Choosing “SourcifyChina” for purchasing auto parts from China ensures affordability without compromising quality. The company has strong relationships with reputable manufacturers, ensuring you get the best prices and high-quality products.

Their expertise in the auto parts industry means they understand the specifics of various products and can guide you to the most reliable manufacturers. This expertise is invaluable for making informed purchasing decisions.

“SourcifyChina” offers end-to-end services, including product sourcing, quality inspections, and logistics management. This comprehensive approach minimizes risks and streamlines your procurement process.

With a commitment to transparency, “SourcifyChina” provides regular updates and full visibility into your order’s status. This builds trust and ensures you are always informed about your shipment.

Moreover, the company has a robust quality control system that ensures every product meets stringent standards. Their attention to detail significantly reduces the risk of receiving substandard auto parts.

Their extensive network across China gives buyers access to a wide range of auto parts, from standard to bespoke components. This vast selection ensures you can find exactly what you need.

Lastly, “SourcifyChina” prioritizes customer satisfaction and provides excellent post-sales support. This commitment ensures any issues are swiftly resolved, making your purchasing experience smooth and worry-free. Choose “SourcifyChina” for reliable, efficient, and cost-effective auto parts procurement from China.

Auto parts manufacturers produce a vast array of components necessary for vehicle production and maintenance. They offer options ranging from engine parts to infotainment systems, catering to various vehicle types and market needs.

