Technology and Applications of 440 ss steel

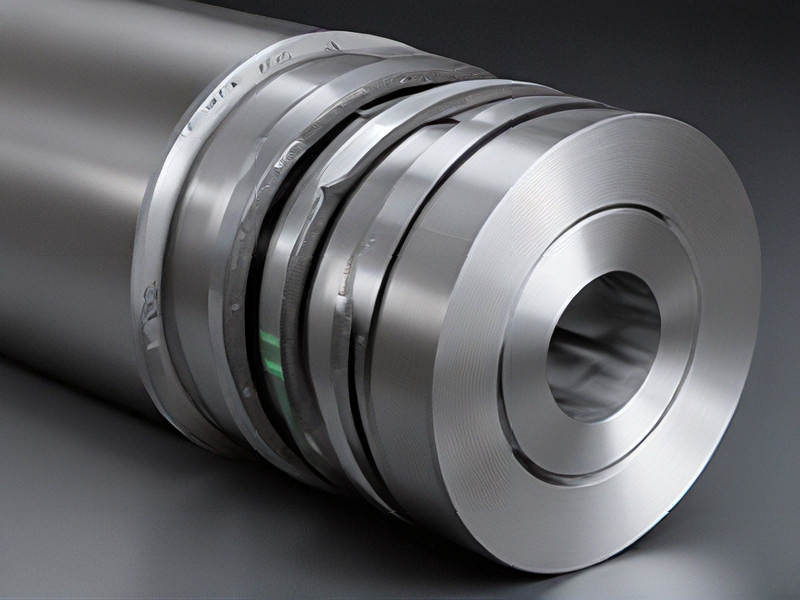

440 stainless steel (440 SS) is a high-carbon martensitic stainless steel renowned for its excellent hardness, wear resistance, and corrosion resistance. It contains around 0.6-0.75% carbon, which contributes to its hardness and edge retention, making it suitable for various applications demanding toughness and edge retention.

Applications:

1. Knife Blades: 440 SS is widely used in knife making due to its ability to hold a sharp edge and resist corrosion. It is favored for both kitchen and outdoor knives.

2. Surgical Instruments: Its corrosion resistance and ability to be hardened and tempered make it suitable for surgical and dental instruments.

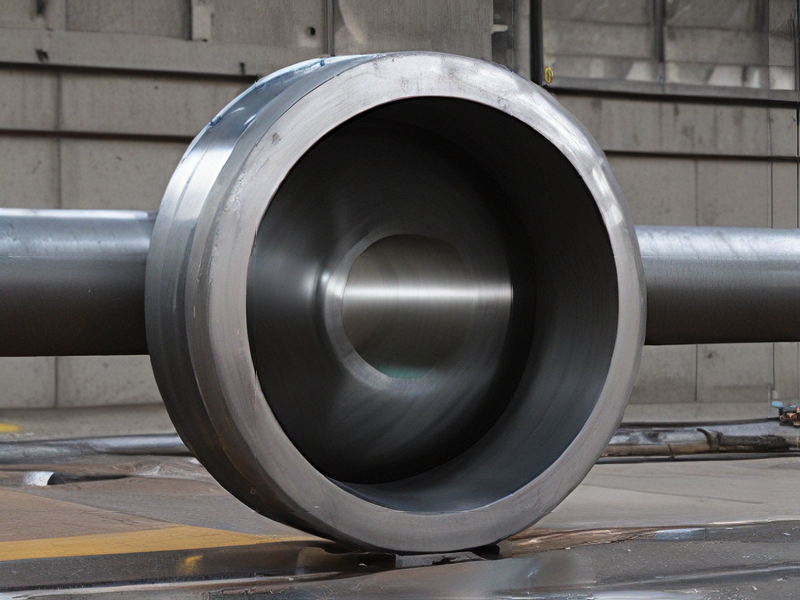

3. Bearings and Valve Parts: Used in applications requiring high wear resistance and hardness, such as bearings, valve components, and pump parts.

