Choosing SourcifyChina Factory for buying acrylic sheets for laser cutting offers unparalleled quality and reliability. Their top-tier products ensure precise, clean cuts, essential for intricate designs. With advanced technology and stringent quality control, they guarantee exceptional durability and clarity in every sheet.

SourcifyChina prioritizes timely delivery, ensuring your projects remain on schedule. Their efficient logistics network and dependable shipping partners make it easy to receive orders promptly, no matter where you are worldwide. This reliability minimizes downtime and enhances workflow efficiency.

They offer competitive pricing without compromising on quality. SourcifyChina leverages its extensive industry experience and robust supplier relationships to provide cost-effective solutions, granting you high-caliber acrylic sheets at affordable rates. This balance of cost and quality is crucial for budget-sensitive projects.

Excellent customer service is another cornerstone of their operation. The dedicated support team is always ready to assist, providing clear communication and tailored advice. From order placement to post-delivery support, their team ensures a smooth, hassle-free experience, addressing any concerns promptly.

SourcifyChina’s commitment to eco-friendly practices is noteworthy. They employ sustainable manufacturing processes and ensure responsible sourcing of raw materials. By choosing them, you contribute to environmentally-conscious practices while receiving top-quality products.

In conclusion, SourcifyChina Factory stands out for its exceptional quality, reliable logistics, competitive pricing, outstanding customer service, and eco-friendly policies. These attributes make them the ideal choice for sourcing acrylic sheets for laser cutting, ensuring your project’s success and sustainability.

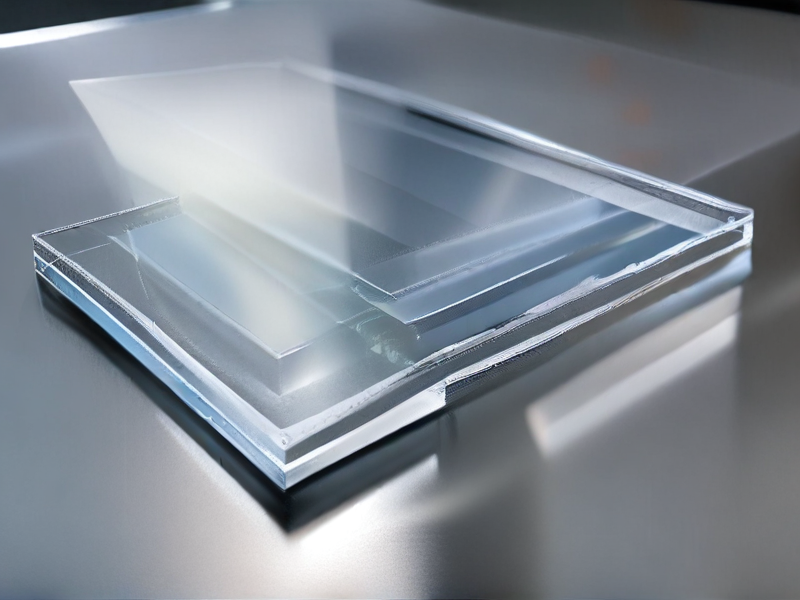

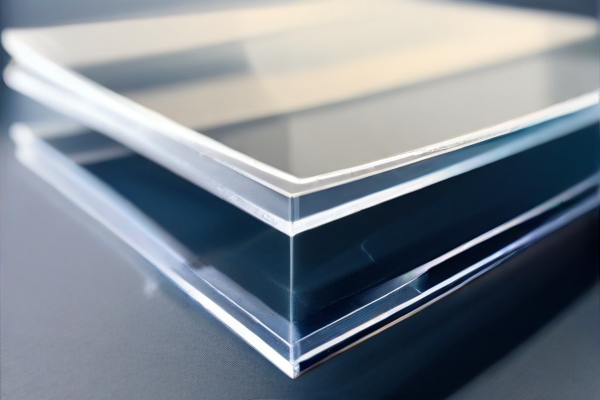

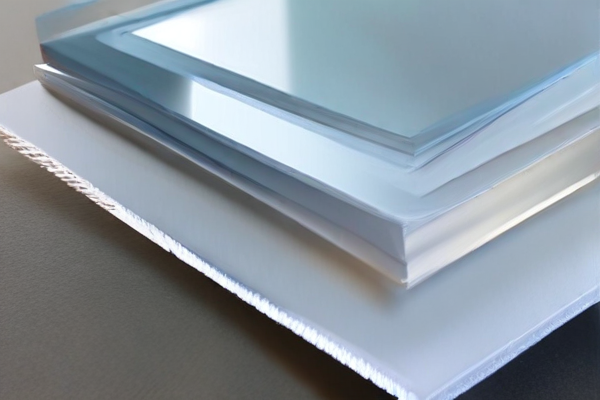

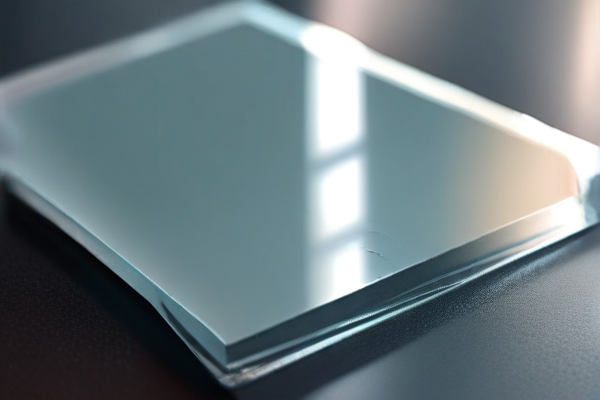

Acrylic sheets for laser cutting offer versatility and come in various types such as cast and extruded. The choice depends on the specific project needs, including transparency, color, thickness, and heat resistance.

