Technology and Applications of laser etching metal

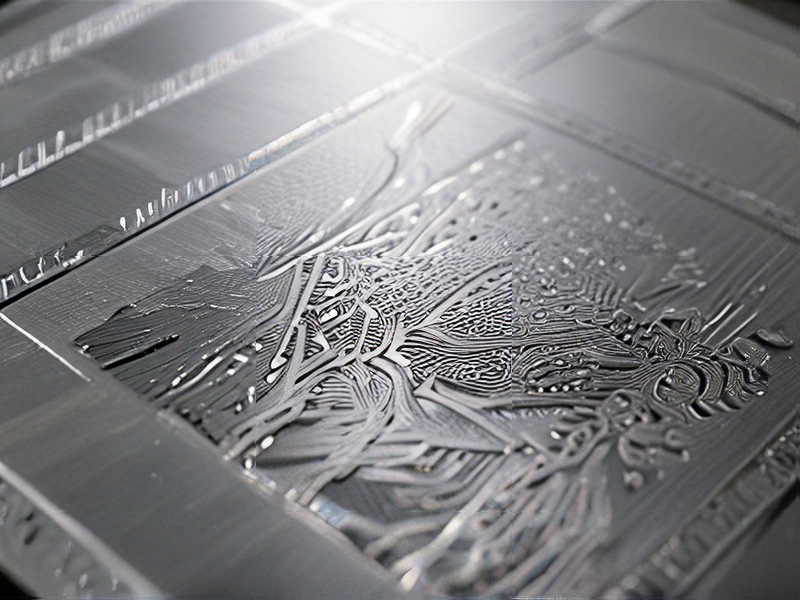

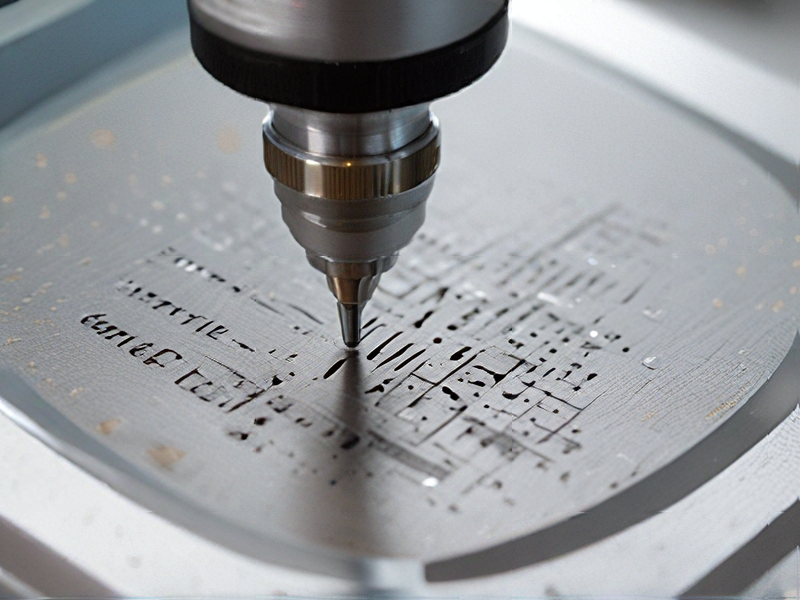

Laser etching metal involves using a laser to remove a portion of the metal surface to create designs, text, or patterns. This technology uses high-intensity light to achieve precise and permanent markings on metals.

Technology

Laser etching utilizes a focused beam of light that vaporizes the surface of the metal. The process can be controlled to create different depths and patterns. Common types of lasers used include CO2 lasers, fiber lasers, and diode lasers. Fiber lasers are particularly favored for metal etching due to their high efficiency, precision, and ability to work with a variety of metals like stainless steel, aluminum, and brass.

Applications

1. Industrial Manufacturing: Laser etching is used to mark parts with serial numbers, barcodes, and logos. This is crucial for traceability and quality control in automotive, aerospace, and electronics industries.

2. Jewelry and Art: It allows for intricate designs and personalization on jewelry, watches, and decorative items, enhancing their aesthetic value.

3. Medical Devices: Ensures compliance with regulatory standards by permanently marking medical instruments with identification codes, improving traceability and reducing counterfeit risks.

4. Tool Marking: Used for labeling tools and equipment, ensuring easy identification and reducing loss.

5. Consumer Products: Personalizes items like smartphones, laptops, and kitchenware, adding a unique touch and enhancing brand identity.

Advantages

– Precision: Delivers highly accurate and detailed markings without contact, minimizing wear and tear on the tool.

– Durability: Marks are resistant to wear, heat, and chemicals.

– Versatility: Suitable for a wide range of metals and applications.

– Efficiency: Fast processing speeds and automation capabilities improve productivity.

Laser etching metal is a versatile and efficient technology widely used across various industries for its precision, durability, and ability to enhance product identification and aesthetics.

Quality Testing Methods for laser etching metal and how to control quality

Quality testing for laser etching on metal involves several methods to ensure precision, durability, and consistency. Key testing methods include:

1. Visual Inspection: Examine the etched metal under magnification to check for clarity, uniformity, and any defects or inconsistencies in the pattern.

2. Microscopy: Use scanning electron microscopy (SEM) to analyze the fine details of the etching, ensuring high resolution and accuracy.

