Technology and Applications of metalloids properties

Metalloids are elements that exhibit properties intermediate between metals and non-metals. Their unique characteristics make them versatile in various technological applications. Silicon, a prominent metalloid, is fundamental in semiconductor technology due to its semiconducting properties. It forms the basis of integrated circuits and microchips, essential components in modern electronics.

Another significant metalloid, germanium, shares similar semiconductor properties with silicon and is used in optical fibers, infrared optics, and solar cells. Metalloids like arsenic and antimony find applications in semiconductor materials, particularly in doping processes to modify conductivity. They are also crucial in the production of diodes and transistors.

Boron, another metalloid, is employed in the production of specialty glasses, ceramics, and as a dopant in semiconductors to enhance their electrical properties. Metalloid compounds such as gallium arsenide (GaAs) are utilized in high-speed electronic devices and in the production of LEDs (Light Emitting Diodes) and laser diodes due to their unique optical and electronic properties.

Metalloids’ ability to exhibit both metallic and non-metallic properties makes them indispensable in advanced materials science. Their applications span across industries including electronics, optics, aerospace, and medicine, where their specific properties are harnessed to enhance performance and functionality in various technological innovations.

Quality Testing Methods for metalloids properties and how to control quality

Quality testing for metalloids involves a range of methods to ensure their properties meet specified standards. Key methods include:

1. Chemical Analysis: Techniques such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS) are used to determine the chemical composition of metalloids. These methods identify and quantify the elements present, ensuring purity and detecting contaminants.

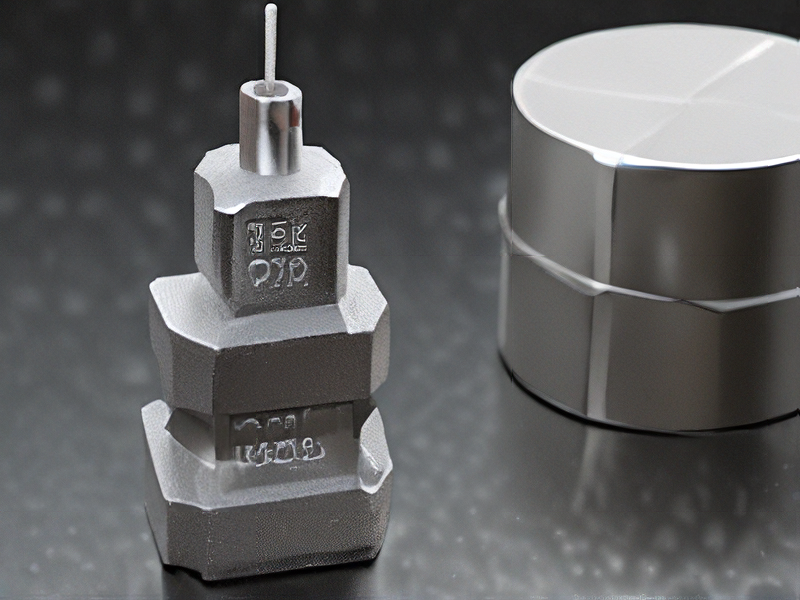

2. Physical Testing: Metalloids’ physical properties, such as hardness, melting point, and electrical conductivity, are tested using methods like Vickers hardness testing, differential scanning calorimetry (DSC), and four-point probe technique. These tests verify that the metalloids meet the required physical characteristics.

3. Structural Analysis: X-ray diffraction (XRD) and scanning electron microscopy (SEM) are employed to analyze the crystalline structure and surface morphology of metalloids. This helps in assessing the structural integrity and identifying any defects or irregularities.

4. Thermal Analysis: Thermogravimetric analysis (TGA) and differential thermal analysis (DTA) measure the thermal stability and decomposition patterns of metalloids. These tests ensure that the metalloids can withstand the temperatures they will be exposed to during use.

Quality control is managed through the following strategies:

– Standard Operating Procedures (SOPs): Establishing and adhering to SOPs ensures consistency in testing and production processes.

– Calibration and Maintenance: Regular calibration and maintenance of testing equipment ensure accuracy and reliability of results.

