Technology and Applications of what metals are in copper

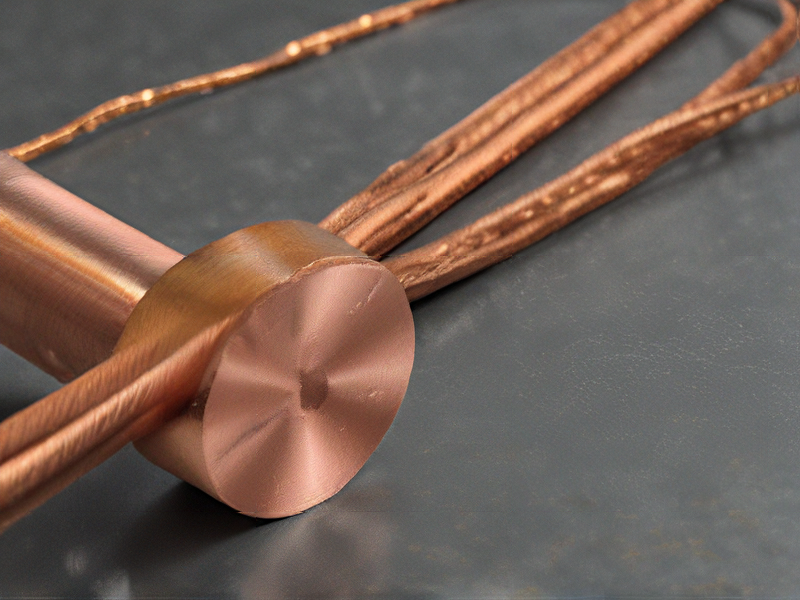

Technology and Applications of Metals in Copper Alloys

Copper is primarily known for its excellent electrical and thermal conductivity, corrosion resistance, and malleability. To enhance its properties for various industrial applications, copper is often alloyed with other metals. Here are some key metals added to copper and their applications:

1. Tin (Bronze):

– Properties: Increases strength, wear resistance, and corrosion resistance.

– Applications: Bearings, gears, and marine hardware.

2. Zinc (Brass):

– Properties: Improves machinability, ductility, and resistance to corrosion.

– Applications: Plumbing fixtures, musical instruments, and decorative items.

3. Nickel:

– Properties: Enhances strength, toughness, and corrosion resistance, especially in harsh environments.

– Applications: Coinage, marine applications, and electrical connectors.

4. Aluminum:

– Properties: Increases strength without significantly compromising conductivity.

– Applications: Heat exchangers, automotive radiators, and air conditioning systems.

5. Silicon:

– Properties: Enhances strength and corrosion resistance, particularly against sulfuric acid.

– Applications: Automotive parts, electrical connectors, and valve seats.

6. Beryllium:

– Properties: Significantly increases hardness, fatigue strength, and resistance to wear.

– Applications: Aerospace components, springs, and electrical contacts.

Technological Applications

1. Electrical and Electronics:

– Copper’s Role: High conductivity and durability.

– Examples: Wires, cables, printed circuit boards, and connectors.

2. Construction:

– Copper’s Role: Corrosion resistance and aesthetic appeal.

– Examples: Roofing, plumbing, and architectural elements.

3. Automotive:

– Copper’s Role: Thermal management and electrical systems.

– Examples: Radiators, brake systems, and wiring harnesses.

4. Telecommunications:

– Copper’s Role: Signal transmission and reliability.

– Examples: Telephone lines and coaxial cables.

5. Marine:

– Copper’s Role: Corrosion resistance in seawater.

– Examples: Ship hulls, propellers, and offshore platforms.

These alloying elements and applications demonstrate the versatility and critical importance of copper in modern technology and industry.

Quality Testing Methods for what metals are in copper and how to control quality

Quality testing for metals in copper involves several analytical techniques to ensure purity and control quality. Here are the primary methods:

1. Spectroscopy:

– Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES): Measures trace metals by analyzing light emitted from a plasma.

– X-ray Fluorescence (XRF): Non-destructive method to identify and quantify metals by measuring fluorescent X-rays emitted from a sample.

2. Mass Spectrometry:

– Inductively Coupled Plasma Mass Spectrometry (ICP-MS): Detects trace elements with high sensitivity and precision by ionizing the sample and measuring the mass-to-charge ratio of ions.

3. Atomic Absorption Spectroscopy (AAS):

– Measures the concentration of metals by absorbing specific wavelengths of light.

4. Wet Chemical Analysis:

– Involves dissolving the copper sample in acid and performing titration or colorimetric analysis to determine metal content.

5. Spark Optical Emission Spectroscopy (Spark OES):

– A rapid method where a spark excites the atoms in the sample, and the emitted light is analyzed to identify metal composition.

