Technology and Applications of laser engraving metals

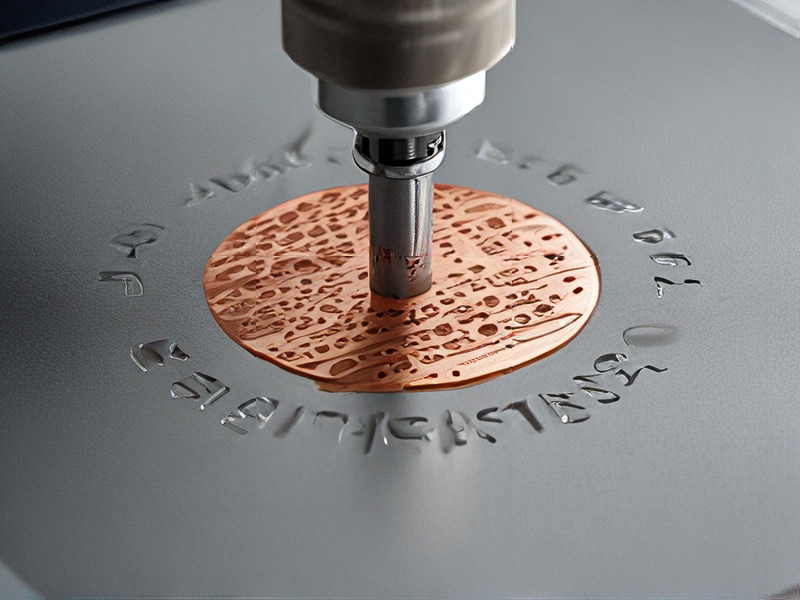

Laser engraving is a cutting-edge technology that uses a focused laser beam to etch designs, patterns, or text onto metal surfaces. This technique offers high precision and durability, making it ideal for a wide range of applications.

Technology

Laser engraving employs a high-intensity laser to remove material from the surface of the metal. The process involves directing a laser beam onto the material, which heats and vaporizes it, leaving a permanent mark. The depth and intensity of the engraving can be controlled by adjusting the laser’s power, speed, and focus. Commonly used lasers for metal engraving include CO2 lasers, fiber lasers, and Nd:YAG lasers. Fiber lasers, in particular, are favored for their efficiency and ability to engrave a variety of metals such as stainless steel, aluminum, copper, and brass.

Applications

1. Industrial Manufacturing:

– Tool Marking: Engraving serial numbers, barcodes, and other identification marks on tools and machinery.

– Electronic Components: Marking circuit boards and other electronic parts with identifiers and logos.

2. Jewelry and Personalization:

– Customization: Creating personalized designs on jewelry, watches, and other metal accessories.

– High Precision: Achieving intricate and detailed designs that are difficult with traditional methods.

3. Automotive Industry:

– Parts Identification: Engraving part numbers, logos, and other critical information on automotive components.

– Aesthetic Enhancements: Adding decorative elements to car interiors and exteriors.

4. Aerospace:

– Traceability: Marking critical parts with information for maintenance and safety.

– Durability: Ensuring marks withstand extreme conditions.

5. Medical Devices:

– Sterilization Resistant: Creating marks that endure sterilization processes without degrading.

– Compliance: Ensuring medical devices meet regulatory requirements with clear, permanent markings.

Benefits

– Precision: High accuracy and fine detail achievable.

– Durability: Marks are resistant to wear and environmental factors.

– Flexibility: Applicable to a variety of metals and alloys.

– Speed: Fast processing time compared to traditional methods.

Laser engraving metals is an innovative technique that combines precision, durability, and versatility, making it essential in various industrial and commercial sectors.

Quality Testing Methods for laser engraving metals and how to control quality

Quality testing for laser engraving on metals involves various methods to ensure precision, durability, and consistency. Key methods include:

1. Visual Inspection:

– Magnification Tools: Using microscopes or magnifying glasses to check for engraving precision, clarity, and consistency.

– Surface Finish Assessment: Ensuring the engraved surface is smooth and free from burrs or unwanted marks.

2. Dimensional Analysis:

– Calipers and Micrometers: Measuring the depth and width of engravings to ensure they meet specified tolerances.

– Coordinate Measuring Machines (CMM): Providing high-precision measurements of the engraving dimensions.

3. Surface Roughness Testing:

– Profilometers: Measuring the roughness of the engraved surface to ensure it meets the required smoothness standards.

4. Material Integrity Tests:

– Hardness Testing: Verifying that the engraving process has not altered the metal’s hardness beyond acceptable limits.

– Microstructural Analysis: Using techniques like scanning electron microscopy (SEM) to ensure the engraving process hasn’t caused micro-cracks or other structural issues.

