Technology and Applications of metal grind

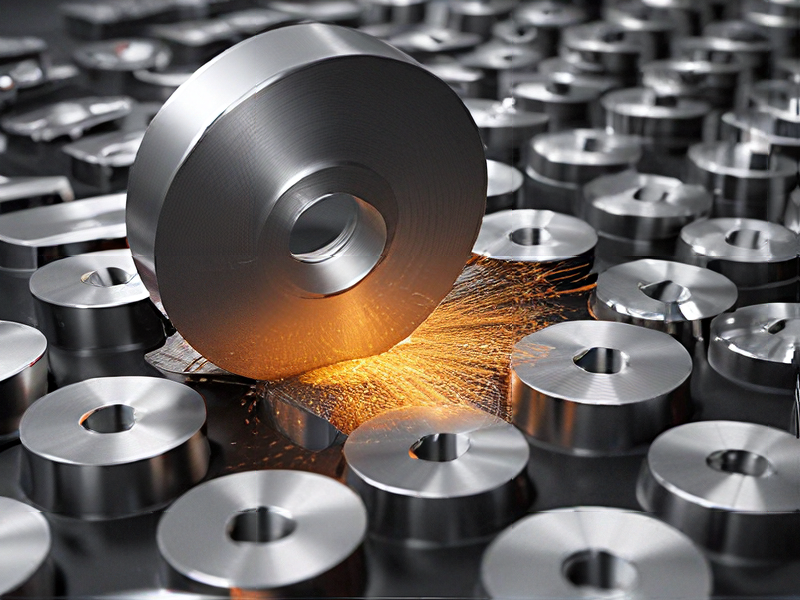

Metal grinding technology involves the process of removing material from a metal workpiece using an abrasive grinding wheel. This process is crucial in manufacturing and fabrication industries for shaping, finishing, and precision machining of metals. The applications of metal grinding are diverse and essential across various sectors:

1. Manufacturing: Metal grinding is integral in manufacturing industries for shaping metal parts to precise dimensions. It’s used in the production of automotive components, aerospace parts, machine tools, and more.

2. Surface Preparation: Before welding or painting, metal surfaces often require preparation to ensure proper adhesion. Grinding helps in cleaning, smoothing, and roughening surfaces as needed.

3. Deburring and Edge Breaking: Grinding is effective in removing burrs and sharp edges from metal parts, which enhances safety, functionality, and aesthetics.

4. Tool and Die Making: Precision grinding is crucial in tool and die making for producing molds, dies, and cutting tools with high accuracy and surface finish.

5. Repair and Maintenance: Metal grinding is used for repairing worn-out parts and restoring dimensions, such as repairing gears, shafts, and bearings.

Technological advancements in metal grinding include CNC (Computer Numerical Control) grinding machines, which automate and enhance precision. Abrasive materials like aluminum oxide, silicon carbide, and cubic boron nitride (CBN) are used depending on the metal type and desired finish. Coolants and lubricants are often employed to control heat generation and improve surface quality.

Overall, metal grinding technology continues to evolve with improved materials, automation, and precision, making it indispensable in modern manufacturing and metalworking processes.

Quality Testing Methods for metal grind and how to control quality

Quality testing methods for metal grinding operations typically focus on ensuring dimensional accuracy, surface finish quality, and structural integrity of the metal components. Here are some key methods and strategies to control quality:

1. Dimensional Accuracy: Use calipers, micrometers, or coordinate measuring machines (CMMs) to measure critical dimensions and tolerances against engineering drawings.

2. Surface Finish: Employ surface roughness testers to quantify the roughness average (Ra) or other surface texture parameters to ensure it meets specified requirements.

3. Visual Inspection: Regular visual checks for defects such as cracks, pits, or improper grinding marks can be conducted by trained inspectors.

4. Non-Destructive Testing (NDT): Techniques like ultrasonic testing (UT) or magnetic particle inspection (MPI) can be used to detect internal defects without damaging the component.

5. Hardness Testing: Measure the hardness of the metal using Rockwell, Brinell, or Vickers hardness testers to ensure it falls within acceptable limits.

