Technology and Applications of what is a cnc machine

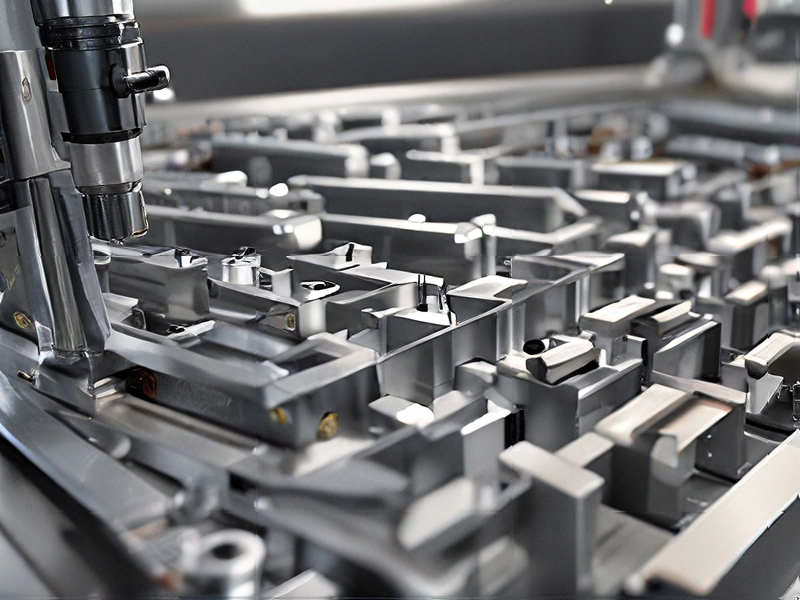

A CNC (Computer Numerical Control) machine is an automated manufacturing tool controlled by a computer, which precisely manages the movement of machinery and tools to shape materials into desired forms. CNC machines can perform various tasks such as cutting, drilling, milling, and turning on materials like metal, plastic, wood, and composites.

Technology

1. Components:

– Controller: The brain of the CNC machine, which interprets the G-code (programming language) and converts it into precise movements.

– Motors and Drive System: These include servo and stepper motors that move the machine’s axes (X, Y, Z).

– Machine Frame: Provides structural support and stability.

– Spindle: The part that holds and rotates the cutting tool.

– Feedback System: Ensures accuracy by constantly monitoring the position of the machine’s components.

2. Process:

– CAD (Computer-Aided Design): A digital model of the part is created.

– CAM (Computer-Aided Manufacturing): The CAD model is converted into G-code.

– CNC Machining: The CNC machine reads the G-code and performs the necessary operations to create the part.

Applications

1. Manufacturing: CNC machines are widely used in manufacturing industries to produce high-precision components for automotive, aerospace, and electronics sectors.

2. Prototyping: Rapid prototyping is possible due to the machine’s ability to quickly switch between different designs.

3. Fabrication: Used in metal fabrication to cut, bend, and assemble metal structures.

4. Woodworking: Enables precise carving and shaping of wood for furniture and decorative items.

5. Medical: Production of precise surgical instruments and implants.

CNC technology revolutionizes manufacturing by providing high precision, repeatability, and efficiency, reducing the need for manual intervention and enabling complex designs that would be difficult or impossible to achieve with traditional machining methods.

Quality Testing Methods for what is a cnc machine and how to control quality

Quality Testing Methods for CNC Machines

CNC (Computer Numerical Control) machines are automated milling devices that make industrial components without human assistance. To ensure the quality of these machines and their output, several testing methods and controls are utilized:

1. Dimensional Accuracy Testing:

– Calibration: Regular calibration using precision tools like micrometers, calipers, and laser interferometers ensures that CNC machines maintain accuracy.

– Test Pieces: Machining standardized test pieces and measuring them against precise standards checks for any deviations.

2. Surface Finish Testing:

– Profilometers: These devices measure the roughness and texture of machined surfaces to ensure they meet specifications.

– Visual Inspection: Using magnification tools to inspect for surface defects like scratches or burrs.

3. Alignment and Positioning Tests:

– Ballbar Testing: This assesses the machine’s geometric accuracy by measuring deviations in circular paths.

– Laser Interferometry: Provides precise measurement of positioning errors over the machine’s operational range.

4. Load and Performance Testing:

– Operational Stress Testing: Running the machine under maximum load conditions to ensure it operates reliably without failure.

– Cycle Time Analysis: Ensuring the machine meets production speed requirements without compromising quality.

