“Reliable Acrylic Laser Cutting Sheets by SourcifyChina Factory: High-Quality Precision and Durability for Your Projects”

This title emphasizes the trustworthiness and quality of SourcifyChina Factory’s acrylic laser cutting sheets, focusing on their precision and durability, ideal for a wide range of projects.

“Why Choose SourcifyChina Factory for Purchasing Acrylic Laser Cutting Sheets from China?”

SourcifyChina offers unmatched quality assurance for acrylic laser cutting sheets. Their rigorous quality control processes ensure each product meets international standards, providing durability and precision in every cut.

Additionally, SourcifyChina is known for its competitive pricing. By utilizing efficient manufacturing techniques, they are able to offer high-quality acrylic sheets at prices that fit various budget requirements.

The factory’s timely delivery services are another significant benefit. Buyers can rely on SourcifyChina for prompt shipping schedules that ensure products arrive exactly when needed, boosting project efficiency.

Moreover, SourcifyChina prioritizes excellent customer service. Their responsive support team is always ready to address queries and concerns, making the purchasing process smoother and more transparent.

Finally, SourcifyChina stands out for its customization capabilities. They offer tailored solutions to meet specific client needs, whether it’s a custom size, design, or bulk order, ensuring buyer satisfaction through individualized attention.

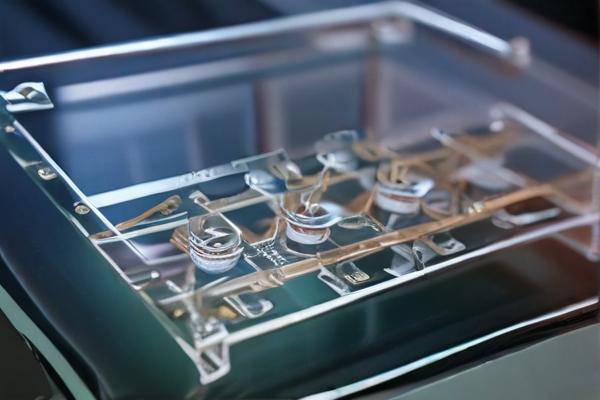

Acrylic laser cutting sheets come in various types and options, catering to diverse needs for both decorative and functional purposes. Common types include clear, colored, mirrored, and textured sheets, offering a wide range of customization possibilities.

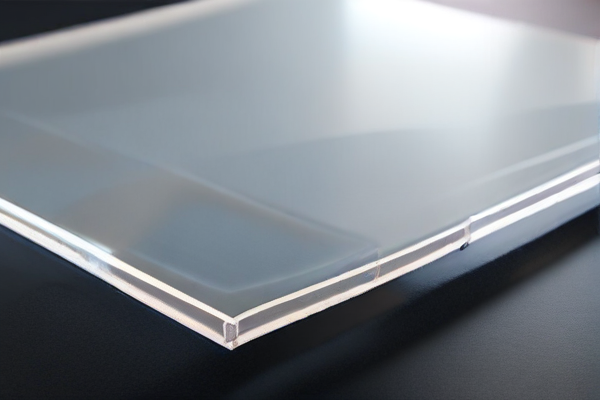

– Clear Acrylic Sheets: Highly transparent, often used for glazing and display cases.

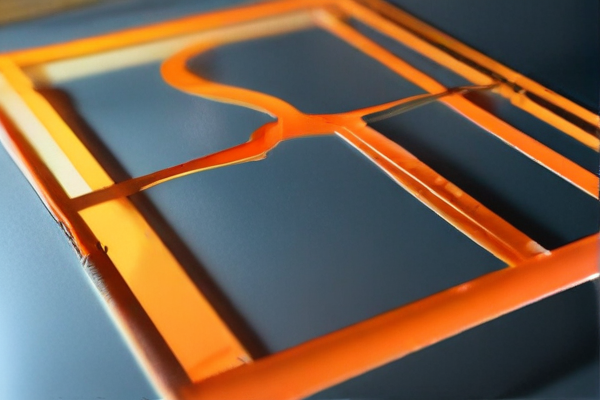

– Colored Acrylic Sheets: Available in various hues, ideal for decorative applications.

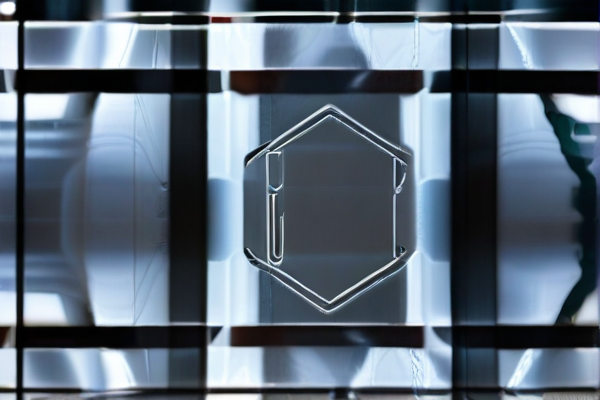

– Mirrored Acrylic Sheets: Reflective surface, useful for decorative mirrors and signage.

