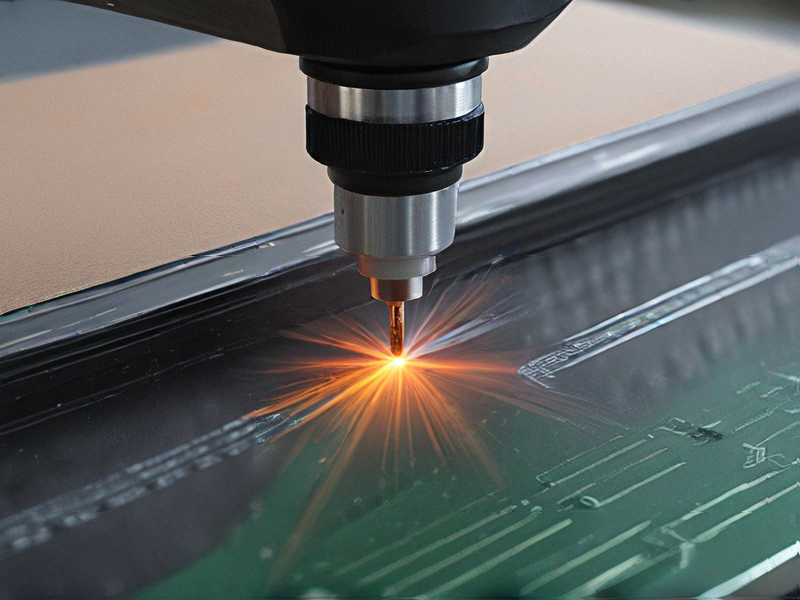

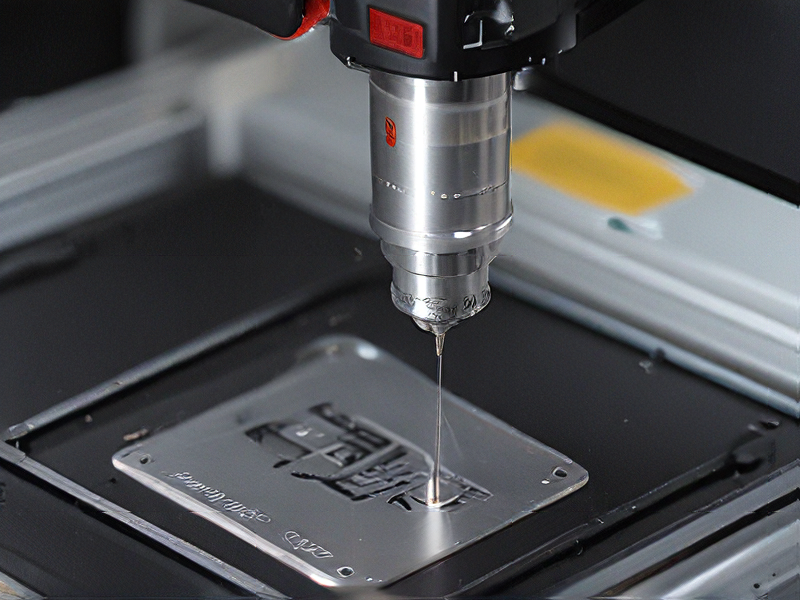

Technology and Applications of laser engraver machine for metal

Laser engraving machines for metal utilize highly focused laser beams to etch designs, text, or patterns onto various metal surfaces with precision and detail. This technology is widely used across industries due to its versatility and efficiency.

Key Applications:

1. Industrial Manufacturing: Laser engravers are integral to industrial manufacturing processes for marking serial numbers, logos, and product information on metal components. This ensures traceability and quality control.

2. Jewelry and Accessories: In the jewelry industry, laser engraving offers intricate designs on metals like gold, silver, and platinum. It enables customization of rings, bracelets, and pendants with fine details.

3. Medical Devices: Laser engraving is crucial for marking surgical instruments and medical implants. It provides permanent identification that withstands sterilization processes.

4. Automotive and Aerospace: Used for part marking and labeling in automotive and aerospace manufacturing, ensuring parts are traceable and compliant with regulatory standards.

Technology Advancements:

1. Fiber Lasers: Most modern metal engraving machines use fiber lasers, known for their high energy efficiency and ability to produce precise markings on various metal types.

2. Computer Control: Integration with CAD (Computer-Aided Design) software allows for precise control over engraving patterns, text, and graphics, enhancing customization capabilities.

3. Automation: Automated loading and unloading systems enable continuous operation and reduce human intervention, increasing productivity in high-volume production environments.

4. Quality and Durability: Laser engraving ensures durability of markings, resistant to wear, fading, and corrosion, crucial for applications requiring long-term reliability.

In conclusion, laser engraving machines for metal offer unparalleled precision, versatility, and durability, making them indispensable across industries ranging from manufacturing and jewelry to healthcare and aerospace. Ongoing technological advancements continue to enhance their capabilities and broaden their applications.

Quality Testing Methods for laser engraver machine for metal and how to control quality

Quality testing methods for laser engraver machines for metal involve several steps to ensure precision, durability, and consistency. Here are the key methods and controls:

1. Calibration Testing:

– Regularly calibrate the laser engraver using standard test patterns to ensure accuracy in engraving depth and positioning. This ensures the machine operates within specified tolerances.

