Technology and Applications of 3d printer custom

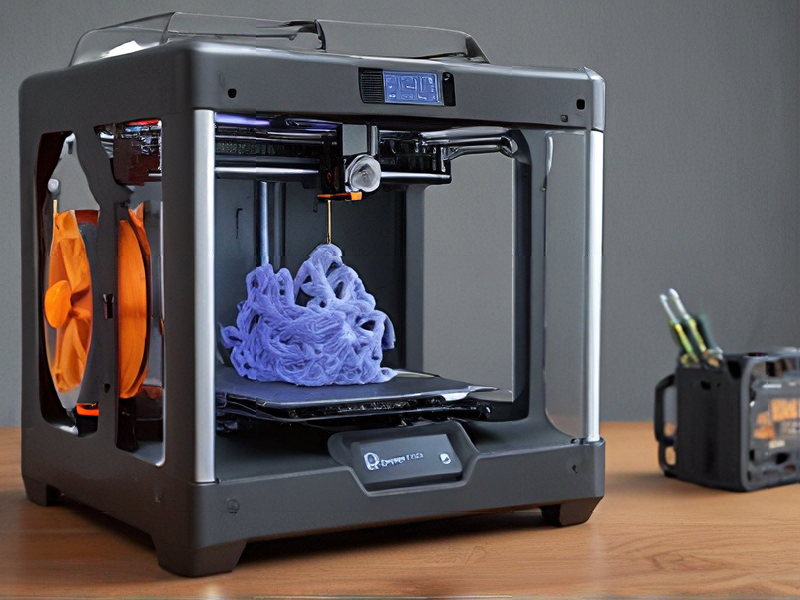

3D printing technology revolutionizes manufacturing by enabling the creation of custom objects directly from digital designs. This additive manufacturing process involves layering materials such as plastics, metals, or ceramics based on computer-generated models.

In various industries, 3D printers are used to produce prototypes quickly and cost-effectively. Engineers and designers benefit from the ability to iterate designs rapidly, reducing time-to-market for new products. Medical applications include creating personalized prosthetics and implants tailored to individual patients’ anatomies, improving comfort and functionality.

Education also embraces 3D printing to enhance learning experiences. Students can visualize complex concepts through tangible models, fostering better understanding in subjects like biology, architecture, and engineering. Artists and designers explore creative possibilities with intricate shapes and textures that traditional manufacturing methods struggle to achieve.

Moreover, the technology supports sustainable practices by minimizing material waste compared to subtractive manufacturing. It enables on-demand production, reducing the need for large inventories and transportation emissions.

Innovations continue to expand the frontiers of 3D printing. Emerging applications include printing electronics, food, and even structures for space exploration. As materials and techniques evolve, the potential for customization grows, promising a future where tailored products are accessible and affordable across diverse fields.

In summary, 3D printing’s versatility and customization capabilities are reshaping industries, education, and everyday life, heralding a new era of personalized manufacturing and innovation.

Quality Testing Methods for 3d printer custom and how to control quality

Quality testing methods for custom 3D prints typically involve several key steps to ensure consistent and high-quality output. Here’s a concise overview of effective approaches:

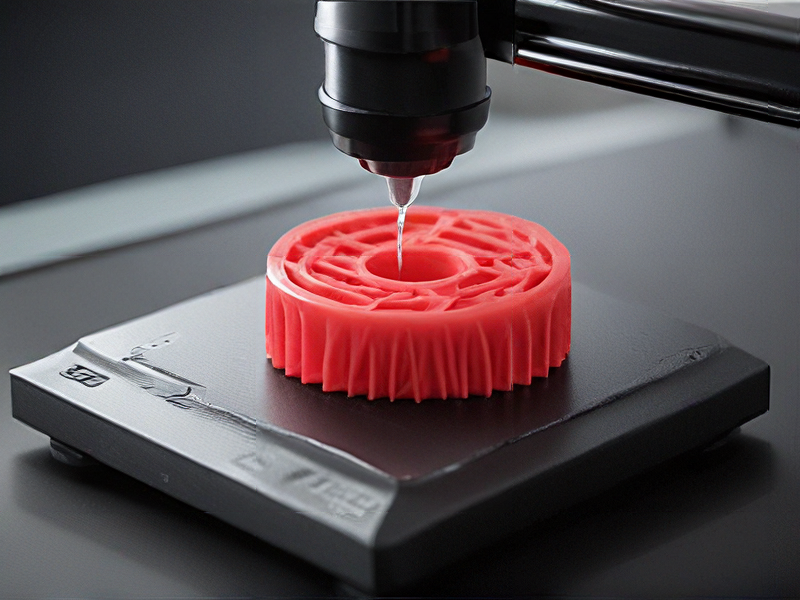

1. Visual Inspection: Conduct a visual check to assess surface finish, layer adhesion, and overall appearance against design specifications.