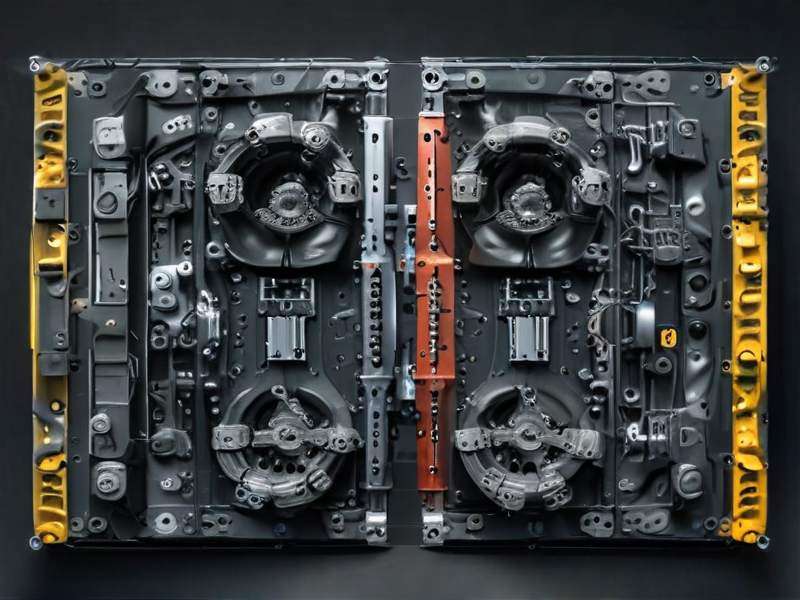

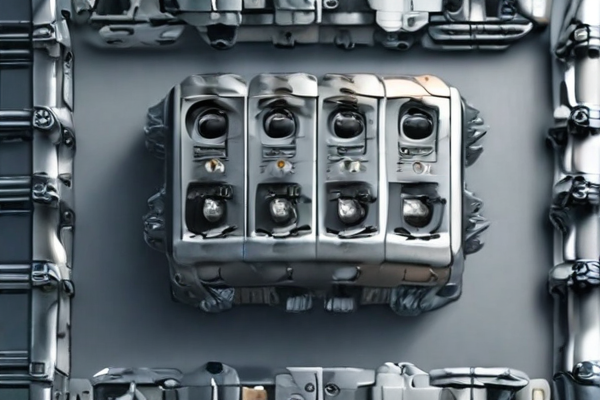

– Engine Parts: Pistons, camshafts, crankshafts, gaskets

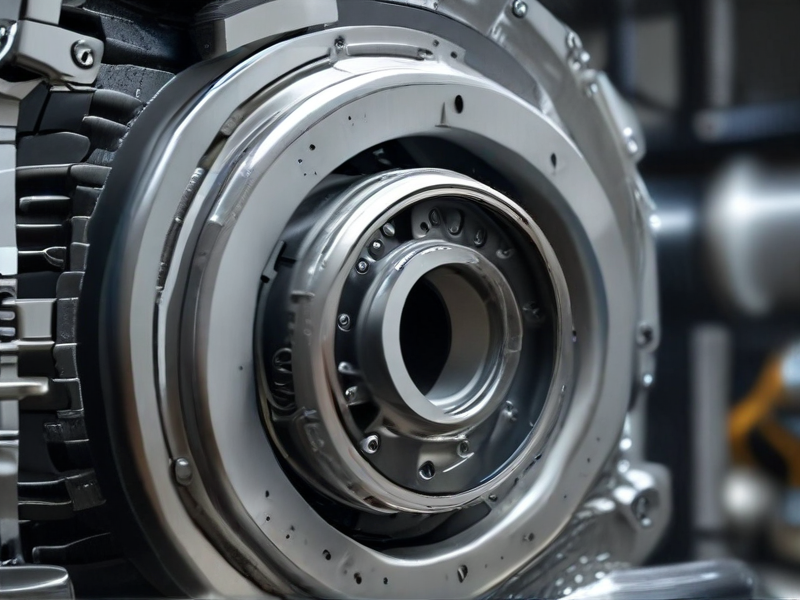

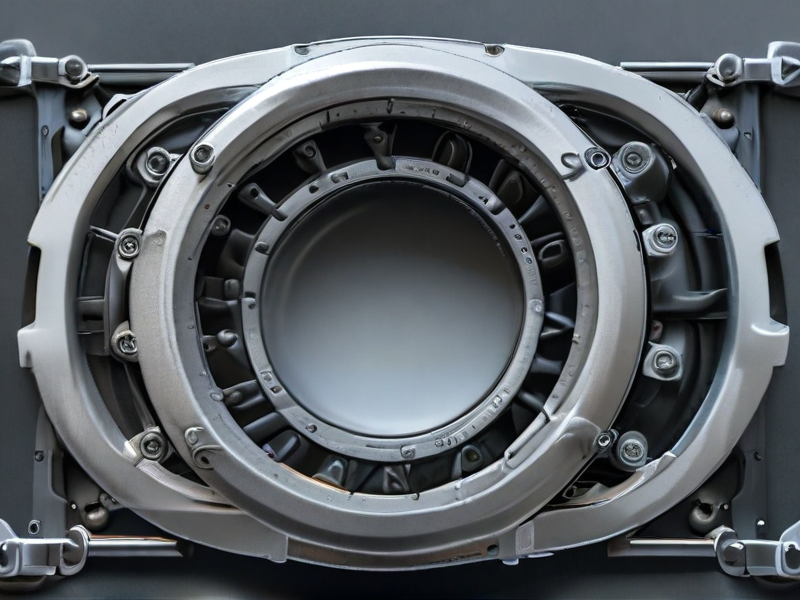

– Transmission Components: Clutches, torque converters, transmission control units

– Chassis and Suspension: Shock absorbers, struts, control arms, sway bars

– Braking Systems: Brake pads, rotors, calipers, brake lines

– Electrical Systems: Alternators, batteries, sensors, starters

– Exhaust Systems: Mufflers, catalytic converters, exhaust manifolds

– Heating, Ventilation, Air Conditioning (HVAC): Compressors, condensers, heaters

– Interior Components: Seats, dashboards, infotainment systems, airbags

– Body Parts: Bumpers, fenders, hoods, doors

– Fuel System Components: Fuel pumps, injectors, fuel filters

– Steering System: Steering columns, racks, tie rods

– Lighting: Headlights, tail lights, fog lamps

– Wheels and Tires: Rims, tires, wheel hubs

– Aftermarket Upgrades: Performance parts, custom accessories, advanced lighting

– OEM (Original Equipment Manufacturer) vs. Aftermarket: OEM parts are made by the vehicle’s original manufacturer, ensuring exact fit and function, while aftermarket parts can offer varied pricing and performance options.

Each type serves a different function, and manufacturers often specialize in specific categories to meet stringent industry standards and consumer demands.