– Cast Acrylic Sheets: Higher-quality, minimal melting during cutting, suitable for detailed work.

– Extruded Acrylic Sheets: More affordable, consistent thickness, melts more during cutting, best for simpler designs.

– Transparent: Clear visibility, used in signage, display cases, and protective barriers.

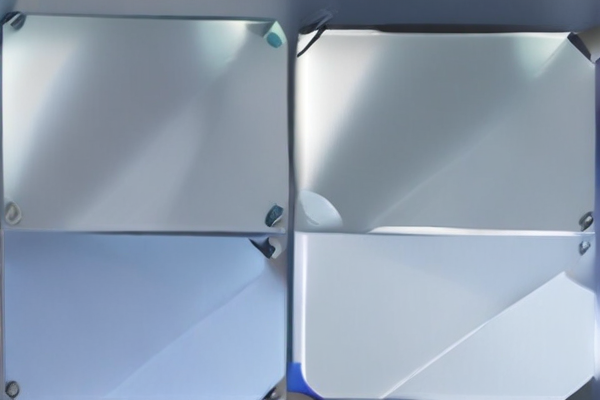

– Colored: Available in numerous hues, ideal for decorative projects.

– Frosted: Matte finish, reducing glare, good for privacy screens and light diffusion.

– Textured: Various patterns for unique visual effects, used in interior design.

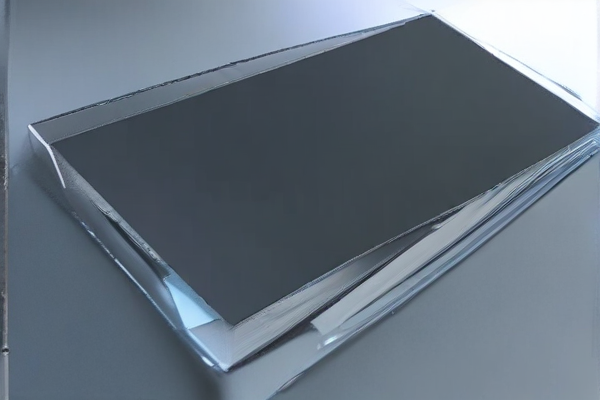

– Mirrored: Reflective surface, often used in decorative items and mirrors.

– UV-Resistant: Withstands prolonged sunlight exposure, perfect for outdoor signage.

– Fluorescent: Vivid, glowing under UV light, ideal for attention-grabbing displays.

– Anti-Static: Reduces static buildup, used in electronics handling.

– Impact-Resistant: Enhanced durability, suitable for high-traffic areas and protective shields.

– Heat-Resistant: Maintains integrity under higher temperatures, useful for high-heat environments.

– Light Diffusing: Specially designed to diffuse light uniformly, perfect for backlit applications.

– Metallic-Finished: Adds a metallic sheen, used for luxury and high-end applications.

Choosing the right acrylic sheet for your laser cutting project involves balancing these properties to meet the intended design, functional requirements, and budget.

Acrylic sheets for laser cutting offer precision, versatility, and durability across various industries. They are ideal for creating intricate designs and high-quality products. Here are several applications:

– Signage: Custom signs for businesses, events, and home decor.

– Model Making: High-detail architectural and engineering models.

– Displays: Retail and trade show displays.

– Art and Crafts: Intricate artistic creations and DIY projects.

– Jewelry: Custom-designed necklaces, bracelets, and earrings.

– Furniture: Unique, modern furniture pieces.

– Trophies and Awards: Personalized awards and recognition items.

– Prototyping: Rapid prototyping of products and parts.

– Home Décor: Custom wall art, coasters, and home fixtures.

– Automotive: Custom car parts and accessories.

– Educational Tools: Teaching aids and hands-on learning tools.

– Lighting Fixtures: Custom light covers and bases.

– Packaging: High-end, custom packaging solutions.

– Medical Devices: Components for medical and dental devices.

– Tech Accessories: Custom phone cases, laptop stands, and electronic enclosures.

These versatile applications make acrylic sheets a preferred material for laser cutting in both commercial and personal projects. By leveraging these capabilities, users can achieve high-quality, custom designs that meet specific needs and preferences.