Quality Control Measures

1. Standardization:

– Use certified reference materials (CRMs) to calibrate instruments, ensuring accurate and consistent measurements.

2. Sampling Protocols:

– Implement stringent sampling procedures to avoid contamination and ensure representative samples.

3. Process Control:

– Monitor and control the production process parameters to maintain consistent quality.

4. Documentation:

– Maintain detailed records of all testing procedures, results, and calibration data to track quality over time.

5. Regular Audits:

– Conduct regular internal and external audits to ensure compliance with industry standards and identify areas for improvement.

By employing these methods and controls, manufacturers can accurately determine the metal content in copper and ensure high-quality standards in their products.

Tips for Procurement and Considerations when Purchasing from what metals are in copper

When procuring copper and its alloys, it’s crucial to understand the metal’s composition, properties, and applications to make informed purchasing decisions. Here are some key tips and considerations:

Composition of Copper Alloys

1. Pure Copper: Contains 99.9% copper. It is highly conductive and malleable, making it ideal for electrical wiring and plumbing.

2. Brass: An alloy of copper and zinc. Varying the zinc content (typically between 5-45%) can enhance strength and corrosion resistance, making brass suitable for fittings, valves, and decorative items.

3. Bronze: Primarily an alloy of copper and tin, but can include other elements like aluminum, silicon, or nickel. It offers excellent wear and corrosion resistance, used in bearings, gears, and sculptures.

4. Cupronickel: An alloy of copper and nickel (typically 10-30% nickel), known for its corrosion resistance in seawater, making it perfect for marine applications.

Tips for Procurement

1. Understand Requirements: Define the specific requirements for your application, including mechanical properties, conductivity, and corrosion resistance.

2. Verify Purity and Composition: Ensure the supplier provides material certification indicating the precise composition and adherence to relevant standards.

3. Supplier Reliability: Choose reputable suppliers with a track record of quality and consistency. Request references and check for industry certifications.

4. Inspect Samples: Before large-scale purchasing, inspect and test samples to verify quality and suitability for your needs.

5. Consider Environmental Factors: Evaluate the environmental conditions where the copper or alloy will be used, such as exposure to corrosive substances or high temperatures.

6. Cost vs. Performance: Balance cost considerations with the performance requirements of the copper or alloy. Cheaper materials may lead to higher long-term costs due to failure or increased maintenance.

7. Bulk Purchasing: If feasible, buy in bulk to reduce costs, but ensure you have proper storage conditions to prevent oxidation or contamination.

8. Sustainability: Consider the environmental impact and sustainability of your procurement. Recycled copper is widely available and often has a lower environmental footprint.

By focusing on these aspects, you can ensure a successful procurement process that meets your technical and economic needs.

FAQs on Sourcing and Manufacturing from what metals are in copper in China

FAQs on Sourcing and Manufacturing Copper in China

1. What are the main metals found in copper ore?

Copper ore primarily contains copper, but it also includes other metals such as iron, nickel, and zinc in trace amounts. The most common copper ores are chalcopyrite, bornite, and malachite.

2. How is copper ore processed in China?

In China, copper ore undergoes a series of processes:

– Mining: Extracting the ore from mines.

– Crushing and Grinding: Breaking down the ore to smaller pieces.

– Concentration: Using flotation to separate copper from other minerals.

– Smelting and Refining: Heating and treating the concentrate to produce pure copper.

3. What types of copper products are manufactured in China?

China produces a wide range of copper products including:

– Electrical Wires and Cables: Used in electrical and electronic industries.

– Pipes and Tubes: Utilized in plumbing, heating, and cooling systems.

– Sheets and Plates: Employed in construction and industrial applications.

4. What are the main regions in China for copper production?

Key copper-producing regions in China include Jiangxi, Yunnan, and Anhui provinces. These areas have extensive mining and refining facilities.

5. How does China ensure the quality of copper products?

Quality control measures include:

– Standards Compliance: Adherence to national and international standards like GB/T and ASTM.

– Testing and Inspection: Rigorous testing for purity, electrical conductivity, and mechanical properties.

– Certification: Obtaining certifications from recognized bodies such as ISO and RoHS.

6. What are the environmental considerations in copper manufacturing?

China has implemented several regulations to mitigate environmental impact:

– Waste Management: Proper disposal and recycling of waste materials.

– Emission Controls: Reducing emissions from smelting and refining processes.

– Energy Efficiency: Using energy-efficient technologies to lower carbon footprint.

7. How can businesses source copper from China?

Businesses can source copper through:

– Direct Purchase: Buying from manufacturers and suppliers.

– Trade Fairs and Exhibitions: Attending events like the China Import and Export Fair.

– Online Platforms: Using B2B marketplaces such as Alibaba and Made-in-China.com.

These FAQs provide a comprehensive overview for anyone looking to source and manufacture copper in China.