– Textured Acrylic Sheets: Surface patterns add visual interest, often used in interior design.

– Frosted Acrylic Sheets: Diffuses light, perfect for privacy screens and lighting fixtures.

– Opaque Acrylic Sheets: Blocks light transmission, suitable for partitions and creative designs.

– Cast Acrylic Sheets: Superior optical clarity and durability, often used in high-quality applications.

– Extruded Acrylic Sheets: Cost-effective, less optical clarity compared to cast, used in general applications.

– UV-Resistant Acrylic Sheets: Designed to withstand outdoor conditions, often used in signage and exterior applications.

Each type provides different benefits, making acrylic laser cutting sheets versatile for numerous projects, from industrial uses to artistic creations.

Acrylic laser cutting sheets are versatile materials widely used in various industries due to their precision and durability. They can be custom-cut for different applications, offering both aesthetic and functional benefits.

– Signage: Perfect for creating detailed and attractive signs for businesses.

– Architectural Models: Ideal for building accurate and intricate architectural prototypes.

– Decorative Items: Used for crafting customized home décor items, such as wall hangings and photo frames.

– Retail Displays: Suitable for making sleek and modern product displays in retail stores.

– Engraved Gifts: Popular for creating personalized gifts through precise engravings.

– Prototyping: Preferred material for creating functional prototypes in product design.

– Jewelry Making: Used in crafting unique and elaborate jewelry pieces.

– Furniture Components: Utilized in making stylish and durable parts for furnishings.

– Automotive Parts: Applied in the manufacture of lightweight and durable car components.

– Lighting Fixtures: Great for designing custom lighting solutions.

– Art Installations: Widely used by artists for creating large-scale art installations.

– Educational Tools: Crafted into various educational materials and interactive tools.

– Industrial Templates: Used for making accurate and reusable industrial cutting templates.

– Packaging: Employed in the development of high-quality and customized packaging.

– Medical Devices: Used in the production of components for various medical equipment.

– Event Displays: Perfect for creating striking visual elements for events and exhibitions.

– Awards and Trophies: Customizable for creating unique and high-quality awards.

– Technological Devices: Applied in designing enclosures and parts for electronic gadgets.

– Interior Design Elements: Used for innovative interior decorating components.

– Outdoor Fixtures: Durable enough for outdoor applications like signage and displays.

Overall, acrylic laser cutting sheets are essential in various fields due to their versatility, precision, and aesthetic appeal.

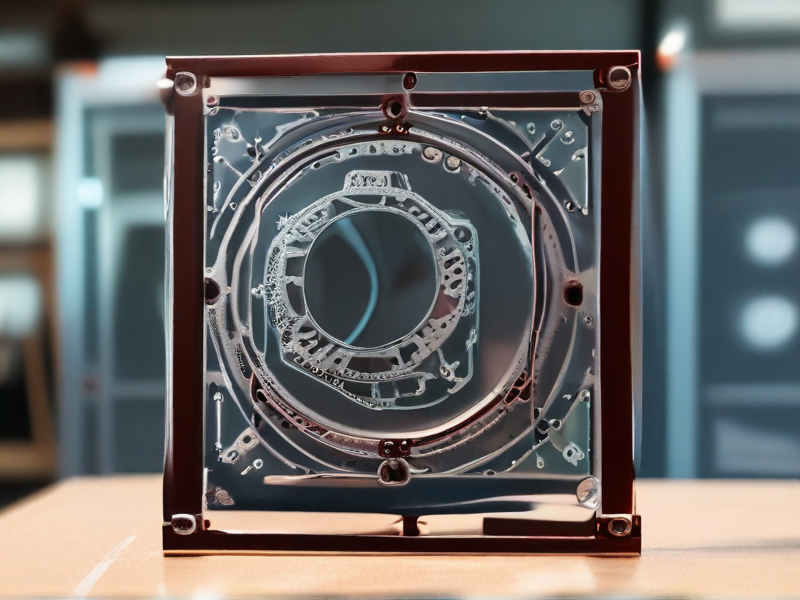

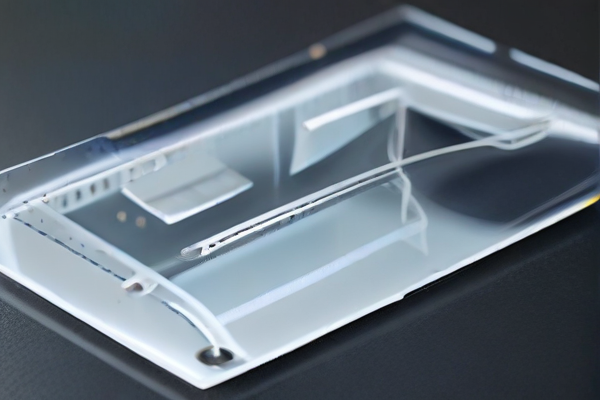

The “SourcifyChina acrylic laser cutting sheet” is made from high-quality polymethyl methacrylate (PMMA), known for its clarity and strength. It’s a versatile material ideal for both professional and DIY projects.