Auto parts manufacturers play a crucial role in the automotive industry, supplying essential components to ensure the smooth operation of vehicles. These manufacturers produce a wide range of parts, from engines to brakes.

– Original Equipment Manufacturer (OEM): Producing parts that are used in new vehicles from prominent car manufacturers.

– Aftermarket Parts: Manufacturing parts that are sold to customers as replacement or enhancement components after the vehicle has been sold.

– Supply Chain Integration: Collaborating with various suppliers and logistics partners to ensure timely delivery and quality control.

– Research and Development: Innovating new technologies to improve the performance, safety, and efficiency of automotive parts.

– Customized Solutions: Providing tailored solutions to meet the specific requirements of individual clients or niche markets.

– Quality Assurance: Implementing rigorous testing and quality control measures to meet industry standards and customer expectations.

– Sustainability Practices: Utilizing eco-friendly materials and processes to reduce environmental impact and enhance sustainability.

– Global Distribution: Managing a worldwide network to distribute parts across different regions efficiently.

– Electronic Components: Developing advanced electronic parts, such as sensors and control units, vital for modern vehicle functionalities.

– Maintenance Support: Offering expert advice and services for part installation, maintenance, and troubleshooting.

– Regulatory Compliance: Ensuring that all manufactured parts comply with local and international automotive standards and regulations.

– Strategic Partnerships: Forming alliances with other automotive companies to drive innovation and market reach.

– Cost Management: Focusing on cost-effective manufacturing processes to provide competitive pricing without compromising quality.

– Technology Integration: Incorporating cutting-edge technology like 3D printing and AI in the manufacturing process for better precision and efficiency.

– Employee Training: Investing in workforce training programs to keep up with the latest manufacturing techniques and safety protocols.

These diverse applications make auto parts manufacturing a dynamic and essential industry within the automotive sector.

SourcifyChina, a renowned auto parts manufacturer, primarily utilizes high-quality steel for its durability and strength. This material is essential in the production of critical components, ensuring longevity and safety in automotive applications.

Aluminum is another key material employed due to its lightweight properties, enhancing vehicle fuel efficiency without compromising structural integrity. It’s widely used for engine parts, transmission casings, and body panels.

Plastic, including polymers like polypropylene and ABS, is extensively used for its versatility and cost-effectiveness. From interior trim to exterior body components, plastic materials contribute to both aesthetic appeal and functional design.

Additionally, SourcifyChina integrates advanced composite materials such as carbon fiber and fiberglass. These materials offer exceptional strength-to-weight ratios, making them ideal for high-performance applications and specialty parts.

All materials undergo rigorous quality control processes to meet industry standards and customer specifications. This commitment to quality ensures that SourcifyChina’s auto parts are reliable, safe, and efficient for all types of vehicles.

SourcifyChina, a leading auto parts manufacturer, places a significant emphasis on stringent quality control processes to ensure top-quality products. Each phase of production undergoes meticulous scrutiny, from raw material inspection to the final assembly.

The initial stage involves selecting premium raw materials and conducting rigorous inspections to meet industry standards. This step ensures the integrity and durability of components used throughout the manufacturing process.

State-of-the-art machinery and skilled technicians oversee the production phase, employing advanced techniques and continuous monitoring. This guarantees precision and uniformity in all auto parts manufactured, minimizing any risk of defects.

After production, every auto part undergoes exhaustive testing to evaluate performance, durability, and compliance with safety regulations. This rigorous testing includes both automated and manual inspections to identify potential flaws or deviations.

SourcifyChina also adopts a continuous improvement approach, gathering data from testing and customer feedback to refine manufacturing processes. This proactive strategy fosters innovation and ensures that the highest quality standards are consistently met.

To finalize the quality control process, comprehensive documentation of each production batch is maintained, enabling traceability and accountability. By implementing these robust quality measures, SourcifyChina guarantees reliable, high-performance auto parts that meet the demands of a global market.

SourcifyChina is a leading auto parts manufacturer located in China, specializing in producing high-quality components for various automotive brands worldwide. Their state-of-the-art production facilities are equipped with advanced machinery and technology, ensuring precision and efficiency in every part they create.

