Technology and Applications of cnc coding

CNC coding, or Computer Numerical Control coding, plays a crucial role in modern manufacturing by automating the operation of machine tools through pre-programmed sequences. It involves writing instructions in a specific programming language (e.g., G-code) that machines understand, enabling precise control over movements and operations.

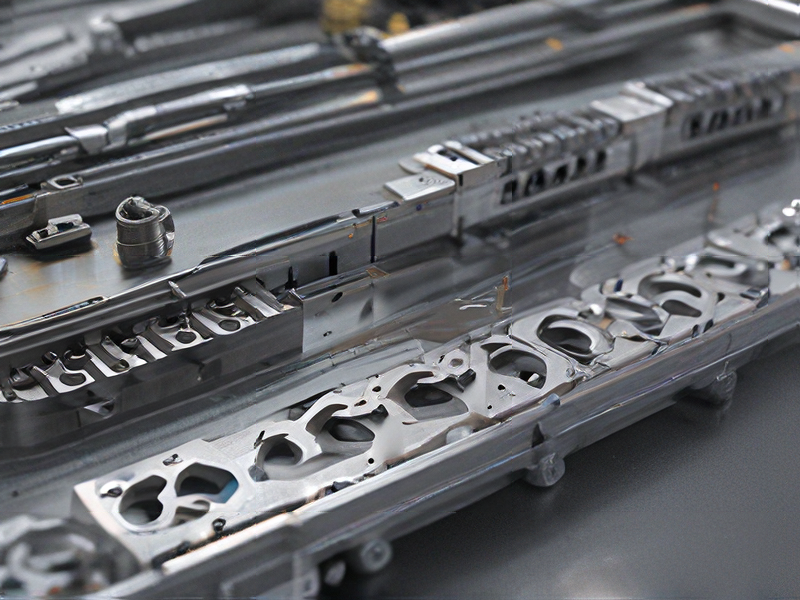

One key application of CNC coding is in machining processes such as milling, turning, drilling, and grinding. These processes are essential across industries like automotive, aerospace, and electronics, where precision and repeatability are critical. CNC machines can execute complex cuts and shapes with high accuracy, making them indispensable for mass production and prototyping.

Moreover, CNC coding facilitates flexibility in manufacturing. It allows rapid adjustments in production lines by simply modifying the code, reducing downtime between different production runs. This adaptability is particularly advantageous in industries requiring frequent design changes or customization.

Additionally, CNC coding supports advanced manufacturing techniques like 3D printing and laser cutting, where intricate designs and fine details are achieved through precise machine control. These technologies rely on CNC instructions to accurately position the print head or laser beam, ensuring the desired output quality.

In conclusion, CNC coding enhances manufacturing efficiency, precision, and versatility across various industries. By enabling automated control over machine tools, it not only optimizes production processes but also supports innovation in manufacturing technologies, driving forward advancements in product design and customization capabilities.

Quality Testing Methods for cnc coding and how to control quality

Quality testing methods for CNC (Computer Numerical Control) coding involve several key practices to ensure precision and reliability:

1. Syntax Verification: Automated tools check CNC code syntax to detect errors like syntax violations or missing parameters, ensuring the code is structurally correct.

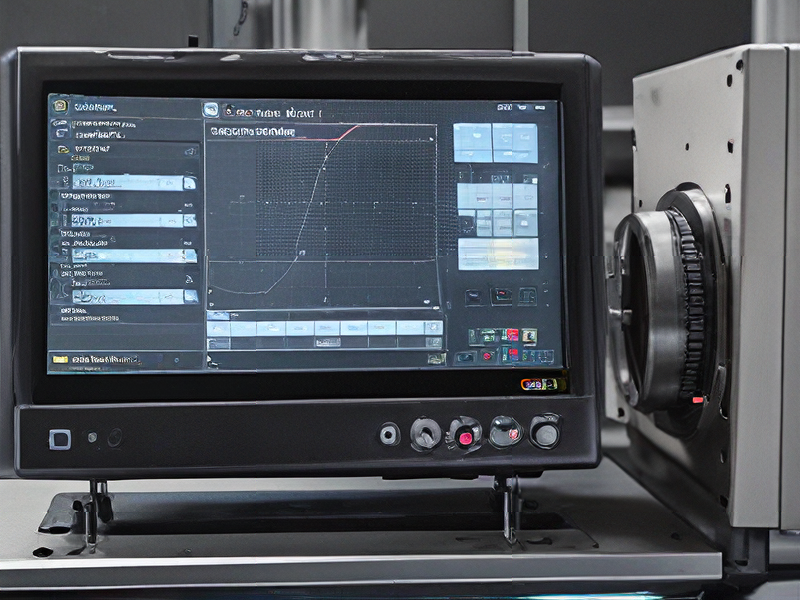

2. Simulation and Verification: CNC simulators are used to visualize toolpaths and simulate machining processes based on the coded instructions. This helps identify potential collisions, toolpath inefficiencies, or inaccuracies before actual machining.