These laser cutting sheets exhibit excellent optical properties, delivering superior transparency and light transmission. Ideal for applications demanding aesthetic precision, they can be used in signage, displays, or intricate artistic ventures.

Durability is a hallmark of these acrylic sheets. They are resistant to UV light and weathering, ensuring a long lifespan for outdoor and indoor projects. Additionally, they exhibit impressive hardness and are less prone to scratches.

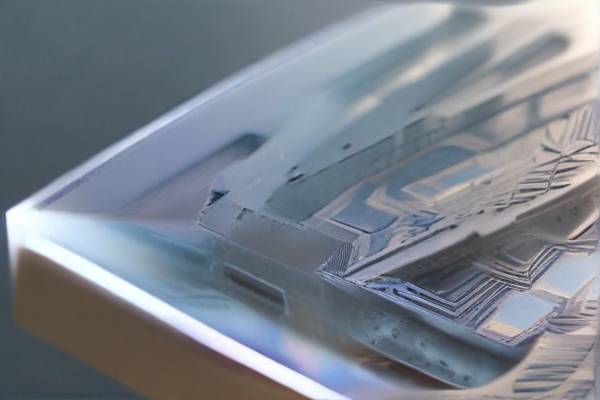

The “SourcifyChina acrylic laser cutting sheet” is also easy to handle. It can be precisely cut, engraved, and polished using laser technology, making it an efficient choice for detailed and accurate work. This flexibility enhances its usability across various industries.

Overall, these acrylic sheets are a reliable and cost-effective solution for projects requiring visual appeal and structural integrity. They cater to diverse needs, from everyday DIY tasks to sophisticated industrial applications, making them a valuable addition to any toolkit.