2. Dimensional Accuracy: Measure critical dimensions using calipers or coordinate measuring machines (CMM) to verify adherence to CAD model dimensions.

3. Layer Adhesion: Perform a strength test (tensile or impact) to evaluate the bonding strength between layers.

4. Material Properties: Test material properties such as tensile strength, elongation, and hardness to ensure they meet required standards.

5. Printing Parameters Verification: Validate printing parameters (temperature, speed, layer height) through test prints and calibration cubes.

6. Surface Quality: Utilize surface profilometers or optical scanning to quantify surface roughness and ensure it meets acceptable standards.

To control quality:

– Document Procedures: Establish clear SOPs for printing, inspection, and testing.

– Regular Maintenance: Maintain and calibrate 3D printers regularly to ensure consistency.

– Training: Train operators on quality standards, inspection techniques, and equipment use.

– Feedback Loop: Implement a feedback mechanism to address issues and continuously improve processes.

By integrating these methods and controls into your workflow, you can effectively manage and enhance the quality of custom 3D prints.

Tips for Procurement and Considerations when Purchasing from 3d printer custom

When purchasing a custom 3D printer, consider several key factors to ensure you get the best value and performance:

1. Specifications: Understand the printer’s build volume, resolution, speed, and material compatibility. These specifications should align with your intended use and future needs.

2. Reliability and Support: Research the manufacturer’s reputation for reliability and customer support. Look for reviews and testimonials to gauge their responsiveness to issues.

3. Customizability: Evaluate how customizable the printer is to your specific requirements. This includes compatibility with different filaments, nozzle sizes, and potential for future upgrades.

4. Software and Compatibility: Check the compatibility of the printer’s software with your operating system and preferred design tools (e.g., CAD software). Ease of use and availability of updates are also crucial.

5. Cost of Ownership: Consider not just the initial purchase price but also ongoing costs like maintenance, filament expenses, and energy consumption. Look for efficiency and cost-effectiveness in long-term use.

6. Community and Resources: A strong user community can provide valuable support, troubleshooting tips, and even custom modifications. Check forums, social media groups, and online resources related to the printer brand.

7. Warranty and Service: Review the warranty terms and conditions. Ensure there’s a clear understanding of what’s covered, including repairs and replacements.

8. Safety Features: For industrial or educational settings, prioritize printers with safety features like enclosed build chambers, filament sensors, and thermal runaway protection.

9. Reviews and Recommendations: Seek feedback from other users or industry experts to validate the printer’s performance and reliability claims.

10. Future Scalability: Consider your future needs and whether the printer can scale with your growing demands, such as larger prints or higher production volumes.

By carefully assessing these factors, you can make an informed decision when purchasing a custom 3D printer that meets your specific requirements and budget constraints.

FAQs on Sourcing and Manufacturing from 3d printer custom in China

Certainly! When sourcing and manufacturing custom 3D printed items from China, it’s essential to address several FAQs:

1. Quality Control: How can I ensure the quality of 3D printed products from Chinese suppliers?

– Answer: Implement thorough supplier vetting, request samples, and establish clear quality standards and inspection protocols.

2. Cost Management: What are the cost factors involved in 3D printing in China?

– Answer: Costs typically include materials, labor, machine usage, and shipping. Negotiate pricing based on volume and complexity.

3. Communication: How can I effectively communicate design specifications and changes?

– Answer: Use detailed drawings or 3D CAD models. Clarify expectations regarding tolerances, finishes, and material choices.

4. Intellectual Property: How do I protect my designs and intellectual property (IP)?

– Answer: Sign non-disclosure agreements (NDAs) and ensure your supplier respects copyright and IP laws. Consider registering designs and patents.

5. Lead Times: What are the typical lead times for custom 3D printing orders?

– Answer: Lead times vary based on complexity and volume. Discuss timelines early and factor in production, shipping, and potential delays.

6. Customization: Can I request customized designs or modifications?

– Answer: Yes, most suppliers accommodate custom designs. Clearly communicate requirements and confirm feasibility beforehand.

7. Volume and Scalability: Can suppliers handle large volumes or scale production?

– Answer: Verify production capacity and scalability options with potential suppliers. Ensure they can meet your future demands.

8. Logistics and Shipping: How should I handle shipping and logistics from China?

– Answer: Choose reliable shipping methods based on urgency and cost-effectiveness. Factor in customs clearance and potential import duties.

By addressing these FAQs, you can navigate the complexities of sourcing and manufacturing custom 3D printed items from China effectively. Clear communication, quality control measures, and legal protections are crucial for a successful partnership with Chinese suppliers.