Technology and Applications of engrave in metal

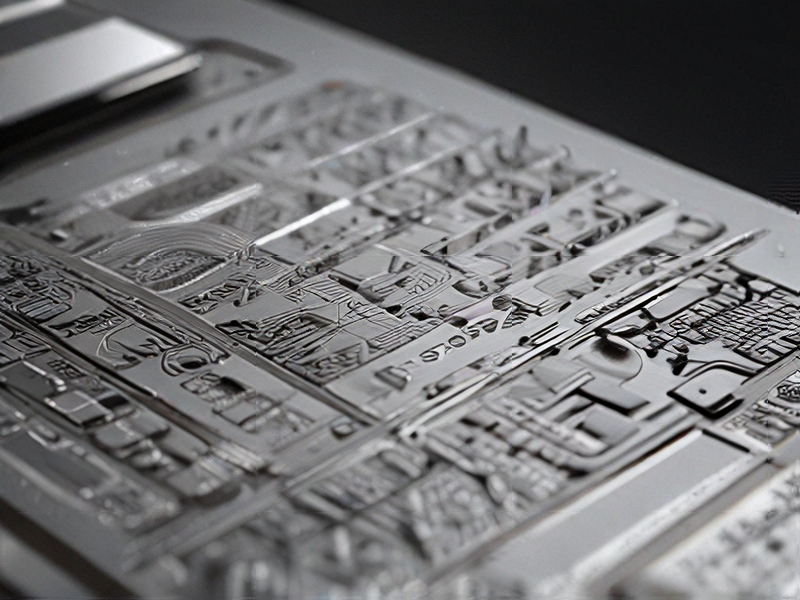

Engraving on metal involves the meticulous art of incising designs, patterns, or text onto various metallic surfaces. Traditional methods employ handheld tools like gravers or burins to carve directly onto metals such as steel, brass, or copper. These techniques are favored for their precision and durability, making them indispensable in industries like jewelry making, firearm manufacturing, and numismatics.

Modern technology has introduced computer numerical control (CNC) engraving, which utilizes computer-guided machinery to automate and enhance engraving processes. This method allows for intricate designs and consistent quality across mass production runs, benefiting industries ranging from aerospace to electronics. Laser engraving represents another advancement, employing high-powered lasers to vaporize material and etch detailed patterns onto metal surfaces with unmatched speed and accuracy.

Applications of metal engraving span diverse fields:

1. Personalization and Branding: Custom engraving on metal items like pens, watches, and trophies adds value and sentimentality, often used for gifts or awards.

2. Industrial Identification: Engraved metal plates and tags are crucial for labeling machinery, parts, and equipment, ensuring traceability and operational efficiency.

3. Security and Anti-counterfeiting: Engraved serial numbers, holograms, or microtext on metals deter forgery and enhance product authenticity.

4. Art and Decor: Artists utilize metal engraving for sculptures, architectural embellishments, and ornamental metalwork due to its aesthetic appeal and permanence.

5. Medical and Aerospace: Engraving on surgical instruments or aerospace components ensures traceability, safety, and compliance with stringent regulations.

In conclusion, the technology and applications of engraving in metal blend traditional craftsmanship with modern innovation, catering to a wide array of industrial, artistic, and personal needs while ensuring enduring quality and functionality.

Quality Testing Methods for engrave in metal and how to control quality

Quality testing methods for engraving on metal typically involve several key techniques to ensure accuracy and durability:

1. Visual Inspection: A fundamental method where engraved pieces are visually inspected under appropriate lighting to detect surface defects, irregularities, or inconsistencies in depth and clarity.

2. Dimensional Verification: Measurements using precision tools such as calipers or micrometers to ensure the engraving meets specified depth and dimensional requirements.

3. Surface Profiling: Techniques like profilometers are used to measure surface roughness and ensure it meets desired smoothness or texture requirements.

4. Durability Testing: Assessing the durability of the engraved mark through methods such as abrasion resistance tests or exposure to harsh environmental conditions to ensure longevity.

5. Image Quality Evaluation: For engraved images or logos, evaluating the fidelity and clarity of the image against a reference standard.

To control quality effectively:

– Establish Standards: Define clear engraving standards including depth, clarity, and dimensional tolerances.

– Regular Inspection: Implement regular inspection schedules at critical stages of production.

