Technology and Applications of engraver machine for metal

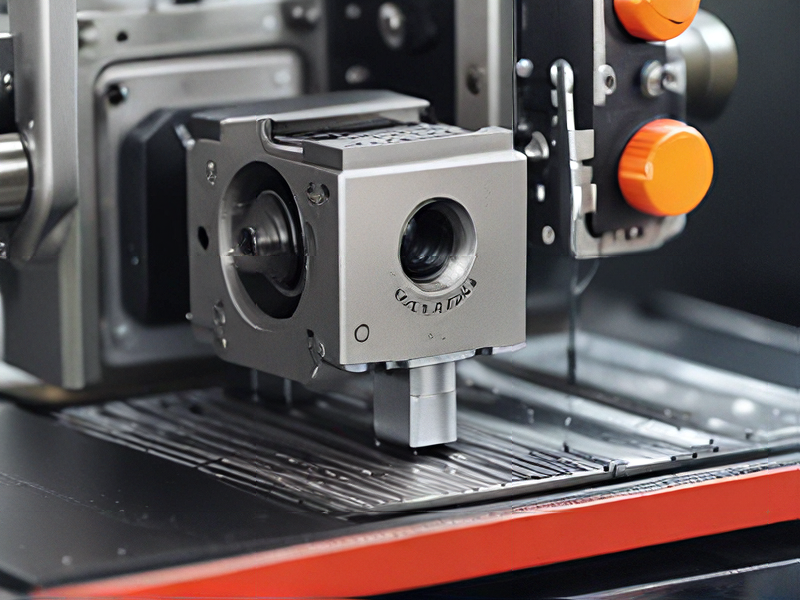

Engraver machines for metal utilize advanced technology to precisely etch designs, patterns, or information onto various metal surfaces. These machines employ CNC (Computer Numerical Control) technology, allowing for automated and highly accurate engraving processes. Key applications include:

1. Industrial Marking and Identification: Engraver machines are extensively used in industries for marking serial numbers, logos, part numbers, and other identifiers on metal components. This helps in traceability, quality control, and branding.

2. Personalization and Customization: They enable personalization of items like jewelry, trophies, and gifts by engraving names, dates, or messages onto metal surfaces. This adds sentimental value and customization options for consumers.

3. Prototyping and Production: In manufacturing, engravers aid in prototyping and producing metal parts with engraved features such as labels, indicators, or functional markers. This supports rapid iteration and customization in production processes.

4. Art and Decoration: Artists and designers use engraver machines to create intricate designs, patterns, or textures on metal surfaces for artistic and decorative purposes. This includes artworks, signage, and architectural elements.

5. Medical and Aerospace Applications: In specialized fields like aerospace and medical device manufacturing, engraving machines are used to mark critical components with part numbers, specifications, or regulatory information for compliance and safety.

Modern engraver machines offer versatility in engraving depth, speed, and precision, thanks to advancements in laser and rotary engraving technologies. They are equipped with intuitive software interfaces that facilitate design input and customization, making them indispensable tools across various industries and creative fields.

Quality Testing Methods for engraver machine for metal and how to control quality

Quality testing methods for engraver machines used for metal typically involve several key approaches to ensure precision and reliability:

1. Dimensional Accuracy Testing: Utilizing precision measurement tools such as calipers and micrometers to verify that the engraved dimensions match design specifications.

2. Surface Finish Inspection: Assessing the surface texture and finish of engraved metal to ensure it meets desired smoothness and aesthetic requirements.

3. Durability and Wear Testing: Subjecting engraved samples to simulated or actual usage conditions to evaluate resistance to wear, corrosion, and other environmental factors.

4. Accuracy of Engraving: Using optical comparators or digital imaging systems to check the fidelity and alignment of engraved patterns and text.

5. Material Composition Analysis: Employing spectroscopy or chemical analysis techniques to confirm the integrity of the engraved metal and verify material composition.

To control quality effectively:

– Establish Clear Specifications: Define precise tolerances, surface finish requirements, and performance standards for engraving.

– Routine Maintenance and Calibration: Regularly maintain and calibrate the engraving machine to ensure consistent performance and accuracy.

– Operator Training: Provide comprehensive training to operators on machine operation, quality standards, and inspection procedures.

