Technology and Applications of channels steel

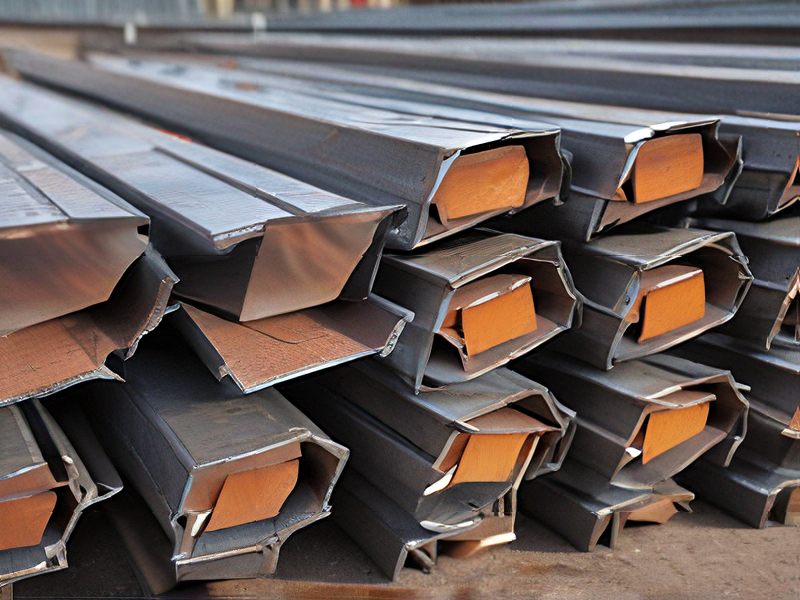

Channel steel, also known as C-beam or U-channel, is a hot-rolled steel with a C-shaped cross-section. Its versatility and structural properties make it widely used in various industries and applications.

Construction and Engineering:

In construction, channel steel is frequently employed as structural support in buildings and bridges. Its shape provides excellent load-bearing capacity, making it suitable for framing and reinforcement. Channels are often used to support floor joists, roof trusses, and columns due to their strength and rigidity. Moreover, their uniform dimensions simplify assembly and welding processes.

Manufacturing and Machinery:

Channel steel is integral to the manufacturing sector, particularly in the production of machinery and equipment. It serves as frames for conveyor systems, machine supports, and frameworks for heavy machinery due to its ability to withstand substantial loads. Manufacturers benefit from its durability and ease of fabrication in constructing robust and reliable equipment.

Transportation and Infrastructure:

In transportation, channel steel finds application in the construction of vehicles and trailers, providing structural integrity while maintaining a lightweight profile. It is also utilized in infrastructure projects such as railways and highways, where it contributes to the support structures of bridges, retaining walls, and overhead gantries.

Storage and Shelving:

Within warehouses and storage facilities, channel steel is employed for shelving units and racks. Its structural strength allows for the efficient storage of heavy goods and materials, ensuring safety and organization within industrial settings.

Renewable Energy and Utilities:

Channel steel is increasingly used in renewable energy sectors, such as solar panel installations and wind turbines. It provides robust support structures that withstand environmental conditions and support the weight of renewable energy components.

In conclusion, channel steel’s adaptability and strength make it indispensable across various sectors, from construction and manufacturing to transportation and renewable energy. Its structural integrity, ease of use, and cost-effectiveness ensure its continued prominence in modern industrial applications.

Quality Testing Methods for channels steel and how to control quality

Quality testing methods for channel steel typically involve both destructive and non-destructive techniques to ensure structural integrity and dimensional accuracy. Here are some common methods:

1. Dimensional Inspection: Measure dimensions such as height, width, and flange thickness using calipers, micrometers, or laser measurement tools.

2. Visual Inspection: Check for surface defects, such as cracks, pitting, or surface discontinuities, which can be indicative of manufacturing issues or handling damage.

3. Chemical Composition Analysis: Utilize spectrometers to verify the chemical composition of the steel, ensuring it meets specified standards for strength and corrosion resistance.

4. Mechanical Testing: Conduct tests like tensile strength, yield strength, and elongation to evaluate the mechanical properties under different loads.

5. Ultrasonic Testing (UT): Use UT to detect internal defects like voids, inclusions, or laminations that may compromise the structural integrity.

6. Magnetic Particle Testing (MPT): Apply magnetic fields and fine iron particles to detect surface and near-surface defects such as cracks or weld discontinuities.

