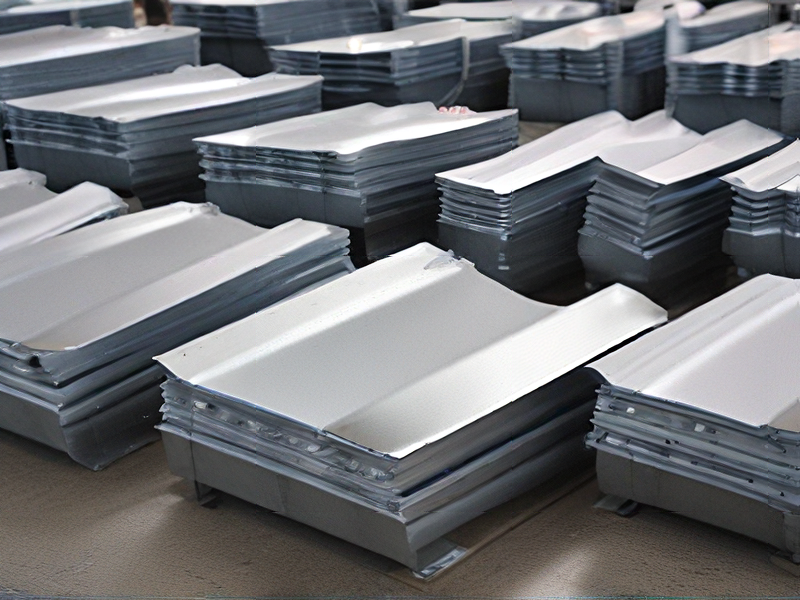

Technology and Applications of price for sheet metal

The pricing of sheet metal is influenced by various technological factors and applications that dictate its manufacturing and usage costs. Technologically, advancements in sheet metal fabrication techniques such as laser cutting, CNC punching, and automated bending have significantly streamlined production processes, reducing labor costs and enhancing precision. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software play crucial roles in optimizing material usage and minimizing waste, thereby impacting overall costs.

Applications of sheet metal span across numerous industries including automotive, aerospace, construction, and electronics, each with specific demands that affect pricing. For instance, automotive applications often require high-strength materials and precise tolerances, driving up costs compared to simpler applications in construction where standard materials suffice. Additionally, the choice of material—whether it’s aluminum, stainless steel, or carbon steel—affects pricing due to varying material costs and fabrication complexities.

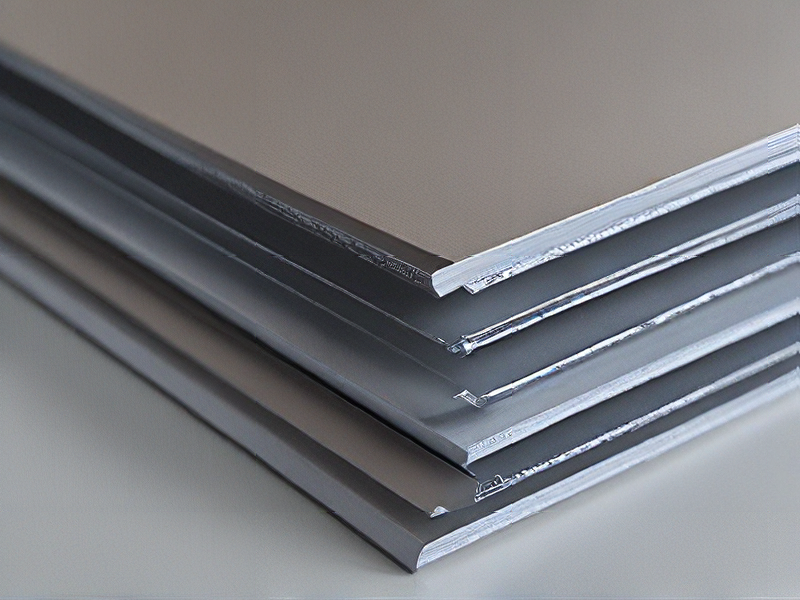

Furthermore, advancements in surface treatment technologies like powder coating or anodizing for corrosion resistance and aesthetic appeal add to the final cost. The integration of IoT (Internet of Things) and industry 4.0 principles into manufacturing processes also contributes to cost considerations, as these technologies improve efficiency and quality control but require initial investments.

