Technology and Applications of engraving machine for metal

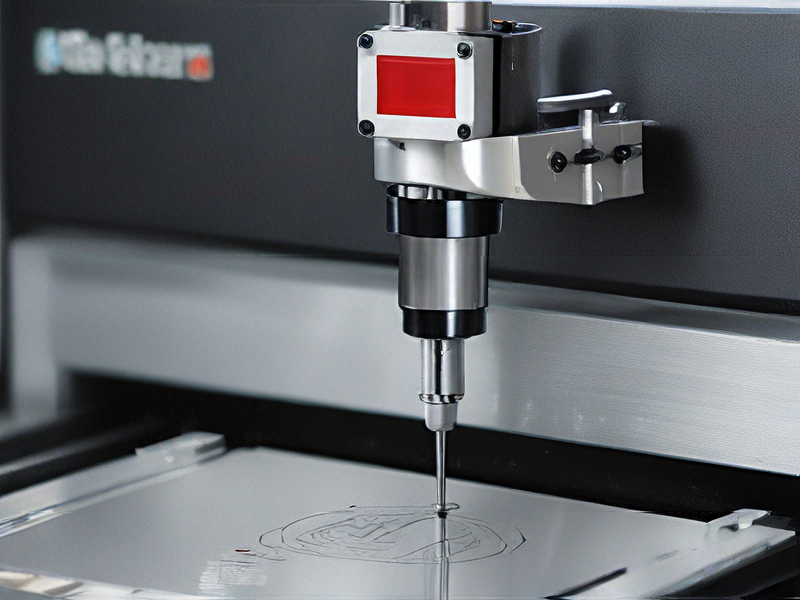

Engraving machines for metal utilize various technologies to achieve precise and detailed markings on metal surfaces. Laser engraving machines use focused laser beams to vaporize material, leaving a permanent mark with high accuracy and speed. This technology is versatile, capable of engraving intricate designs and text on a variety of metals including steel, aluminum, and titanium. It’s widely used in industrial applications for serial numbers, logos, and product identification.

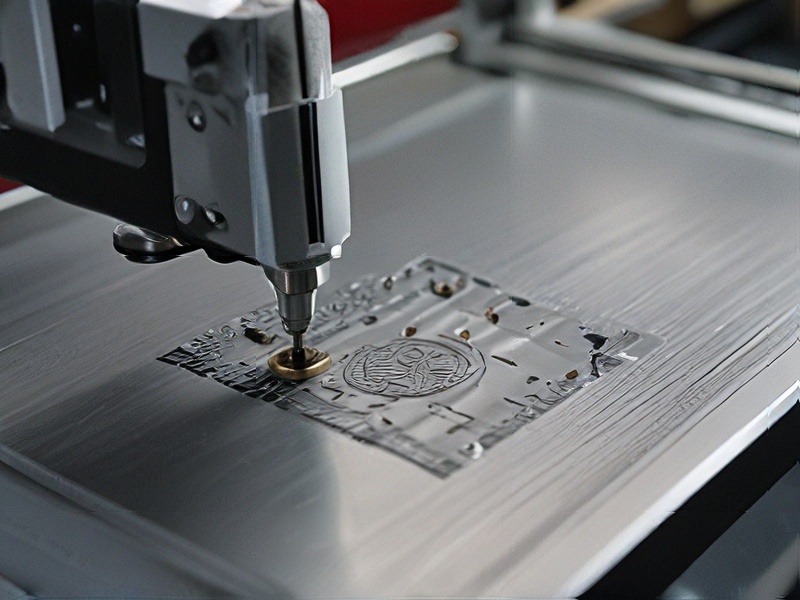

Rotary engraving machines, on the other hand, employ rotating cutting tools to physically etch into the metal surface. This method is effective for creating deep, durable marks on harder metals like stainless steel. It’s commonly used in manufacturing for part identification, signage, and personalized items.

Applications of metal engraving machines span multiple industries. In manufacturing, they’re crucial for traceability and branding purposes, ensuring products meet quality standards and regulatory requirements. In jewelry making, engraving adds value by personalizing pieces with initials, dates, or decorative patterns. In aerospace and automotive sectors, engraving machines mark critical components for identification and tracking throughout their lifecycle.

Advancements in engraving technology continue to improve speed, precision, and versatility. Software integration allows for automated workflows and customization, making these machines essential tools in modern manufacturing and personalization industries. As demands for customization and product traceability grow, engraving machines play a pivotal role in meeting these needs efficiently and effectively.

Quality Testing Methods for engraving machine for metal and how to control quality

Ensuring high-quality output from a metal engraving machine involves several key methods and controls:

1. Material Selection: Use high-quality metals suited for engraving to ensure durability and clarity of the engraved markings.