2. Material Compatibility Testing:

– Test different types of metals (e.g., stainless steel, aluminum, brass) to verify the laser’s effectiveness across various materials. This helps in optimizing laser settings for different metals.

3. Power and Speed Testing:

– Conduct tests at varying power levels and speeds to determine optimal settings for different engraving tasks. This ensures clean and precise engravings without damaging the material.

4. Resolution and Detail Testing:

– Use high-resolution test images to evaluate the machine’s ability to engrave fine details. Check for sharpness and clarity to ensure the machine can handle intricate designs.

5. Consistency Checks:

– Perform repeated engravings of the same design to check for consistency. This helps identify any variations that could indicate mechanical or software issues.

6. Durability Testing:

– Subject engraved samples to environmental stress tests (e.g., temperature variations, corrosion) to assess the durability of the engravings over time.

Quality Control Measures:

1. Routine Maintenance:

– Regularly clean and maintain the laser engraver components, including lenses and mirrors, to ensure optimal performance.

2. Software Updates:

– Keep the engraving software updated to benefit from the latest improvements and bug fixes, ensuring the machine operates efficiently.

3. Operator Training:

– Ensure operators are well-trained in using the machine and interpreting test results to maintain high-quality outputs.

4. Documentation and Record-Keeping:

– Maintain detailed records of all tests, settings used, and outcomes. This helps in tracing back any issues and refining processes.

5. Quality Audits:

– Conduct periodic quality audits to review processes, identify potential improvements, and ensure compliance with quality standards.

Implementing these testing methods and quality control measures helps ensure that the laser engraver machine consistently produces high-quality engravings on metal.

Tips for Procurement and Considerations when Purchasing from laser engraver machine for metal

When procuring a laser engraver for metal, consider the following tips and factors:

1. Purpose and Material Compatibility: Define the primary use of the laser engraver. Ensure the machine is compatible with the specific types of metals you plan to engrave, such as stainless steel, aluminum, or titanium.

2. Power and Speed: Higher wattage provides deeper engravings and faster processing speeds. Match the power output with your production needs. Typically, 30-50 watts is suitable for marking, while 50-100 watts is better for cutting and deeper engravings.

3. Precision and Resolution: Look for high-resolution capabilities if fine details are essential. The DPI (dots per inch) and spot size influence the engraving quality.

4. Software Compatibility: Ensure the machine comes with user-friendly software compatible with your design programs. Software should support vector and raster graphics for versatile design input.

5. Cooling System: Laser engravers generate heat. A robust cooling system (air-cooled or water-cooled) prolongs the machine’s life and ensures consistent performance.

6. Maintenance and Support: Check for ease of maintenance and availability of customer support. Regular maintenance can extend the machine’s lifespan. Opt for suppliers who offer comprehensive support and readily available spare parts.

7. Safety Features: Laser machines can be hazardous. Look for features like enclosed workspaces, emergency stop buttons, and proper ventilation to ensure operator safety.

8. Budget and ROI: Balance between cost and features. Consider long-term ROI, including potential productivity gains, reduced manual labor, and improved product quality.

9. Warranty and Training: Choose machines with a solid warranty and training programs. Adequate training ensures efficient use and reduces the learning curve for operators.

10. Vendor Reputation: Research vendor reviews and reputation. A reliable vendor provides quality machines, transparent terms, and excellent after-sales service.

By considering these factors, you can make an informed decision that meets your specific engraving needs while ensuring safety, efficiency, and long-term value.

FAQs on Sourcing and Manufacturing from laser engraver machine for metal in China

Certainly! Here are some FAQs on sourcing and manufacturing a laser engraver machine for metal in China:

1. What are the key considerations when sourcing a laser engraver machine from China?

– Ensure the supplier has experience in manufacturing laser engravers for metal.

– Verify the quality certifications and standards compliance.

– Clarify shipping logistics, import duties, and lead times.

2. How can I ensure product quality when sourcing from China?

– Request samples and conduct thorough quality inspections.

– Establish clear specifications and requirements upfront.

– Consider visiting the manufacturer or hiring a third-party inspection service.

3. What are common challenges when manufacturing in China?

– Communication barriers due to language and cultural differences.

– Potential delays in production or shipping.

– Intellectual property protection concerns.

4. How do I choose the right manufacturer for a laser engraver machine?

– Research manufacturers with a proven track record in producing similar equipment.

– Check customer reviews and testimonials.

– Seek recommendations from industry peers or use sourcing platforms.

5. What should be included in the manufacturing agreement or contract?

– Detailed specifications, including materials, dimensions, and performance metrics.

– Payment terms, including milestones and penalties for delays.

– Confidentiality and intellectual property protection clauses.

6. What are the advantages of sourcing from China for a laser engraver machine?

– Cost-effective manufacturing due to lower labor and production costs.

– Access to a wide range of suppliers and manufacturing expertise.

– Ability to scale production quickly based on demand.

7. How do I handle shipping and logistics when importing from China?

– Choose reliable shipping methods and logistics partners.

– Understand import regulations and customs clearance procedures.

– Factor in shipping costs and potential delays in your planning.

These FAQs provide a foundation for navigating the sourcing and manufacturing process for a laser engraver machine in China, emphasizing preparation, communication, and quality assurance measures.