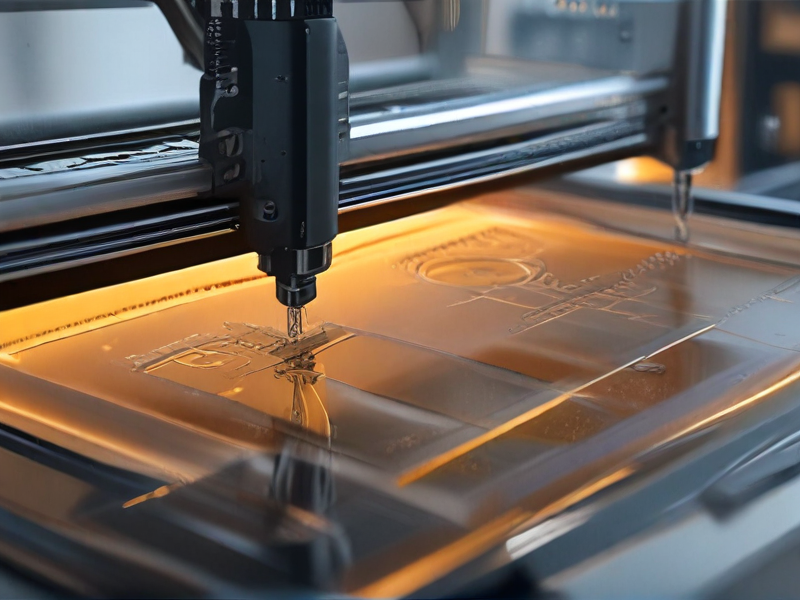

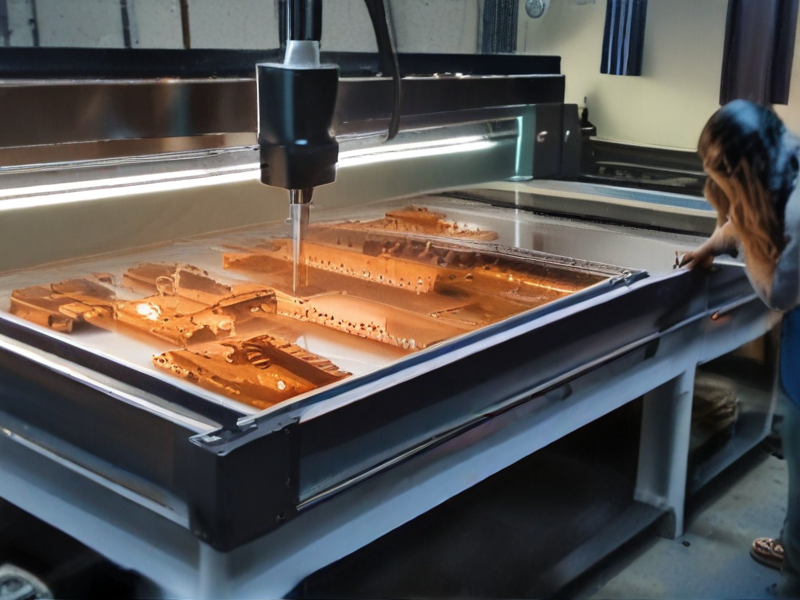

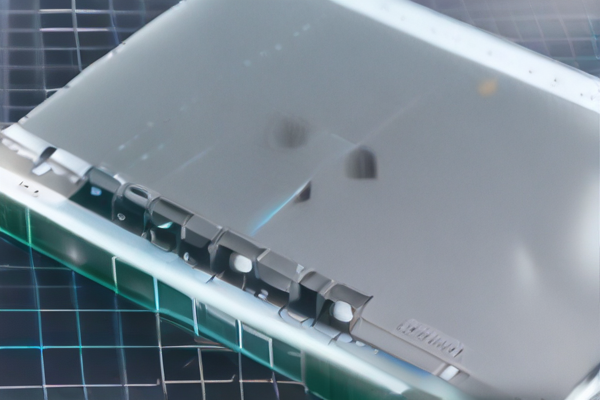

SourcifyChina’s acrylic laser-cutting sheet quality control manufacturing process ensures top-tier precision and clarity. The process begins with sourcing high-quality raw acrylic material, which undergoes stringent inspections to ensure it meets industry standards for strength and transparency.

Next, this material is fed into advanced laser cutting machines. These machines are regularly calibrated to maintain exacting tolerances, ensuring each cut is sharp and dimensionally accurate. Laser operators are highly trained, contributing to consistent, high-quality results.

Additionally, each sheet is visually inspected and measured post-cutting. This step ensures that there are no defects like chipping, cracking, or dimensional inaccuracies. Any sheets failing to meet specifications are immediately discarded or recycled.

Finally, SourcifyChina implements a robust final inspection before packaging and shipping. This includes quality assurance checks for the thickness, clarity, and adherence to customer specifications. Only sheets that pass this rigorous scrutiny are deemed ready for delivery, ensuring that clients receive nothing but the best.

SourcifyChina’s acrylic laser cutting sheets offer precision and versatility, making them ideal for intricate designs. The sheets boast smooth edges and clean cuts, enhancing aesthetic appeal.

These acrylic sheets are durable and resilient, perfect for both indoor and outdoor projects. Their excellent light transmission properties make them suitable for signage, displays, and decorative elements.

Available in various thicknesses and colors, the sheets cater to specific needs, providing a tailored approach for diverse applications. Their uniformity and quality meet industry standards, ensuring consistent performance and satisfaction.

SourcifyChina’s offerings include custom-cutting services, meeting unique design requirements with accuracy. The sheets’ adaptability and high-quality finish make them an excellent choice for businesses and hobbyists alike, promising impressive results for any project.

Acrylic laser cutting sheets are versatile, offering precision and high-quality finishes ideal for various applications, from signage to architectural models.

Benefits

of Acrylic Laser Cutting Sheets:

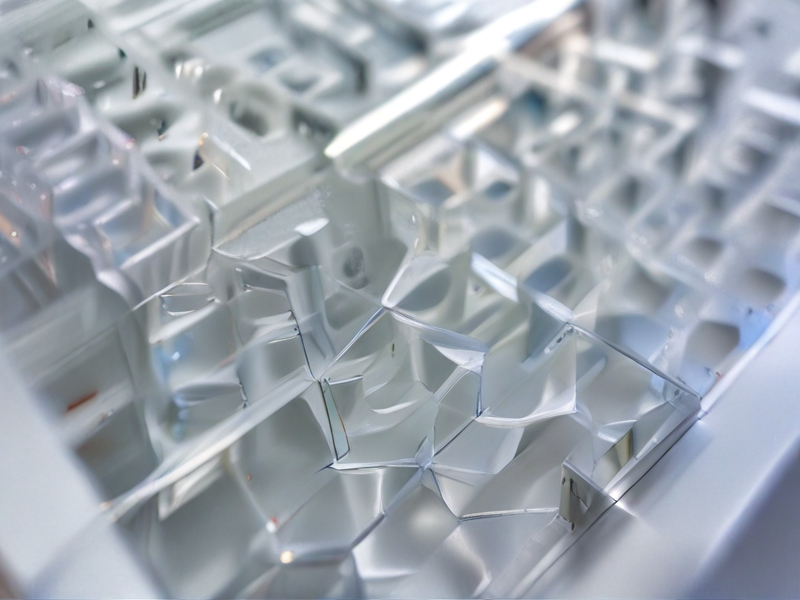

– Precision Cutting: Achieves intricate and accurate designs, ensuring detailed craftsmanship.

