Technology and Applications of engrave metal

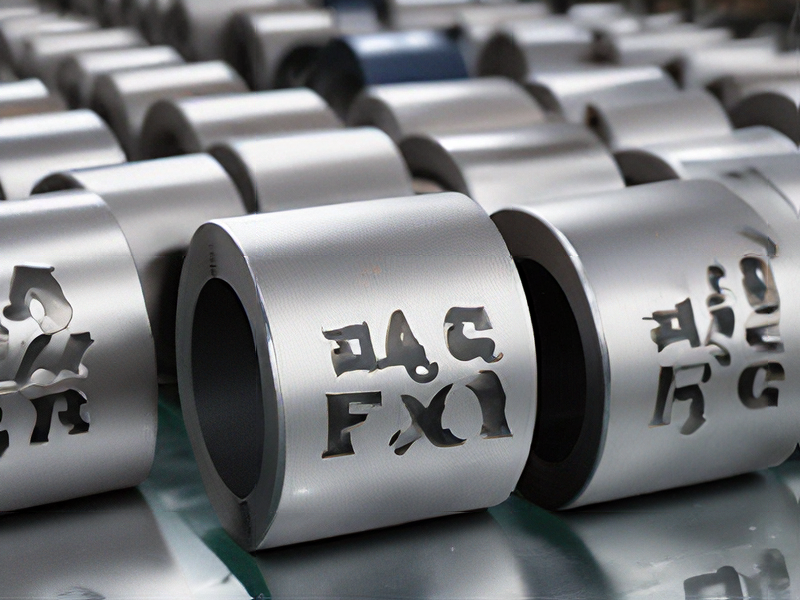

Engraving on metal involves using various techniques to create designs, patterns, or text on metal surfaces. Traditional methods include hand engraving with tools like gravers, which are small chisels, or etching with chemicals and acids. Modern technologies have introduced computerized methods such as laser engraving and CNC (Computer Numerical Control) machining.

Hand engraving requires skilled artisans who use specialized tools to cut into the metal’s surface. This method allows for intricate details and artistic flourishes, making it popular for custom jewelry, trophies, and decorative items. Chemical etching involves applying an acid-resistant mask to the metal, exposing it to acid, and then removing the mask to reveal the engraved design.

Laser engraving uses focused laser beams to vaporize the metal’s surface, creating precise and clean markings. It is highly versatile and suitable for mass production of items like signage, serial numbers on industrial parts, and personalized gifts. CNC machining utilizes computer-controlled tools to engrave metals with precision and consistency, often used in manufacturing for creating detailed molds, dies, and prototypes.

Applications of engraved metal span across industries including aerospace, automotive, jewelry, and electronics. It serves purposes ranging from decorative artistry to functional labeling and branding. Whether for intricate designs on jewelry or durable serial numbers on machinery parts, engraving technologies continue to evolve, offering diverse solutions for both artistic expression and industrial needs.

Quality Testing Methods for engrave metal and how to control quality

Quality testing methods for engraved metal typically include visual inspection, dimensional measurements, surface roughness analysis, and material composition analysis. Visual inspection ensures the engraving meets design specifications without defects like scratches or inconsistent depth. Dimensional measurements verify the engraved dimensions against CAD designs, ensuring accuracy. Surface roughness analysis assesses the texture of the engraving to ensure it meets required smoothness or texture specifications. Material composition analysis, such as using techniques like X-ray fluorescence (XRF), ensures the metal used meets required material standards.

To control quality effectively, implement rigorous inspection protocols at key stages of production. Establish clear criteria for acceptable engraved products based on design specifications and industry standards. Train staff comprehensively in inspection techniques and criteria interpretation to maintain consistency. Utilize calibrated measurement tools regularly to ensure accuracy in dimensional and surface roughness assessments. Document inspection results systematically to track trends and identify potential process improvements. Regularly review and update quality control procedures based on feedback and data analysis to continually enhance product quality and customer satisfaction.

Tips for Procurement and Considerations when Purchasing from engrave metal

When purchasing engraved metal products through procurement, several key considerations ensure a successful acquisition:

1. Quality Standards: Specify the desired quality of the metal and the engraving. This includes material type (e.g., stainless steel, aluminum), thickness, and engraving depth to meet durability and aesthetic requirements.

2. Supplier Selection: Choose reputable suppliers with a track record in metal engraving. Consider their experience, certifications, and ability to meet deadlines and quality expectations.

3. Cost and Budget: Determine a clear budget that includes costs for materials, engraving, and any additional services (e.g., shipping, customization). Compare quotes from multiple suppliers to ensure competitiveness.

4. Customization Options: Evaluate the supplier’s capability for customization, such as different fonts, designs, and sizes. Ensure they can accommodate specific needs like logos, serial numbers, or unique identifiers.

5. Durability and Maintenance: Assess the durability of the engraved metal for its intended use. Consider factors like resistance to corrosion, scratch resistance, and ease of maintenance.

6. Lead Times and Production Capacity: Clarify lead times for production and delivery to align with project timelines. Understand the supplier’s production capacity to handle the required quantity within the specified timeframe.

7. Communication and Support: Ensure clear communication channels with the supplier to address any concerns or revisions during the engraving process. Confirm post-purchase support for any issues that may arise.

8. Environmental Considerations: If relevant, inquire about the supplier’s environmental policies and practices concerning materials sourcing and waste management.

By carefully considering these factors in the procurement process, you can optimize the purchase of engraved metal products to meet both functional requirements and aesthetic preferences.

FAQs on Sourcing and Manufacturing from engrave metal in China

Certainly! Here are some FAQs regarding sourcing and manufacturing engraved metal products in China:

1. How can I find a reliable manufacturer for engraved metal products in China?

– Research online directories like Alibaba or Global Sources. Seek recommendations from industry peers or use services of sourcing agents who have local expertise.

2. What are the typical production times for engraved metal products in China?

– Production times can vary based on complexity and order size but generally range from 2 to 6 weeks for standard orders. Complex designs or customizations may require additional time.

3. How can I ensure product quality when sourcing from China?

– Conduct thorough due diligence on potential suppliers. Request samples, visit factories if feasible, and implement quality control inspections throughout production.

4. What are common challenges when manufacturing engraved metal products in China?

– Language barriers, cultural differences, intellectual property protection, and logistical issues can pose challenges. Clear communication and robust contracts can mitigate these risks.

5. What are the typical payment terms when working with Chinese manufacturers?

– Payment terms often involve an initial deposit (30-50%) with the balance due upon completion or shipment. Negotiate terms that align with your risk tolerance and cash flow.

6. How can I handle shipping and logistics from China?

– Work with freight forwarders experienced in international shipments. Consider factors like shipping methods, customs clearance, and incoterms to ensure smooth delivery.

Navigating these aspects thoughtfully can help streamline the process of sourcing and manufacturing engraved metal products from China while minimizing risks and ensuring quality outcomes.