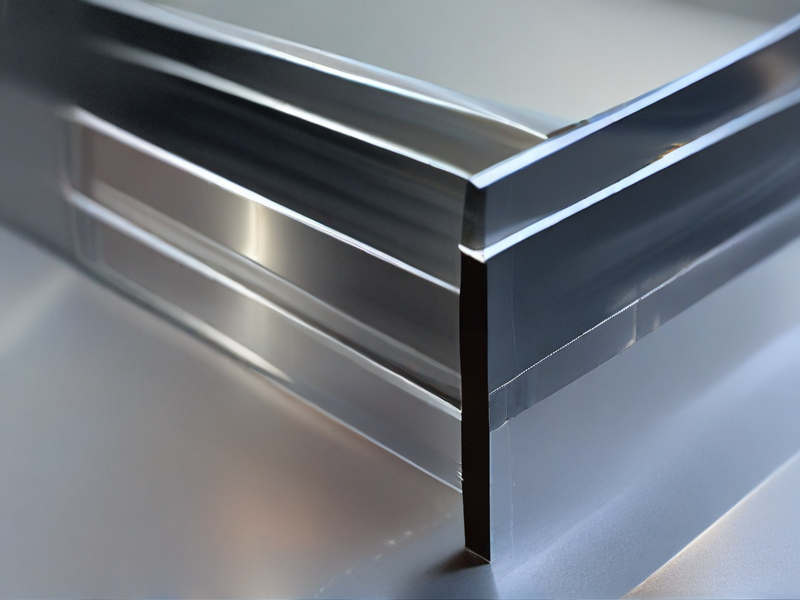

“SourcifyChina” offers precision-engineered acrylic sheets designed specifically for laser cutting applications. These sheets are known for their superb clarity and durability, making them an excellent choice for various industrial and creative projects.

The acrylic sheets from SourcifyChina boast excellent light transmission properties, reaching up to 92%. This high level of transparency makes them ideal for applications requiring visual clarity, such as signage and display cases.

Durability is a key feature of SourcifyChina acrylic sheets. They are resistant to UV rays and weathering, ensuring longevity even when used in outdoor environments. This resilience makes them a reliable material for both indoor and outdoor projects.

In terms of versatility, these acrylic sheets can be easily cut, engraved, and shaped with precision using laser cutting technology. The material’s high flexibility allows for a wide array of intricate designs, making it popular among hobbyists and professionals alike.

SourcifyChina also takes environmental concerns seriously. Their acrylic sheets are eco-friendly and recyclable, contributing to sustainable practices in manufacturing and application. Using eco-friendly materials can be a significant advantage in projects aiming for sustainability.

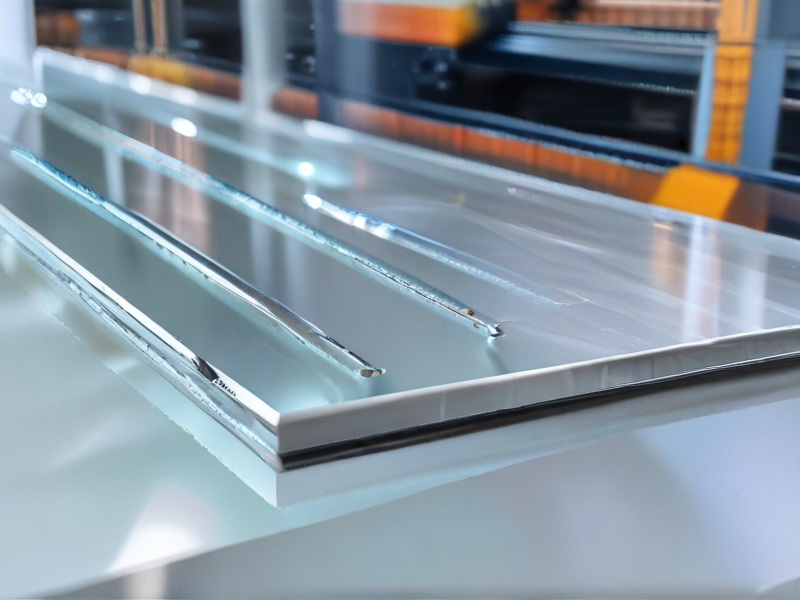

SourcifyChina ensures top-notch quality control throughout the manufacturing process of their acrylic sheets for laser cutting. They start by sourcing raw materials from reputable suppliers to guarantee optimal transparency and durability.

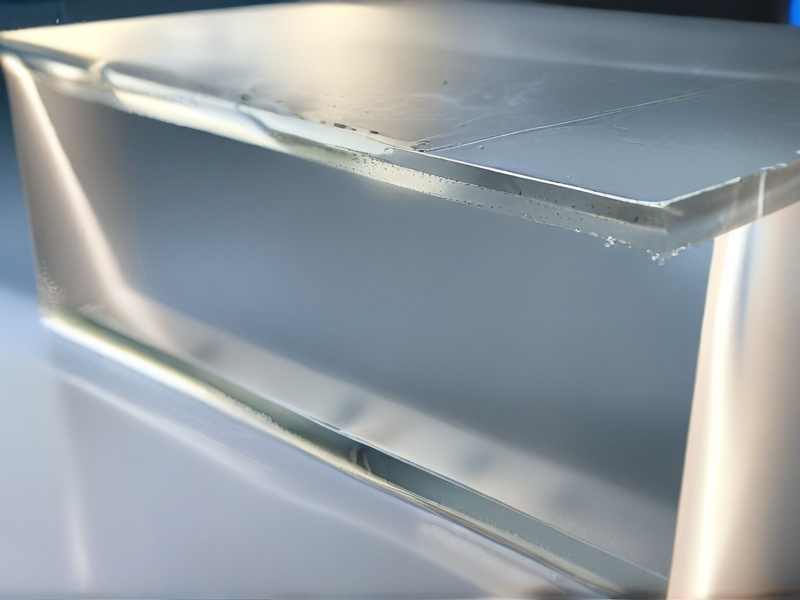

During production, the company employs precision molding techniques to achieve uniform thickness across all acrylic sheets. Regular inspections are performed to detect any imperfections or inconsistencies that could impact the laser cutting process.