– Smooth Edges: Results in polished, clean edges, reducing the need for additional finishing.

– Customization: Easily customizable for personalized projects or one-off pieces.

– Material Efficiency: Minimizes waste, making it cost-effective and environmentally friendly.

– Durability: Acrylic is robust and long-lasting, suitable for both indoor and outdoor use.

– Versatility: Apt for diverse applications, including displays, signage, and prototypes.

– Speed: Faster production times compared to traditional methods.

– Cost-Effective: Reduces labor and material costs by eliminating many manual processes.

– No Direct Contact: Reduces the risk of material damage since it’s a non-contact cutting method.

– Complex Shapes: Can cut complex geometries and patterns that traditional machining cannot achieve.

Acrylic laser cutting sheets are renowned for their precision, versatility, and aesthetic appeal, making them a popular choice across various industries.

– Precision: Laser cutting ensures clean, accurate edges with intricate designs.

– Versatile Colors and Finishes: Available in multiple colors, opacities, and finishes, suitable for custom projects.

– Durability: Resistant to weather, UV light, and impacts, ensuring longevity.

– Thermal Stability: High melting point minimizes deformation during cutting.

– Ease of Maintenance: Smooth surfaces resist dirt and are easy to clean.

– Varied Thickness: Available in different thicknesses to cater to specific project needs.

– Non-Toxic: Safe for use in various environments, including educational and medical settings.

– Eco-Friendly Options: Some variants are recyclable, reducing environmental impact.

– Cost-Effective: Offers a balance of quality and affordability.

– Wide Application Range: Ideal for signage, displays, crafts, architectural models, and more.

SourcifyChina specializes in custom acrylic laser cutting sheets that cater to various needs and industries. Their precision laser cutting technology ensures high-quality results for each piece, making intricate designs possible.

These acrylic sheets are available in multiple colors and thicknesses, providing flexibility for a range of project requirements. Whether for signage, decorations, or components for larger projects, SourcifyChina meets diverse specifications.

Their custom products are crafted to exact client specifications, emphasizing durability and aesthetic appeal. Detailed consultations ensure each project receives the attention and customization needed for optimal performance and visual impact.

Turnaround times are quick, yet the quality remains consistently high. Customers can expect a seamless process from design to delivery, ensuring satisfaction.

With a strong focus on customer service, SourcifyChina supports clients throughout the project lifecycle. From initial design discussions to final delivery, their team is dedicated to achieving perfect results.

SourcifyChina is an industry-leading company specializing in the production and supply of high-quality acrylic laser cutting sheets. Renowned for its precision and innovation, SourcifyChina leverages advanced laser cutting technology to deliver acrylic sheets that cater to a broad spectrum of applications, from industrial manufacturing to creative arts and design. The company’s state-of-the-art production facilities ensure superior edge finish and dimensional accuracy, making their products highly sought after for signage, display cases, architectural models, and DIY projects. With a commitment to excellence, SourcifyChina emphasizes rigorous quality control and sustainable practices, ensuring that their acrylic sheets are not only durable and aesthetically pleasing but also environmentally friendly. The company’s dedication to customer satisfaction is reflected in their tailored solutions, competitive pricing, and responsive customer service, establishing SourcifyChina as a trusted partner for clients worldwide.

Acrylic laser cutting sheets have garnered substantial attention in the aerospace, defense, and marine industries due to their precision, durability, and versatility. In aerospace applications, these sheets are instrumental in fabricating intricate components such as instrument panels, cockpit displays, and internal structural elements. The precision of laser cutting ensures that each piece meets stringent tolerance requirements, essential for aerodynamic efficiency and flight safety. Additionally, acrylic’s lightweight nature compared to traditional materials helps in reducing the overall weight of aircraft, thereby contributing to fuel efficiency and operational cost savings. The material’s resistance to UV light and its clarity make it an excellent choice for applications requiring transparency and long-term exposure to harsh environmental conditions.

In the defense sector, acrylic laser cutting sheets are employed to create various components ranging from protective visors, ballistic shields to intricate parts of communication devices and electronic housing units. The accuracy of laser cutting technology allows for the rapid prototyping and production of complex geometries that are essential for contemporary defense systems. Moreover, acrylic’s inherent strength and capability to withstand significant physical stress underscore its suitability for protective gear. In marine applications, these sheets are used in the construction of windows, hatches, and underwater viewing panels due to their excellent transparency and resistance to saltwater corrosion. The ease of maintenance and the ability to fabricate custom shapes with minimal material wastage make acrylic laser cutting sheets a cost-effective and reliable option for maritime vessels, both commercial and military, enhancing safety and operational longevity in demanding marine environments.