In conclusion, the pricing of sheet metal is intricately tied to technological advancements in fabrication methods, material selection, and specific application requirements across diverse industries, reflecting the ongoing evolution and specialization within the manufacturing sector.

Quality Testing Methods for price for sheet metal and how to control quality

To ensure quality in sheet metal pricing and manufacturing, several methods can be employed:

1. Material Inspection: Verify the quality and specifications of raw materials before production to ensure they meet required standards.

2. Dimensional Checks: Regularly measure dimensions of sheet metal parts during and after production to ensure they conform to design specifications.

3. Visual Inspection: Inspect for surface defects, scratches, dents, or other imperfections that could affect product quality.

4. Testing for Strength and Durability: Conduct tests such as tensile strength tests, hardness tests, and impact resistance tests to ensure the sheet metal can withstand intended use conditions.

5. Process Control: Implement strict process controls at every stage of manufacturing to minimize variability and ensure consistency in product quality.

6. Supplier Quality Management: Maintain good relationships with suppliers and conduct regular audits to ensure they adhere to quality standards.

7. Quality Documentation: Keep comprehensive records of inspections, tests, and any deviations encountered during production for traceability and continuous improvement purposes.

By employing these methods, manufacturers can effectively control the quality of sheet metal products and ensure they are priced competitively while meeting customer expectations.

Tips for Procurement and Considerations when Purchasing from price for sheet metal

When procuring sheet metal, several considerations can optimize your purchasing decisions:

1. Supplier Selection: Choose suppliers based not only on price but also on reliability, quality standards, and their ability to meet delivery timelines. Look for suppliers with a proven track record in sheet metal fabrication.

2. Material Specifications: Clearly define the required material specifications including type (e.g., stainless steel, aluminum), gauge (thickness), and finish (e.g., polished, painted). This ensures consistency and meets your project’s needs.

3. Cost Efficiency: While price is crucial, prioritize value over the lowest cost. Consider long-term benefits such as reduced scrap rates, fewer defects, and better performance to cost-effectively manage your procurement.

4. Quality Assurance: Implement quality control measures to ensure the purchased sheet metal meets required standards and specifications. This can involve inspections, certifications (e.g., ISO standards), and supplier audits.

5. Lead Times and Logistics: Evaluate suppliers based on their ability to meet your lead time requirements and their proximity to your location to minimize shipping costs and delays.

6. Supplier Relationships: Foster good relationships with suppliers to facilitate smoother transactions, better communication, and potential cost savings through long-term partnerships.

7. Risk Management: Identify and mitigate risks such as supply chain disruptions, fluctuating material prices, and geopolitical factors that could impact procurement and project timelines.

8. Sustainability: Consider suppliers’ environmental practices and their commitment to sustainability if it aligns with your organization’s values and goals.

By balancing these considerations, you can make informed procurement decisions that not only optimize costs but also ensure quality, reliability, and sustainability in sourcing sheet metal.

FAQs on Sourcing and Manufacturing from price for sheet metal in China

Certainly! Sourcing sheet metal from China involves several considerations:

1. Cost Factors: Prices for sheet metal in China vary based on material type (e.g., stainless steel, aluminum), thickness, and quantity ordered. Generally, larger orders lead to lower unit costs due to economies of scale.

2. Supplier Selection: Choose suppliers based on their specialization, experience, and certifications (e.g., ISO 9001). Verify their manufacturing capabilities and quality control processes to ensure they meet your standards.

3. Communication: Effective communication is crucial. Ensure clear specifications, including material grade, thickness tolerance, surface finish, and packaging requirements. Language barriers can be overcome with translators or bilingual representatives.

4. Quality Assurance: Conduct regular inspections during production and before shipment to maintain product quality. Consider hiring a third-party inspection service if needed.

5. Logistics and Shipping: Plan logistics well in advance. Understand shipping costs, lead times, and customs duties. Choose between air, sea, or rail freight based on urgency and cost-effectiveness.

6. Intellectual Property: Protect your designs and intellectual property rights. Use non-disclosure agreements (NDAs) and consider patenting if necessary.

7. Payment Terms: Negotiate favorable payment terms to manage cash flow and mitigate risks. Consider options like Letters of Credit (LC) or payment upon inspection.

By carefully managing these factors, you can effectively source sheet metal from China while minimizing risks and maximizing cost-efficiency.