Technology and Applications of laser engraving machines for metal

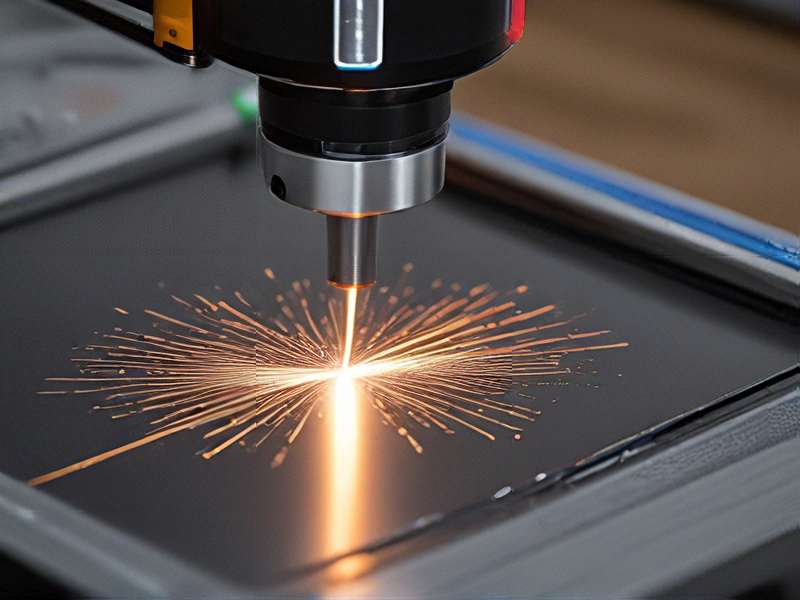

Laser engraving machines for metal utilize high-powered lasers to etch or engrave designs, text, or patterns directly onto metal surfaces. This technology is widely acclaimed for its precision, speed, and versatility in material handling.

Technology: Laser engraving systems generally operate using CO2, fiber, or solid-state lasers. Fiber lasers are particularly effective for metal, offering high peak power and excellent beam quality, allowing for deep and detailed engraving. The laser beam vaporizes the material at a microscopic level, creating detailed engravings without the need for physical tools or engravers, which minimizes wear and maintenance.

Applications: The applications of laser engraving on metal are extensive. Industries such as jewelry, automotive, aerospace, and electronics frequently utilize this technology for applications ranging from creating intricate designs and serial numbers to marking logos and barcodes. In the jewelry sector, for example, personalized engravings enhance the value of pieces, while aerospace and automotive fields require precise identification for components to ensure safety and compliance.

Additionally, laser engraving machines can mark various metal types, including stainless steel, aluminum, brass, and titanium. They also enable customization, allowing businesses to offer tailored products that meet specific customer needs, which is increasingly important in today’s market.

Overall, the integration of laser engraving machines in metalworking enhances productivity, promotes creative freedom, and ensures high-quality outputs, making it an essential tool in modern manufacturing and craftsmanship.

Quality Testing Methods for laser engraving machines for metal and how to control quality

Quality testing methods for laser engraving machines for metal typically include the following approaches to ensure precision and consistency:

1. Dimensional Accuracy: Use precision measurement tools like calipers or coordinate measuring machines (CMMs) to verify that engraved dimensions meet specifications.

2. Surface Finish: Visual inspection and tactile assessment to ensure the engraved surface is smooth and free from rough edges or burrs.

3. Edge Definition: Microscopic examination or high-resolution imaging to assess the clarity and sharpness of engraved edges.

4. Durability Testing: Abrasion testing or exposure to harsh environmental conditions (e.g., corrosion tests) to evaluate the longevity of the engraving.

5. Contrast and Legibility: Visual inspection under different lighting conditions to confirm readability and contrast of the engraved marks.

To control quality effectively:

– Establish Standards: Define clear quality standards and acceptance criteria for engraved products.

– Regular Calibration: Ensure laser machines are calibrated regularly to maintain accuracy.

