## Reliable CNC Router from SourcifyChina: The Best Choice for Woodworking Factories

SourcifyChina offers the best CNC routers for woodworking factories, renowned for their reliability and precision. Enhance your production with advanced technology and trusted performance from the industry leader. Discover why SourcifyChina is the top choice for woodworking professionals.

Choosing “SourcifyChina” Factory for purchasing a woodworking CNC router ensures high quality and reliability. Their products feature cutting-edge technology, offering precision and efficiency. Additionally, they are celebrated for their excellent customer service and support, assisting buyers throughout the entire purchasing process.

“SourcifyChina” Factory provides competitive prices without compromising on quality. They possess a remarkable track record in the industry, consistently meeting and exceeding customer expectations. Buyers can rest assured that they are investing in a product that offers long-term value and performance.

Shipping and logistics are streamlined and efficient with “SourcifyChina” Factory. They offer timely deliveries and handle all necessary documentation, which removes the hassle from the buyer’s end. Transparency in tracking and updates also adds a layer of confidence for international buyers.

Customer satisfaction is a top priority for “SourcifyChina” Factory. Their team offers extensive ongoing support, from installation to maintenance advice. Responsive and knowledgeable, they ensure that every customer query is addressed promptly and effectively.

In conclusion, “SourcifyChina” Factory stands out as the ideal choice for acquiring a high-quality woodworking CNC router from China. Combining stellar customer service, advanced technology, competitive pricing, and efficient logistics, they offer a seamless and reliable purchasing experience. Buyers can confidently choose “SourcifyChina” Factory for their woodworking needs, ensuring satisfaction and value.

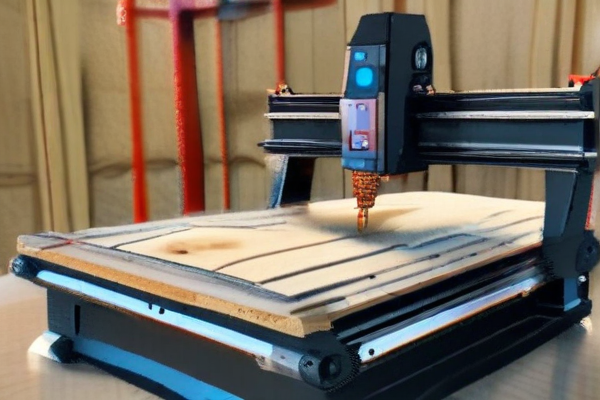

Finding the best woodworking CNC router involves considering various factors such as precision, durability, ease of use, and software compatibility. Key options include desktop, mid-size, and industrial-grade models, each catering to different needs and budgets.

– Desktop CNC Routers

– Ideal for hobbyists and small workshops

– Compact and affordable

– Examples: Shapeoko, X-Carve

– Mid-Size CNC Routers

– Suitable for small to medium businesses

– Greater work area and better precision

– Examples: Avid CNC, BobsCNC E4

– Industrial-Grade CNC Routers

– Designed for large-scale production

– High precision and durability

– Examples: Laguna Tools, ShopSabre

– Features to Consider

– Spindle Power: Higher power for tougher materials

– Work Area: Larger for bigger projects

– Software Compatibility: User-friendly and versatile

– Build Quality: Robust for extended use

– Customer Support: Reliable technical assistance

– Top Brands

– Inventables: Known for user-friendly designs

– Carbide 3D: Shares powerful options for various needs

– BobsCNC: Balances affordability and quality

– Laguna Tools: Industry leader for professional use

– ShopBot: Offers customizable solutions

– Additional Accessories

– Dust collection systems

– Vacuum tables

– Tool changers

– High-performance cutting tools

Choosing the right CNC router depends on your specific requirements and budget. Weighing these options and features will help ensure a suitable investment for your woodworking projects.

A CNC router for woodworking offers precision and efficiency, making it ideal for various applications from intricate designs to large-scale productions. These routers cater to professionals and hobbyists alike, providing versatility and reliability.

– Custom furniture: Create bespoke furniture pieces with intricate details and precise cuts.

– Cabinetry: Efficiently produce cabinet parts with accuracy, ensuring perfect fits.

– Signmaking: Craft detailed and durable signs with various fonts and designs.

– Prototyping: Rapidly develop prototypes for new products, facilitating innovation and testing.