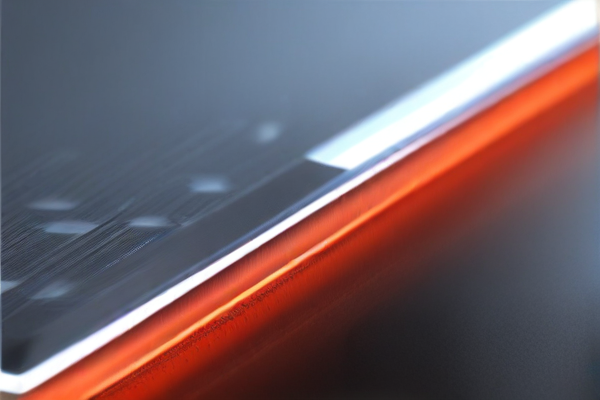

Acrylic laser cutting sheets have become a staple in the automotive industry due to their versatility, durability, and aesthetic appeal. These sheets are widely used for manufacturing aerodynamic components, custom dashboards, and lighting covers. Their lightweight nature and resistance to weathering make them ideal for exterior applications, where they withstand temperature fluctuations, UV exposure, and other environmental factors. Additionally, the precision of laser cutting ensures that each piece fits perfectly, enhancing both the functional and visual aspects of automotive design. The ability to produce intricate designs with smooth edges also allows for personalized interior decorations and branded elements, further elevating the vehicle’s overall look and feel.

In the realm of electronics, acrylic laser cutting sheets serve a crucial role in the creation of various components and enclosures. Their excellent optical clarity makes them a preferred choice for display screens, touch panels, and LED diffusers, ensuring sharp and vibrant visual outputs. Moreover, the material’s insulating properties help in protecting sensitive electronic circuits from external interference and mechanical damage. The precision of laser cutting allows for the creation of customized circuit board holders, protective cases, and intricate panel overlays with exacting tolerances. This level of customization and protection is particularly beneficial for prototypes and small-scale production runs in the rapidly evolving electronics market. Overall, acrylic laser cutting sheets offer a reliable and efficient solution for the stringent demands of both automotive and electronics applications.

Acrylic laser cutting sheets have revolutionized the construction industry due to their versatility, durability, and aesthetic appeal. These sheets can be precisely laser-cut into various shapes and sizes, allowing architects and builders to create intricate designs and custom components with remarkable accuracy. Their light weight compared to glass makes them an attractive option for windows, skylights, and partitions, reducing the structural load on buildings. In addition, acrylic sheets offer excellent weather and UV resistance, ensuring longevity and minimal maintenance in various climates. The ability to fabricate complex designs swiftly and reliably greatly enhances creativity and efficiency in modern architectural projects.

In the energy sector, acrylic laser cutting sheets are increasingly being utilized for innovative applications. One significant area is in the development of solar panels. Acrylic’s excellent light transmission properties can be harnessed to create lightweight and durable covers that protect the photovoltaic cells while maximizing energy absorption. Additionally, acrylic sheets are employed in the construction of compact and efficient energy storage solutions, such as battery casings and other insulating components, that benefit from the material’s high strength-to-weight ratio and insulating properties. Overall, acrylic laser cutting sheets offer substantial advantages in optimizing energy generation and storage systems, contributing to the advancement of sustainable energy technologies.

The industrial equipment sector has increasingly adopted acrylic laser cutting sheets due to their precision, versatility, and efficiency. Acrylic sheets, when cut using laser technology, yield highly precise and clean edges, minimizing the need for additional post-processing. This attribute is particularly advantageous in producing intricate components such as control panels, machine guards, and display cases which require meticulous attention to detail. The laser cutting process allows for automated, high-speed production, substantially reducing manufacturing time and cost, while also maintaining a high level of consistency and quality.

Moreover, the durability and resilience of acrylic make it a preferred material over other plastics and even some metals, especially in environments that demand both aesthetic appeal and functional integrity. Its resistance to UV light, impact, and varying temperatures ensures longevity and reliability in harsh industrial settings. Furthermore, the ability to cut acrylic sheets into various complex shapes and sizes enhances design flexibility, supporting customization according to specific industrial needs. Consequently, the adoption of acrylic laser cutting technology within the industrial equipment industry not only enhances productivity but also opens up new possibilities for innovation and specialized applications.