– Operator Training: Provide comprehensive training for operators on machine operation, maintenance, and quality standards.

– Process Monitoring: Implement process controls such as real-time monitoring of engraving parameters (e.g., power, speed) to detect deviations promptly.

– Quality Assurance Checks: Conduct routine quality checks at various stages of production to identify and rectify issues early.

By integrating these methods and controls, manufacturers can consistently produce high-quality metal engravings that meet customer expectations and industry standards.

Tips for Procurement and Considerations when Purchasing from laser engraving machines for metal

When procuring laser engraving machines for metal, several key considerations can ensure you make an informed decision:

1. Laser Type and Power: Choose between CO2 and fiber lasers based on your material and application needs. Fiber lasers are ideal for metal due to their high intensity and precision.

2. Workspace Size: Consider the maximum area the machine can engrave to ensure it accommodates your typical metal sizes and shapes.

3. Accuracy and Resolution: Look for machines with high DPI (dots per inch) for intricate designs and fine details, crucial for metal engraving.

4. Ease of Use and Software Compatibility: User-friendly interfaces and compatible software (like CAD programs) streamline operations and design transfer.

5. Maintenance and Support: Ensure the supplier offers adequate support, training, and maintenance services to keep your machine operational and minimize downtime.

6. Speed and Efficiency: Evaluate engraving speed relative to your production needs, balancing it with engraving quality.

7. Safety Features: Laser safety is paramount; ensure the machine meets safety standards and has features like enclosed working areas and emergency stop buttons.

8. Cost and ROI: Consider upfront costs, ongoing maintenance, and potential return on investment (ROI) based on increased productivity and capabilities.

9. Customer Reviews and Reputation: Research supplier reputation and customer reviews to gauge reliability and service quality.

10. Future Scalability: Choose a machine that aligns with your growth plans and future production needs to avoid early obsolescence.

By focusing on these factors, you can confidently select a laser engraving machine that meets your specific metal engraving requirements efficiently and effectively.

FAQs on Sourcing and Manufacturing from laser engraving machines for metal in China

When sourcing laser engraving machines for metal from China, it’s essential to address several frequently asked questions (FAQs) to ensure a smooth manufacturing process:

1. Quality Assurance: How can I ensure the quality of laser engraving machines from Chinese suppliers?

– Seek suppliers with ISO certifications or industry-specific quality standards. Request samples or visit manufacturing facilities if possible.

2. Customization: Can I request customization or specific features?

– Many Chinese manufacturers offer customization options. Clearly communicate your requirements and ensure they can be met within your budget and timeline.

3. Lead Times: What are the typical lead times for manufacturing and delivery?

– Lead times can vary based on machine complexity and supplier capacity. Get clear timelines upfront and factor in shipping time.

4. MOQ (Minimum Order Quantity): Is there a minimum order requirement?

– MOQs vary by supplier and product. Negotiate based on your initial requirements and projected demand.

5. Support and Training: Do suppliers offer training and technical support?

– Ensure suppliers provide adequate training for machine operation and offer technical support post-purchase.

6. Warranty and Service: What warranty options are available?

– Understand the warranty terms and conditions. Some suppliers offer extended warranties or service agreements for additional peace of mind.

7. Compliance and Certification: Are the machines compliant with international standards?

– Verify compliance with relevant safety and environmental regulations for your market.

8. Payment Terms: What are the payment terms?

– Negotiate favorable payment terms that balance financial security with supplier requirements.

9. Logistics and Shipping: How will the machines be shipped, and who handles logistics?

– Discuss shipping options, costs, and responsibilities to avoid delays or unexpected fees.

10. After-Sales Service: How responsive is the supplier’s after-sales service?

– Check customer reviews and ask about the supplier’s reputation for resolving issues promptly.

By addressing these FAQs when sourcing laser engraving machines from China, you can mitigate risks and ensure a successful manufacturing process tailored to your needs.