4. Scissors and Shears: 440 SS is used in manufacturing high-quality scissors and shears due to its hardness and edge retention properties.

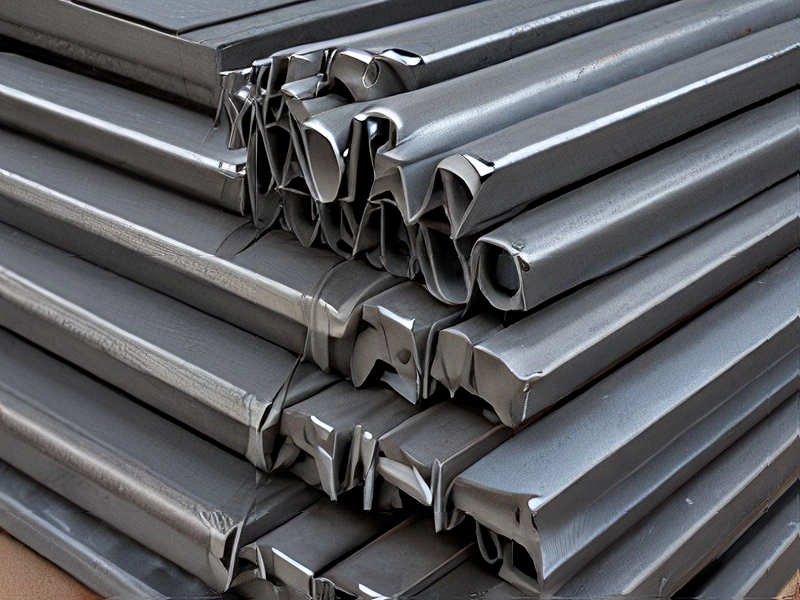

5. Industrial Applications: It finds use in various industrial applications requiring resistance to abrasion and wear, such as molding dies, cutlery, and hand tools.

Technological Properties:

– Hardness: Can be hardened to approximately Rockwell C 56-60, making it one of the hardest stainless steels available.

– Corrosion Resistance: While not as corrosion-resistant as austenitic stainless steels, 440 SS offers good resistance to moisture and mildly corrosive environments.

– Machinability: It can be machined in the annealed condition but becomes difficult to machine once hardened.

– Weldability: It has poor weldability and is generally not recommended for welding.

In conclusion, 440 stainless steel is valued for its hardness, wear resistance, and edge retention, making it suitable for a variety of applications where these properties are crucial. Its use spans from surgical instruments and cutlery to industrial tools and components requiring high hardness and corrosion resistance.

Quality Testing Methods for 440 ss steel and how to control quality

To ensure quality control for 440 stainless steel (440 SS), several testing methods are crucial:

1. Chemical Composition Analysis: Utilizing techniques like Optical Emission Spectroscopy (OES) or X-ray Fluorescence (XRF) to verify the elemental composition of the steel, ensuring it meets specified standards.

2. Mechanical Testing: Conducting tests such as tensile strength, hardness (Rockwell hardness test), and impact resistance assessments to ensure the material meets required mechanical properties.

3. Microstructure Examination: Using metallographic techniques like microscopy to examine grain size, inclusion content, and overall microstructure integrity.

4. Non-Destructive Testing (NDT): Employing methods like ultrasonic testing or magnetic particle inspection to detect internal defects or inconsistencies without damaging the material.

5. Surface Inspection: Visual inspection and dye penetrant testing to ensure there are no surface defects or cracks that could compromise the material’s quality.

To control quality effectively:

– Establish Clear Specifications: Define precise requirements for chemical composition, mechanical properties, and surface quality.

– Supplier Qualification: Verify the capabilities and quality management systems of suppliers.

– Process Control: Implement stringent process controls throughout manufacturing, including temperature control during heat treatment and precise machining techniques.

– Quality Assurance Testing: Conduct regular sampling and testing at different stages of production to identify and rectify any deviations early.