– Wood art: Produce detailed wood carvings and artistic pieces with consistency.

– Panel processing: Cut and shape panels for doors, walls, and other large-scale projects.

– Joinery: Perfectly cut joints like dovetails, tenons, and mortises for strong, seamless connections.

– Educational purposes: Equip schools and training centers with tools to teach advanced woodworking skills.

– Mass production: Streamline production lines for high-volume manufacturing, reducing errors and increasing output.

– Acoustic instrument making: Craft musical instruments with precision, ensuring quality sound and aesthetics.

– Decorative elements: Design and fabricate decorative architectural elements like moldings and trims.

– Embedded inlay work: Create intricate inlays in wood surfaces for decorative and functional purposes.

– Model making: Build scale models for architectural, educational, and entertainment uses.

– Home decor: Manufacture custom home decor items like picture frames and wall panels.

– Giftware: Produce personalized gifts and novelties with unique designs and engravings.

– Signage production: Produce high-quality commercial signage for businesses, including retail and promotional displays.

– Milling complex shapes: Accurately mill complex shapes and patterns that would be difficult manually.

– Automated nesting: Optimize material usage with software-driven nesting capabilities.

– 3D carving: Create three-dimensional carvings and sculptures.

– Component manufacturing: Produce consistent parts for assembly lines or kit-based products.

In summary, a high-quality woodworking CNC router expands the capabilities of woodworkers, enabling them to achieve precision, reduce waste, and enhance creativity across various applications.

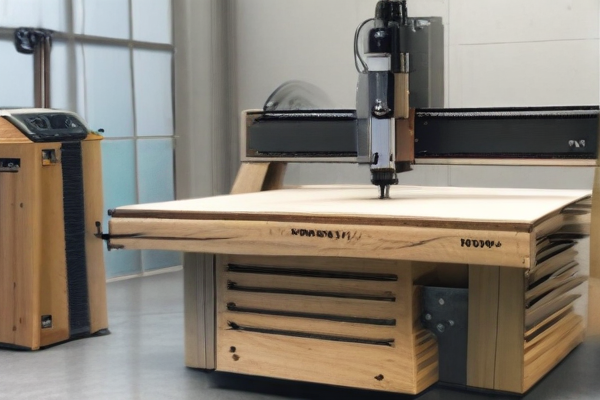

“SourcifyChina best woodworking CNC router” is a high-precision machine renowned for its robust construction. It features a solid steel frame that ensures durability and stability during operation. Each component is meticulously crafted to maintain accuracy and longevity.

The cutting bed of the CNC router is typically made of aluminum or phenolic composite, which resists warping and provides a flat and stable surface. This material choice contributes to the precise cutting and carving required in fine woodworking projects.

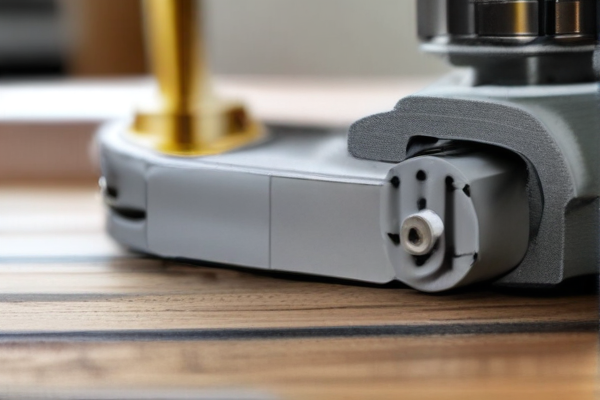

High-quality spindle motors are used in these routers, often made from aerospace-grade aluminum. This ensures efficient cooling and minimal vibration, enhancing the machine’s precision and operational life. These spindles are critical for achieving smooth and accurate cuts.

Additionally, the guide rails are constructed from hardened steel. This material choice is essential for reducing wear and tear over time. The hardened steel guide rails contribute to the smooth operation and sustained accuracy of the CNC router.

Another significant material used is industrial-grade electronics, which ensures reliable and consistent performance. These components are designed to withstand intense use, providing longevity and reducing maintenance needs for the machine.

In conclusion, the “SourcifyChina best woodworking CNC router” is engineered from top-tier materials such as solid steel, aerospace-grade aluminum, and hardened steel. The combination of these materials ensures unparalleled durability, precision, and reliability, making it an excellent investment for professional woodworkers. These high-quality components come together to form a machine that excels in delivering consistent and high-quality results in woodworking tasks.

