Technology and Applications of metals ferrous and non ferrous

Technology and Applications of Metals: Ferrous and Non-Ferrous

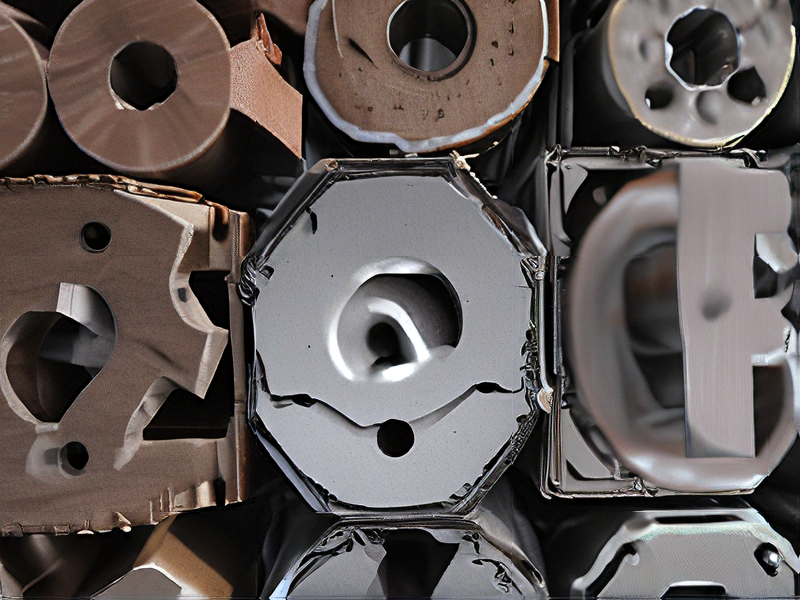

#### Ferrous Metals

Ferrous metals contain iron and are known for their strength and durability. Key technologies involve steelmaking, which includes processes like basic oxygen steelmaking (BOS) and electric arc furnaces (EAF). These methods produce various steel types with differing properties.

– Steel: Utilized in construction (beams, rebar), automotive industries (bodies, frames), and manufacturing (tools, machinery).

– Cast Iron: Known for excellent castability and compressive strength, used in pipes, automotive parts, and cookware.

– Wrought Iron: Malleable and corrosion-resistant, used in decorative gates, railings, and furniture.

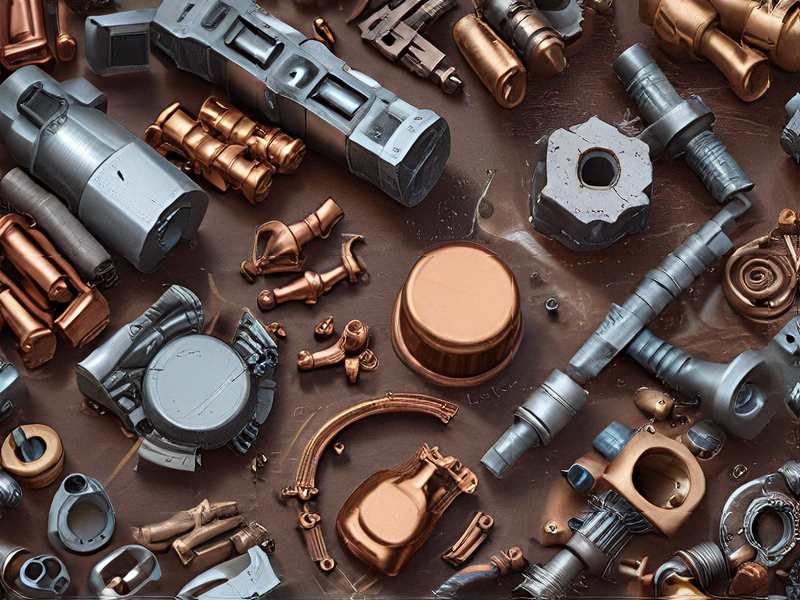

#### Non-Ferrous Metals

Non-ferrous metals do not contain iron, making them resistant to rust and corrosion. Technologies for processing these metals include electrolytic refining, vacuum distillation, and advanced alloying techniques.

– Aluminum: Lightweight and strong, used in aerospace (aircraft bodies), automotive (engine parts), packaging (cans, foils), and construction (windows, doors).

– Copper: Excellent electrical and thermal conductivity, essential in electrical wiring, plumbing, and electronics.

– Titanium: High strength-to-weight ratio and corrosion resistance, used in aerospace, medical implants, and sports equipment.

– Zinc: Primarily for galvanizing steel to prevent rust, also used in die-casting alloys, batteries, and as a component in brass.

– Nickel: Corrosion resistance and high-temperature stability, used in stainless steel, superalloys for turbines, and rechargeable batteries.

Both ferrous and non-ferrous metals are critical in modern technology, driving advancements in industries from construction and transportation to electronics and healthcare.

Quality Testing Methods for metals ferrous and non ferrous and how to control quality

Quality Testing Methods for Metals

1. Visual Inspection:

– Purpose: Identify surface defects such as cracks, porosity, and inclusions.

– Tools: Magnifying glasses, microscopes.

2. Chemical Analysis:

– Purpose: Determine the elemental composition.

– Methods: Spectroscopy (e.g., XRF, OES).

3. Mechanical Testing:

– Purpose: Assess strength, ductility, hardness.

