Technology and Applications of what is cnc machining

CNC Machining: Technology and Applications

Technology:

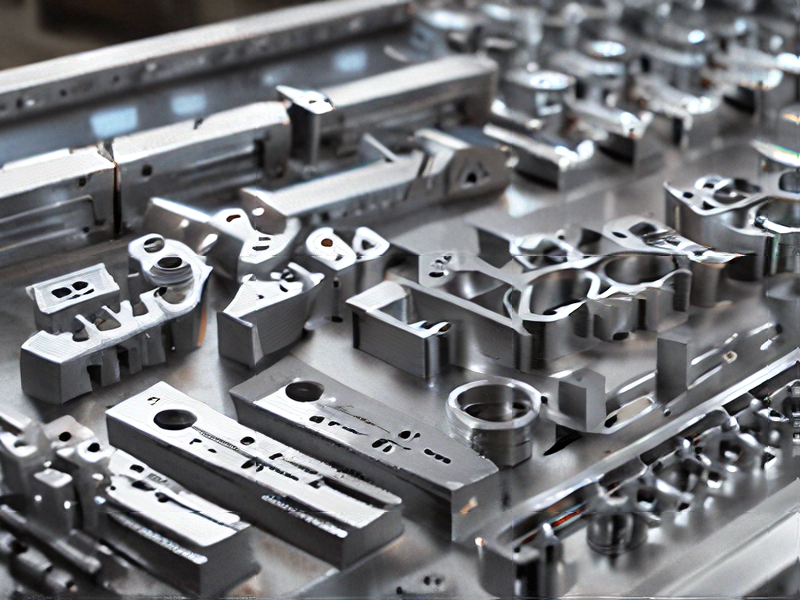

CNC (Computer Numerical Control) machining utilizes pre-programmed software to dictate the movement of factory tools and machinery. This technology automates the control of machine tools through computers executing precise commands. CNC machining can operate various tools like lathes, mills, routers, and grinders. The process begins with designing a CAD (Computer-Aided Design) model, which is then converted into a CNC program (often G-code). This program instructs the machine on how to cut, shape, and finish the material, which can be metals, plastics, wood, composites, or foam.

Applications:

1. Aerospace: CNC machining produces high-precision components such as engine parts, landing gear, and airframes, ensuring they meet stringent safety and performance standards.

2. Automotive: It manufactures intricate engine parts, transmission components, and custom car parts, contributing to the efficiency and performance of vehicles.

3. Medical Devices: CNC machines create surgical instruments, orthopedic implants, and prosthetics, requiring high precision and biocompatible materials.

4. Electronics: They produce enclosures, connectors, and heat sinks, vital for maintaining the functionality and reliability of electronic devices.

5. Prototyping: CNC machining is essential for rapid prototyping, allowing designers to quickly produce and test physical models of their designs.

6. Industrial Equipment: It fabricates various machinery components, enhancing the durability and efficiency of industrial operations.

7. Jewelry and Art: CNC machines are used to craft intricate designs in metals and other materials, allowing for precision and creativity in custom jewelry and art pieces.

Conclusion:

CNC machining stands out for its precision, repeatability, and efficiency, making it indispensable across numerous industries. It has revolutionized manufacturing by enabling the production of complex parts with minimal human intervention, thereby improving quality and reducing costs.

Quality Testing Methods for what is cnc machining and how to control quality

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This method controls complex machinery from grinders and lathes to mills and routers, allowing for three-dimensional cutting tasks to be accomplished in a single set of prompts.

Quality Testing Methods in CNC Machining:

1. First Article Inspection (FAI):

– Initial pieces are produced and meticulously checked against specified standards to ensure that production meets design requirements.

2. In-Process Inspection:

– Continuous monitoring during the machining process. This involves using precision measurement tools such as calipers, micrometers, and coordinate measuring machines (CMMs) to measure dimensions and tolerances of parts.

3. Statistical Process Control (SPC):

– This involves collecting data from the CNC processes and using statistical methods to monitor and control the production. It helps in identifying trends and variations that could lead to defects.

4. Non-Destructive Testing (NDT):

– Techniques like ultrasonic testing, magnetic particle testing, and dye penetrant testing are used to inspect the integrity of parts without causing damage.