The company boasts a diverse product range, including engine components, brake systems, suspension parts, and electrical elements, catering to both OEMs and the aftermarket. With a strong focus on research and development, SourcifyChina continually innovates, enhancing product performance and durability.

Quality assurance is at the core of SourcifyChina’s operations. They adhere to stringent international standards and employ rigorous testing protocols, ensuring that each product meets or exceeds industry requirements. This commitment to quality has earned them numerous certifications and a reputation for reliability.

SourcifyChina also places a high emphasis on customer satisfaction, providing tailored solutions to meet specific client needs. Their dedicated customer service team offers comprehensive support, from initial inquiry through to post-purchase assistance, ensuring a seamless experience.

Environmental sustainability is another key priority for the manufacturer. SourcifyChina implements eco-friendly practices in their production processes, reducing waste, and lowering their carbon footprint. This proactive approach aligns with global sustainability goals and promotes responsible industrial practices.

Furthermore, SourcifyChina benefits from strategic logistics capabilities, ensuring timely delivery to global markets. Their extensive distribution network and established partnerships with leading logistics providers enable quick and efficient shipping, minimizing downtime for customers’ operations.

In conclusion, SourcifyChina stands out in the competitive auto parts manufacturing industry through their advanced production techniques, dedication to quality, customer-centric approach, and commitment to sustainability. These strengths make them a preferred partner for automotive companies seeking reliable and innovative solutions.

Auto parts manufacturers play a crucial role in keeping vehicles running optimally by providing high-quality, reliable components for repair and maintenance.

– Cost Savings: Replacement parts from specialized manufacturers can often be more affordable than those from original equipment manufacturers, reducing maintenance costs.

– Enhanced Performance: Specialized parts can be designed to improve vehicle performance, optimizing engine efficiency, fuel consumption, and overall reliability.

– Customization: Manufacturers can produce bespoke components tailored to specific requirements, offering unique solutions to customers.

– Availability: Auto parts manufacturers often provide a vast selection of parts, ensuring that even rare or outdated models can be serviced.

– Quality Assurance: Adhering to industry standards and rigorous testing procedures ensures that products meet high-quality criteria, increasing durability and safety.

– Innovation: Continuous research and development lead to advancements in technology, such as hybrid systems and electric vehicle components.

– Environmental Impact: Many manufacturers focus on creating eco-friendly products, using sustainable materials and processes to reduce environmental footprints.

– Warranty and Support: Products often come with warranties and customer support services, giving peace of mind and assistance when needed.

– Boost Local Economy: Supporting local auto parts manufacturers can drive job creation and economic growth within communities.

Auto parts manufacturers contribute significantly to the automotive industry by ensuring the availability and advancement of essential vehicle components, ultimately enhancing vehicle longevity and performance.

An auto parts manufacturer produces essential components for vehicles, ensuring quality, precision, and reliability. This includes a wide range of parts from engines to accessories. Key features include:

– Precision Engineering: Advanced machinery and skilled labor ensure each part is manufactured to exact specifications.

– Quality Assurance: Rigorous testing processes to ensure parts meet industry standards and safety regulations.

– Customization Capabilities: Ability to create custom parts based on specific client needs or modifications.

– Innovative Technology: Usage of cutting-edge technology such as 3D printing and AI for improved production processes.

– Scalability: Capability to handle both small-scale and large-scale orders efficiently.

– Sustainability Practices: Implementation of eco-friendly processes and materials to reduce environmental impact.

– Wide Product Range: Offering a comprehensive selection of parts, from simple components to complex assemblies.

– Global Distribution Network: Extensive logistics to supply parts to clients worldwide quickly and effectively.

– Customer Support and Service: Dedicated teams to assist clients with inquiries, orders, and after-sales service.

– R&D Investment: Continuous investment in research and development to innovate and improve products.

These features make auto parts manufacturers crucial in the automotive industry.

SourcifyChina is a prominent auto parts manufacturer known for its custom product offerings. They specialize in creating tailored solutions for a diverse range of automotive needs, ensuring high-quality and precision in every piece.

The company boasts state-of-the-art facilities equipped with advanced machinery and technology. This allows them to produce a wide variety of auto parts, from simple components to complex assemblies, with exceptional accuracy and consistency.

