Technology and Applications of wooden laser cutter machine

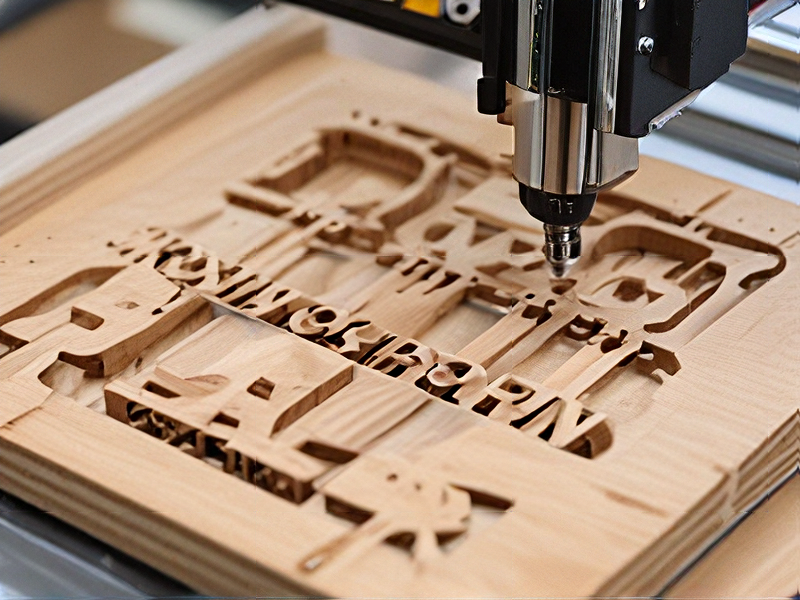

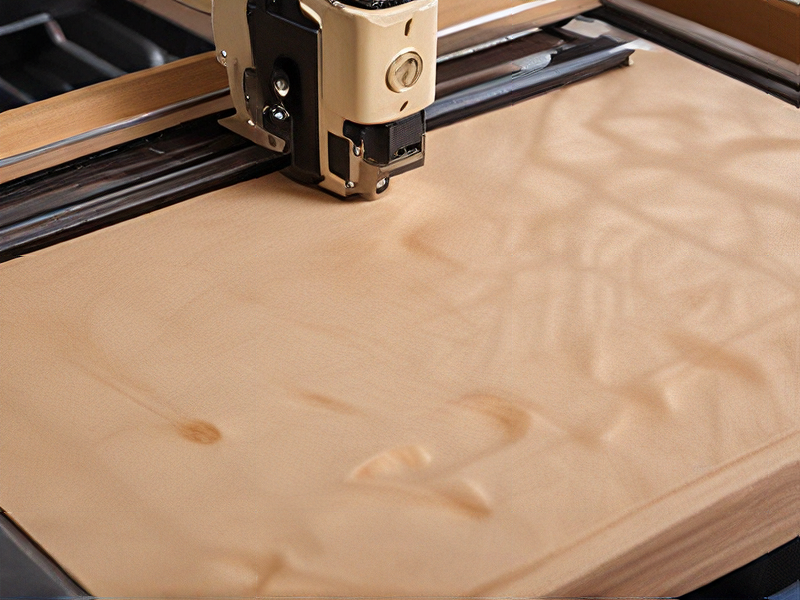

A wooden laser cutter machine utilizes laser technology for precise cutting, engraving, and etching on various types of wood and wood-based materials. These machines are equipped with high-powered lasers that can vaporize or burn away material with exceptional accuracy, allowing for intricate designs and precise cuts that traditional tools may struggle to achieve.

Applications:

1. Custom Woodworking: Enables the creation of detailed patterns, custom shapes, and intricate designs in wood, enhancing the capabilities of furniture makers, artisans, and hobbyists.

2. Prototyping and Model Making: Ideal for rapid prototyping in industries like architecture, product design, and manufacturing, where precise models and prototypes are required.

3. Personalized Items: Allows for the customization of wooden products such as gifts, signage, and promotional items with logos, names, or decorative elements.

4. Art and Décor: Artists can use laser cutters to create artwork, sculptures, ornaments, and decorative panels with fine details and complex patterns.

5. Jewelry and Fashion: Used to cut and engrave wooden jewelry, accessories, and embellishments for fashion items.

Technology:

– CO2 Lasers: Most wooden laser cutters use CO2 lasers which are effective on wood due to its absorption of the wavelength emitted (10.6 micrometers).

– Precision Control: CNC (Computer Numerical Control) technology ensures precise control over the laser beam’s movement, depth, and intensity, allowing for complex shapes and detailed designs.

– Safety Features: Typically equipped with safety measures such as exhaust systems for fumes, enclosed workspaces, and laser beam shields to protect operators from hazards.