– Calibration and Maintenance: Ensure engraving equipment is regularly calibrated and maintained for consistent results.

– Training: Train personnel in proper engraving techniques and quality standards to minimize errors.

– Feedback Loop: Establish a feedback loop where issues detected during quality testing are promptly addressed and corrective actions implemented.

By employing these methods and controls, manufacturers can ensure that engraved metal products meet high-quality standards consistently.

Tips for Procurement and Considerations when Purchasing from engrave in metal

When procuring engraved metal items, several tips and considerations can ensure quality and satisfaction:

1. Material Quality: Choose metals that suit the intended use, whether it’s for industrial, decorative, or functional purposes. Common choices include stainless steel for durability, brass for its aesthetic appeal, and aluminum for its lightweight properties.

2. Engraving Techniques: Different engraving methods offer various finishes. Laser engraving provides precise, clean lines suitable for detailed work, while mechanical engraving might be better for deeper cuts and more substantial materials.

3. Vendor Reputation: Research the supplier’s reputation. Look for reviews, customer testimonials, and samples of previous work. Reliable suppliers often have consistent quality and customer service.

4. Customization Capabilities: Ensure the supplier can accommodate your specific design needs, including custom logos, text, or intricate patterns. Discuss the complexity of your design to ensure feasibility and quality.

5. Proof and Prototypes: Request proofs or prototypes before final production. This helps in verifying the design, alignment, and overall appearance, reducing the risk of errors in the final product.

6. Cost Considerations: Compare prices from different suppliers but be cautious of significantly lower prices, which might indicate inferior quality. Balance cost with the quality of materials and workmanship.

7. Lead Time and Delivery: Confirm the lead time for production and delivery to align with your schedule. Ensure that the supplier can meet deadlines, especially for large or time-sensitive orders.

8. Compliance and Standards: Verify that the products meet relevant industry standards and regulations, particularly if they will be used in critical applications or environments.

9. After-Sales Support: Check if the supplier offers after-sales support, such as warranties, maintenance services, or replacements for defective items. This ensures long-term satisfaction and reliability.

10. Environmental Considerations: Consider the environmental impact of your procurement. Opt for suppliers who use sustainable practices and materials, and inquire about recycling or disposal options for the metal products.

By considering these factors, you can make informed decisions and procure high-quality engraved metal products that meet your needs and expectations.

FAQs on Sourcing and Manufacturing from engrave in metal in China

FAQs on Sourcing and Manufacturing Engraved Metal Products in China

1. Why should I consider sourcing engraved metal products from China?

China offers competitive pricing, a wide variety of suppliers, and advanced manufacturing capabilities. The country is known for its expertise in metalworking and engraving, ensuring high-quality products.

2. How do I find reliable suppliers in China?

Use platforms like Alibaba, Global Sources, and Made-in-China. Additionally, attending trade shows like the Canton Fair can help you meet potential suppliers in person.

3. What are the key factors to consider when choosing a supplier?

Evaluate the supplier’s experience, production capacity, quality control processes, and customer reviews. Request samples to assess product quality before placing large orders.

4. What is the typical lead time for manufacturing engraved metal products?

Lead times vary depending on the complexity of the product and the supplier’s workload. Generally, it can range from 2 to 6 weeks.

5. How can I ensure the quality of the products?

Implement stringent quality control measures, such as third-party inspections and in-process quality checks. Communicating your quality standards clearly to the supplier is crucial.

6. What are the common methods of engraving used?

Laser engraving, CNC engraving, and chemical etching are common methods. Each has its own advantages and is suitable for different types of metals and design intricacies.

7. How do I handle shipping and logistics?

Choose between FOB (Free on Board) and CIF (Cost, Insurance, and Freight) shipping terms. Working with a reputable freight forwarder can simplify the process. Ensure compliance with import regulations in your country.

8. What are the payment terms typically offered?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal. Initial orders might require a deposit, with the balance paid upon shipment.

9. Are there any risks involved in sourcing from China?

Risks include quality issues, delays, and communication barriers. Mitigate these by doing thorough research, maintaining clear communication, and building strong relationships with suppliers.

10. How can I protect my intellectual property (IP)?

Sign Non-Disclosure Agreements (NDAs) and ensure that your designs are patented. Working with suppliers who have a good reputation for IP protection is also advisable.

By considering these factors and doing due diligence, you can effectively source and manufacture high-quality engraved metal products from China.