5. Consistency Checks:

– Automated Optical Inspection (AOI): Using cameras and software to automatically inspect and compare engraved parts against design specifications.

– Sample Testing: Periodically testing random samples from production batches to ensure consistent quality.

6. Durability Testing:

– Abrasion Tests: Assessing the resistance of the engraving to wear and tear.

– Environmental Testing: Exposing engraved samples to various environmental conditions (humidity, temperature, corrosive environments) to ensure long-term durability.

Quality Control Practices

1. Standard Operating Procedures (SOPs): Establishing detailed SOPs for the laser engraving process to ensure consistency.

2. Training and Certification: Ensuring that operators are well-trained and certified to handle laser engraving equipment.

3. Calibration of Equipment: Regular calibration of laser engraving machines to maintain precision.

4. Documentation and Traceability: Keeping detailed records of each batch, including inspection results and any deviations from standards.

5. Continuous Improvement: Implementing a feedback loop to continually refine the process based on testing outcomes and technological advancements.

By integrating these methods and practices, manufacturers can maintain high-quality standards in laser engraving on metals.

Tips for Procurement and Considerations when Purchasing from laser engraving metals

When procuring laser engraving metals, several key considerations and tips can ensure a smooth and successful purchase:

1. Material Compatibility: Verify that the metals you intend to purchase are compatible with laser engraving. Common metals include stainless steel, aluminum, brass, copper, and titanium. Different metals react differently to laser engraving, impacting the quality and precision of the engravings.

2. Supplier Reputation: Choose reputable suppliers with positive reviews and a track record of providing high-quality metals. Check for certifications and customer testimonials to gauge reliability.

3. Metal Quality: Ensure the metals are of high quality, free from impurities, and have consistent thickness. Poor-quality metals can result in subpar engravings and damage to laser equipment.

4. Specification Accuracy: Clearly specify the dimensions, thickness, and any other relevant properties of the metals. Accurate specifications help avoid issues during the engraving process.

5. Sample Testing: Request samples from potential suppliers and perform test engravings. This helps assess the metal’s performance with your laser equipment and ensures it meets your standards.

6. Bulk Purchasing: Consider bulk purchasing to reduce costs. Negotiate pricing based on volume and establish long-term relationships with suppliers for better deals and reliable supply.

7. Lead Time and Delivery: Confirm the lead time and delivery schedules with suppliers. Ensure that the delivery times align with your project timelines to avoid delays.

8. Technical Support: Opt for suppliers that offer technical support and after-sales service. This can be crucial for troubleshooting and optimizing the engraving process.

9. Cost Considerations: Evaluate the cost of metals, including shipping and handling. Compare prices from different suppliers to ensure competitive rates without compromising quality.

10. Compliance and Standards: Ensure that the metals comply with industry standards and regulations. This is especially important if the engraved products are for specific industries like medical or aerospace.

By following these tips and carefully considering the outlined factors, you can make informed decisions and achieve optimal results in your laser engraving projects.

FAQs on Sourcing and Manufacturing from laser engraving metals in China

FAQs on Sourcing and Manufacturing Laser Engraving Metals in China

1. Why source laser engraving metals from China?

China offers a vast range of materials at competitive prices due to its extensive manufacturing infrastructure. Additionally, many suppliers have advanced technology and expertise in laser engraving.

2. How do I find reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with high ratings, positive reviews, and verified status. Request samples and verify their quality before making large orders.

3. What types of metals are available for laser engraving?

Common metals include stainless steel, aluminum, brass, and titanium. Each metal has different properties, making it suitable for various applications.

4. What are the quality standards?

Ensure suppliers comply with international standards like ISO 9001. You can also request third-party inspections to verify quality.

5. How do I communicate with suppliers?

English is commonly used for business. Use clear, concise language and confirm details through written agreements. WeChat and email are popular communication tools.

6. What are the typical lead times?

Lead times vary depending on the order size and customization. Generally, expect 2-4 weeks for production and additional time for shipping.

7. How is shipping handled?

Suppliers usually handle shipping through international couriers or freight forwarders. Ensure you understand the Incoterms (e.g., FOB, CIF) to know your responsibilities and costs.

8. What are the payment terms?

Common terms include a 30% deposit before production and 70% balance before shipment. Payment methods often include wire transfers, PayPal, and letters of credit.

9. How can I ensure my intellectual property is protected?

Use non-disclosure agreements (NDAs) and work with suppliers who respect IP rights. Registering your IP in China can offer additional protection.

10. What are the potential risks?

Risks include quality issues, communication barriers, and delays. Mitigate these by working with reputable suppliers, conducting due diligence, and having contingency plans.

By following these guidelines, you can efficiently source and manufacture laser engraving metals from China.