Post-production, each acrylic sheet undergoes rigorous testing for clarity, strength, and smoothness. SourcifyChina’s quality control team uses advanced equipment to measure and verify every aspect of the sheet’s specifications.

Additionally, the company implements strict environmental controls within the manufacturing facility to minimize contamination. This ensures that each acrylic sheet is free from dust and other particles that might affect quality.

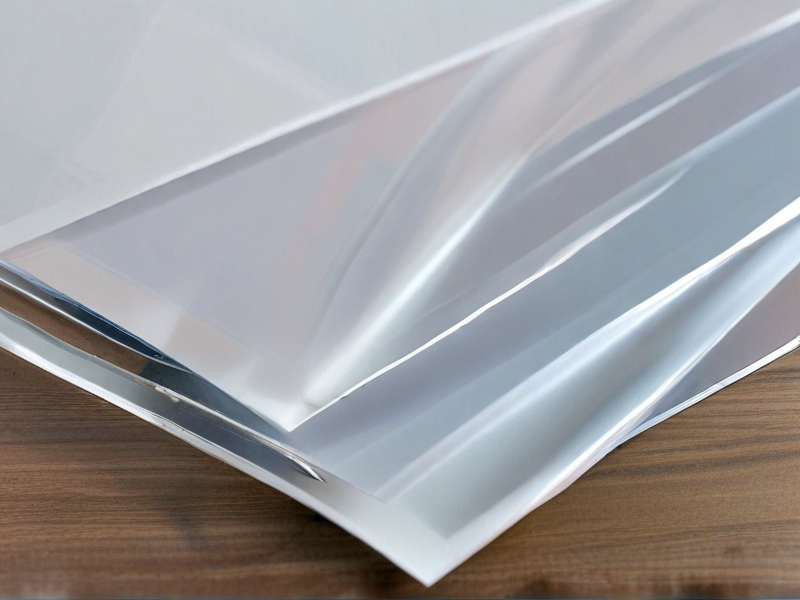

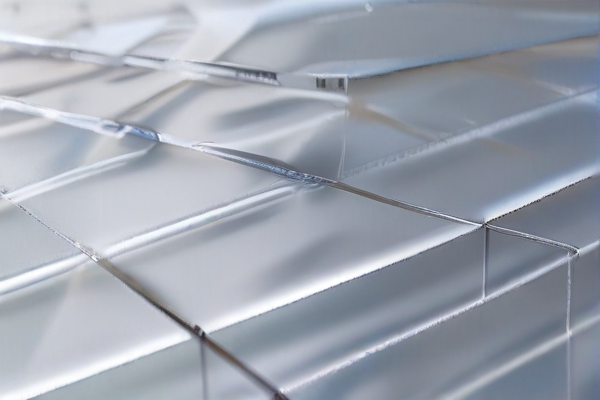

Finally, SourcifyChina packages the acrylic sheets with protective materials to prevent damage during shipping. Each package is labeled with detailed information for easy identification and traceability, ensuring buyers receive products that meet their high standards.

SourcifyChina offers high-quality acrylic sheets ideal for laser cutting. These sheets provide precise cuts and intricate designs, making them suitable for various applications. They are available in multiple thicknesses and colors to meet diverse project needs.

The acrylic sheets are known for their clarity and strength, ensuring durability and an appealing finish. They maintain sharp edges without cracking or chipping, vital for both functional and decorative projects. With their excellent optical properties, they are perfect for signage, displays, and more.

SourcifyChina’s acrylic sheets are also highly customizable. Customers can order sheets tailored to specific dimensions and requirements. This flexibility streamlines the production process, reducing waste and maximizing efficiency.

Beyond aesthetics and functionality, these acrylic sheets offer easy maintenance and longevity. They resist UV rays and weathering, ensuring the finished products remain vibrant and intact over time.

In summary, SourcifyChina’s acrylic sheets for laser cutting stand out for their precision, durability, and customization options. These features make them an excellent choice for a wide range of applications, from commercial to artistic endeavors.

Acrylic sheets are highly favored in laser cutting due to their versatility, precision, and excellent optical properties, making them ideal for various applications.

Benefits of Acrylic Sheets for Laser Cutting:

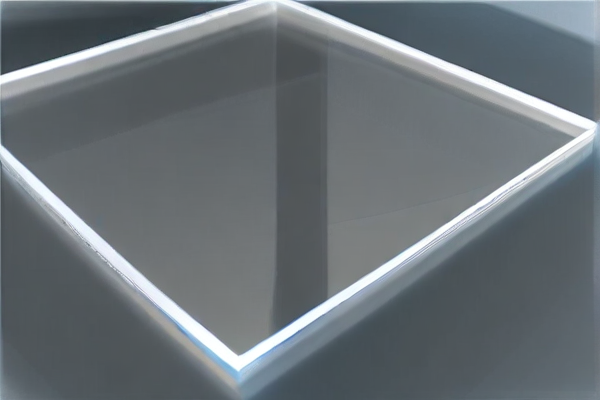

– Precision: Acrylic allows for incredibly detailed and intricate designs due to its uniform thickness and quality.

– Smooth Edges: Laser cutting results in polished, clean edges, reducing the need for additional finishing.

– Variety of Colors and Finishes: Available in numerous colors and finishes, acrylic sheets can cater to diverse aesthetic requirements.

– Durability: Acrylic is highly durable and impact-resistant, ensuring long-lasting end products.

