Technology and Applications of 4×8 sheets of plastic

4×8 sheets of plastic, typically made from materials like acrylic, polycarbonate, or PVC, find widespread use across various industries due to their versatility and practical applications. One significant use is in construction and building materials. These sheets are employed for windows, skylights, and protective barriers due to their transparency, durability, and weather resistance. In interior design, they serve as decorative panels or partitions, offering flexibility in design and easy installation.

In manufacturing, 4×8 plastic sheets are utilized for creating prototypes, machine guards, and packaging materials. Their lightweight nature and ease of fabrication make them ideal for custom enclosures and covers. In agriculture, they are used in greenhouse construction, providing a controlled environment for plant growth while offering UV protection and insulation properties.

The signage industry benefits from these sheets for outdoor and indoor signs, as they can be easily cut, painted, and shaped to meet specific design requirements. In the automotive sector, plastic sheets are used for interior components, light covers, and even structural elements due to their impact resistance and design flexibility.

Furthermore, these sheets play a crucial role in DIY projects and crafts, serving as substrates for artistic creations, furniture components, and protective coverings. Their availability in different thicknesses and colors enhances their usability across diverse applications.

Advancements in material technology have led to innovations such as flame-retardant and anti-static properties, expanding their applications in sensitive environments like electronics manufacturing and clean rooms.

In summary, 4×8 plastic sheets are valued for their durability, versatility, and ease of use across industries ranging from construction to automotive to crafts. Their ability to combine functionality with design aesthetics continues to drive their popularity in various sectors globally.

Quality Testing Methods for 4×8 sheets of plastic and how to control quality

Quality testing methods for 4×8 sheets of plastic typically involve several key approaches to ensure consistent quality:

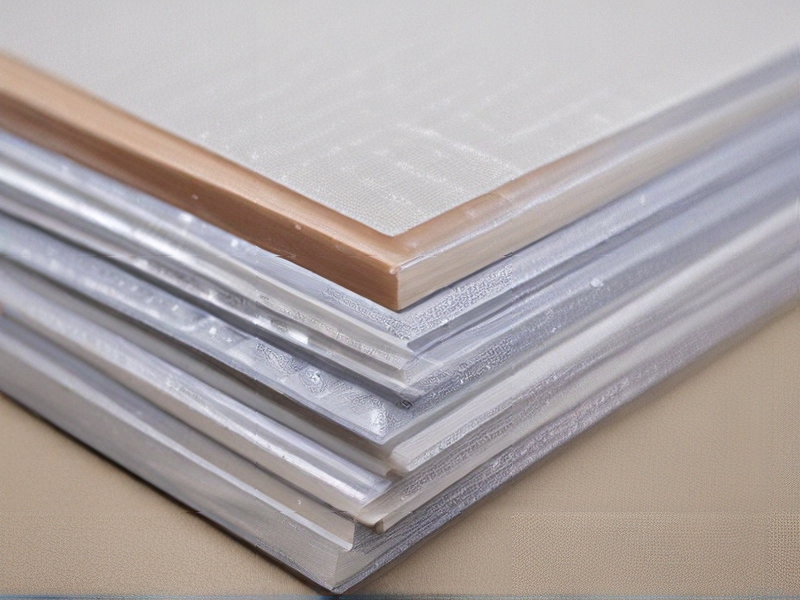

1. Dimensional Inspection: Measure the length, width, and thickness of each sheet using calibrated instruments to ensure they meet specifications. Variations can indicate potential defects or deviations from standards.

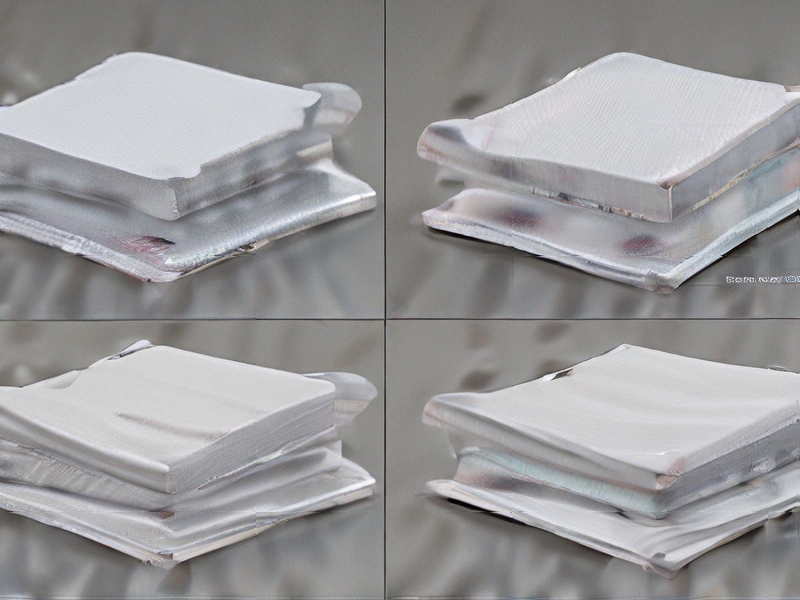

2. Visual Inspection: Examine the surface for defects such as scratches, dents, discoloration, or warping that could affect usability or aesthetics. This is often done manually or with automated vision systems.