Customer satisfaction is a top priority at SourcifyChina. They work closely with clients to understand their specific requirements and deliver products that meet or exceed expectations, ensuring optimal performance and durability.

Their experienced engineering team is adept at managing custom projects, providing valuable insights and innovative solutions. From initial design to final production, SourcifyChina ensures seamless execution and timely delivery, making them a reliable partner in the automotive industry.

In conclusion, SourcifyChina’s commitment to quality, customization, and customer satisfaction sets them apart as a leading auto parts manufacturer. Their expertise and dedication to excellence make them a preferred choice for custom automotive solutions, driving the industry forward.

SourcifyChina, a preeminent auto parts manufacturer based in China, stands out as a beacon of innovation and quality in the automotive industry. By leveraging state-of-the-art technology and rigorous quality control processes, the company delivers a comprehensive range of auto components that meet international standards. From essential engine parts to advanced electronic systems, each product is crafted with precision and reliability in mind. With a strong commitment to sustainability, SourcifyChina also focuses on reducing its environmental footprint through eco-friendly manufacturing practices. Collaborative partnerships with global automotive brands have cemented its reputation as a dependable supplier, while extensive R&D efforts ensure that the company remains at the forefront of technological advancements. SourcifyChina’s unwavering dedication to customer satisfaction is evident in its responsive service and flexible solutions, making it a trusted partner in the global automotive landscape.

Auto parts manufacturers have increasingly diversified their portfolios to cater to the aerospace, defense, and marine industries, tapping into high-demand sectors that require precision and durability. In aerospace, these manufacturers provide critical components such as specialized gears, bearings, and fasteners that must adhere to stringent quality and safety standards due to the high-stakes nature of aviation. The transfer of technology from auto parts manufacturing to aerospace allows for the implementation of advanced materials and manufacturing techniques, such as carbon fiber composites and additive manufacturing, which are essential for creating lightweight, robust components that can withstand extreme conditions.

In the defense sector, auto parts manufacturers produce a range of components for military vehicles, drones, and support systems. Their expertise in mass production, combined with a focus on reliability and performance, ensures that defense applications benefit from the same high-quality standards found in automotive manufacturing. Meanwhile, the marine industry leverages the technical capabilities of auto parts manufacturers to produce parts that endure harsh marine environments. Components like propeller shafts, hydraulics systems, and engine parts must resist corrosion and operate flawlessly under high pressure and continuous use. By entering these sectors, auto parts manufacturers not only expand their market reach but also contribute to advancements in technology and engineering across critical fields.

Auto parts manufacturers play an indispensable role in the automotive industry, providing a wide array of components essential for vehicle assembly, maintenance, and enhancement. These manufacturers produce critical parts such as engines, transmissions, brakes, and suspension systems, which ensure the safety and performance of automobiles. Additionally, they develop specialized components for electric vehicles, hybrid systems, and advanced driver-assistance systems (ADAS), which are pivotal in the transition towards more sustainable and autonomous driving technologies. Through rigorous quality control and innovation in design and materials, auto parts manufacturers contribute to the reliability and longevity of vehicles, helping automakers meet stringent regulatory standards and satisfy consumer demands for high-performing, fuel-efficient cars.

In the realm of electronics, auto parts manufacturers are instrumental in the integration of cutting-edge technology into modern vehicles. They produce sophisticated electronic components and systems, such as infotainment systems, telematics, and advanced safety features including collision avoidance and lane departure warning systems. As vehicles become increasingly connected and automated, the demand for high-quality electronic parts continues to grow. These manufacturers also focus on developing robust electronic control units (ECUs) that manage the various electronic systems within a vehicle, ensuring seamless operation and enhancing the overall driving experience. By continuously innovating and adapting to technological advancements, auto parts manufacturers support the automotive industry’s evolution, paving the way for smarter, safer, and more efficient vehicles.

