Technology and Applications of cnc machine what is

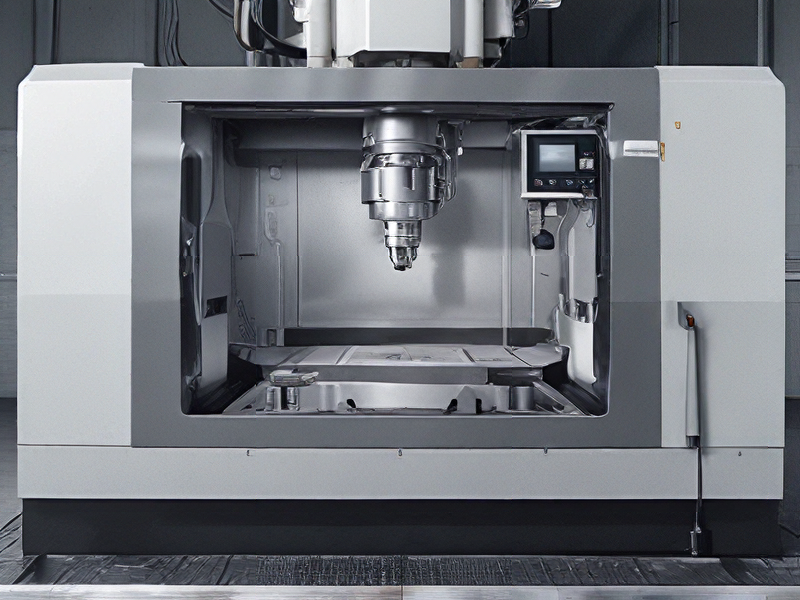

CNC (Computer Numerical Control) machines are automated manufacturing tools controlled by a computer, which executes pre-programmed sequences of machine control commands. These machines are pivotal in modern manufacturing, offering precision, efficiency, and the ability to produce complex parts with minimal human intervention.

Technology

CNC machines utilize a range of technologies:

1. CAD/CAM Software: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are used to create and convert designs into digital instructions.

2. Control System: This includes the computer and interface hardware that reads the digital instructions and converts them into electrical signals to drive the motors.

3. Servo Motors and Drive Systems: These ensure precise movement of the machine’s components.

4. Feedback Systems: Sensors and encoders provide real-time data to adjust the machine’s operations, ensuring accuracy.

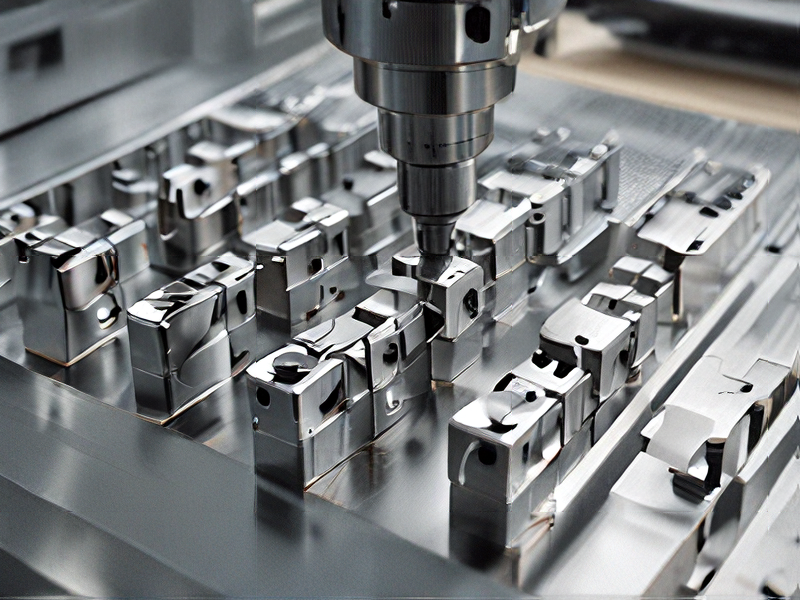

5. Tooling and Spindles: These are the physical parts that interact with the material, such as cutting, drilling, or milling tools.

Applications

1. Manufacturing: CNC machines are extensively used in the automotive, aerospace, and electronics industries to produce parts with high precision and repeatability.

2. Prototyping: They enable rapid prototyping by allowing quick changes to designs, which can be tested and iterated upon.

3. Woodworking: CNC routers can create intricate designs and carvings in wood, increasing efficiency and reducing manual labor.

4. Metalworking: CNC lathes and mills are used to produce detailed metal parts, from simple bolts to complex engine components.

5. Medical: They manufacture precise components for medical devices and implants.

6. Jewelry and Crafts: CNC machines are used to create detailed and custom designs in various materials.

Advantages

– Precision and Consistency: They produce parts with high accuracy and uniformity.

– Efficiency: CNC machines can operate continuously and are faster than manual machining.

– Flexibility: Easy to switch between different tasks with minimal downtime.

– Reduced Labor Costs: Automation reduces the need for manual intervention.

In summary, CNC machines integrate advanced technology to offer versatile, precise, and efficient manufacturing solutions across various industries.

Quality Testing Methods for cnc machine what is and how to control quality

Quality testing for CNC (Computer Numerical Control) machines involves several methods to ensure precision, accuracy, and reliability. Here’s an overview of key methods and how to control quality:

1. Dimensional Inspection:

– Method: Use micrometers, calipers, and coordinate measuring machines (CMMs) to verify dimensions against design specifications.

– Control: Regularly calibrate measuring tools and perform random inspections on produced parts.

2. Surface Finish Testing:

– Method: Employ surface roughness testers to measure the finish quality.

– Control: Implement a standard finish requirement and conduct tests at set intervals.

