Technology and Applications of laser cutting machines for wood

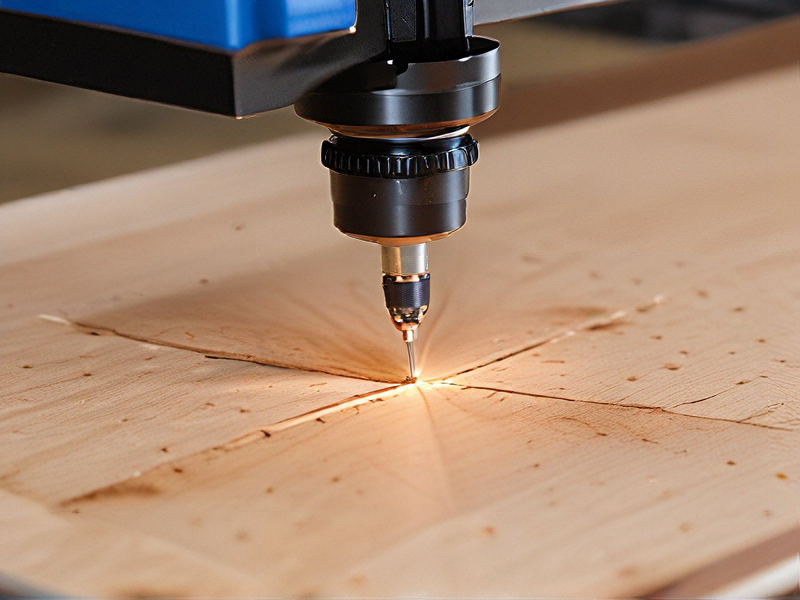

Laser cutting machines have revolutionized woodworking by offering precision, versatility, and efficiency. These machines utilize focused laser beams to cut through various wood materials with high accuracy, making them invaluable in both industrial and artisanal settings.

Technology: Laser cutting machines for wood typically employ CO2 lasers due to their ability to efficiently cut through organic materials like wood. These machines use mirrors to direct the laser beam onto the wood surface, guided by computer numerical control (CNC) systems. The laser beam heats and vaporizes the wood along the cutting path, creating clean and precise edges. Advanced systems may include autofocus capabilities to maintain consistent cutting depth across uneven surfaces.

Applications: The applications of laser cutting machines in woodworking are diverse and expanding:

1. Custom Furniture: Laser cutters enable intricate designs and precise cuts, facilitating the creation of bespoke furniture pieces.

2. Inlays and Engravings: They are used for creating detailed inlays and engravings on wooden surfaces, adding decorative elements to furniture, flooring, and cabinetry.

3. Prototyping and Model Making: Rapid prototyping benefits from the ability to quickly produce complex shapes and designs without the need for extensive tooling.

4. Architectural Models: Laser cutting aids in the creation of architectural models and mock-ups with precise detailing.

5. Art and Craft: Artists and craftsmen utilize laser cutting for creating art pieces, sculptures, and intricate wooden decorations.

6. Automated Production: In industrial settings, laser cutting machines streamline production processes by automating repetitive tasks and minimizing material waste.

Overall, laser cutting machines for wood combine technological innovation with practical applications, catering to both large-scale manufacturing and small-scale artisanal craftsmanship in the woodworking industry.

Quality Testing Methods for laser cutting machines for wood and how to control quality

Quality testing methods for laser cutting machines used on wood typically involve both process control during cutting and inspection of the final products. Here are key methods and strategies:

1. Power and Speed Settings Verification: Regularly check and adjust laser power and cutting speed settings to ensure consistent cutting quality. Use test cuts on sacrificial pieces of wood to verify optimal settings.

2. Edge Quality Inspection: Examine the edges of cut pieces for smoothness, charring, or excessive burning. This can be done visually or using a magnifier to detect imperfections.

3. Dimensional Accuracy: Measure the dimensions of cut pieces using calipers or other precision tools to ensure they meet specifications. Deviations can indicate issues with machine calibration or material alignment.

4. Joint Fit Testing: If the laser cutter is used for joinery or intricate fittings, test the fit of joints to ensure pieces align correctly without gaps or misalignment.

5. Material Integrity Checks: Inspect for signs of material damage such as excessive scorching, burning, or warping. This ensures that the laser power and speed settings are appropriate for the type and thickness of wood being cut.