3. Weight and Density Checks: Weigh each sheet to verify it meets the expected density and material composition. Deviations may indicate inconsistencies in manufacturing or material quality.

4. Mechanical Properties Testing: Conduct tests for mechanical strength, including tensile strength, impact resistance, and flexural strength. These tests ensure the plastic sheets can withstand intended applications.

5. Chemical Resistance Testing: Assess the sheets’ resistance to chemicals, solvents, and environmental factors to ensure they meet performance requirements in various conditions.

To control quality effectively:

– Establish Standards: Define clear quality standards and specifications for each parameter, such as dimensions, appearance, and performance characteristics.

– Regular Sampling: Implement a sampling plan to test sheets at regular intervals during production. This ensures early detection of deviations and minimizes defects in finished products.

– Calibration and Maintenance: Regularly calibrate testing equipment and maintain them according to manufacturer guidelines to ensure accuracy and reliability of test results.

– Training and Documentation: Train personnel on quality standards and testing procedures. Maintain comprehensive documentation of test results and any corrective actions taken.

– Feedback Loop: Establish a feedback loop between production, quality control, and suppliers to address any recurring issues promptly and continuously improve processes.

By integrating these methods and controls, manufacturers can consistently produce high-quality 4×8 plastic sheets that meet customer expectations and industry standards.

Tips for Procurement and Considerations when Purchasing from 4×8 sheets of plastic

When purchasing 4×8 sheets of plastic, several key considerations can ensure you make an informed procurement decision:

1. Material Type: Understand the specific plastic material required (e.g., acrylic, polycarbonate, PVC) based on factors like durability, transparency, and chemical resistance.

2. Thickness: Determine the appropriate thickness based on structural requirements and intended use, balancing between strength and cost.

3. Quality Standards: Ensure the sheets meet relevant industry standards (e.g., ASTM for plastics) to guarantee quality and performance.

4. Finish and Texture: Consider surface finish options (smooth, textured) depending on aesthetic preferences and functional needs (e.g., glare reduction).

5. Size Accuracy: Verify that the dimensions (4×8 feet) are precise to avoid compatibility issues in applications where exact sizing matters.

6. Color Options: Evaluate available color choices if aesthetics or color-coding are important for your project.

7. Supplier Reputation: Select a reputable supplier known for quality products and reliable customer service to ensure timely delivery and support.

8. Environmental Considerations: Assess if the plastic is recyclable or has sustainable sourcing options if environmental impact is a concern.

9. Cost and Budget: Compare prices among suppliers while considering shipping costs and bulk discounts to optimize budget allocation.

10. Application Suitability: Confirm that the selected plastic material and specifications align with the specific requirements of your application (e.g., indoor vs. outdoor use, exposure to chemicals).

By carefully evaluating these factors, you can confidently choose 4×8 plastic sheets that align with your project’s requirements in terms of performance, durability, and budget efficiency.

FAQs on Sourcing and Manufacturing from 4×8 sheets of plastic in China

When sourcing and manufacturing 4×8 sheets of plastic in China, consider the following FAQs:

1. Can I customize the size and thickness of the sheets?

Yes, most manufacturers in China offer customization options for sheet size and thickness. Provide detailed specifications to ensure they meet your requirements.

2. What types of plastic materials are available?

Chinese manufacturers typically offer a wide range of plastic materials such as PVC, acrylic, polycarbonate, and HDPE. Verify material availability based on your specific needs.

3. Are there minimum order quantities (MOQs) for 4×8 plastic sheets?

MOQs vary by manufacturer and material type. Expect lower MOQs for standard materials and potentially higher MOQs for specialized or custom materials.

4. What quality standards should I expect?

Ensure the manufacturer adheres to international quality standards like ISO or ASTM. Request samples and visit the factory if possible to assess their production capabilities.

5. What are the typical lead times for production and shipping?

Lead times depend on factors like order size, material availability, and production schedules. Discuss timelines with manufacturers to plan accordingly.

6. Can the manufacturer provide packaging and shipping services?

Many manufacturers offer packaging solutions suitable for international shipping. Inquire about packaging options and shipping logistics to ensure safe delivery.

7. What about import duties and customs clearance?

Understand import duties and customs regulations for importing plastic sheets into your country. Work with a freight forwarder or logistics provider experienced in handling imports from China.

8. How do I ensure product quality and avoid defects?

Implement quality control measures throughout production. Specify quality checkpoints, conduct inspections, and outline expectations in your contract with the manufacturer.

9. What payment terms are common?

Payment terms vary but typically involve an initial deposit, with balance payment upon completion or shipment. Negotiate terms that are favorable and secure for both parties.

10. What support does the manufacturer offer after sales?

Confirm the manufacturer’s policy on after-sales support, warranties, and handling of any issues post-delivery.

By addressing these FAQs, you can navigate the sourcing and manufacturing process of 4×8 plastic sheets in China more effectively while ensuring quality and meeting your business needs.