Auto parts manufacturers are increasingly finding their expertise and advanced technologies valuable in the construction industry. Leveraging precision engineering and materials science expertise, these manufacturers are now producing durable, high-performance components for construction machinery such as bulldozers, cranes, and excavators. Innovations like lightweight alloy materials and high-efficiency hydraulic systems, originally developed for automotive applications, are being adapted for construction equipment to enhance durability, fuel efficiency, and operational performance. The shift toward automated and interconnected machinery in construction also benefits from the advanced control systems and sensors developed by auto parts manufacturers, resulting in more efficient, safer, and smarter construction processes.

In the energy sector, auto parts manufacturers are contributing significantly to advancements in renewable and efficient energy solutions. Electric vehicle (EV) technologies, such as batteries and electric drivetrains, are being adapted for use in energy storage systems and renewable energy applications. For instance, the high-capacity batteries designed for electric cars are now being scaled to store energy from renewable sources like wind and solar power. Additionally, manufacturers’ expertise in fuel systems and combustion technology aids the development of more efficient and cleaner power generation methods. These contributions not only foster the transition to sustainable energy but also open up new markets and revenue streams for auto parts manufacturers beyond traditional automotive uses.

The industrial equipment industry plays a crucial role in the auto parts manufacturing sector, enhancing production capabilities, efficiency, and precision. Automated machinery such as CNC (Computer Numerical Control) machines, robotic welders, and automated assembly lines have revolutionized the way auto parts are produced. These technologies enable manufacturers to maintain high consistency and quality, key criteria given the strict standards and safety concerns in the automotive industry. For instance, CNC machines allow for the precise machining of components like engine parts and transmission systems, ensuring that they meet exact specifications. Robotic welders, on the other hand, provide robust and reliable welds on parts such as chassis and frames, which are essential for vehicle integrity and safety.

Moreover, the implementation of advanced industrial equipment facilitates rapid prototyping and scalability in the auto parts manufacturing industry. 3D printing and automated fabrication systems allow for the swift iteration and development of new parts, reducing lead times and accelerating the innovation cycle. This capability is particularly invaluable in responding to evolving market demands and automotive trends such as electric vehicles, where new types of parts and materials are continually being developed. Advanced sensor technology and IoT (Internet of Things) integration in industrial equipment also contribute to enhanced monitoring, predictive maintenance, and real-time adjustments, minimizing downtime and prolonging the lifespan of machinery. Consequently, the intersection of industrial equipment and auto parts manufacturing not only boosts productivity but also drives continuous improvement and adaptability in the competitive automotive market.

The intersection between auto parts manufacturing and the medical devices industry may initially seem unexpected, yet it showcases an intriguing domain of innovation and precision engineering. Auto parts manufacturers, known for their stringent standards and high-quality output, are increasingly channeling their expertise into the medical device sector. Components such as precision seals, gears, and micro-motors that are typically used in automotive applications are being adapted for medical devices to improve their functionality and reliability. For example, the advanced materials and sophisticated manufacturing techniques used to produce engine parts are now being employed to create durable and high-performance prosthetics, cardiovascular devices, and surgical instruments. Applying automotive technologies to medical devices is paving the way for innovations like motorized prosthetic limbs that provide greater mobility and life-like functionality to patients.

Moreover, auto parts manufacturers utilize advanced technologies such as Computer Numerical Control (CNC) machining, additive manufacturing, and robotics — all pivotal in producing the intricate components required for high-precision medical devices. CNC machining ensures that components like implants or diagnostic tool parts are crafted with incredible accuracy, meeting rigorous regulatory standards. Additive manufacturing, or 3D printing, enables the creation of highly customized medical solutions, such as patient-specific implants and anatomical models, which can drastically improve the effectiveness of treatments. Robotics, which has been optimized for precision tasks in automotive assembly lines, is also being adapted to automate the assembly of complex medical devices, ensuring consistent quality and reducing production times. This cross-industry application underscores the versatility of auto parts manufacturing technologies and their potential to significantly advance healthcare delivery.

Machining and manufacturing play a crucial role in the auto parts manufacturing industry, where precision, efficiency, and quality are paramount. Machining involves the use of various cutting tools and computer numerical control (CNC) machines to shape raw materials into precise components. This process ensures that parts such as engine blocks, transmission components, and brake rotors meet the stringent specifications required for high performance and safety in automobiles. Advanced machining techniques, including multi-axis machining and high-speed milling, enable manufacturers to produce intricate designs with tight tolerances, thereby enhancing the overall functionality and reliability of the parts. The use of CNC machines also allows for greater consistency and repeatability in production, minimizing the risk of defects and reducing waste.