– Lightweight: Despite its strength, acrylic is lightweight, making it easier to handle and transport.

– Weather Resistant: Acrylic’s resistance to weathering makes it suitable for both indoor and outdoor projects.

– Cost-Effective: The material is reasonably priced, offering a cost-efficient solution for many projects.

– Thermoplastic Properties: Acrylic can be heated and reshaped, providing flexibility in design and application.

– Recyclable: Acrylic is recyclable, aiding in sustainability and reducing environmental impact.

– Clarity and Transparency: High clarity and transparency levels make acrylic ideal for optical applications and display cases.

– Ease of Fabrication: Acrylic is easy to cut, drill, and polish, enhancing its utility in various industries.

– Minimal Wastage: Efficient laser cutting minimizes material wastage, contributing to cost-effectiveness and sustainability.

– Non-toxic fumes: When laser cut, acrylic releases minimal, non-toxic fumes—safer for users and the environment.

– Consistent Quality: Premium-grade acrylic sheets ensure consistent quality and performance in finished products.

In conclusion, the diverse benefits of acrylic sheets make them a preferred material for laser cutting in multiple industries, providing an optimal balance of aesthetics, functionality, and cost-efficiency.

Acrylic sheets, known for their versatility and durability, are a popular choice for laser cutting projects. They offer clear, clean edges and a high-quality finish.

– Transparency: Available in clear or colored options; maintains high optical clarity.

– Thickness Range: Various thicknesses to cater to different project needs, typically from 1mm to 20mm.

– Durability: Strong and impact-resistant, less prone to cracking compared to glass.

– Lightweight: Easier to handle and manipulate, reducing wear on equipment.

– Consistency: Uniform material quality ensures predictable cutting results.

– Versatility: Suitable for intricate designs and complex shapes due to precision cuts.

– Ease of Use: Requires minimal post-processing, producing smooth, polished edges.

– Cost-effective: Often more affordable than glass or polycarbonate alternatives.

– Compatibility: Works well with various adhesives and finishes for diverse applications.

– Environmentally Friendly: Can be recycled, reducing waste.

Acrylic sheets are an excellent choice for both professionals and hobbyists, providing a balance of aesthetics and practicality in laser cutting tasks.

SourcifyChina offers premium acrylic sheets for laser cutting, ideal for both custom products and innovative projects. Their high-quality material ensures crisp, clean cuts, enhancing your creativity and project outcomes.

These acrylic sheets are available in multiple colors, thicknesses, and finishes to suit various needs. Customization options allow you to create unique, tailored designs that stand out. SourcifyChina empowers project makers with its rich variety, perfect for professional and hobbyist endeavors alike.

Durability and ease of use are key features of SourcifyChina acrylic sheets. They provide a robust, stable foundation for intricate work, making them an essential tool for creators. Their laser-cutting capability ensures precision, allowing detailed and intricate designs to come to life effortlessly.

Customer satisfaction is a top priority for SourcifyChina. They offer timely delivery and excellent support, ensuring your creative process is smooth and hassle-free. With their comprehensive catalog, you can find the perfect acrylic sheet to complement your project.

Choosing SourcifyChina means investing in quality and reliability. Their acrylic sheets are designed to meet the highest standards, providing a professional finish every time. Whether you’re working on signage, art, or functional prototypes, SourcifyChina acrylic sheets make your vision a reality.

SourcifyChina stands out as a reputable supplier of high-quality acrylic sheets specifically tailored for laser cutting applications. An industry leader, the company prides itself on delivering precision-engineered acrylic products that cater to a wide range of creative and industrial needs. Understanding the nuances of laser cutting, SourcifyChina offers acrylic sheets that boast exceptional clarity, durability, and ease of use. Their products are engineered to produce clean, crisp edges and intricate details, which makes them a favorite among designers, manufacturers, and hobbyists. Committed to sustainability and innovation, the company invests in advanced manufacturing processes to reduce waste and improve efficiency. Furthermore, SourcifyChina emphasizes customer satisfaction with a robust support system and an extensive range of customizable options, enabling clients to specify dimensions, thicknesses, and colors to meet their specific project requirements. By combining high-quality materials with impeccable service, SourcifyChina has solidified its reputation as a go-to source for premium acrylic sheets in the laser cutting industry.

Acrylic sheets for laser cutting have become indispensable in the aerospace, defense, and marine industries due to their versatility, durability, and precision. In aerospace applications, acrylic sheets are utilized to create lightweight, yet strong components for aircraft interiors, such as windows, skylights, and paneling. The clarity of acrylic ensures a high level of visibility and light transmission, which is crucial for cockpit windows and cabin interiors. Laser cutting allows for the precision needed to create complex geometries and tight tolerances, which are essential in aerospace engineering to ensure both safety and performance. Additionally, acrylic’s resistance to UV rays and impact makes it an ideal material for exterior components that must withstand harsh environmental conditions encountered at high altitudes.

In the defense sector, the combination of acrylic sheets and laser cutting technology is employed to produce a variety of components, including protective barriers, visors, and instrumentation housings. The ability to cut intricate designs with laser precision ensures that each component fits perfectly within the complex assemblies typical of military equipment. This precision helps in maintaining the integrity of sensitive equipment and enables rapid prototyping and deployment of new technologies. In marine applications, the robustness and resistance to saltwater corrosion make acrylic sheets an excellent choice for fabricating windows, hatches, and instrument covers on both civilian and military vessels. The adaptability of acrylic to laser cutting means custom parts can be quickly produced to meet specific marine requirements, enhancing both functionality and aesthetics. Overall, the use of laser-cut acrylic sheets proves to be a crucial advantage in these high-demand fields, offering tailored solutions that meet stringent performance and safety standards.