6. Process Control: Implement strict process controls such as machine calibration, tool maintenance, and operator training to maintain consistency in grinding operations.

7. Statistical Process Control (SPC): Monitor key process parameters over time using control charts to detect trends or variations that could impact quality.

8. Quality Management Systems: Adhere to ISO 9001 or other quality management standards to establish procedures, documentation, and continuous improvement processes.

By integrating these methods into your quality control processes, you can effectively ensure that metal grinding operations produce components that meet customer specifications and quality standards.

Tips for Procurement and Considerations when Purchasing from metal grind

Tips for Procurement

1. Identify Requirements: Clearly define the specifications and requirements for the metal grind. This includes material type, size, grade, and any specific processing needs.

2. Vendor Research: Investigate potential suppliers. Look for reputable vendors with a proven track record, good customer reviews, and certification standards (e.g., ISO 9001).

3. Request for Quotation (RFQ): Send detailed RFQs to multiple suppliers to get competitive bids. Ensure that the RFQ covers all aspects of the product, including delivery terms and quality assurance.

4. Evaluate Proposals: Compare the quotations not just on price, but also on quality, delivery schedules, and supplier reliability. Consider the total cost of ownership, including shipping and handling.

5. Negotiate Terms: Engage in negotiations to secure favorable terms. This may include discounts, payment terms, and guarantees on delivery and quality.

6. Trial Orders: If feasible, place small trial orders to test the supplier’s capabilities before committing to larger purchases.

Considerations When Purchasing

1. Quality Assurance: Ensure that the supplier has robust quality control processes. Request certifications and consider arranging for third-party inspections if necessary.

2. Material Specifications: Verify that the material specifications match your requirements. This includes chemical composition, mechanical properties, and any required coatings or treatments.

3. Lead Times: Assess the lead times for production and delivery. Ensure that the supplier can meet your timeline requirements without compromising quality.

4. Supplier Stability: Evaluate the financial and operational stability of the supplier. Reliable suppliers are crucial for maintaining consistent quality and avoiding supply chain disruptions.

5. Sustainability: Consider the environmental impact of the procurement. Opt for suppliers who practice sustainable sourcing and have environmentally friendly manufacturing processes.

6. Compliance and Standards: Ensure that the supplier complies with industry standards and regulations. This may include ASTM, ANSI, or other relevant standards for metal products.

By following these tips and considerations, you can streamline your procurement process and secure high-quality metal grind that meets your specific needs.

FAQs on Sourcing and Manufacturing from metal grind in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from metal grind in China:

1. What are the advantages of sourcing metal grind from China?

Sourcing metal grind from China can offer cost advantages due to lower labor and production costs compared to many Western countries. China also has a robust industrial infrastructure supporting a wide range of manufacturing capabilities.

2. How can I find reliable suppliers for metal grind in China?

Utilize online platforms like Alibaba or Made-in-China.com to search for suppliers. It’s crucial to vet potential suppliers thoroughly by checking their certifications, customer reviews, and visiting their facilities if possible. Engaging with a sourcing agent or attending trade shows in China can also help establish relationships with trustworthy suppliers.

3. What are the key considerations for manufacturing metal grind in China?

Quality control is paramount. Clearly communicate your quality standards and conduct regular inspections during production. Intellectual property protection is another concern; ensure your designs and proprietary information are safeguarded through contracts and non-disclosure agreements.

4. How can I manage logistics and shipping challenges when importing metal grind from China?

Work with experienced freight forwarders who specialize in shipping from China. Consider factors such as shipping costs, customs clearance procedures, and import duties when planning your logistics strategy.

5. What are common pitfalls to avoid when sourcing from China?

Avoid relying solely on price as the determining factor for choosing suppliers. Conduct due diligence to prevent issues such as quality discrepancies, communication gaps, and delivery delays. Clear contractual agreements and regular communication are essential to mitigate risks.

Navigating sourcing and manufacturing from China requires thorough planning, diligent supplier selection, and effective logistics management to ensure a successful partnership and product delivery.