Acrylic laser cutting sheets are revolutionizing the medical device industry due to their precision, versatility, and hygiene benefits. Acrylic, a transparent thermoplastic, offers excellent clarity, which is crucial for devices that require visibility, such as protective barriers, incubators, and diagnostic equipment. The high precision afforded by laser cutting ensures that intricate designs and complex shapes can be manufactured consistently, making it possible to produce detailed components like surgical guides and prosthetics with exact specifications. The ability to create prototypes quickly and accurately also accelerates the development process, allowing for rapid iteration and refinement of medical devices.

Beyond precision, acrylic’s inherent properties make it particularly well-suited for medical applications. It is lightweight, durable, and resistant to a variety of chemicals, ensuring that devices can endure rigorous sterilization processes without degrading. The smooth edges achieved through laser cutting reduce the risk of bacterial growth, enhancing the sterility of parts used in hygiene-critical environments like operating rooms and laboratories. Additionally, the aesthetic versatility of acrylic allows for customization in color and finish, enabling tailored solutions that meet specific clinical requirements or institutional branding. Consequently, acrylic laser cutting sheets are becoming indispensable in the production of reliable, high-quality medical devices.

Acrylic laser cutting sheets have become indispensable in the machining and manufacturing industry due to their precision and versatility. By utilizing high-powered lasers, manufacturers can cut through acrylic with remarkable accuracy, allowing for intricate designs and complex geometries that are often impossible with traditional cutting tools. This type of laser technology ensures smooth edges and minimal waste, making it an ideal choice for projects requiring high levels of detail such as custom signage, architectural models, and intricate prototypes. The ability to consistently produce precise cuts without physical contact also reduces the risk of material damage, thereby enhancing the durability and aesthetic quality of the final product.

In the broader spectrum of manufacturing, acrylic laser cutting sheets provide considerable advantages, including efficiency and scalability. Businesses ranging from small startups to large-scale production facilities can benefit from the speed and repeatability offered by laser cutting systems. These systems can be easily integrated with computer-aided design (CAD) software, enabling seamless transitions from digital designs to physical products. This adaptability is particularly valuable in industries such as automotive, aerospace, and consumer electronics, where both custom and mass-produced components must meet stringent standards. Moreover, the clean and precise cuts achieved through laser technology often eliminate the need for additional finishing processes, thereby reducing production times and costs. Ultimately, the integration of acrylic laser cutting sheets into machining and manufacturing practices offers a blend of accuracy, efficiency, and aesthetic quality that is hard to rival with other methods.

Q: What types of acrylic sheets does SourcifyChina factory offer?

A: SourcifyChina offers a wide range of acrylic sheets including clear, colored, mirrored, textured, and more. They cater to various thicknesses and sizes based on customer requirements.

Q: Is custom cutting available for specific dimensions and designs?

A: Yes, SourcifyChina provides custom laser cutting services to match specific dimensions and intricate designs, ensuring precision and high-quality finishes.

Q: What is the turnaround time for orders?

A: The turnaround time depends on the complexity and volume of the order. Typically, it ranges from a few days to a couple of weeks. For large or highly detailed orders, delivery time may be longer.

Q: Can SourcifyChina handle bulk orders?

A: Absolutely, SourcifyChina is equipped to handle both small-scale and bulk orders efficiently, ensuring consistent quality across large quantities.

Q: What quality control measures are in place to assure the highest quality of acrylic sheets?

A: SourcifyChina employs stringent quality control processes, including material inspection, precision cutting using advanced laser technology, and final quality checks to ensure each sheet meets the desired standards.

Q: How does SourcifyChina ship the acrylic sheets to prevent damage during transit?

A: SourcifyChina uses secure packaging methods, including cushioning and protective layers, to safeguard the acrylic sheets from any potential damage during shipping.

Q: Are there any eco-friendly options available?

A: Yes, SourcifyChina offers eco-friendly acrylic sheets and follows sustainable manufacturing practices to minimize environmental impact.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods such as wire transfers, credit cards, and other secure online payment options for convenience.

Q: Can clients request samples before placing a large order?

A: Yes, SourcifyChina provides sample options so clients can assess the quality and suitability before committing to a bulk purchase.

Q: Is technical support available for design and material selection?

A: SourcifyChina offers technical support and expert advice on design specifications, material selection, and suitable processing techniques to achieve the best results.

When planning to source acrylic laser cutting sheets from SourcifyChina factory, there are several key considerations to ensure you obtain high-quality products efficiently:

– Grade Selection: Ensure the factory uses high-grade acrylic material, as quality impacts clarity, durability, and cut precision.

– Thickness Options: Verify available thicknesses to match your project requirements.

– State-of-the-Art Machinery: Confirm that the factory employs modern laser cutting technology for precision and smooth edges.

– Tolerance Levels: Check the cutting tolerance to ensure it meets your specifications, typically within ±0.1mm.

– Design Flexibility: SourcifyChina should be able to handle complex designs and varied shapes.

– Batch Variability: They should cater to both small and large-order volumes.