3. Surface Profilometry: Measure the depth and profile of the etched areas using a profilometer to ensure they meet the specified dimensions and tolerances.

4. Material Contrast Testing: Evaluate the contrast between the etched and non-etched areas, ensuring the etching is easily visible and meets aesthetic requirements.

5. Durability Testing: Perform abrasion and corrosion tests to ensure the etched markings can withstand environmental and physical stress without degradation.

6. Adhesion Testing: For coatings or surface treatments, test the adhesion of the etched layer to the metal substrate to ensure it remains intact during use.

To control quality, implement these strategies:

1. Standard Operating Procedures (SOPs): Establish clear SOPs for the laser etching process, including machine settings, material handling, and safety protocols.

2. Regular Calibration: Ensure laser equipment is regularly calibrated to maintain consistent performance and accuracy.

3. Process Monitoring: Continuously monitor key process parameters, such as laser power, speed, and focus, to ensure they remain within specified limits.

4. Sample Testing: Conduct regular sample testing during production runs to catch any deviations early.

5. Training: Provide thorough training for operators on equipment use, maintenance, and quality inspection techniques.

6. Documentation: Keep detailed records of process parameters, inspection results, and any corrective actions taken to maintain traceability and continuous improvement.

By employing these methods and controls, manufacturers can achieve high-quality, consistent laser etching on metal surfaces.

Tips for Procurement and Considerations when Purchasing from laser etching metal

When procuring and purchasing from laser etching metal services, several key tips and considerations can ensure quality and value:

1. Vendor Expertise and Reputation:

– Research Vendors: Choose suppliers with a proven track record in laser etching. Check reviews and ask for references.

– Certifications and Standards: Ensure the vendor adheres to industry standards and holds relevant certifications, which can indicate quality and reliability.

2. Material Compatibility:

– Material Types: Confirm that the vendor can work with the specific metal types you require, such as stainless steel, aluminum, or titanium.

– Sample Testing: Request samples to assess the quality of etching on your specific metal before committing to large orders.

3. Precision and Accuracy:

– Technology and Equipment: Inquire about the laser technology used. Modern, high-precision lasers can produce more detailed and accurate results.

– Tolerance Levels: Discuss tolerance levels and ensure the vendor can meet the required specifications for your project.

4. Design Capabilities:

– Design Flexibility: Ensure the vendor can handle complex designs and customizations as needed.

– File Formats: Confirm which design file formats the vendor accepts and ensure compatibility with your design software.

5. Turnaround Time and Capacity:

– Production Capacity: Make sure the vendor can handle your order volume within your required timeline.

– Lead Times: Get clear estimates on lead times to avoid delays in your project.

6. Cost Considerations:

– Price Quotes: Obtain detailed quotes that break down costs for materials, labor, and any additional services.

– Bulk Discounts: Ask about discounts for bulk orders or long-term contracts to optimize costs.

7. Quality Assurance:

– Inspection and Testing: Ensure the vendor has robust quality control measures, including inspections and testing of finished products.

– Defect Handling: Understand the vendor’s policy on handling defects or issues with the finished products.

8. Customer Service:

– Communication: Choose a vendor that provides clear and responsive communication throughout the procurement process.

– Support Services: Check if the vendor offers post-purchase support, such as maintenance tips or repair services.

By carefully considering these factors, you can ensure a smooth procurement process and high-quality results from your laser etching metal vendor.

FAQs on Sourcing and Manufacturing from laser etching metal in China

FAQs on Sourcing and Manufacturing Laser Etched Metal Products in China

1. Why source laser etched metal products from China?

China offers competitive pricing, advanced technology, and a large pool of experienced manufacturers, making it a cost-effective choice for high-quality laser etched metal products.

2. How do I find a reliable manufacturer?

Use platforms like Alibaba, Global Sources, and Made-in-China. Look for manufacturers with verified profiles, positive reviews, and extensive experience in laser etching.

3. What factors should I consider when choosing a manufacturer?

Evaluate their production capabilities, quality control processes, lead times, minimum order quantities, and compliance with international standards. Request samples to assess quality.

4. What is the typical production lead time?

Lead times vary but generally range from 2-6 weeks, depending on order size and complexity. Custom orders may require additional time.

5. How do I ensure quality control?

Conduct pre-production and post-production inspections. Use third-party inspection services to verify product quality and adherence to specifications.

6. What are the common payment terms?

Most manufacturers require a deposit (30-50%) before production, with the balance paid upon completion. Payment methods typically include wire transfer, PayPal, or through secure escrow services.

7. Can I customize designs?

Yes, Chinese manufacturers often offer extensive customization options. Provide detailed specifications, drawings, and materials to ensure accurate production.

8. What shipping options are available?

Shipping can be arranged via air, sea, or express courier services. Sea freight is cost-effective for large orders, while air freight is faster but more expensive.

9. How do I handle tariffs and import duties?

Research the import duties and tariffs applicable to your country. Work with a customs broker to ensure proper documentation and compliance with regulations.

10. What are the potential risks and how can they be mitigated?

Risks include quality issues, delays, and communication barriers. Mitigate these by selecting reputable manufacturers, maintaining clear communication, and using contracts that specify terms and conditions.

By considering these factors, you can successfully source and manufacture high-quality laser etched metal products from China.