7. Radiographic Testing (RT): Employ X-rays or gamma rays to examine internal and external welds for defects that may not be visible to the naked eye.

To control quality effectively:

– Establish Standards: Define clear quality standards and specifications that channel steel must meet.

– Supplier Qualification: Partner with reputable suppliers who adhere to quality management systems and certifications.

– Process Control: Implement strict process controls during manufacturing to minimize variability and ensure consistency.

– Regular Inspections: Conduct regular inspections at different stages of production to detect issues early and take corrective actions promptly.

– Training and Certification: Train personnel in quality control procedures and ensure they are certified to perform specific tests.

By integrating these methods and controls into the manufacturing process, manufacturers can consistently produce high-quality channel steel that meets industry standards and customer requirements.

Tips for Procurement and Considerations when Purchasing from channels steel

When procuring channels steel, consider the following tips and key considerations:

1. Specifications and Standards: Ensure the channels steel meets the required specifications such as size dimensions (height, width, thickness), material grade (e.g., ASTM A36, S275JR), and any specific industry standards (e.g., ASTM, DIN, BS).

2. Supplier Reputation: Choose suppliers with a proven track record for quality and reliability. Check references, certifications (ISO 9001), and customer reviews to gauge their reputation.

3. Price and Cost: Compare prices from multiple suppliers while considering shipping, delivery charges, and any additional fees. Opt for competitive pricing without compromising on quality.

4. Material Quality: Inspect samples or request material test certificates (MTCs) to verify the quality and conformity of the channels steel to required standards. Ensure the steel has adequate strength, durability, and corrosion resistance as per application needs.

5. Lead Times and Availability: Confirm lead times for production and delivery to align with project schedules. Ensure the supplier has sufficient stock or production capabilities to meet your volume requirements.

6. Logistics and Transportation: Evaluate logistics options to minimize transportation costs and ensure timely delivery. Consider factors such as distance, handling requirements, and packaging.

7. Customer Support and Service: Choose suppliers who offer excellent customer support, including responsiveness to queries, after-sales service, and resolution of issues promptly.

8. Sustainability and Compliance: Verify environmental and sustainability credentials of the supplier, including compliance with regulations such as REACH, RoHS, and sustainable sourcing practices.

9. Long-Term Relationship: Prioritize suppliers who are willing to build a long-term partnership based on trust, reliability, and mutual benefit.

10. Contractual Agreements: Review and negotiate contractual terms regarding payment terms, warranties, returns policy, and dispute resolution mechanisms to protect your interests.

By focusing on these considerations, you can ensure a successful procurement process for channels steel that meets your project requirements effectively and efficiently.

FAQs on Sourcing and Manufacturing from channels steel in China

Certainly! When sourcing and manufacturing channels steel from China, it’s crucial to address several key FAQs:

1. How do I find reliable suppliers?

Begin by researching online platforms like Alibaba or Global Sources. Verify supplier credentials, such as business licenses and certifications. Request samples and check customer reviews for reliability indicators.

2. What are typical lead times for manufacturing?

Lead times vary but generally range from 4 to 12 weeks, depending on order complexity, customization, and supplier capacity. Clarify lead times upfront to align with your project timelines.

3. What quality control measures should I implement?

Conduct factory audits to ensure compliance with international standards. Define product specifications clearly and consider hiring a third-party inspection service to monitor quality throughout production.

4. How can I manage logistics and shipping?

Coordinate with suppliers on shipping terms (FOB, CIF, etc.) and choose reliable freight forwarders to handle logistics. Factor in customs duties, taxes, and potential delays when planning timelines.

5. What are the payment terms typically used?

Negotiate payment terms based on mutual trust and risk management. Common terms include T/T (Telegraphic Transfer) and L/C (Letter of Credit). Consider using secure payment methods to protect transactions.

6. How can I handle language and cultural barriers?

Maintain clear communication through translators or bilingual staff. Understand cultural nuances to foster effective partnerships and avoid misunderstandings.

7. What should I know about intellectual property protection?

Safeguard your designs and patents by registering them in China and internationally. Use non-disclosure agreements (NDAs) and contracts to protect intellectual property during negotiations.

By addressing these FAQs, you can navigate sourcing and manufacturing channels steel from China more effectively while minimizing risks and ensuring quality and compliance with your requirements.