5. Software and Control Verification:

– Simulation: Using software to simulate machining operations before actual production to identify potential issues.

– Feedback Systems: Implementing closed-loop control systems that continuously monitor and adjust machining parameters.

6. Material and Tooling Checks:

– Tool Wear Monitoring: Regularly inspecting and replacing cutting tools to maintain machining precision.

– Material Testing: Ensuring raw materials meet quality standards to prevent defects in finished products.

Controlling Quality:

– Regular Maintenance: Scheduled maintenance to prevent wear and tear.

– Operator Training: Skilled operators are crucial for handling complex machinery and troubleshooting issues.

– Quality Management Systems: Adopting standards like ISO 9001 to ensure consistent quality control practices.

By integrating these methods, manufacturers can maintain high quality and precision in CNC machined components.

Tips for Procurement and Considerations when Purchasing from what is a cnc machine

Tips for Procurement and Considerations When Purchasing a CNC Machine

1. Assess Your Needs:

– Determine the types of materials you will be machining.

– Identify the complexity and precision required for your projects.

– Consider the volume of production to decide on the machine’s capacity.

2. Budget Planning:

– Establish a budget, including not just the purchase price but also installation, training, maintenance, and potential upgrades.

– Explore financing options if the initial cost is prohibitive.

3. Machine Specifications:

– Check the machine’s spindle speed, power, axis travel, and precision.

– Ensure it has the necessary software compatibility and user-friendly interface.

4. Vendor Reputation:

– Research the manufacturer’s reputation for reliability, customer service, and support.

– Look for reviews and testimonials from other users.

5. After-Sales Support:

– Verify the availability of technical support, training programs, and spare parts.

– Ensure there is a warranty and understand its coverage.

6. Customization and Upgradability:

– Consider if the machine can be customized or upgraded as your business grows.

– Evaluate the availability of add-ons and accessories.

7. Compliance and Standards:

– Ensure the machine complies with industry standards and safety regulations.

– Verify certifications and quality assurance protocols.

8. Energy Efficiency:

– Look for energy-efficient models to reduce operational costs.

– Consider the environmental impact and potential sustainability benefits.

9. Trial and Demonstration:

– Request a demo to see the machine in action and understand its operational nuances.

– Evaluate the ease of use and training requirements for your team.

By considering these factors, you can make a well-informed decision when procuring a CNC machine, ensuring it meets your operational needs and offers long-term value.

FAQs on Sourcing and Manufacturing from what is a cnc machine in China

FAQs on Sourcing and Manufacturing CNC Machines in China

1. What is a CNC machine?

A CNC (Computer Numerical Control) machine is an automated tool that performs precision cutting, drilling, and milling based on pre-programmed computer software. These machines are essential in various industries, including manufacturing, automotive, and aerospace, for their ability to produce high-precision parts.

2. Why source CNC machines from China?

China is a leading manufacturer of CNC machines due to its advanced manufacturing capabilities, cost-effective labor, and extensive supply chain network. The competitive pricing and technological advancements make Chinese CNC machines attractive for businesses worldwide.

3. How to ensure the quality of CNC machines from China?

– Research and Due Diligence: Investigate potential suppliers, check their reputation, certifications, and client feedback.

– Factory Visits: Visit the manufacturing site to verify their production process and quality control measures.

– Third-Party Inspections: Engage third-party inspection agencies to conduct pre-shipment inspections and quality checks.

4. What are the common types of CNC machines available in China?

– CNC Milling Machines: Used for cutting and drilling tasks.

– CNC Lathes: Ideal for producing cylindrical parts.

– CNC Routers: Suitable for cutting various materials like wood, plastic, and metal.

– CNC Plasma Cutters: Used for cutting conductive materials with high precision.

5. What factors to consider when choosing a CNC machine supplier in China?

– Technical Support and Training: Ensure the supplier offers adequate technical support and training for machine operation and maintenance.

– After-Sales Service: Reliable after-sales service is crucial for addressing any issues that may arise post-purchase.

– Warranty and Spare Parts: Check the warranty terms and availability of spare parts to ensure long-term usability.

6. How to manage logistics and shipping from China?

– Incoterms: Understand Incoterms to clarify the responsibilities of the buyer and seller in the shipping process.

– Freight Forwarders: Work with reputable freight forwarders to handle shipping logistics efficiently.

– Customs Clearance: Ensure all necessary documentation and compliance for smooth customs clearance.

By following these guidelines, businesses can effectively source and manufacture CNC machines from China, ensuring quality and reliability while optimizing costs.