2. Machine Calibration: Regularly calibrate the engraving machine to maintain accuracy and consistency in the depth and alignment of engravings.

3. Testing Samples: Periodically engrave test samples using different settings (speed, depth, etc.) to assess the machine’s performance and ensure consistent quality.

4. Inspecting Finished Products: Implement a rigorous inspection process to check engraved metal pieces for any defects, inaccuracies, or inconsistencies.

5. Quality Control Checks: Establish checkpoints throughout the engraving process to monitor quality, such as checking engraved depth, ensuring legibility, and verifying adherence to specifications.

6. Maintenance and Cleaning: Keep the machine clean and well-maintained to prevent debris or malfunctions that could affect engraving quality.

7. Operator Training: Ensure operators are trained in machine operation, maintenance, and quality standards to minimize errors and maximize output quality.

By implementing these methods and controls, manufacturers can consistently produce high-quality engraved metal products, meeting customer expectations and industry standards.

Tips for Procurement and Considerations when Purchasing from engraving machine for metal

When purchasing an engraving machine for metal, consider the following tips and key considerations:

1. Machine Capability: Ensure the machine is specifically designed for engraving on metal. Check the specifications for compatibility with different types of metals (e.g., aluminum, stainless steel) and the maximum thickness it can handle.

2. Engraving Precision: Look for a machine that offers high precision and accuracy in engraving details. This is crucial for intricate designs and fine lettering.

3. Ease of Use: User-friendly interfaces and intuitive software are essential, especially if operators are not highly specialized. Consider the learning curve and training required.

4. Durability and Maintenance: Metal engraving can be demanding on equipment. Choose a machine known for its durability and reliability under continuous operation. Check maintenance requirements and costs.

5. Speed and Efficiency: Assess the engraving speed relative to your production needs. Balancing speed with quality is important to maintain productivity without compromising on output quality.

6. Software Compatibility: Ensure the engraving machine is compatible with the design software you use or plan to use. Compatibility issues can lead to inefficiencies and additional costs.

7. Support and Training: Check what support options the manufacturer offers, including training for operators. Good support can mitigate downtime and ensure optimal use of the machine.

8. Budget Considerations: Define your budget and compare machines within that range. Consider not only the initial purchase cost but also ongoing operational costs like maintenance and consumables.

9. Reviews and Recommendations: Research customer reviews and seek recommendations from others in your industry who have experience with metal engraving machines. Their insights can be invaluable in making an informed decision.

10. Safety Features: Engraving machines should have adequate safety features to protect operators from potential hazards associated with metalworking.

By carefully evaluating these factors and aligning them with your specific requirements, you can choose an engraving machine that enhances your capability to work with metal while ensuring efficiency and quality in your operations.

FAQs on Sourcing and Manufacturing from engraving machine for metal in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from engraving machines for metal in China:

1. What types of engraving machines are available in China?

China offers a wide range of engraving machines for metal, including laser engravers, CNC routers, and handheld engraving tools.

2. How do I choose the right supplier in China?

Research extensively, read reviews, ask for referrals, and verify certifications like ISO standards. Directly communicate to understand their capabilities and quality control measures.

3. What are the typical lead times for manufacturing engraving machines?

Lead times vary based on the type and complexity of the machine. Generally, they range from a few weeks to several months, including production and shipping.

4. Can Chinese suppliers customize engraving machines?

Yes, many suppliers offer customization services. Specify your requirements clearly regarding machine specifications, software compatibility, and additional features.

5. What are the quality standards I should expect?

Reputable Chinese manufacturers adhere to international quality standards. Ensure your supplier provides detailed quality assurance processes and possibly visit their facilities if feasible.

6. How can I handle logistics and shipping from China?

Work with experienced freight forwarders who specialize in shipping machinery. They can handle documentation, customs clearance, and logistics efficiently.

7. What about after-sales support and warranties?

Clarify warranty terms, technical support availability, and maintenance services before finalizing your supplier. Reliable suppliers offer comprehensive after-sales support.

8. What are the common challenges when sourcing from China?

Challenges include language barriers, cultural differences, intellectual property protection, and ensuring compliance with import regulations.

9. How can I ensure product quality and avoid scams?

Conduct thorough due diligence, request samples or prototypes, use secure payment methods, and consider hiring a third-party inspection service.

10. Are there specific regulations or certifications I need to consider?

Ensure compliance with your country’s import regulations and standards for electrical machinery. Suppliers should provide necessary certifications like CE or UL.

By addressing these FAQs, you’ll be better prepared to navigate the sourcing and manufacturing process for engraving machines from China effectively.