Technology and Applications of metal stamping kit

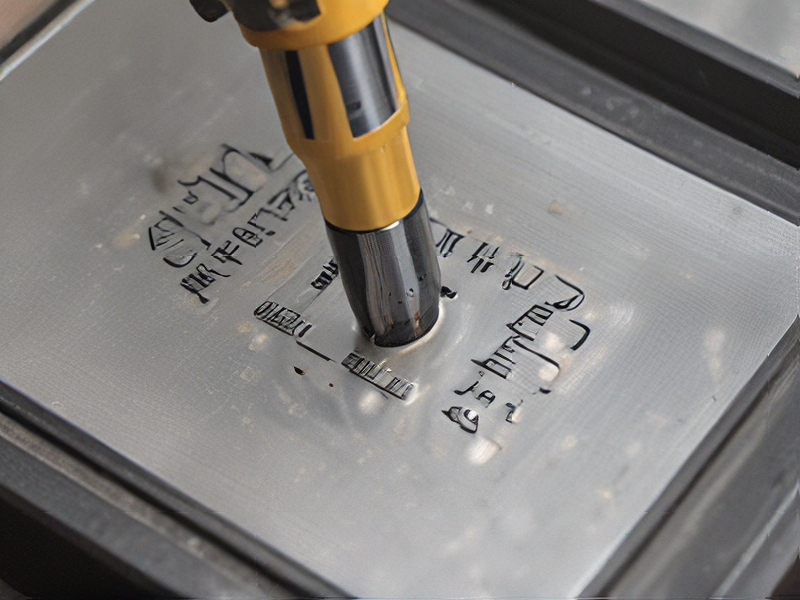

Metal stamping kits are versatile tools used in various applications, primarily in crafting, jewelry making, and metalworking. These kits typically include steel stamps with different designs or letters, a hammer or mallet for striking the stamps, and sometimes an anvil or hard surface for support. Here are some common uses and applications:

1. Jewelry Making: Metal stamping kits are popular among jewelry makers for personalizing metal pieces like bracelets, necklaces, and pendants. They allow artisans to imprint names, dates, symbols, or intricate designs onto metal surfaces, adding a unique touch to their creations.

2. Identification and Marking: In industrial settings, metal stamping kits are used for identification purposes. Manufacturers use them to imprint serial numbers, part numbers, or company logos onto metal components. This helps in inventory tracking, quality control, and branding.

3. Crafting and DIY Projects: Hobbyists and DIY enthusiasts use metal stamping kits for a wide range of projects. They can customize keychains, bookmarks, decorative plates, and even leather goods by stamping meaningful phrases or decorative patterns onto metal or leather surfaces.

4. Art and Decoration: Artists incorporate metal stamping into their artworks to create textured surfaces, patterns, or unique designs on metal sheets or sculptures. This technique adds depth and visual interest to their pieces, enhancing their artistic appeal.

5. Educational Purposes: Metal stamping kits are also used in educational settings to teach students about metallurgy, manufacturing processes, and craftsmanship. They provide hands-on experience and demonstrate the principles of stamping, forming, and marking metals.

Overall, metal stamping kits are valued for their versatility, ease of use, and ability to add personalized or decorative elements to a variety of metal and leather items. Whether for commercial production or creative hobbies, these kits remain essential tools in the realm of metalworking and crafting.

Quality Testing Methods for metal stamping kit and how to control quality

Quality testing methods for a metal stamping kit typically include:

1. Dimensional Inspection: Use calipers, micrometers, or coordinate measuring machines (CMM) to verify dimensions of stamped parts against specifications.

2. Surface Quality: Visual inspection or use of surface roughness testers to ensure smoothness and absence of defects like burrs or scratches.

3. Material Testing: Conduct tests like hardness testing (Rockwell or Brinell) to verify material strength and durability.

4. Functionality Testing: Assemble stamped parts as per design and check functionality (e.g., fit, movement, alignment) under simulated operational conditions.

5. Tolerance Testing: Ensure stamped parts meet specified tolerances for critical dimensions.

To control quality:

1. Establish Standards: Define clear quality standards and specifications for each stamped part.

2. Process Control: Implement process controls at every stage of manufacturing to minimize variations and defects.

3. Training: Train operators in proper stamping techniques and quality inspection methods.

4. Inspection Points: Incorporate checkpoints throughout production to catch defects early.

5. Feedback Loop: Establish a feedback loop where quality issues are analyzed, root causes identified, and corrective actions implemented.

6. Documentation: Maintain comprehensive records of inspections, tests, and corrective actions taken.

By employing these methods and controls, manufacturers can ensure consistent quality in metal stamping kits, meeting customer expectations and regulatory requirements.

Tips for Procurement and Considerations when Purchasing from metal stamping kit

When purchasing a metal stamping kit, consider these key tips and considerations:

1. Quality of Stamps: Ensure the stamps are made from durable materials like hardened steel to withstand repeated use without deformation.

2. Stamp Size and Variety: Choose a kit that offers a variety of sizes and fonts to suit different projects and needs.

3. Ease of Use: Look for kits that include easy-grip handles or ergonomic designs to minimize hand fatigue during stamping.

4. Compatibility: Ensure the stamps are compatible with the types of metals you intend to stamp (e.g., aluminum, brass, stainless steel).

5. Precision and Accuracy: Kits with well-defined and sharp characters ensure clear and precise impressions.

6. Safety Features: Consider kits with safety features such as non-slip surfaces or protective coatings to prevent accidents.

7. Reviews and Reputation: Read reviews to gauge the kit’s reliability, customer support, and overall satisfaction from other users.

8. Price and Value: Compare prices while considering the quality and completeness of the kit (number of stamps, accessories included).

9. Additional Accessories: Some kits include alignment guides, storage cases, or cleaning tools which can add value.

10. Durability and Maintenance: Opt for kits that are rust-resistant and easy to clean for prolonged durability.

By considering these factors, you can choose a metal stamping kit that meets your needs for quality, usability, and durability, ensuring successful and satisfying projects.

FAQs on Sourcing and Manufacturing from metal stamping kit in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from a metal stamping kit in China:

1. What are the advantages of sourcing metal stamping kits from China?

China offers cost-effective manufacturing due to lower labor costs and established infrastructure for metalworking. It also provides access to a wide range of suppliers and materials.

2. How can I ensure quality when sourcing from China?

Quality assurance can be ensured by conducting thorough supplier audits, requesting samples, and implementing clear quality control standards in your manufacturing agreement.

3. What are the typical lead times for manufacturing metal stamping kits in China?

Lead times vary based on complexity and volume but generally range from 4 to 12 weeks. Factors such as customization and material availability can influence lead times.

4. How do I handle intellectual property (IP) protection?

Protecting IP involves working with trusted suppliers, signing non-disclosure agreements (NDAs), and considering legal protections like patents where applicable.

5. What are the challenges of sourcing from China?

Challenges include language barriers, cultural differences, logistics management, and potential for counterfeit products. Working with reputable agents or sourcing companies can mitigate these risks.

6. Can I customize metal stamping kits to meet specific requirements?

Yes, many Chinese manufacturers offer customization services. Detailed specifications and clear communication are essential to achieving the desired product.

Navigating sourcing and manufacturing in China requires careful planning, communication, and a proactive approach to quality assurance and IP protection.