– Quality Assurance Checks: Implement systematic checks at various stages of the engraving process to detect and correct any deviations from standards.

– Feedback and Improvement: Establish a feedback loop to continuously improve processes based on quality metrics and customer feedback.

By integrating these methods and controls into the production process, manufacturers can ensure that engraver machines for metal deliver high-quality, precise, and durable engravings that meet customer expectations.

Tips for Procurement and Considerations when Purchasing from engraver machine for metal

When purchasing an engraving machine for metal, several key considerations can ensure you make an informed procurement decision:

1. Accuracy and Precision: Look for machines that offer high precision engraving capabilities suitable for metals. This includes considering the resolution of the engraving and the ability to handle intricate designs.

2. Material Compatibility: Ensure the machine is designed specifically for engraving metals such as steel, aluminum, brass, and titanium. Check if it can handle varying hardness levels and surface finishes.

3. Ease of Use and Automation: Consider user-friendly interfaces and automation features like CNC (Computer Numerical Control) capabilities for precise and repeatable engraving tasks.

4. Speed and Efficiency: Evaluate the engraving speed to ensure it meets your production requirements without compromising on quality. Faster machines can increase throughput.

5. Durability and Maintenance: Opt for machines built with robust materials and components to withstand the rigors of metal engraving. Consider ease of maintenance and availability of technical support.

6. Software Compatibility: Check compatibility with design software you intend to use. Some machines come with proprietary software, while others are compatible with industry-standard programs.

7. Cost and ROI: Assess the initial investment against long-term benefits and ROI (Return on Investment). Factor in operational costs such as power consumption and maintenance.

8. Size and Workspace Requirements: Ensure the machine fits within your workspace and consider any additional requirements for ventilation, power supply, or noise levels.

9. Supplier Reputation and Support: Choose a reputable supplier known for quality products and excellent customer support. Reviews and testimonials can provide insights into supplier reliability.

10. Safety Features: Prioritize machines with safety features such as emergency stop buttons, protective enclosures, and ergonomic designs to minimize risks during operation.

By focusing on these considerations, you can select an engraving machine that aligns with your metal engraving needs, ensuring efficiency, quality, and long-term satisfaction with your purchase.

FAQs on Sourcing and Manufacturing from engraver machine for metal in China

FAQs on Sourcing and Manufacturing Engraver Machines for Metal in China

1. Why source engraver machines from China?

China is a global hub for manufacturing, offering competitive prices, a wide range of products, and advanced technology. Chinese manufacturers also provide customized solutions and have a track record of timely delivery.

2. How to find reliable suppliers?

Utilize online platforms like Alibaba, Made-in-China, and Global Sources. Verify supplier credentials, read reviews, and request samples. Attending trade shows such as the Canton Fair can also help in direct assessment.

3. What certifications should I look for?

Ensure the machine meets international standards by checking for certifications like CE (Europe), RoHS, and ISO 9001. These certifications ensure quality, safety, and environmental compliance.

4. What is the typical lead time for manufacturing?

Lead times vary but generally range from 30 to 60 days, depending on customization and order size. Discuss timelines explicitly with the supplier to avoid delays.

5. How can I ensure the quality of the machines?

Conduct factory audits, request pre-shipment inspections, and hire third-party quality control services. Testing the machine upon delivery is crucial to ensure it meets your specifications.

6. What are the payment terms?

Common terms include 30% deposit upon order and 70% balance before shipment. Using secure payment methods like PayPal, Escrow, or Letters of Credit can offer added protection.

7. What shipping options are available?

Options include air freight, sea freight, and courier services. Sea freight is cost-effective for large orders, while air freight is faster but more expensive.

8. How do I handle customs and import duties?

Work with a freight forwarder or customs broker to navigate import regulations. Understand the HS codes and associated duties for your products to avoid unexpected costs.

9. What after-sales support can I expect?

Reputable suppliers offer warranties, technical support, and spare parts. Ensure clear communication about after-sales services and any additional costs involved.

10. Are there any risks involved?

Risks include quality discrepancies, delays, and potential communication barriers. Mitigate these by maintaining clear, documented communication, conducting due diligence, and having contingency plans in place.

By addressing these common questions, you can navigate the process of sourcing and manufacturing engraver machines for metal from China more effectively.