Acrylic sheets have become increasingly popular in automotive applications, particularly for their compatibility with precision laser cutting technology. These sheets are used to create various interior and exterior components such as custom dashboards, instrument panels, and lighting fixtures. The lightweight and durable nature of acrylic makes it an ideal material for automotive parts that require intricate designs and high resistance to wear and tear. Laser cutting allows for accurate, clean cuts and the ability to replicate complex patterns with consistent reliability, reducing material waste and production time. Additionally, the optical clarity of acrylic sheets ensures that any transparent or translucent components, such as light covers or display panels, maintain a pristine and appealing appearance, enhancing both functionality and aesthetics.

In the realm of electronics, acrylic sheets are widely utilized for creating enclosures, displays, and decorative elements, taking full advantage of their compatibility with laser cutting tools. Enclosures made from laser-cut acrylic can house delicate electronic circuits and components, offering both protection and an aesthetically pleasing transparent view. For consumer electronics, precise laser cutting allows manufacturers to produce intricate designs and detailed patterns that may be difficult or impossible to achieve with other materials. Acrylic’s excellent insulating properties and resistance to electrical discharge make it suitable for safeguarding electronic components. Furthermore, custom keypads, touchscreen protectors, and LED displays are just some examples of how laser-cut acrylic sheets can enhance the functionality and visual appeal of modern electronic devices. The precision of laser cutting ensures that these components fit perfectly within electronic devices, boosting overall performance and user experience.

Acrylic sheets are increasingly favored in the construction industry due to their versatility and efficiency, especially when processed with laser cutting technology. Laser cutting enables precision shaping of acrylic sheets, which contributes to cleaner, more accurate cuts, reducing waste material and labor costs. The high transparency and aesthetic appeal of acrylic make it ideal for architectural features like windows, skylights, and partitions. Its durability and resistance to UV light and weather elements ensure that acrylic structures maintain their appearance and functionality over time. Moreover, laser-cut acrylic can be customized to include intricate designs and patterns, enabling it to serve both functional and decorative purposes in modern construction projects.

In the realm of energy applications, acrylic sheets processed by laser cutting play a pivotal role, particularly in the manufacturing of solar panels and light guides. The superior light transmission properties of acrylic make it an excellent material for enhancing the efficiency of photovoltaic cells. Laser cutting allows for precise fabrication of acrylic components, ensuring optimal alignment and minimal material loss. This precision contributes to the production of lightweight and durable solar panels, which are key to improving energy capture and efficiency. Additionally, laser-cut acrylic sheets are used in the creation of optical light guides for LED lighting systems, which are integral to energy-efficient lighting solutions. Acrylic’s ability to diffuse light evenly improves the performance and longevity of these systems, underscoring its importance in advancing sustainable energy technologies.

The industrial equipment sector significantly benefits from incorporating acrylic sheets for laser cutting due to the material’s versatility and efficiency. Acrylic sheets are highly favored in this industry because they provide excellent clarity, ease of fabrication, and resistance to weathering. These characteristics make them ideal for creating a variety of components such as machine guards, control panels, and display cases. When processed with laser cutting technology, acrylic sheets can be cut with high precision and smooth edges, reducing the need for post-processing work. Moreover, laser cutting allows for intricate designs and complex geometries to be achieved with minimal material wastage, optimizing cost-efficiency and resource management within industrial operations.

Furthermore, acrylic sheets offer significant durability and strength-to-weight ratio advantages. They are substantially lighter than glass yet possess a comparable transparency, making them excellent for safety shields and enclosures in industrial environments. The ability to laser cut acrylic sheets swiftly and accurately also leads to quicker turnaround times in manufacturing processes, enhancing overall productivity. This can be particularly beneficial in applications where custom parts or rapid prototyping are required to meet specific industrial needs. Additionally, acrylic’s resistance to UV light and chemicals ensures longevity and reliability of the parts, which can be crucial in demanding industrial settings. As industries increasingly seek materials that combine functionality with efficiency, acrylic sheets for laser cutting continue to stand out as a highly effective solution.

Acrylic sheets used in laser cutting have found significant application in the medical devices industry due to their precision, versatility, and clarity. These sheets, often made from polymethyl methacrylate (PMMA), offer excellent optical clarity, which is crucial in many medical applications where visibility is paramount. During laser cutting, the acrylic sheets can be precisely and intricately shaped, making them ideal for creating customized components like diagnostic tools, enclosures for delicate medical equipment, and various protective covers. The non-reactive nature of acrylic ensures that it does not interfere with the sensitive functions of medical devices, a critical attribute in maintaining the reliability and accuracy of medical diagnostics and treatment processes.

Furthermore, the durability and ease of sterilization of laser-cut acrylic sheets make them suitable for use in healthcare environments where hygene is of utmost importance. Acrylic’s resistance to breaking and shattering reduces the risk of contamination and injury, making it a safer alternative to glass in many applications. Laser cutting technology ensures that the edges of the acrylic components are smooth and free from burrs, reducing the potential for microbial growth. Additionally, the ability to produce complex and precise shapes with laser cutting facilitates the development of innovative medical devices and tools that can offer enhanced functionalities and improved patient outcomes. Overall, the use of acrylic sheets in laser cutting presents a valuable combination of safety, precision, and reliability essential for the medical devices industry.

