by conducting thorough research, maintaining clear communication, and using trusted inspection and logistics services.

By addressing these key points, you can make informed decisions when sourcing metal engraver lasers from China, ensuring quality and reliability in your manufacturing process.