In addition to machining, the broader scope of manufacturing in the auto parts sector encompasses various other processes, such as casting, forging, stamping, and assembly. Casting and forging are employed to create parts that need to withstand high stress, such as crankshafts and suspension components. Stamping is used for producing body panels and structural components with high dimensional accuracy at scale. The assembly process integrates these machined and fabricated parts into subassemblies and full assemblies that are ready for installation in vehicles. The implementation of automation and robotics in manufacturing has further enhanced productivity and precision, allowing auto parts manufacturers to meet the high demand and rigorous quality standards of the automotive industry. Together, machining and manufacturing ensure that the auto parts produced contribute to the safety, performance, and longevity of modern vehicles.

Sure, here is a list of frequently asked questions (FAQ) with answers about manufacturing quality auto parts at SourcifyChina factory:

1. What types of auto parts does SourcifyChina manufacture?

SourcifyChina specializes in manufacturing a wide range of auto parts, including engine components, transmission systems, braking systems, electrical parts, and body parts for various vehicle makes and models.

2. How does SourcifyChina ensure the quality of its auto parts?

Quality is ensured through a stringent quality control system that includes raw material inspection, process control, and final product inspection. The factory is ISO certified, and all parts undergo rigorous testing to meet international standards.

3. What materials are used in the manufacturing process?

We use high-grade materials such as steel, aluminum, plastics, and specialized alloys. The choice of material depends on the specific requirements of the part and the customer’s specifications.

4. Can SourcifyChina produce custom auto parts?

Yes, SourcifyChina offers custom manufacturing services. Clients can submit their designs or samples, and our engineering team will work to produce parts that meet their exact specifications.

5. What is the turnaround time for orders?

The turnaround time varies based on the complexity and quantity of the order. Typically, it ranges from 30 to 60 days. We can provide more accurate timelines upon reviewing specific requirements.

6. Does SourcifyChina provide samples before mass production?

Yes, we provide samples for approval before beginning mass production to ensure that our products meet the client’s specifications and quality standards.

7. How does SourcifyChina handle logistics and shipping?

We handle all logistics and shipping arrangements, providing global delivery options. We work with reputable logistics companies to ensure timely and safe delivery of orders.

8. What are the minimum order quantities (MOQs)?

Minimum order quantities vary depending on the product type and complexity. Typically, the MOQ is set to ensure cost-effective production, but specific MOQs can be discussed during the consultation process.

9. How does SourcifyChina support customers post-delivery?

We provide ongoing customer support, including technical assistance and warranty services, to address any issues that may arise post-delivery.

10. How can potential customers get in touch with SourcifyChina?

Potential customers can contact us via our website, email, or phone to discuss their requirements, request quotes, and seek further information about our services.

Choosing the right auto parts manufacturer is crucial for your business’s success. If you’re considering manufacturing through a SourcifyChina factory, here are some essential tips to guide you:

1. Research and Verify:

Ensure the factory has a good track record. Look for certifications like ISO/TS 16949 which indicate adherence to quality management systems.

2. Quality Control:

Implement strict quality control measures. Request regular audits and detailed reports. Consider hiring third-party inspectors to ensure compliance.

3. Communication:

Clear and consistent communication is vital. Make sure there’s no language barrier and both parties clearly understand specifications, timelines, and quality expectations.

4. Prototyping:

Always start with a prototype. This step helps identify potential issues early and ensures the final product meets your requirements.

5. Logistics:

Plan your supply chain meticulously. Consider lead times, shipping methods, and tariffs. Collaborate with reliable logistics partners to avoid delays.

6. Cost Analysis:

Compare costs, but don’t compromise on quality. Factor in all expenses including shipping, duties, and potential rework costs.

7. Legal Aspects:

Protect your intellectual property. Enforce Non-Disclosure Agreements (NDAs) and make sure contracts are clear in terms of deliverables and penalties for non-compliance.

