Technology and Applications of what is cnc equipment

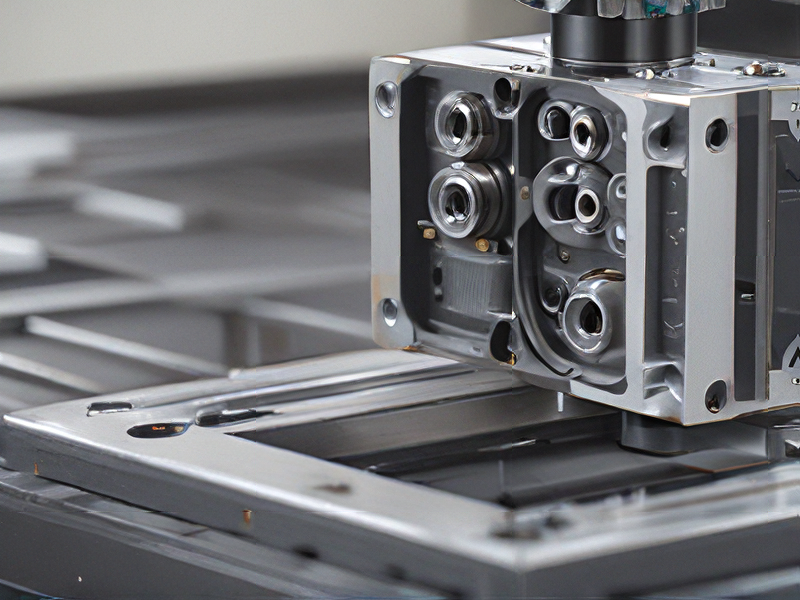

CNC (Computer Numerical Control) equipment refers to machines that are operated through programmed commands encoded in software, rather than being manually controlled by a human operator. The technology behind CNC involves integrating a computer with a machine tool, enabling precise, automated control of machining processes.

Technology:

1. Control Unit: The brain of the CNC machine, it reads the G-code and converts it into electrical signals to control the movement of the machine’s components.

2. G-code: A programming language used to instruct the CNC machine on how to perform tasks such as cutting, drilling, or milling.

3. Servo Motors and Drives: These control the movement of the machine’s axes with high precision.

4. Feedback System: Ensures that the machine performs tasks accurately by continuously comparing the actual position with the commanded position.

5. Tooling System: Includes various tools (cutters, drills, etc.) that perform the machining operations.

Applications:

1. Manufacturing: CNC machines are extensively used in manufacturing for producing complex parts with high precision. This includes automotive components, aerospace parts, and consumer electronics.

2. Prototyping: Rapid prototyping using CNC allows designers to quickly create and test models before full-scale production.

3. Medical Industry: Used for making precise components for medical devices and implants.

4. Aerospace: Produces components with stringent tolerances required in the aerospace industry.

5. Custom Manufacturing: Enables custom and small-batch production, allowing for flexibility in design changes and specific customer requirements.

6. Art and Sculpture: Artists and sculptors use CNC machines to create detailed and intricate designs.

CNC technology revolutionizes production by increasing efficiency, accuracy, and repeatability, reducing human error, and enabling complex and precise manufacturing processes.

Quality Testing Methods for what is cnc equipment and how to control quality

Quality Testing Methods for CNC Equipment and Quality Control

1. Dimensional Inspection:

– Tools Used: Micrometers, calipers, coordinate measuring machines (CMM).

– Purpose: To ensure parts meet precise dimensional specifications.

2. Surface Finish Inspection:

– Tools Used: Surface roughness testers, profilometers.

– Purpose: To check the surface quality, ensuring it meets the required finish standards.

3. Visual Inspection:

– Tools Used: Magnifying glasses, microscopes.

– Purpose: To detect visible defects such as cracks, scratches, and tool marks.

4. Non-Destructive Testing (NDT):

– Methods: Ultrasonic testing, X-ray, dye penetrant testing, magnetic particle testing.

– Purpose: To identify internal defects without damaging the part.

5. Hardness Testing:

– Tools Used: Hardness testers (Rockwell, Vickers, Brinell).

– Purpose: To ensure material hardness is within specified limits.

6. Material Composition Analysis:

– Tools Used: Spectrometers, X-ray fluorescence (XRF) analyzers.

– Purpose: To verify the chemical composition of the materials used.

7. Functional Testing:

– Tools Used: Custom test rigs, dynamic testing machines.

– Purpose: To ensure the part functions correctly under operational conditions.

