Technology and Applications of cnc router projects

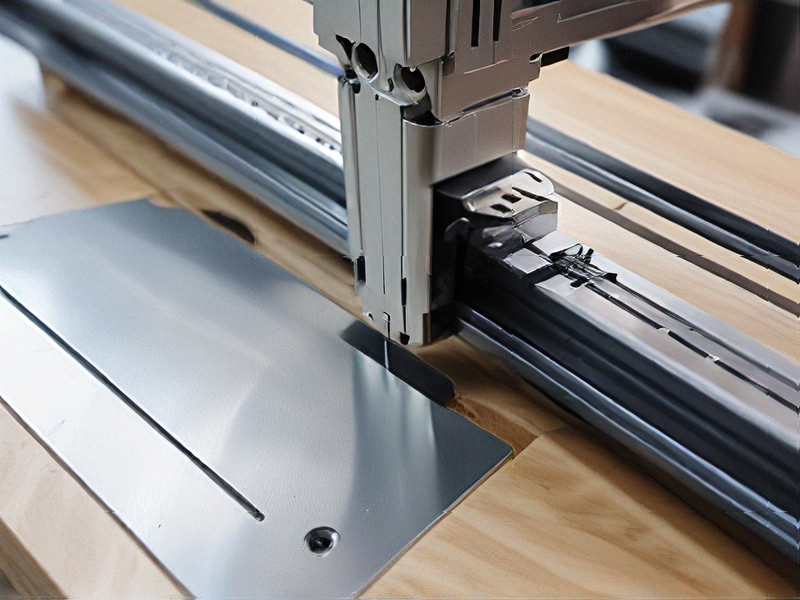

CNC routers are pivotal in modern manufacturing and woodworking for their precision and versatility. These machines operate based on computer numerical control (CNC), allowing for automated cutting, carving, and shaping of various materials such as wood, plastics, metals, and composites.

Applications:

1. Woodworking: CNC routers excel in creating intricate designs, furniture components, cabinetry, and artistic wood carvings with consistent precision.

2. Sign Making: They are widely used in the production of custom signs, logos, and lettering from materials like wood, acrylics, and foams.

3. Prototyping: Rapid prototyping benefits from CNC routers due to their ability to quickly translate digital designs into physical models and parts.

4. Metal Fabrication: Although primarily used for softer materials, CNC routers equipped with appropriate tooling can also cut and engrave metals for various applications.

5. Foam Cutting: Ideal for creating packaging inserts, architectural models, and themed environments due to their ability to cut intricate shapes in foam materials.

Technology:

CNC routers utilize CAD (Computer-Aided Design) software to generate designs, which are then translated into machine-readable instructions (G-code). The machine’s spindle, analogous to a drill bit in handheld routers, precisely cuts into the material following the specified paths and depths. Advanced models offer multi-axis movement for complex 3D shapes.

Benefits:

– Precision: Ensures consistent, high-quality results with minimal errors compared to manual methods.

– Efficiency: Reduces material waste and labor costs by automating repetitive tasks.

– Versatility: Handles a wide range of materials and design complexities.

– Scalability: From small workshops to large-scale manufacturing, CNC routers accommodate various production needs.

In conclusion, CNC routers stand as indispensable tools across industries for their ability to streamline production processes, enhance design capabilities, and deliver reliable output with unmatched precision.

Quality Testing Methods for cnc router projects and how to control quality

Quality testing for CNC router projects involves several methods to ensure precision, accuracy, and consistency. Here are the primary methods and control measures:

1. Dimensional Inspection:

– Tools: Calipers, micrometers, and coordinate measuring machines (CMM).

– Process: Measure critical dimensions and compare them against the design specifications.

2. Surface Finish Testing:

– Tools: Surface roughness testers (profilometers).

– Process: Assess the surface texture and finish to meet the required standards.

3. Material Verification:

– Tools: Spectrometers, hardness testers.

– Process: Verify that the material used matches the project specifications.

4. Visual Inspection:

– Process: Detect surface defects, tool marks, or other visible imperfections.

– Standards: Use standardized checklists to ensure consistency.

5. Functional Testing:

– Process: Test parts in real-world scenarios or under simulated conditions to ensure they perform as intended.