– Continuous Improvement: Regularly review and optimize processes based on quality data and customer feedback to enhance product consistency and performance.

By integrating these methods and controls, manufacturers can ensure that 440 stainless steel meets stringent quality standards, fostering reliability and performance in various applications.

Tips for Procurement and Considerations when Purchasing from 440 ss steel

When procuring 440 stainless steel (440 SS), a high-carbon martensitic stainless steel known for its high hardness and wear resistance, consider these tips and considerations:

Tips for Procurement:

1. Supplier Verification: Ensure the supplier is reputable and certified to provide high-quality 440 SS. Verify their production standards and material traceability.

2. Material Certification: Request mill test certificates to confirm the chemical composition and mechanical properties meet your specifications.

3. Bulk Ordering: If your project requires a large quantity, consider bulk purchasing to negotiate better prices and ensure consistency across the batch.

4. Lead Time: Confirm the lead time for delivery, especially if you need the steel for a time-sensitive project.

5. Sample Testing: Obtain samples for testing to verify the material’s properties and suitability for your application before committing to a large order.

Considerations when Purchasing:

1. Application Requirements: Determine the specific requirements of your application, such as hardness, tensile strength, corrosion resistance, and thermal properties, to ensure 440 SS is the right choice.

2. Heat Treatment: 440 SS often requires heat treatment to achieve desired hardness and mechanical properties. Consider whether you have the capabilities for this process or need a supplier who offers pre-treated materials.

3. Machinability: 440 SS can be challenging to machine due to its high hardness. Ensure your manufacturing process can handle the material without excessive tool wear or damage.

4. Corrosion Resistance: While 440 SS offers good corrosion resistance, it’s less than other stainless steels like 304 or 316. Assess whether the corrosion resistance is adequate for your environment.

5. Cost vs. Performance: Balance the cost of 440 SS against its performance benefits for your specific application. High hardness and wear resistance may justify a higher cost if it leads to longer service life and reduced maintenance.

By carefully considering these factors and tips, you can make informed decisions and optimize your procurement of 440 SS for your projects.

FAQs on Sourcing and Manufacturing from 440 ss steel in China

When sourcing and manufacturing 440 stainless steel in China, consider these FAQs:

1. What is 440 stainless steel?

440 stainless steel is a high-carbon martensitic stainless steel that offers good corrosion resistance, wear resistance, and hardness.

2. Is sourcing 440 stainless steel from China reliable?

Yes, China is a major producer of stainless steel, including 440 grade. Ensure you vet suppliers for quality certifications and track record.

3. What should I look for in a supplier?

Look for suppliers with ISO certifications (e.g., ISO 9001 for quality management) and experience in producing stainless steel alloys.

4. How can I ensure quality?

Conduct thorough supplier audits, request samples for testing, and use third-party inspection services to verify material quality and consistency.

5. Are there specific challenges when manufacturing with 440 stainless steel in China?

Challenges may include maintaining precise chemical compositions and achieving consistent heat treatment processes required for optimal material properties.

6. What are the typical lead times and MOQs?

Lead times can vary but generally range from weeks to months depending on order size and supplier capacity. Minimum Order Quantities (MOQs) also vary by supplier.

7. What about intellectual property protection?

Ensure suppliers respect intellectual property rights. Use non-disclosure agreements (NDAs) and consider registering patents or trademarks where applicable.

8. How can I manage logistics and shipping?

Work closely with suppliers to coordinate logistics and choose reliable shipping methods to ensure timely delivery and minimize risks.

9. What are the cost considerations?

Costs will vary based on market conditions, material specifications, and order volume. Obtain detailed quotations and factor in shipping, tariffs, and import duties.

10. What support can I expect from Chinese suppliers?

Suppliers typically offer technical support, customization options, and after-sales service. Clarify expectations upfront to avoid misunderstandings.

By addressing these FAQs, you can navigate sourcing and manufacturing 440 stainless steel from China effectively, ensuring quality and compliance with your requirements.