Quality Control Methods:

1. Statistical Process Control (SPC):

– Tools Used: Control charts, histograms.

– Purpose: To monitor and control the manufacturing process using statistical methods.

2. Six Sigma:

– Approach: DMAIC (Define, Measure, Analyze, Improve, Control).

– Purpose: To reduce defects and improve process quality.

3. Total Quality Management (TQM):

– Approach: Company-wide effort to improve quality, involving all employees.

– Purpose: To enhance customer satisfaction and continuous improvement.

4. ISO 9001:

– Standard: International standard for quality management systems.

– Purpose: To ensure consistent quality through standardized processes.

By implementing these methods, manufacturers can control and ensure the quality of CNC machined parts, meeting precise specifications and maintaining high standards.

Tips for Procurement and Considerations when Purchasing from what is cnc equipment

When procuring CNC (Computer Numerical Control) equipment, consider the following tips and considerations to ensure a successful purchase:

Tips for Procurement:

1. Define Requirements: Clearly outline your manufacturing needs, including the types of materials to be machined, production volume, precision requirements, and specific features required in the CNC equipment.

2. Budget Planning: Establish a realistic budget that includes not only the initial purchase price but also additional costs like installation, training, maintenance, and potential upgrades.

3. Vendor Selection: Research and select reputable vendors with a history of providing reliable CNC machines and good after-sales support. Consider vendors that offer comprehensive warranties and service agreements.

4. Technology Assessment: Evaluate the latest CNC technologies to ensure the machine you choose meets current industry standards and can adapt to future advancements.

5. Customization Options: Determine if the CNC equipment can be customized or upgraded to suit evolving production needs, ensuring long-term usability and investment protection.

6. Training and Support: Ensure the vendor provides adequate training for your staff and robust technical support to minimize downtime and maintain production efficiency.

Considerations when Purchasing:

1. Machine Specifications: Assess the machine’s capabilities, such as spindle speed, axis travel distance, and precision levels, to ensure it aligns with your production requirements.

2. Software Compatibility: Verify that the CNC machine’s software is compatible with your existing systems and supports necessary design and production software.

3. Maintenance and Spare Parts: Consider the availability of maintenance services and the ease of obtaining spare parts. Opt for machines with a good track record of reliability and low maintenance needs.

4. Energy Efficiency: Evaluate the energy consumption of the CNC equipment to ensure it aligns with your company’s sustainability goals and operational cost considerations.

5. Resale Value: Consider the machine’s resale value, which can be an indicator of its quality and long-term reliability.

By carefully considering these factors, you can make an informed decision that aligns with your operational needs and financial constraints, ensuring a smooth and efficient procurement process for CNC equipment.

FAQs on Sourcing and Manufacturing from what is cnc equipment in China

FAQs on Sourcing and Manufacturing with CNC Equipment in China

1. What is CNC equipment?

CNC (Computer Numerical Control) equipment refers to machines that are controlled by computers to perform precise manufacturing tasks. Common CNC machines include lathes, mills, routers, and plasma cutters.

2. Why source CNC equipment from China?

China offers cost-effective manufacturing solutions, a wide variety of CNC machines, and a robust supply chain network. This can lead to significant cost savings and access to advanced technology.

3. How to find reliable CNC equipment manufacturers in China?

Research online marketplaces like Alibaba, attend trade shows (e.g., Canton Fair), and seek referrals. Verify the manufacturer’s credentials, request samples, and check customer reviews.

4. What are the common challenges in sourcing CNC equipment from China?

Language barriers, quality control, and shipping logistics can be challenging. Mitigating these issues involves clear communication, using third-party quality inspection services, and understanding import regulations.

5. How to ensure the quality of CNC equipment from Chinese manufacturers?

Visit the factory if possible, request detailed product specifications, and use third-party quality inspection services. Establish clear quality standards and ensure they are documented in contracts.

6. What are the typical lead times for CNC equipment from China?

Lead times can vary from a few weeks to several months, depending on the complexity of the equipment and order volume. It’s important to plan accordingly and maintain open communication with the supplier.

7. What are the payment terms for sourcing CNC equipment from China?

Common payment terms include a deposit (30%) before production and the balance (70%) upon shipment. Letters of credit and escrow services can offer additional security.

8. How to handle shipping and customs for CNC equipment?

Work with experienced freight forwarders and customs brokers who can navigate international shipping and import regulations. Ensure all necessary documentation is prepared and accurate.

By understanding these key aspects, businesses can effectively source and manufacture CNC equipment from China, leveraging its cost advantages and manufacturing capabilities.