3. Alignment and Positioning Accuracy:

– Method: Utilize laser interferometers or ballbar systems to check the machine’s geometric accuracy and positioning.

– Control: Schedule periodic alignment checks and maintenance routines to correct any deviations.

4. Material Hardness Testing:

– Method: Use Rockwell or Brinell hardness testers to measure the hardness of machined parts.

– Control: Ensure consistent material properties by testing raw materials and maintaining machine stability.

5. Thermal Stability:

– Method: Monitor the machine’s thermal behavior using thermal imaging or sensors.

– Control: Maintain a controlled environment and allow the machine to reach thermal equilibrium before precision operations.

6. Tool Wear Monitoring:

– Method: Inspect tools visually and use tool condition monitoring systems.

– Control: Replace or recondition tools regularly based on wear patterns and cutting performance.

7. Process Capability Analysis:

– Method: Use statistical process control (SPC) to analyze the consistency and capability of the manufacturing process.

– Control: Implement control charts and perform regular capability studies to detect and address variations.

8. Functional Testing:

– Method: Perform assembly and functional tests to ensure parts fit and work as intended.

– Control: Create detailed test procedures and criteria for each product type.

By combining these methods, CNC machine quality can be controlled effectively. Regular calibration, maintenance, and statistical analysis are crucial to maintaining high standards and identifying potential issues before they affect production.

Tips for Procurement and Considerations when Purchasing from cnc machine what is

Tips for Procurement

1. Define Requirements Clearly:

– Identify the specific needs of your operation, including the type of materials you will work with and the precision required.

2. Research and Compare Suppliers:

– Look for suppliers with a good reputation and extensive experience in CNC machining. Compare their offerings, quality standards, and customer reviews.

3. Evaluate Technical Specifications:

– Ensure the CNC machine’s specifications meet your needs. Key specs include spindle speed, power, precision, and the number of axes.

4. Assess Total Cost of Ownership:

– Consider not only the initial purchase price but also maintenance costs, energy consumption, and potential downtime.

5. Request Demonstrations:

– If possible, see the machine in action. This can help you understand its capabilities and limitations.

6. Check for Support and Training:

– Ensure the supplier provides adequate technical support and training for your team to operate the machine effectively.

7. Review Warranty and Service Agreements:

– Look for comprehensive warranties and service agreements to cover potential issues and ensure long-term reliability.

Considerations When Purchasing

1. Machine Capability:

– Assess the machine’s capability to handle the size, complexity, and volume of parts you plan to produce.

2. Software Compatibility:

– Ensure the CNC machine is compatible with your existing CAD/CAM software or that the necessary software is included.

3. Flexibility and Upgradability:

– Choose a machine that can adapt to future needs, such as new materials or production methods.

4. Quality and Precision:

– Verify the machine’s precision and ability to maintain tight tolerances consistently.

5. Speed and Efficiency:

– Evaluate the machine’s speed and efficiency to ensure it meets your production timelines.

6. Ease of Maintenance:

– Consider the ease of performing regular maintenance and the availability of spare parts.

7. Environmental and Safety Standards:

– Ensure the machine complies with environmental regulations and safety standards to protect operators and the workplace.

By focusing on these tips and considerations, you can make a more informed decision when procuring a CNC machine, ensuring it aligns with your operational needs and long-term goals.

FAQs on Sourcing and Manufacturing from cnc machine what is in China

FAQs on Sourcing and Manufacturing CNC Machines from China

#### 1. Why source CNC machines from China?

China offers a competitive edge in manufacturing due to lower labor costs, advanced technology, and a well-established supply chain. Many Chinese manufacturers produce high-quality CNC machines at a fraction of the cost compared to Western manufacturers.

#### 2. How to find reliable CNC machine manufacturers in China?

Utilize online platforms like Alibaba, Made-in-China, and Global Sources. Attending trade shows like the China CNC Machine Tool Fair (CCMT) can also help. Conduct thorough research, read reviews, and request references from potential suppliers.

#### 3. What are the key considerations when selecting a supplier?

– Quality and Certification: Ensure the manufacturer meets international quality standards (ISO, CE).

– Reputation: Check their history and customer reviews.

– Capacity: Verify their production capacity and lead times.

– Support: Ensure they offer adequate after-sales support and warranty.

#### 4. What are the common types of CNC machines available?

China manufactures a wide range of CNC machines including:

– CNC Milling Machines

– CNC Lathes

– CNC Routers

– CNC Plasma Cutters

– CNC Laser Cutters

#### 5. How to ensure product quality?

– Factory Visits: Visit the factory to inspect their production processes.

– Third-Party Inspections: Hire independent inspection services to verify quality.

– Samples: Request samples before placing bulk orders.

#### 6. What are the payment terms and conditions?

Common payment terms include:

– T/T (Telegraphic Transfer): Often 30% deposit and 70% before shipment.

– L/C (Letter of Credit): Ensures security for large transactions.

– Escrow Services: Offered by platforms like Alibaba for added security.

#### 7. How long does shipping take?

Shipping typically takes 4-6 weeks by sea. Air freight is faster but more expensive, usually taking 1-2 weeks.

#### 8. Are there any import duties or taxes?

Yes, import duties and taxes vary by country. Check with local customs authorities to understand the applicable rates and regulations.

#### 9. What are the potential risks and how to mitigate them?

– Quality Issues: Mitigate by thorough vetting and inspections.

– Intellectual Property (IP) Risks: Protect IP by registering patents and trademarks in China.

– Communication Barriers: Use bilingual contracts and employ translators if necessary.

By considering these factors, businesses can effectively source and manufacture CNC machines from China, leveraging the cost benefits and manufacturing capabilities available.