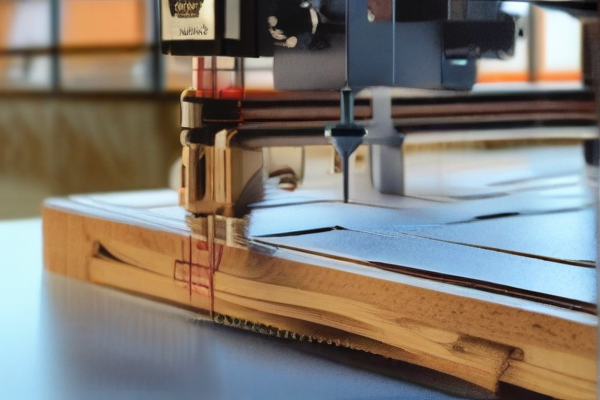

The SourcifyChina woodworking CNC router undergoes rigorous quality control stages to ensure top-notch performance and reliability. Each machine part is meticulously inspected using high-precision instruments to detect any possible defects.

Assembling components requires skilled craftsmen who follow stringent protocols to guarantee optimal alignment and functionality. Advanced calibration procedures are employed, ensuring that every router meets the desired accuracy and efficiency standards.

Post-assembly testing is critical, involving simulations of various woodworking tasks to validate the machine’s precision and durability. These tests help identify any inconsistencies that must be rectified before the final product is approved.

Finally, each CNC router passes through a comprehensive final inspection, checking everything from electrical systems to build integrity. This multi-layered quality control process ensures that SourcifyChina delivers exceptional CNC routers, bolstering their reputation for excellence in the woodworking industry.

The SourcifyChina best woodworking CNC router boasts exceptional precision and efficiency, automating intricate wood designs with unparalleled accuracy. Its advanced control system ensures flawless execution of complex patterns, meeting the demands of master craftsmen and manufacturers alike.

Engineered for durability, this CNC router features a robust build and high-quality components, guaranteeing long-term operational stability and minimal downtime. Its heavy-duty frame stands firm even during the most challenging tasks, making it a reliable asset in any production line.

Versatility defines the SourcifyChina best woodworking CNC router, capable of working with various types of wood and composites. It can handle tasks ranging from simple carvings to detailed three-dimensional sculptures, providing a flexible solution for diverse woodworking needs.

User-friendly interfaces are integral, offering intuitive controls and easy programming that even novices can navigate. This accessibility ensures that businesses can train staff quickly and maintain high productivity without extensive downtime for learning.

Moreover, the router’s high-speed spindle and advanced servo motors facilitate rapid processing, significantly reducing production time. This efficiency results in higher output rates, accelerating project timelines and enhancing overall profitability for businesses.

In summation, the SourcifyChina best woodworking CNC router combines precision, durability, versatility, user-friendliness, and speed, making it a comprehensive tool for modern woodworking applications. Whether for bespoke crafting or mass production, it stands out as a top-tier choice for professionals aiming to elevate their woodworking capabilities.

A high-quality woodworking CNC router offers precise, efficient, and versatile cutting capabilities, making it an essential tool for both hobbyists and professionals in the woodworking industry.

– Precision and Accuracy: Ensures exact cuts and designs, reducing material waste and ensuring consistency.

– Time Efficiency: Automates complex tasks, significantly speeding up the production process.

– Versatility: Capable of handling various materials like wood, MDF, plywood, and plastic.

– Complex Designs: Easily creates intricate patterns and custom designs that would be difficult with manual tools.

– Consistency: Guarantees uniform output, essential for mass production.

– Cost-Effective: Reduces the need for manual labor, minimizing errors and rework.

– User-Friendly: Often comes with easy-to-use software, making it accessible even for beginners.

– Customization: Offers endless possibilities for bespoke projects and products.

– Enhanced Safety: Minimizes accidents associated with manual cutting and sculpting tools.

– Scalability: Easily adapts to various project sizes, from small crafts to large-scale production runs.

– Durability: Built to last, capable of handling heavy-duty tasks over extended periods.

– Innovation: Keeps up with technological advancements, continually improving features and capabilities.

– Eco-Friendly: Reduces material waste through precise cutting and efficient use of resources.