Acrylic sheets have gained widespread acclaim in machining and manufacturing industries for their exceptional qualities when used in laser cutting processes. This application leverages the material’s excellent optical clarity, lightweight nature, and thermal stability. When subjected to laser cutting, acrylic sheets produce smooth, polished edges without the need for additional finishing steps, making the process highly efficient and cost-effective. The precision of laser cutting allows for intricate designs and detailed cuts, enabling manufacturers to produce complex parts and components with high accuracy. Additionally, acrylic’s uniform composition ensures consistent cutting performance, reducing waste and enhancing overall production quality.

In manufacturing, the versatility of acrylic sheets extends to various industries, including automotive, aerospace, signage, and consumer products. The ability to customize and fabricate intricate designs swiftly is particularly beneficial for prototyping and short-run productions. In the signage industry, for example, acrylic sheets are frequently used to create eye-catching displays and lit signs due to their excellent light transmission properties. Moreover, the lightweight and durable nature of acrylic makes it a preferred choice for components that require both strength and aesthetic appeal. In consumer products, laser-cut acrylic can be used for anything from protective covers to decorative items, highlighting the material’s adaptability and broad applicability. Overall, acrylic sheets for laser cutting offer a perfect blend of precision, efficiency, and versatility, meeting the diverse needs of modern manufacturing applications.

Sure, here are a few frequently asked questions (FAQ) with their respective answers for manufacturing acrylic sheets for laser cutting quality work from the SourcifyChina factory:

1. What types of acrylic sheets do you manufacture?

We manufacture a wide range of acrylic sheets including cast acrylic, extruded acrylic, frosted acrylic, colored acrylic, and mirrored acrylic sheets. These are available in various thicknesses and dimensions to suit your laser cutting requirements.

2. Are your acrylic sheets suitable for laser cutting?

Yes, our acrylic sheets are specifically designed for laser cutting. They have excellent clarity, strength, and are easy to cut, ensuring high-quality, clean edges suitable for precision work.

3. What is the maximum sheet size you can produce?

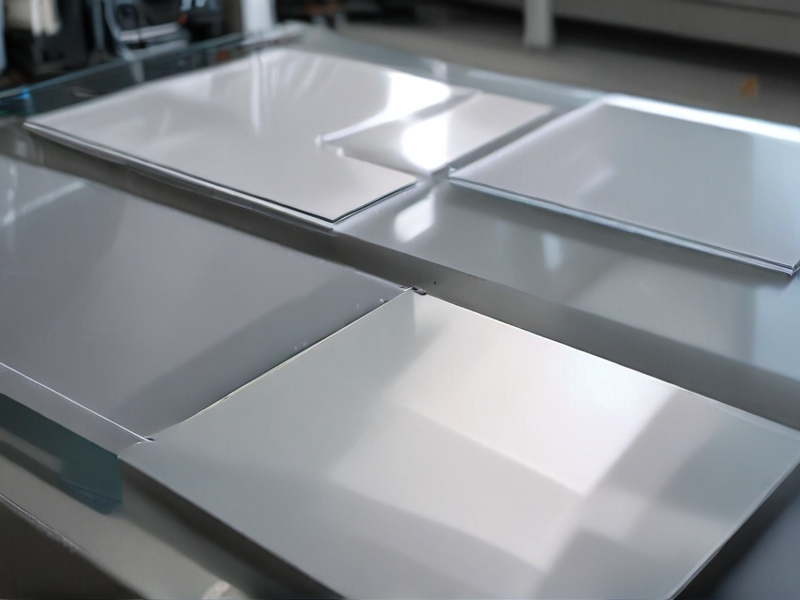

We can produce acrylic sheets up to a size of 1220mm by 2440mm. Custom sizes are also available on request to match your specific requirements.

4. Do you offer custom colors and finishes?

Yes, we offer custom colors and finishes to meet your specific needs. Our team can match any color and finish based on your samples or requirements, ensuring consistency and quality.

5. How do you ensure the quality of your acrylic sheets?

At SourcifyChina, we follow strict quality control protocols. Each sheet undergoes rigorous testing for optical clarity, strength, and thickness uniformity. We also perform random inspections to ensure consistency and adherence to specifications.

6. What is your production lead time?

Our standard production lead time ranges from 15 to 30 days, depending on the order size and customization requirements. We strive to meet urgent deadlines upon request.

7. Can you provide samples before placing a bulk order?

Yes, we offer samples for evaluation before you place a bulk order. This ensures that our products meet your quality and specification requirements.

8. What are your payment terms?

Our payment terms are typically 30% deposit with the balance payable before shipment. We accept multiple payment methods including T/T, L/C, and PayPal.

9. Do you provide shipping and logistics support?

Yes, we offer comprehensive shipping and logistics support. We can handle everything from packaging to delivery, ensuring your acrylic sheets arrive safely and on time.

10. How can I place an order or get a quote?

You can place an order or request a quote by contacting us through our website, email, or phone. Our customer service team is ready to assist you with any inquiries or orders.

When considering “acrylic sheets for laser cutting manufacturing” from the SourcifyChina factory, several key tips can help you optimize your purchasing and production processes.