– Software Integration: Compatible with design software like Adobe Illustrator, AutoCAD, or specialized programs that convert designs into instructions for the laser cutter.

Wooden laser cutter machines have revolutionized woodworking by offering versatility, speed, and precision, making them indispensable in both industrial and small-scale creative applications. Their ability to handle a variety of woods, from hardwoods to plywood and MDF (Medium-Density Fiberboard), further enhances their utility across different sectors.

Quality Testing Methods for wooden laser cutter machine and how to control quality

Quality testing methods for a wooden laser cutter machine typically include:

1. Dimensional Accuracy Check: Verify if the machine cuts according to specified dimensions using calibrated measuring tools.

2. Material Inspection: Ensure the machine can handle various types of wood without burning or charring excessively.

3. Edge Quality Assessment: Examine cut edges for smoothness and precision, ensuring they meet desired finish standards.

4. Alignment Verification: Test the laser alignment to confirm it cuts along the intended path accurately.

5. Durability Testing: Run the machine continuously to assess its longevity and reliability under normal operating conditions.

To control quality effectively:

– Establish Clear Standards: Define acceptable tolerances for dimensional accuracy, material handling, and edge quality.

– Regular Maintenance: Implement a maintenance schedule to keep the machine in optimal condition.

– Operator Training: Train operators thoroughly on machine operation and quality standards.

– Documented Inspections: Maintain records of quality tests and inspections to track performance and identify areas for improvement.

By following these methods and controls, you can ensure consistent and high-quality output from your wooden laser cutter machine.

Tips for Procurement and Considerations when Purchasing from wooden laser cutter machine

When purchasing a wooden laser cutter machine, consider the following tips and factors to ensure you make an informed decision:

1. Machine Specifications: Assess the laser power, cutting bed size, and maximum material thickness it can handle. Ensure these specifications align with your intended use and material requirements.

2. Software Compatibility: Check if the machine is compatible with the design software you use (e.g., Adobe Illustrator, CorelDRAW). Compatibility ensures seamless workflow from design to production.

3. Build Quality and Durability: Look for machines built with sturdy materials that can withstand continuous use. A robust build contributes to longevity and reliability.

4. Ease of Use: User-friendly interfaces and intuitive controls can reduce learning curves and increase productivity. Consider the accessibility of maintenance and servicing requirements.

5. Safety Features: Laser cutters involve high-power lasers, so safety features such as emergency stop buttons, enclosed cutting areas, and exhaust systems for fumes are essential for safe operation.

6. Customer Support and Training: Evaluate the availability of technical support, training resources, and warranties offered by the manufacturer or supplier. Good support can be crucial for troubleshooting and maximizing machine uptime.

7. Reviews and Reputation: Research customer reviews and testimonials to gauge user satisfaction and the machine’s performance in real-world applications.

8. Cost and Return on Investment (ROI): Compare prices while considering the long-term ROI. Factors like maintenance costs, energy efficiency, and productivity enhancements should all be factored into your decision.

9. Additional Features and Options: Depending on your specific needs, consider additional features such as rotary attachments for engraving cylindrical objects, autofocus systems, or camera systems for precise positioning.

10. Future Scalability: Assess whether the machine can accommodate future business growth or expansion into new applications or materials.

By carefully considering these factors and conducting thorough research, you can select a wooden laser cutter machine that meets your operational requirements and budget while ensuring reliability and safety in your procurement process.

FAQs on Sourcing and Manufacturing from wooden laser cutter machine in China

Certainly! When sourcing a wooden laser cutter machine from China, it’s essential to consider several FAQs:

1. Quality Assurance: How can I ensure the quality of the machine?

– Answer: Research the manufacturer’s reputation, request samples or visit their facility if possible. Consider using a third-party inspection service.

2. Cost and Pricing: What factors influence the pricing?

– Answer: Factors include machine specifications, customization, shipping costs, and import duties.

3. Communication: How do I overcome language barriers?

– Answer: Use clear, concise communication. Consider hiring a translator or using a bilingual agent.

4. Customization: Can the machine be customized to my specifications?

– Answer: Many manufacturers offer customization options. Specify your requirements clearly and confirm feasibility.

5. Lead Time: What is the expected lead time for production and delivery?

– Answer: Lead times vary but typically range from a few weeks to several months depending on complexity and quantity.

6. After-Sales Support: What kind of support is provided after purchase?

– Answer: Inquire about warranties, technical support availability, and spare parts.

7. Compliance and Certification: What certifications does the machine comply with?

– Answer: Ensure the machine meets relevant safety and quality standards for your region.

8. Payment Terms: What are the accepted payment terms?

– Answer: Negotiate terms that protect both parties, such as using a letter of credit or payment upon inspection.

Navigating these FAQs will help you make informed decisions when sourcing a wooden laser cutter machine from China, ensuring a smoother procurement process.