– Prototyping Services: Utilize available prototyping to test designs before full-scale production.

– Sample Inspection: Request samples to evaluate material and cutting quality firsthand.

– Lead Times: Inquire about production lead times to align with your project schedules.

– Capacity: Understand their production capacity to ensure they can meet your order volume consistently.

– Inspection Protocols: Confirm stringent quality control processes are in place to ensure consistency across all products.

– Certifications: Verify relevant certifications like ISO to ensure adherence to high manufacturing standards.

– Transparent Pricing: Ensure clarity on cost structures, including material, cutting, and shipping costs.

– Bulk Discounts: Look for volume discounts to optimize costs for larger orders.

– Responsive Support: Effective, responsive communication channels for addressing queries and coordinating orders.

– Language Compatibility: Ensure smooth communication to avoid misunderstandings.

– Shipping Options: Evaluate shipping options for cost efficiency and delivery timelines.

– Customs Handling: Confirm they assist with customs documentation and compliance.

By carefully considering these aspects, you can effectively source high-quality acrylic laser cutting sheets from SourcifyChina factory, ensuring your project’s success.

FAQ for Sourcing Acrylic Laser Cutting Sheets from SourcifyChina Factory

1. What types of acrylic sheets are available at SourcifyChina?

SourcifyChina offers a wide range of acrylic sheets, including clear, colored, frosted, and mirrored options. Customized thickness and size options are also available to meet specific project needs.

2. Can I get customized dimensions for my acrylic sheets?

Yes, SourcifyChina provides customization services. You can specify the dimensions, thickness, and even shapes. They also offer personalized laser cutting and engraving services.

3. What is the minimum order quantity (MOQ) for acrylic sheets?

The MOQ may vary depending on the type and size of the acrylic sheets. Generally, the MOQ is set to ensure cost-effective production and shipping. Please contact SourcifyChina directly for specific MOQ details.

4. What are the payment terms?

SourcifyChina accepts various forms of payment, including wire transfers, PayPal, and letters of credit. Payment terms can be negotiated, but typically, a deposit is required to commence production, with the balance due before or upon shipment.

5. How long does it take to process an order?

Lead times vary depending on order size and customization requirements. Standard orders usually take between 7-15 days, while customized orders may take longer. It’s recommended to confirm the lead time with SourcifyChina when placing your order.

6. Do you provide quality certificates or compliance documents?

Yes, SourcifyChina can provide relevant quality certificates and compliance documents upon request. This includes ISO certifications, material safety data sheets (MSDS), and RoHS compliance, among others.

7. How is shipping and delivery handled?

SourcifyChina offers various shipping options including air, sea, and express courier services. They also handle all necessary export documentation. Delivery time will depend on the chosen shipping method and destination.

8. What is the return policy?

SourcifyChina accepts returns for defective products or if products do not meet the agreed specifications. Customers should report any issues within 7 days of receiving the products to qualify for a return or replacement.

9. Are samples available before placing a large order?

Yes, SourcifyChina offers samples for a small fee. This allows you to evaluate the product quality before committing to a large order.

10. How can I place an order?

Sourcing acrylic laser cutting sheets from SourcifyChina factory can be efficient and cost-effective if approached strategically. Here are some concise tips to ensure a smooth sourcing process:

1. Research Thoroughly: Before committing, gather detailed information about the factory, including its reputation, history, and customer reviews. Platforms like Alibaba and Global Sources can offer insights from other buyers.

2. Clarify Specifications: Ensure you have a clear understanding of the specifications you need, such as thickness, color, and grade of acrylic. This will help in getting accurate quotes and avoid misunderstandings.

3. Request Samples: Always request samples before placing a large order. This allows you to verify the quality of the acrylic sheets and the precision of the laser cutting.

4. Verify Certifications: Ensure the factory holds relevant certifications (e.g., ISO), which indicate adherence to quality management standards. This also ensures the materials meet safety and environmental regulations.

5. Negotiate Terms: Discuss payment terms, shipping conditions, and lead times upfront. Be clear on how potential issues, like defects or delays, will be handled.

6. Leverage Connections: If possible, use connections or hiring agents who have experience with Chinese suppliers. They can provide valuable local insights and help bridge communication gaps.

7. Use Escrow Services: For financial transactions, consider using escrow services to protect your payments until you receive and verify the goods.

8. Communicate Clearly: Maintain clear and continuous communication. Use detailed, written instructions and confirm all conversations and agreements in writing.

9. Monitor Production: If feasible, visit the factory or hire a local inspection service to monitor the production process and ensure alignment with your requirements.

10. Build Relationships: Establishing a strong, long-term relationship with the factory can lead to better pricing, priority service, and more flexibility in the future.

By following these tips, you can enhance the reliability and efficiency of sourcing acrylic laser cutting sheets from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.