– Tests: Tensile, hardness (e.g., Rockwell, Brinell), impact (Charpy, Izod).

4. Non-Destructive Testing (NDT):

– Purpose: Detect internal defects without damaging the material.

– Methods: Ultrasonic testing, radiographic testing, magnetic particle testing, dye penetrant testing.

5. Metallographic Examination:

– Purpose: Study the microstructure.

– Tools: Optical microscopes, scanning electron microscopes (SEM).

6. Corrosion Testing:

– Purpose: Evaluate resistance to corrosion.

– Methods: Salt spray tests, electrochemical tests.

Quality Control Methods

1. Incoming Material Inspection:

– Inspect and test raw materials before production to ensure they meet specifications.

2. In-Process Inspection:

– Conduct regular checks during production to detect and address defects early.

3. Final Product Testing:

– Perform comprehensive tests on finished products to ensure they meet all quality standards.

4. Statistical Process Control (SPC):

– Use statistical methods to monitor and control the production process, ensuring consistent quality.

5. ISO 9001 Certification:

– Implement and maintain a quality management system according to ISO 9001 standards to ensure continuous improvement.

6. Training and Competence:

– Ensure that personnel are properly trained in quality control procedures and the use of testing equipment.

By integrating these testing and control methods, manufacturers can maintain high standards of quality for both ferrous and non-ferrous metals.

Tips for Procurement and Considerations when Purchasing from metals ferrous and non ferrous

When procuring ferrous and non-ferrous metals, consider these key tips:

1. Understand Material Properties:

– Ferrous metals (e.g., steel, iron) are strong, durable, and magnetic but prone to rust.

– Non-ferrous metals (e.g., aluminum, copper, brass) are lighter, corrosion-resistant, and non-magnetic.

2. Quality and Standards:

– Verify the metal grade and ensure it meets relevant industry standards.

– Request material certifications and testing reports to confirm specifications.

3. Supplier Selection:

– Choose reputable suppliers with a proven track record.

– Evaluate suppliers based on quality, reliability, and compliance with regulations.

4. Cost Considerations:

– Compare prices from multiple suppliers to ensure competitive rates.

– Factor in total cost of ownership, including delivery, handling, and potential waste.

5. Lead Time and Availability:

– Assess lead times and ensure timely delivery to avoid production delays.

– Check stock availability to handle urgent requirements.

6. Sustainability:

– Consider suppliers who offer recycled or eco-friendly materials.

– Evaluate the environmental impact of the metals and their sourcing practices.

7. Logistics and Storage:

– Plan for secure and appropriate storage to prevent damage and deterioration.

– Optimize logistics to reduce costs and ensure safe transportation.

8. Customization and Processing:

– Determine if the supplier offers custom sizes or processing services such as cutting, welding, or coating.

– Ensure these services meet your quality requirements.

9. Legal and Compliance:

– Ensure compliance with local and international trade regulations.

– Verify certifications related to environmental, health, and safety standards.

By considering these factors, you can make informed decisions that align with your project requirements and business goals.

FAQs on Sourcing and Manufacturing from metals ferrous and non ferrous in China

FAQs on Sourcing and Manufacturing Ferrous and Non-Ferrous Metals in China

#### 1. What are ferrous and non-ferrous metals?

– Ferrous metals contain iron and are magnetic, such as steel and cast iron.

– Non-ferrous metals do not contain iron, are non-magnetic, and include aluminum, copper, and zinc.

#### 2. Why source metals from China?

– Cost Efficiency: Lower production and labor costs.

– Advanced Manufacturing: Access to advanced technologies and large-scale manufacturing capabilities.

– Diverse Suppliers: Wide range of suppliers offering various metals and alloys.

#### 3. What are the key considerations when sourcing from China?

– Quality Control: Ensure the supplier follows international quality standards.

– Supplier Verification: Verify the legitimacy and reliability of suppliers.

– Logistics: Plan for shipping times, customs, and tariffs.

#### 4. How to verify the quality of metals?

– Certifications: Look for ISO, ASTM, or other relevant certifications.

– Third-party Inspections: Utilize independent inspection services to verify quality.

– Sample Testing: Request samples and conduct material testing before bulk orders.

#### 5. What are common challenges in sourcing metals from China?

– Communication Barriers: Language differences can lead to misunderstandings.

– Quality Variations: Inconsistent quality control among different suppliers.

– Intellectual Property (IP) Risks: Protect your designs and specifications from being copied.

#### 6. How to find reliable suppliers?

– Online Marketplaces: Platforms like Alibaba, Made-in-China, and Global Sources.

– Trade Shows: Attend industry-specific trade fairs such as the Canton Fair.

– Consulting Firms: Use sourcing agents or consulting firms with local expertise.

#### 7. What are the shipping considerations?

– Incoterms: Understand international commercial terms (e.g., FOB, CIF).

– Lead Times: Plan for production and shipping times, considering potential delays.

– Customs: Be aware of import duties, taxes, and compliance with local regulations.

#### 8. How to handle payments?

– Payment Terms: Negotiate favorable terms (e.g., Letter of Credit, T/T).

– Currency Exchange: Consider the impact of currency fluctuations on costs.

By considering these factors, businesses can effectively navigate the complexities of sourcing and manufacturing ferrous and non-ferrous metals from China.