1. Material Quality: Ensure the acrylic sheets meet high standards for clarity and durability. SourcifyChina offers various grades; select one best suited for your application to avoid issues like cracking or discoloration during cutting.

2. Thickness Consistency: Laser cutting requires precise material thickness for accurate cuts. Verify that SourcifyChina’s sheets maintain consistent thickness to ensure uniform results and reduce wastage.

3. Sheet Size: Choose the correct sheet size for your laser cutter bed to minimize material handling. SourcifyChina provides custom dimensions, which can help streamline your workflow.

4. Protective Coating: Ask if the sheets come with a protective film to prevent scratches and dust accumulation during transport and handling. This ensures the finished product has a professional appearance.

5. Edge Quality: High-quality acrylic sheets tend to produce cleaner edges when cut. SourcifyChina’s products are known for minimizing post-cutting finishing work.

6. Cost Efficiency: While SourcifyChina offers competitive pricing, bulk orders typically attract further discounts. Calculate your needs ahead of time to take advantage of volume purchasing.

7. Lead Time: Confirm lead times with SourcifyChina to ensure timely delivery that aligns with your production schedule. Delays can disrupt your manufacturing timeline and customer satisfaction.

8. Customization Options: SourcifyChina often offers additional services such as pre-cutting or custom finishes. Utilizing these can simplify your process and reduce on-site labor.

9. Shipping and Handling: Evaluate shipping options to mitigate potential damage during transit. Proper packaging can preserve the quality of the acrylic sheets upon arrival.

10. Technical Support: Establish communication with SourcifyChina for support on material selection and cutting parameters to maximize efficiency and product quality.

By carefully considering these aspects, you can enhance your manufacturing process using acrylic sheets from SourcifyChina, ensuring high-quality output and efficiency.

Q: What types of acrylic sheets does SourcifyChina factory offer for laser cutting?

A: SourcifyChina factory provides a variety of acrylic sheets, including clear, colored, and frosted options. They also have cast and extruded acrylic sheets, which are ideal for precise laser cutting projects.

Q: What is the minimum order quantity (MOQ) for acrylic sheets?

A: The MOQ for acrylic sheets typically varies based on the size, thickness, and type of acrylic. SourcifyChina factory generally requires a minimum order quantity to ensure cost-effective production, but this can be discussed and negotiated.

Q: Can I get custom-sized acrylic sheets from SourcifyChina?

A: Yes, SourcifyChina factory offers custom-sized acrylic sheets tailored to your specific requirements. You need to provide the exact dimensions, and they will cut the sheets accordingly.

Q: What thickness options are available for the acrylic sheets?

A: SourcifyChina offers a wide range of thickness options for acrylic sheets, typically ranging from 1mm to 20mm. The desired thickness can be chosen based on your project needs.

Q: Does SourcifyChina factory provide samples before bulk orders?

A: Yes, SourcifyChina factory can provide samples of acrylic sheets to ensure they meet your specifications before placing a bulk order. This helps verify the quality and suitability of the material for your project.

Q: How is the quality of acrylic sheets ensured by SourcifyChina?

A: SourcifyChina factory maintains strict quality control measures throughout the manufacturing process. They utilize high-quality raw materials and advanced machinery to produce durable and high-clarity acrylic sheets.

Q: What are the payment terms for ordering acrylic sheets?

A: The factory offers flexible payment terms, including T/T (telegraphic transfer), L/C (letter of credit), and other common methods. Specific terms can be negotiated based on the order volume and customer requirements.

Q: How does SourcifyChina factory handle shipping and delivery?

A: SourcifyChina factory provides reliable shipping options, including air and sea freight. They work with trusted logistics partners to ensure timely and safe delivery of the acrylic sheets to your location.

Q: Is there any after-sales support available?

1. Research and Verification:

– Company Background: Visit the SourcifyChina factory’s official website to gather information about their product offerings and company credentials. Ensure they have a good reputation for quality and reliability.

– Reviews and Testimonials: Look for reviews or testimonials from other businesses that have sourced acrylic sheets from SourcifyChina.

2. Define Specifications:

– Material Specifications: Clearly define the acrylic sheet thickness, dimensions, colors, and any other specific requirements you need for laser cutting.

– Quality Standards: Specify the quality standards you expect (e.g., scratch resistance, clarity, UV resistance).

3. Requesting Quotes:

– Detailed Inquiry: Submit a detailed request for a quote to SourcifyChina including your specifications, order quantity, and delivery timelines.

– Sample Request: Ask for samples to assess the quality before placing a large order.

4. Negotiation and Terms:

– Pricing: Negotiate the pricing based on volume, and inquire about any bulk discounts.

– Delivery Terms: Clarify delivery timelines and shipping costs. Make sure the shipping method can handle the delicate nature of acrylic sheets.

5. Quality Assurance:

– Certifications: Ensure the factory holds certifications such as ISO for quality assurance.

– Inspection: Arrange for pre-shipment inspections to verify the product quality matches your requirements.

6. Legal and Payment Security:

– Contracts: Draft a contract that outlines all terms and conditions clearly to protect your interests.

– Payment Terms: Discuss secure payment methods, and consider using an escrow service for the initial transactions to build trust.

Using these tips, you can effectively source high-quality acrylic sheets for laser cutting from SourcifyChina factory, ensuring reliability and satisfaction.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.