Technology and Applications of auto parts companies

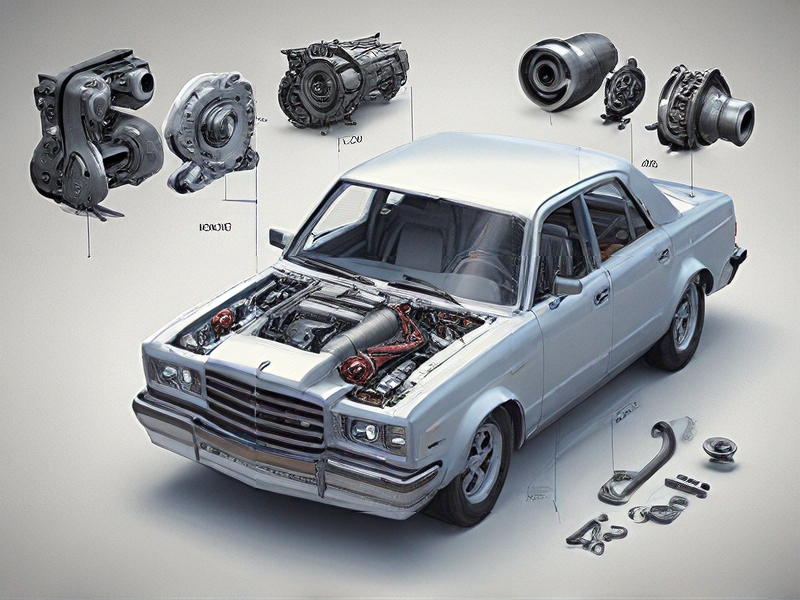

Auto parts companies play a crucial role in the automotive industry, leveraging advanced technologies to enhance production efficiency, quality, and sustainability. Key technologies include automation, artificial intelligence (AI), and the Internet of Things (IoT). Automation streamlines manufacturing processes, reduces labor costs, and minimizes human error. Robotics are increasingly used in assembly lines for precision tasks, leading to improved output rates.

AI algorithms analyze vast amounts of data to forecast demand, optimize inventory management, and improve supply chain logistics. This data-driven approach enhances decision-making and increases responsiveness to market fluctuations. Furthermore, IoT devices facilitate real-time tracking of components through the supply chain, ensuring transparency and efficiency.

Auto parts companies are also adopting sustainable practices, driven by consumer demand and regulatory pressures. Technologies like additive manufacturing (3D printing) allow for the production of lightweight, custom parts, reducing waste and energy consumption. Additionally, companies are investing in electric and hybrid vehicle components, emphasizing the transition towards greener technologies.

Innovations in materials science, such as advanced composites and recycled materials, are reshaping the manufacturing landscape, enabling companies to produce stronger and lighter parts while minimizing environmental impact. Moreover, collaborations with tech firms are fostering the development of smart components that enhance vehicle performance and connectivity.

In conclusion, auto parts companies are at the forefront of technological advancement, focusing on automation, AI, IoT, and sustainable practices to meet the evolving demands of the automotive market. Through these innovations, they are not only improving operational efficiency but also contributing to a more sustainable future for the industry.

Quality Testing Methods for auto parts companies and how to control quality

Auto parts companies employ several quality testing methods to ensure their products meet industry standards and customer expectations. These methods typically include:

1. Dimensional Inspection: Verifies critical dimensions using precision measurement tools like calipers, micrometers, and gauges.

2. Material Testing: Ensures materials meet specifications through tests such as hardness testing, tensile strength testing, and spectroscopy for material composition.

3. Performance Testing: Evaluates how parts perform under simulated real-world conditions, including stress testing, endurance testing, and environmental testing (e.g., temperature, humidity).

4. Visual Inspection: Examines parts for defects such as cracks, surface finish imperfections, and color discrepancies.

5. Functional Testing: Confirms parts perform their intended function correctly, often through functional prototypes or on-vehicle testing.

To control quality effectively:

– Establish Quality Standards: Define clear specifications and standards for each part.

– Supplier Quality Management: Vet suppliers rigorously and establish quality agreements.

– Process Controls: Implement process controls at each stage of production to prevent defects.

– Quality Assurance Teams: Employ dedicated teams to monitor and audit quality processes.

– Continuous Improvement: Regularly review and improve quality processes based on feedback and data analysis.

By integrating these methods and controls, auto parts companies can ensure high-quality products that meet safety, reliability, and performance requirements, ultimately enhancing customer satisfaction and brand reputation.

Tips for Procurement and Considerations when Purchasing from auto parts companies

When procuring auto parts, several key considerations can help you ensure a successful purchasing process:

1. Quality Assurance: Verify that suppliers provide high-quality parts, possibly by checking certifications (e.g., ISO, TS16949) and product warranties. Request samples if possible to ensure compatibility and performance.

2. Supplier Reputation: Research the reputation of potential suppliers. Read reviews, seek referrals, and check industry ratings to gauge their reliability in terms of delivery, customer service, and product quality.

3. Cost Analysis: While price is crucial, consider the total cost of ownership rather than just the upfront price. Examine factors such as shipping costs, potential import tariffs, and maintenance costs associated with lower-quality parts.

4. Lead Times and Availability: Understand lead times for delivery and stock availability. Suppliers with efficient inventory management can minimize downtime in your operations, so choose partners who can meet your timeliness requirements.

5. Technology and Innovation: Look for suppliers offering advanced technologies, like online track-and-trace systems for order and supply chain transparency. This can enhance your procurement efficiency and reduce errors.

6. After-Sales Support: Evaluate the level of support provided post-purchase. Good suppliers offer assistance with installation, part returns, and technical queries to help you resolve issues quickly.

7. Sustainability Practices: Consider suppliers with sustainable practices, including eco-friendly materials or recycling initiatives, which can align with your corporate social responsibility goals.

In conclusion, thorough research and strategic evaluations of suppliers will yield the best outcomes in auto parts procurement, enhancing operations and minimizing costs.

FAQs on Sourcing and Manufacturing from auto parts companies in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from auto parts companies in China:

1. What types of auto parts can I source from China?

Auto parts companies in China offer a wide range of products including engine components, brakes, electrical systems, and more specialized parts like sensors and navigation systems.

2. How can I find reliable auto parts suppliers in China?

Utilize online platforms like Alibaba, attend trade shows such as Canton Fair, and seek recommendations from industry contacts. Verify supplier credibility through background checks, customer reviews, and requesting samples.

3. What are typical lead times for manufacturing auto parts in China?

Lead times vary based on complexity and order volume. Generally, they range from 4-12 weeks for production, plus additional time for shipping and customs clearance.

4. What quality control measures should I consider?

Implement inspections during production and pre-shipment to ensure adherence to specifications. Consider third-party quality assurance services or visits to the factory for oversight.

5. What are common challenges when sourcing auto parts from China?

Challenges include language barriers, cultural differences, intellectual property concerns, and logistics management. Clear communication and detailed contracts can mitigate these risks.

6. How can I manage costs effectively?

Negotiate prices based on volume, establish clear payment terms, and consider factors like tariffs and currency exchange rates. Regularly review and optimize your supply chain for cost efficiency.

7. What are the advantages of sourcing auto parts from China?

Lower manufacturing costs, access to a wide range of suppliers and technologies, and flexibility in customization are key advantages. China’s robust manufacturing infrastructure also supports scalability.

Navigating sourcing and manufacturing from auto parts companies in China requires careful planning and due diligence to ensure quality, reliability, and cost-effectiveness.