– High ROI: Quickly pays for itself through enhanced productivity and reduced labor costs.

– Professional Finish: Achieves high-quality results that can elevate the aesthetic and functional value of the products.

Investing in a top-notch woodworking CNC router can transform workflows, elevate product quality, and boost overall efficiency in any woodworking enterprise.

A high-quality woodworking CNC router is an invaluable tool for precision, efficiency, and versatility in woodworking projects. It offers numerous features that enhance performance and ease of use.

– Precision and Accuracy: Delivers precise cuts to the millimeter, ensuring a flawless finish.

– High-Speed Spindle: Provides robust cutting power for various types of wood.

– Durable Construction: Built with sturdy materials to withstand constant use.

– User-Friendly Interface: Easy-to-navigate control systems, often with touchscreens.

– Compatibility: Supports various design software, enhancing design flexibility.

– Dust Collection System: Keeps the work area clean, improving visibility and health.

– Auto-Tool Changing: Automates switching between different tools, increasing efficiency.

– Robust Motor: Ensures smooth and stable operation even during intensive tasks.

– Work Area Size: Offers ample space to accommodate large projects.

– Safety Features: Includes emergency stop buttons and safety guards.

– Customizable Settings: Allows users to tailor operations based on specific project needs.

– Network Connectivity: Enables remote monitoring and control.

These features collectively make a CNC router an excellent investment for professional and amateur woodworkers alike.

SourcifyChina’s woodworking CNC routers are renowned for their high precision and reliability. These machines cater to custom woodworking projects, offering unparalleled accuracy and efficiency for intricate designs. Whether for small businesses or large-scale productions, their routers make complex tasks easier.

The CNC routers utilize advanced technology that seamlessly interfaces with various software, ensuring a streamlined operation. From crafting detailed furniture to designing custom wood panels, these machines deliver excellence in every cut. The robust build of the routers ensures long-term durability, an essential factor for continual use in any workshop.

SourcifyChina provides tailored solutions for a wide range of woodworking needs. They understand that every project has unique requirements, and thus offer customizable router options. Clients can choose from different sizes, power specs, and additional features to best suit their specific projects. The company’s commitment to customization ensures that you get a machine perfectly aligned with your project goals.

Customer support from SourcifyChina is exceptional, with a focus on helping clients maximize the efficiency of their CNC routers. From installation guidance to troubleshooting, their support team stands ready to assist. This level of support ensures that users can fully exploit the capabilities of their woodworking routers, leading to higher productivity and superior project outcomes. For custom products and bespoke woodworking projects, SourcifyChina’s CNC routers are an invaluable tool, providing precision, reliability, and outstanding customer service.

SourcifyChina stands out as a premier manufacturer and supplier of high-quality woodworking CNC routers, serving a diverse global clientele with unmatched precision and reliability. As an industry leader based in China, SourcifyChina leverages cutting-edge technology and innovative engineering to produce CNC routers that cater to the versatile needs of woodworkers, from hobbyists to industrial professionals. Their product lineup features a range of models designed for various applications, ensuring that every customer finds the ideal machine to enhance their craftsmanship. Precision and durability are hallmarks of their CNC routers, which are meticulously crafted to handle complex engraving, intricate cutting, and detailed shaping tasks with ease. Customer satisfaction is a cornerstone of SourcifyChina’s business ethos, demonstrated by their exceptional after-sales support and ongoing commitment to technical advancements. By consistently delivering superior performance and value, SourcifyChina has earned a stellar reputation, making them a trusted name in the woodworking community worldwide.

The aerospace, defense, and marine industries demand precision and reliability in their components, making the use of best woodworking CNC routers highly advantageous. These advanced machines offer unparalleled accuracy, capable of executing intricate designs with exacting tolerances. In aerospace, the use of CNC routers facilitates the creation of complex parts for aircraft interiors and structural components from high-performance composites and lightweight materials. The router’s ability to maintain consistent quality and produce repeatable results ensures that critical specifications are met, enhancing the safety and efficiency of aircraft operations. Similarly, in the defense sector, CNC routers contribute to the manufacturing of mission-critical components, from control panels to custom storage solutions, where precision and durability are paramount.

