Technology and Applications of plastic sheet thickness

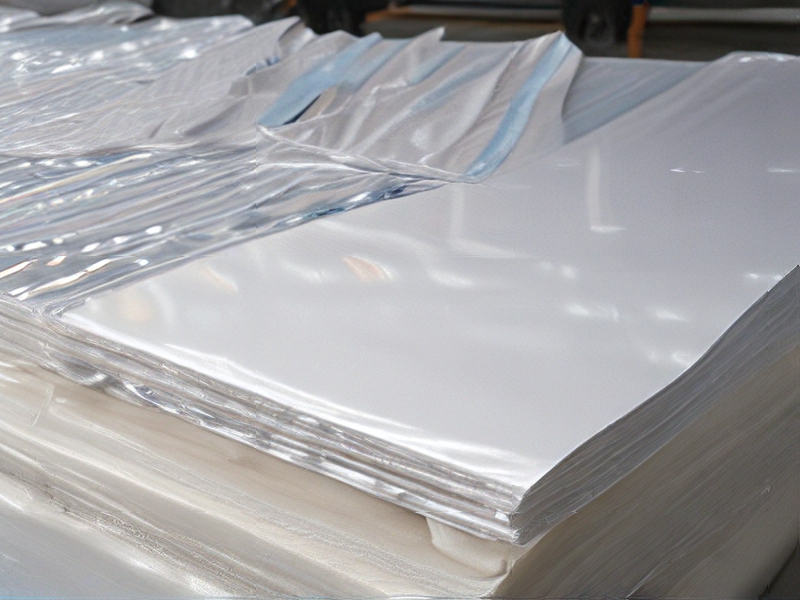

Plastic sheet thickness plays a crucial role across various industries and applications, influencing both functionality and performance. In manufacturing, sheets are typically measured in millimeters (mm) or micrometers (μm), with thickness ranging widely based on intended use.

In packaging, thin plastic sheets (typically less than 1 mm thick) offer flexibility and cost-effectiveness, ideal for products like food containers, shrink wrap, and blister packs. Thicker sheets (1-5 mm) find use in heavier-duty applications such as industrial packaging and automotive components due to their enhanced durability and strength.

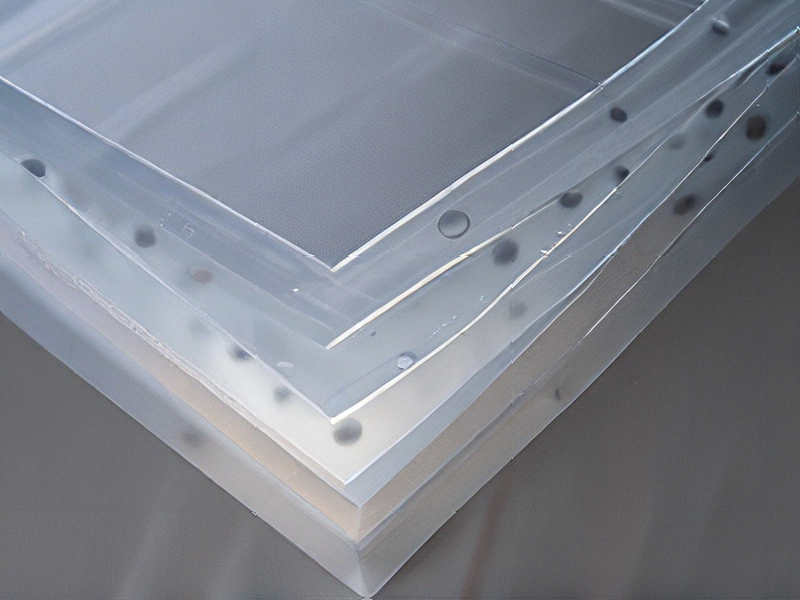

Construction benefits significantly from plastic sheets of varying thicknesses. Thin, transparent sheets (around 2-6 mm) serve as protective barriers in windows, providing insulation and weatherproofing while allowing light transmission. Thicker sheets (up to 25 mm or more) contribute to structural integrity as roofing materials or partitions, offering impact resistance and noise reduction.