6. Maintenance Logs and Calibration: Maintain detailed logs of machine maintenance, including lens cleaning, alignment checks, and calibration procedures. Regularly calibrate the laser cutter according to manufacturer guidelines.

7. Operator Training and Supervision: Ensure operators are trained in proper machine operation, maintenance, and troubleshooting. Supervise operations to detect and correct quality issues early.

By implementing these methods, laser cutting machine operators can effectively control and maintain the quality of wood cutting processes, ensuring consistent output that meets customer expectations. Regular monitoring and adjustment of machine settings, coupled with thorough inspection of finished products, are key to achieving high-quality results in wood laser cutting operations.

Tips for Procurement and Considerations when Purchasing from laser cutting machines for wood

When purchasing laser cutting machines for wood, consider these key procurement tips:

1. Laser Power and Type: Ensure the machine has sufficient laser power (measured in watts) to cut through your desired wood thickness. CO2 lasers are versatile for wood, offering good power efficiency.

2. Bed Size and Material Handling: Choose a machine with a bed size that accommodates your typical wood sheet dimensions. Check if it includes features for easy loading and unloading of materials.

3. Precision and Cutting Speed: Look for machines offering high precision and adjustable cutting speeds. This ensures quality cuts across different wood types and thicknesses.

4. Software and Compatibility: Evaluate the machine’s software capabilities. User-friendly software with CAD/CAM compatibility simplifies design import and customization.

5. Maintenance and Support: Consider the supplier’s reputation for customer support and availability of maintenance services. Reliable technical assistance reduces downtime.

6. Safety Features: Laser machines require robust safety features, including enclosures, emergency stop buttons, and exhaust systems for fumes.

7. Cost and ROI: Compare initial costs with long-term return on investment (ROI). Factor in operational costs like electricity, maintenance, and consumables.

8. User Training and Manuals: Ensure the supplier provides comprehensive training for operators. Accessible manuals and online resources support ongoing machine use.

9. References and Reviews: Seek testimonials or reviews from other woodworkers using similar machines. Their experiences can provide valuable insights.

10. Future Expansion: Consider scalability if you plan to expand your woodworking capabilities. Some machines offer modular upgrades for added functionalities.

By considering these factors, you can select a laser cutting machine that meets your woodworking needs efficiently and effectively.

FAQs on Sourcing and Manufacturing from laser cutting machines for wood in China

FAQs on Sourcing and Manufacturing Laser Cutting Machines for Wood in China

#### 1. Why source laser cutting machines for wood from China?

China is a leading manufacturer of laser cutting machines due to its advanced technology, cost-effective production, and wide range of options. Manufacturers in China offer competitive pricing and customization, making it an attractive option for buyers worldwide.

#### 2. What should I consider when selecting a manufacturer?

Look for manufacturers with a strong reputation, certifications (like ISO and CE), and positive customer reviews. Evaluate their experience in producing laser cutting machines specifically for wood and their after-sales service.

#### 3. How can I ensure the quality of the machines?

Request samples or visit the manufacturer’s facility if possible. Ask for detailed specifications, quality control processes, and references from previous clients. Many reputable manufacturers also provide warranties and comprehensive testing reports.

#### 4. What are the typical lead times for production and delivery?

Lead times vary depending on the manufacturer and the complexity of the machine. On average, it takes 4-6 weeks for production, with an additional 2-4 weeks for shipping, depending on the destination.

#### 5. What are the common payment terms?

Payment terms typically include a deposit (usually 30%) with the balance paid before shipment. Payment methods often accepted are wire transfers (T/T), Letters of Credit (L/C), and sometimes online escrow services.

#### 6. Are there any import regulations I should be aware of?

Check the import regulations of your country, including tariffs, customs duties, and required certifications. Work with a customs broker to ensure all paperwork and compliance measures are in order.

#### 7. How can I handle after-sales service and maintenance?

Choose a manufacturer that offers comprehensive after-sales support, including online troubleshooting, spare parts supply, and maintenance services. Ensure they have a responsive customer service team.

#### 8. Can these machines be customized?

Yes, many Chinese manufacturers offer customization options to meet specific needs, including machine size, power, and additional features like software integration or automation.

By considering these factors, you can effectively source high-quality laser cutting machines for wood from China, ensuring a smooth and profitable procurement process.