Quality Control Measures

1. Process Control:

– Tool Calibration: Regular calibration of CNC machines and measuring tools to maintain accuracy.

– Documentation: Maintain detailed records of process parameters and inspection results.

2. In-Process Inspection:

– Sampling: Inspect parts at various stages of production to catch defects early.

– Adjustments: Make real-time adjustments based on inspection data to avoid cumulative errors.

3. Post-Production Inspection:

– Comprehensive Testing: Conduct a final inspection of all finished parts before shipment.

4. Standard Operating Procedures (SOPs):

– Guidelines: Develop and adhere to SOPs for all stages of production and quality testing.

– Training: Regularly train personnel on quality standards and inspection techniques.

5. Quality Management Systems (QMS):

– Implementation: Adopt systems like ISO 9001 to establish a structured approach to quality control.

– Continuous Improvement: Use feedback loops to continuously improve processes based on inspection data.

By employing these methods and control measures, manufacturers can ensure high-quality CNC router projects that meet or exceed client expectations.

Tips for Procurement and Considerations when Purchasing from cnc router projects

When procuring a CNC router for projects, consider the following tips and considerations:

1. Machine Specifications: Evaluate the router’s capabilities such as bed size, spindle power, and axis movement. Ensure they meet your project requirements for material size and complexity.

2. Accuracy and Precision: Check the machine’s precision through reviews, specifications, and preferably a test run. Accuracy is crucial for intricate designs and parts consistency.

3. Ease of Use and Software Compatibility: User-friendly interfaces and compatible software are essential. Consider the learning curve for operators and the compatibility of design software with the router’s control system.

4. Maintenance and Support: Research the manufacturer’s reputation for customer support and availability of spare parts. A reliable support network minimizes downtime and ensures longevity.

5. Cost and Return on Investment (ROI): Balance initial costs with long-term benefits. Consider operational costs, maintenance expenses, and potential ROI based on increased production capabilities.

6. Safety Features and Compliance: Ensure the router meets safety standards relevant to your location. Safety features like emergency stop buttons and protective enclosures are critical for operator well-being.

7. Reviews and Recommendations: Seek feedback from other users or industry professionals. Their experiences can provide valuable insights into performance, reliability, and service.

8. Customization and Upgradability: Assess whether the router can be upgraded or customized to adapt to future project requirements or technological advancements.

9. Space and Environment: Consider the physical space available for installation and operation. Additionally, assess environmental factors such as ventilation and power requirements.

10. Training and Skill Development: Plan for training to maximize operational efficiency and utilize the router’s full capabilities. Skilled operators enhance productivity and minimize errors.

By focusing on these considerations, you can effectively procure a CNC router that aligns with your project needs, enhances production efficiency, and ensures long-term value for your investment.

FAQs on Sourcing and Manufacturing from cnc router projects in China

When sourcing and manufacturing CNC router projects in China, it’s crucial to consider several key FAQs:

1. Quality Control: How can I ensure the quality of CNC router products from China?

– Engage with suppliers who have certifications like ISO 9001. Conduct factory audits or hire a third-party inspection service.

2. Communication: How do I effectively communicate my requirements?

– Use clear and detailed specifications. Confirm understanding through samples or prototypes before full production.

3. Lead Times: What are typical lead times for CNC router projects?

– Lead times can vary based on complexity and quantity. Clarify production schedules and shipping times upfront.

4. Costs: How can I manage costs effectively?

– Obtain detailed quotes including all costs (material, labor, shipping). Negotiate based on volume and long-term partnerships.

5. Intellectual Property: How can I protect my designs and intellectual property?

– Sign non-disclosure agreements (NDAs) and ensure suppliers respect intellectual property rights. Consider patent protection where applicable.

6. Logistics: What logistics challenges should I anticipate?

– Plan for potential delays in shipping and customs clearance. Use reputable freight forwarders and clarify incoterms.

7. After-Sales Support: What support can I expect after purchase?

– Clarify warranty terms and availability of spare parts. Establish a communication channel for ongoing support.

By addressing these FAQs proactively, you can navigate sourcing and manufacturing CNC router projects in China with greater confidence and efficiency.