In agriculture, plastic sheets (typically 50-200 μm thick) are pivotal for greenhouse construction, providing climate control and shielding crops from adverse weather conditions. These sheets are chosen for their light transmission properties and ability to retain heat.

Moreover, advancements in plastic sheet manufacturing have introduced specialized materials like polycarbonate and acrylic, offering improved strength, transparency, and UV resistance compared to traditional plastics.

Overall, the versatility of plastic sheet thicknesses enables their application across diverse sectors, enhancing product performance, durability, and cost-efficiency in industries ranging from packaging and construction to agriculture and beyond.

Quality Testing Methods for plastic sheet thickness and how to control quality

Quality testing methods for plastic sheet thickness typically involve precise measurement techniques and controls to ensure consistency and adherence to specifications. Here are key methods and controls used:

1. Caliper Measurement: A digital or mechanical caliper is used to directly measure the thickness at various points across the sheet. This method provides accurate readings but requires skilled operators to ensure consistency.

2. Micrometer Measurement: Similar to calipers but with higher precision, micrometers measure thickness with a finer resolution, suitable for thinner sheets or critical applications.

3. Laser Gauging: Laser sensors can quickly scan the surface of the sheet to measure thickness non-destructively and provide real-time feedback. This method is efficient for continuous production lines.

4. Ultrasound Testing: Utilizes ultrasound waves to measure thickness by analyzing the time taken for the wave to bounce back from the sheet. It’s non-contact and useful for thicker materials.

5. Statistical Process Control (SPC): Implementing SPC involves continuously monitoring production processes to detect variations in thickness. Control charts and data analysis help in maintaining consistent quality.

To control quality effectively:

– Establish Standards: Define precise thickness tolerances based on product specifications and customer requirements.

– Regular Calibration: Ensure all measurement tools are calibrated regularly to maintain accuracy.

– Training and Skills: Train operators on proper measurement techniques and the importance of maintaining consistent thickness.

– Process Optimization: Continuously improve production processes to minimize variations and ensure uniform thickness.

– Quality Assurance Checks: Implement regular inspections and quality checks throughout production to catch deviations early.

By integrating these methods and controls, manufacturers can uphold high standards of quality for plastic sheet thickness, meeting customer expectations and regulatory requirements effectively.

Tips for Procurement and Considerations when Purchasing from plastic sheet thickness

When procuring plastic sheets, several factors must be considered to ensure optimal performance and cost-efficiency. Here are some tips and considerations:

Material Type

1. PVC (Polyvinyl Chloride): Suitable for high-impact applications and offers good chemical resistance.

2. Polycarbonate: Known for its high impact resistance and transparency.

3. Acrylic: Lightweight and provides excellent optical clarity, often used for displays.

4. HDPE (High-Density Polyethylene): Offers high strength-to-density ratio, ideal for corrosion-resistant piping.

Thickness Considerations

1. Load-Bearing Requirements: Thicker sheets (6mm or more) are necessary for structural applications or high-stress environments.