3. Dimensional Analysis: After machining, parts are measured using coordinate measuring machines (CMMs) or other precision instruments to verify dimensional accuracy against CAD/CAM specifications.

4. Toolpath Optimization: Software tools analyze toolpaths to minimize cycle times, reduce tool wear, and improve surface finish, ensuring efficient and high-quality machining.

5. Process Monitoring: Real-time monitoring systems track machine parameters such as spindle speed, feed rate, and tool wear during machining. Deviations from set parameters trigger alarms for immediate corrective action.

To control quality effectively:

– Standardization: Establish standard CNC programming practices and templates to maintain consistency and reduce errors.

– Training and Certification: Ensure programmers and operators are trained in CNC programming and quality control measures.

– Continuous Improvement: Regularly update CNC programs based on feedback and lessons learned from previous machining operations.

– Documentation: Maintain comprehensive records of CNC programs, machining parameters, and inspection results for traceability and future reference.

By integrating these methods and controls into CNC coding processes, manufacturers can enhance productivity, minimize scrap, and deliver high-quality machined parts consistently.

Tips for Procurement and Considerations when Purchasing from cnc coding

When engaging in procurement involving CNC coding, several key considerations can optimize the process:

1. Technical Specifications: Ensure a clear understanding of the required CNC coding specifications such as G-codes and M-codes, ensuring they align with your manufacturing needs.

2. Supplier Capability: Assess the supplier’s expertise in CNC coding. Verify their experience, certifications, and previous projects to ensure they can meet your requirements.

3. Quality Standards: Define quality metrics and standards for CNC-coded parts or components. Ensure the supplier adheres to industry standards and has robust quality control processes in place.

4. Cost Efficiency: Compare quotes from different suppliers to find a balance between cost and quality. Consider long-term costs including maintenance, support, and potential re-coding needs.

5. Lead Times: Evaluate the supplier’s ability to meet your production timelines. Clear communication on lead times and delivery schedules is crucial to avoid production delays.

6. Communication and Support: Establish clear lines of communication with the supplier. Ensure they provide adequate support for technical queries, modifications, and troubleshooting.

7. Flexibility and Scalability: Assess the supplier’s ability to scale production according to your future needs. Consider their flexibility in accommodating changes or customization requests.

8. Risk Management: Identify potential risks such as intellectual property protection, supply chain disruptions, and data security when sharing CNC coding files.

9. Contractual Agreements: Draft comprehensive contracts covering terms of service, warranties, liabilities, and confidentiality agreements to protect both parties’ interests.

10. Feedback and Continuous Improvement: Regularly review supplier performance and gather feedback from stakeholders to drive continuous improvement in procurement processes.

By addressing these considerations, you can enhance efficiency, mitigate risks, and ensure successful procurement when purchasing services involving CNC coding.

FAQs on Sourcing and Manufacturing from cnc coding in China

When sourcing CNC coding services or manufacturing in China, consider these FAQs:

1. What are the benefits of sourcing CNC coding in China?

China offers cost-effective solutions due to lower labor and operational costs. It also has a vast network of suppliers and manufacturers specializing in CNC machining.

2. How do I ensure quality when sourcing from China?

Vet potential suppliers thoroughly. Conduct factory audits, request samples, and establish clear quality standards and inspections throughout production.

3. What are common challenges when sourcing from China?

Language barriers, cultural differences, and logistics can pose challenges. Miscommunication can lead to delays or errors in production.

4. What factors influence manufacturing costs in China?

Costs depend on material quality, complexity of CNC programming, batch size, and finishing requirements. Negotiate pricing based on these factors.

5. How can I protect my intellectual property (IP)?

Use non-disclosure agreements (NDAs), contracts, and consider registering patents or trademarks in China. Work with reputable suppliers with a good IP protection record.

6. What are the typical lead times for CNC machining in China?

Lead times vary based on project complexity and supplier capabilities. Discuss timelines early and monitor progress closely.

7. What are the payment terms usually accepted?

Common terms include initial deposits, progress payments, and final payments upon completion and inspection of goods. Clarify payment terms in the contract.

8. How can I manage logistics and shipping?

Work with suppliers who have experience in international shipping. Consider using Incoterms to define responsibilities and costs clearly.

9. What are the regulatory requirements for importing CNC machined parts?

Ensure compliance with import regulations, tariffs, and certifications required in your country. Work with freight forwarders who understand these requirements.

10. How do I resolve disputes with Chinese suppliers?

Resolve issues amicably through open communication and documentation. Seek mediation or legal assistance if necessary.

Navigating CNC coding and manufacturing in China requires thorough preparation, clear communication, and diligent oversight to ensure successful outcomes.