– Statistical Process Control (SPC): Using SPC techniques to monitor and control the production process helps in identifying and addressing variations before they result in quality issues.

– Regular Audits and Inspections: Conducting routine audits and inspections ensures compliance with quality standards and helps in identifying areas for improvement.

– Training and Certification: Ensuring that personnel are properly trained and certified guarantees that they can competently perform quality testing and control tasks.

By integrating these methods and control strategies, the quality of metalloids can be effectively managed, ensuring they meet the required standards for their intended applications.

Tips for Procurement and Considerations when Purchasing from metalloids properties

When procuring metalloids, such as boron, silicon, germanium, arsenic, antimony, and tellurium, several considerations are crucial:

1. Material Specifications: Define the exact requirements for purity, form (solid, powder), and grade (industrial, electronic grade) based on your application needs. Metalloids vary significantly in their properties, so specifications must align closely with intended use.

2. Supplier Evaluation: Assess suppliers based on their reliability, quality certifications (ISO, ASTM), and ability to meet specific material requirements. Consider their track record in delivering metalloids that meet industry standards.

3. Quality Control: Implement stringent quality control measures to ensure the purchased metalloids conform to specified standards. This may involve testing for purity levels, chemical composition, and physical properties like crystalline structure.

4. Handling and Storage: Metalloids can be sensitive to environmental conditions (moisture, temperature). Ensure proper handling procedures and adequate storage facilities to maintain their integrity before use.

5. Cost and Lead Times: Compare prices from different suppliers while considering shipping costs and lead times. Balance cost-effectiveness with the need for timely delivery to avoid production delays.

6. Safety and Regulatory Compliance: Verify compliance with safety regulations and environmental standards, especially if handling hazardous metalloids. Ensure suppliers provide Material Safety Data Sheets (MSDS) and adhere to relevant regulatory requirements.

7. Technical Support: Choose suppliers capable of providing technical support and assistance in case of issues related to material performance or application-specific challenges.

8. Long-Term Supply Assurance: Evaluate suppliers based on their ability to sustain a reliable supply chain over time, considering market fluctuations and availability of metalloids.

By addressing these considerations systematically, you can enhance the procurement process for metalloids, ensuring they meet your specific technical and operational requirements effectively.

FAQs on Sourcing and Manufacturing from metalloids properties in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from metalloid properties in China:

1. What are metalloids?

Metalloids are elements that have properties intermediate between metals and non-metals. They are crucial in various industries for their semiconductor properties and other unique characteristics.

2. Why source from China?

China is a major global hub for metalloid production due to its abundant natural resources, established manufacturing infrastructure, and competitive pricing.

3. What types of metalloids are commonly sourced from China?

China produces a wide range of metalloids including silicon, germanium, arsenic, antimony, and tellurium, among others.

4. What factors should be considered when sourcing from China?

Key factors include quality standards, manufacturing capabilities, environmental regulations compliance, intellectual property protection, and logistics efficiency.

5. How can quality control be ensured?

Working with reputable manufacturers, conducting regular inspections, and implementing stringent quality assurance protocols are essential steps.

6. Are there any regulatory considerations?

Compliance with Chinese regulations on environmental protection, import/export regulations, and intellectual property rights is crucial.

7. What are the typical challenges when sourcing from China?

Challenges may include language barriers, cultural differences, supply chain disruptions, and fluctuating raw material prices.

8. How can intellectual property rights be protected?

Implementing non-disclosure agreements (NDAs), registering trademarks, patents, and designs in China, and working with legal experts are effective strategies.

9. What are the trends in metalloid sourcing from China?

Increasing focus on sustainable practices, advancements in manufacturing technologies, and rising demand for high-purity materials are notable trends.

10. How can I find reliable suppliers in China?

Utilizing online platforms, attending trade fairs, seeking recommendations from industry networks, and conducting thorough background checks are recommended approaches.

Navigating the sourcing and manufacturing landscape in China requires careful planning, compliance adherence, and strategic partnerships to leverage the country’s strengths in metalloid production effectively.