8. Sustainability:

With increasing emphasis on sustainability, ensure the factory complies with environmental regulations and ethical labor practices.

9. Feedback Loop:

Maintain a feedback loop with the factory. Regular performance reviews can help address issues promptly and improve future production runs.

10. Visit the Factory:

Visit the factory if possible. This allows you to see firsthand the operations, meet the team, and establish a stronger business relationship.

Following these tips can help you navigate the complexities of manufacturing auto parts in China effectively while ensuring high-quality production.

Q1: What types of auto parts can be sourced from SourcifyChina factories?

A1: SourcifyChina factories offer a wide range of auto parts including engine components, transmission parts, suspension systems, braking systems, body parts, and electrical components. They cater to both OEM and aftermarket requirements.

Q2: How do I verify the quality of auto parts from SourcifyChina factories?

A2: Quality verification can be done through third-party inspections, reviewing factory certifications (such as ISO/TS 16949 for automotive), requesting sample parts, and checking past client reviews or references.

Q3: What are the lead times for orders from SourcifyChina factories?

A3: Lead times vary depending on the complexity and quantity of the order, typically ranging from 30 to 90 days. It is advisable to get a specific timeline from the supplier.

Q4: Are SourcifyChina factories capable of providing custom-made auto parts?

A4: Yes, many SourcifyChina factories offer custom manufacturing services. They can work with your specifications and designs to produce custom parts that meet your exact requirements.

Q5: How can I ensure that the factory adheres to international standards?

A5: Ensure the factory has relevant certifications such as ISO 9001 or IATF 16949. Additionally, you can conduct audits or request compliance documentation to verify adherence to international standards.

Q6: What are the payment terms typically offered by SourcifyChina factories?

A6: Common payment terms include TT (Telegraphic Transfer), LC (Letter of Credit), and sometimes PayPal for smaller transactions. Negotiations on payment terms can be done based on the order size and relationship with the factory.

Q7: Can SourcifyChina help with logistics and shipping arrangements?

A7: Yes, SourcifyChina can assist in arranging logistics and shipping. They often partner with freight forwarders to provide seamless delivery services from the factory to your desired location.

Q8: How do I initiate a business inquiry with a SourcifyChina factory?

A8: Begin by submitting an inquiry through the SourcifyChina website or directly contacting their sales team. Provide detailed information about your requirements to receive a tailored quote and further assistance.

Sourcing auto parts from a manufacturer via SourcifyChina can be an efficient and cost-effective way to procure high-quality components. Here are some tips to help you navigate the process:

1. Define Your Needs: Be very specific about the auto parts you need, including specifications, materials, and quantities. Clear requirements will streamline communication and help you get precise quotes.

2. Research Thoroughly: Use SourcifyChina’s platform to identify potential manufacturers. Check company profiles, capabilities, and previous production examples. Look for manufacturers with experience in the specific auto parts you’re sourcing.

3. Check Certifications: Ensure the manufacturer has necessary certifications, such as ISO/TS 16949 for automotive parts, which indicates adherence to international standards.

4. Request Samples: Before placing a large order, request samples to evaluate the quality of the products. This helps in verifying that the manufacturer can meet your quality standards.

5. Assess Communication: Effective communication is crucial. Choose manufacturers who respond promptly and clearly. Good communication can prevent many potential issues down the line.

6. Negotiate Terms: Discuss pricing, minimum order quantities (MOQs), lead times, and payment terms upfront. Aim to get a detailed contract that delineates all terms and conditions.

7. Consider Logistics: Factor in shipping costs, customs duties, and delivery times. Discuss with the manufacturer their packaging and shipping procedures to ensure your products arrive safely and on time.

8. Visit the Factory: If possible, arrange a visit to the manufacturer’s facility. This allows you to inspect their operations firsthand and establish a stronger business relationship.

9. Quality Control: Implement a quality control process. Either inspect the goods personally before shipment or hire a third-party quality inspection service.

10. Build Relationships: Developing a strong relationship with the manufacturer can lead to better terms, more flexibility, and a more reliable supply chain.

Following these tips can improve your chances of finding a reliable auto parts manufacturer through SourcifyChina, ensuring quality and efficiency in your supply chain.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.