5. Visual Inspection:

– Skilled inspectors visually check for surface finish, defects, and overall appearance to ensure they meet the quality standards.

Controlling Quality in CNC Machining:

1. Proper Machine Calibration:

– Regular calibration of CNC machines ensures that they produce parts within specified tolerances.

2. Tool Maintenance:

– Regular inspection and maintenance of cutting tools to prevent wear and tear that can affect precision.

3. Software Updates:

– Ensuring the CNC software is up-to-date to take advantage of the latest features and improvements in machining precision.

4. Training and Skill Development:

– Continuous training for operators to ensure they are proficient in operating the machines and understanding quality standards.

5. Documented Procedures:

– Having detailed documentation of procedures and standards ensures consistency and repeatability in the manufacturing process.

By integrating these quality testing methods and controls, CNC machining can maintain high precision, consistency, and overall product quality.

Tips for Procurement and Considerations when Purchasing from what is cnc machining

CNC machining offers precise and efficient manufacturing of components from various materials. Here are some tips for procurement and considerations:

1. Define Your Requirements: Clearly specify the material, dimensions, tolerances, surface finish, and quantities needed.

2. Choose a Reliable Supplier: Research and select a reputable CNC machining company with experience in your industry and material expertise.

3. Request Quotes: Obtain quotes from multiple suppliers, ensuring they include details like lead times, costs, and quality assurance procedures.

4. Evaluate Capabilities: Assess the supplier’s CNC machines, software, and certifications to ensure they meet your production needs.

5. Communication is Key: Maintain clear and open communication with the supplier throughout the process, from design to delivery.

6. Quality Control: Establish quality control measures, including inspection procedures and tolerance limits, to ensure the final product meets your specifications.

7. Consider Lead Times: Understand the production timeline and factor in lead times for design, machining, and delivery.

8. Cost Analysis: Compare quotes carefully, considering not only the upfront cost but also factors like tooling, setup, and potential for volume discounts.

By following these tips, you can ensure a successful procurement experience and receive high-quality CNC machined components that meet your specific requirements.

FAQs on Sourcing and Manufacturing from what is cnc machining in China

FAQs on Sourcing and Manufacturing from China: CNC Machining

1. What is CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software dictates the movement of factory tools and machinery. This technology controls various complex machinery, from grinders and lathes to mills and routers, allowing three-dimensional cutting tasks to be accomplished with precision.

2. Why source CNC machining services from China?

China is a leading hub for CNC machining due to its advanced technology, skilled labor, and cost-effective production. Chinese manufacturers often offer high-quality services at competitive prices, benefiting companies looking to reduce costs without compromising quality.

3. How do I find a reliable CNC machining supplier in China?

To find a reliable supplier, utilize online platforms like Alibaba, Made-in-China, or Global Sources. Look for suppliers with good reviews, verified certifications, and transparent communication. Visiting trade shows and seeking referrals from industry contacts can also help.

4. What should I consider when selecting a CNC machining supplier?

Consider the supplier’s experience, production capacity, quality control processes, certifications (e.g., ISO 9001), and the ability to meet specific technical requirements. Additionally, evaluate their communication skills and responsiveness.

5. How can I ensure the quality of CNC machined parts from China?

Ensure quality by requesting samples, visiting the supplier’s facility, and conducting third-party inspections. Clearly define quality standards and include them in the contract. Regular audits and maintaining open communication also help in maintaining quality.

6. What are the common challenges when sourcing CNC machining from China?

Common challenges include language barriers, time zone differences, and variations in quality standards. These can be mitigated by clear communication, detailed contracts, and using third-party inspection services.

7. How does the shipping process work?

After production, the parts are typically shipped via air or sea freight. The supplier will handle packaging and logistics, but it’s crucial to work with a reliable freight forwarder to manage the shipping process effectively and ensure timely delivery.

8. What is the typical lead time for CNC machined parts from China?

Lead times vary depending on the complexity and volume of the order, usually ranging from 2 to 8 weeks. It’s important to discuss and agree on the timeline with the supplier beforehand.

These FAQs provide a foundational understanding of CNC machining in China, helping businesses navigate the process of sourcing and manufacturing effectively.