In the marine industry, CNC routers are indispensable for crafting boat interiors, from cabinetry to decorative elements, and even essential structural parts. The routers’ precision allows for optimal use of expensive materials, reducing waste and ensuring the integrity of the final product. By utilizing CNC technology, marine manufacturers can produce highly customized and intricate designs that meet the unique requirements of luxury yachts or specialized vessels. Additionally, the efficiency and speed of CNC routers streamline production processes, reducing lead times and labor costs. This not only boosts productivity but also allows for more innovative and complex design possibilities, driving advancements in marine technology and craftsmanship.

In the automotive industry, the best woodworking CNC router has revolutionized the way custom and prototype components are manufactured. Precision and repeatability are paramount in automotive applications, and these CNC routers excel in delivering both. By utilizing advanced software, engineers and designers can create intricate dashboard panels, custom interior trims, and complex wooden moldings efficiently. The routers’ ability to handle a wide variety of wood materials with high accuracy ensures that every piece meets stringent quality standards. Furthermore, the adaptability of CNC routers allows for rapid prototyping, significantly reducing the time from design to production. This translates to faster development cycles and greater flexibility in making design adjustments or producing limited-edition components.

In the realm of electronics, woodworking CNC routers find a niche in crafting high-precision enclosures and casings for various devices. Wooden laptop shells, smartphone cases, and speaker cabinets not only offer a unique aesthetic but also provide environmental benefits over plastic counterparts. These CNC routers enable manufacturers to produce detailed and consistent cuts that match specific design requirements, ensuring the final product’s functionality and visual appeal. Additionally, the capability to incorporate intricate venting and port patterns into wooden housings enhances both cooling efficiency and acoustics for electronics. This technological integration underscores the versatility of the best woodworking CNC routers, demonstrating their application in producing not just practical, but also eco-friendly and stylish electronic products.

The construction industry has seen significant advancements through the use of best woodworking CNC routers, particularly in creating precise, customized components. These routers allow for the cutting, carving, and shaping of wood with exact precision, which is essential for architectural elements like ornate moldings, intricate staircases, and detailed cabinetry. Using advanced software, users can design complex structures that are effortlessly translated into physical components, thus speeding up the construction process while ensuring higher accuracy and reducing material wastage. This precision manufacturing also allows for the prefabrication of components, which can be quickly assembled onsite, further enhancing the efficiency and sustainability of construction projects.

In the realm of energy applications, woodworking CNC routers play a crucial role in the production of efficient wooden components for renewable energy systems. For example, wind turbine blades crafted from composite wood materials benefit from the precision and consistency offered by CNC routers. This allows for the production of blades that not only meet stringent aerodynamic requirements but also exhibit high durability and reduced production costs. In the solar energy sector, CNC routers can be used to create precise frames and structural supports for photovoltaic panels, ensuring optimal alignment and stability. These applications significantly contribute to the renewable energy industry’s focus on sustainable and high-performance materials, reinforcing the role of advanced woodworking technology in driving both innovation and environmental stewardship in energy production.

The industrial equipment industry has significantly benefited from advancements in woodworking CNC router technology, revolutionizing the way wood products are designed and manufactured. Best woodworking CNC routers offer unparalleled precision, efficiency, and versatility, making them indispensable in producing complex wood components with high consistency. These machines are equipped with computer numerical control (CNC) systems that allow for precise cutting, drilling, and carving based on digital designs, reducing human error and waste. In large-scale manufacturing, this translates to increased productivity and reduced costs, as intricate designs can be replicated swiftly and accurately. Additionally, CNC routers are capable of working with various types of wood and composite materials, making them suitable for diverse applications, from furniture making to cabinetry and decorative elements.

Incorporating the best woodworking CNC routers into industrial operations also enhances the quality and customization capabilities of wood products. These routers can execute detailed and intricate patterns that would be difficult, if not impossible, to achieve manually, allowing manufacturers to meet specific customer requirements and market trends. The automation and precision offered by CNC routers improve not only the aesthetics of the final products but also their structural integrity, as the consistent cuts and fittings ensure better assembly and durability. Furthermore, the integration of advanced software with CNC routers facilitates real-time monitoring and adjustments, streamlining the production process and enabling quicker turnaround times. As a result, the industrial equipment industry can maintain high standards of quality while scaling up production to meet increasing demands.