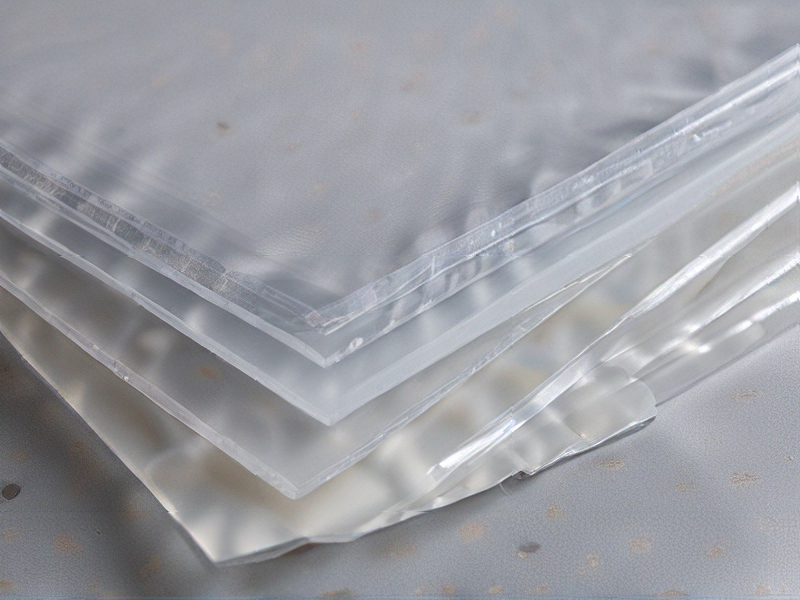

2. Flexibility Needs: Thinner sheets (1-3mm) are better for applications requiring bending or shaping.

3. Weight: Thicker sheets are heavier, which can impact shipping costs and ease of handling.

4. Cost: Thicker sheets are generally more expensive, so balance thickness with budget constraints.

Surface Finish

1. Glossy: Provides a sleek look, suitable for aesthetic applications.

2. Matte: Reduces glare, ideal for display surfaces.

3. Textured: Improves grip and reduces visibility of scratches, suitable for high-traffic areas.

Durability

1. UV Resistance: Essential for outdoor applications to prevent degradation.

2. Chemical Resistance: Important for environments exposed to solvents or corrosive substances.

3. Impact Resistance: Necessary for high-impact areas to avoid frequent replacements.

Supplier Considerations

1. Reputation: Choose suppliers with good reviews and a proven track record.

2. Certifications: Ensure materials meet relevant industry standards.

3. Customization Options: Select suppliers offering customization to meet specific project requirements.

4. Lead Times: Verify the supplier’s ability to meet your project timelines.

Environmental Impact

1. Recyclability: Prefer materials that can be recycled to support sustainability.

2. Manufacturing Process: Consider suppliers using eco-friendly manufacturing practices.

By carefully evaluating these factors, you can make informed procurement decisions that balance quality, performance, and cost.

FAQs on Sourcing and Manufacturing from plastic sheet thickness in China

When sourcing plastic sheet thickness from China, consider these FAQs:

1. What thicknesses are available?

Plastic sheets in China typically range from 0.2mm to 10mm thick, with variations depending on the specific material and supplier capabilities.

2. Can I customize thicknesses?

Yes, many manufacturers offer customization services to meet specific thickness requirements beyond standard sizes.

3. What materials are commonly used?

Polyethylene (PE), polypropylene (PP), polycarbonate (PC), and acrylic (PMMA) are popular choices. Each offers different strengths and properties.

4. How do I ensure quality?

Conduct due diligence on suppliers: review certifications, request samples, and consider third-party inspections.

5. What are typical production lead times?

Lead times vary but are generally influenced by order size, customization, and supplier capacity. Expect around 2-4 weeks for standard orders.

6. What about minimum order quantities (MOQs)?

MOQs can vary widely. Negotiate based on your needs and clarify cost implications for smaller orders.

7. What packaging options are available?

Suppliers typically offer standard packaging to protect sheets during transit. Custom packaging may be available upon request.

8. Are there environmental considerations?

Verify suppliers’ adherence to environmental standards and inquire about recyclability options for chosen materials.

9. What payment terms are usual?

Payment terms often include options like T/T (Telegraphic Transfer) or L/C (Letter of Credit), with specific terms negotiated based on order size and relationship with the supplier.

10. How can I manage shipping logistics?

Coordinate with suppliers to arrange shipping, considering factors like incoterms, freight forwarders, and customs clearance.

By addressing these FAQs, you can navigate sourcing and manufacturing plastic sheet thickness from China more effectively while ensuring quality, customization, and logistical considerations are met.