The use of a best woodworking CNC router in the medical devices industry revolutionizes the production of precise and complex components, essential for creating high-quality medical equipment. These advanced routers employ computer-controlled cutting technology to craft intricate shapes and designs with remarkable accuracy and consistency, thereby ensuring that medical devices meet stringent regulatory standards. By utilizing such high-precision tools, manufacturers can produce components with tight tolerances, enhancing the performance and reliability of medical instruments like prosthetics, dental implants, and surgical tools. CNC routers streamline the production process, reduce human error, and significantly cut down on manufacturing time, ultimately leading to more cost-effective and efficient medical device production.

Moreover, the versatility of a best woodworking CNC router extends beyond wood and can include various bio-compatible materials required in medical device manufacturing. These routers can handle materials such as plastics, composites, and even soft metals, providing the flexibility needed to cater to diverse medical applications. The ability to prototype quickly and make rapid adjustments to designs plays a crucial role in innovation within the medical field, allowing for swift development and testing of new devices. This agility is particularly vital in response to emerging healthcare needs and advancements in medical technology. By integrating CNC routing into the workflow, medical device manufacturers can maintain high standards of quality while staying ahead in a competitive and rapidly evolving market.

The “best woodworking CNC router” serves as a transformative tool in the realm of machining and manufacturing, particularly within the woodworking industry. This advanced machine is equipped with computer-controlled programming that enables high precision and efficiency in carving, cutting, and shaping wood. When utilized in machining applications, a top-tier CNC router can significantly reduce production times while maintaining remarkable accuracy and repeatability. This precision minimizes waste and maximizes material use, which is essential for cost-effective operations. The router’s capabilities extend to producing complex geometries and intricate designs that would be incredibly challenging or time-consuming to achieve manually. Hence, the adoption of high-quality CNC routers streamlines workflows and enhances overall productivity in both small-scale and large-scale woodworking shops.

In the broader scope of manufacturing, the best woodworking CNC router opens up new possibilities for product innovation and customization. For furniture makers, cabinetry, and other wood product manufacturers, the level of detail and consistency provided by CNC routing ensures that each piece meets exacting standards of quality. These machines support mass production without compromising individual craftsmanship, allowing for bespoke design elements and variations that cater to today’s market demands. Furthermore, the technological advancements integrated into these premium routers—such as advanced software capabilities, versatile tool changers, and robust spindle options—empower manufacturers to diversify their product offerings. Whether it’s creating custom furniture, detailed moldings, or intricate inlays, the best woodworking CNC router proves indispensable, fostering a blend of artisanal skill and modern efficiency in the manufacturing landscape.

Certainly! Here are some FAQs with answers about manufacturing the best woodworking CNC router with quality work from SourcifyChina factory:

Q1: What distinguishes SourcifyChina’s woodworking CNC routers from others?

A1: SourcifyChina’s CNC routers are known for their precision engineering, robust build quality, and advanced features that ensure superior performance and longevity. We use premium materials and the latest technology to deliver unmatched accuracy and efficiency.

Q2: What types of woodworking projects are suitable for SourcifyChina’s CNC routers?

A2: Our CNC routers are versatile and ideal for a wide range of woodworking projects, including cabinetry, furniture making, moldings, sign-making, and intricate carvings. They are designed to handle both small and large-scale productions with ease.

Q3: How do I ensure the quality of the CNC router I purchase?

A3: At SourcifyChina, we adhere to stringent quality control processes. Each CNC router undergoes rigorous testing and inspection. Additionally, we are ISO certified, which guarantees our machinery meets international quality standards.

Q4: Can I customize the CNC router specifications to suit my needs?

A4: Yes, we offer customized CNC routers tailored to your specific requirements. You can choose features like table size, spindle power, and tool-changing capabilities to ensure it meets your workshop’s exact needs.

Q5: What kind of support and after-sales service can I expect?

A5: SourcifyChina provides comprehensive after-sales support, including installation guidance, training, and troubleshooting assistance. Our technical support team is available 24/7 to help you with any issues or questions.

Q6: How long does it take to receive an order?

A6: The delivery time depends on the order specifications and quantity. Typically, it takes about 4-6 weeks from order confirmation to shipping. We strive to meet deadlines and ensure timely delivery.

Q7: What are the payment options available?

A7: We offer flexible payment terms, including wire transfers, L/C, and other secure methods. Our sales team will work with you to determine the best payment option for your purchase.

Q8: Is training available for operating the CNC router?

A8: Yes, we provide comprehensive training for your team, ensuring they are proficient in operating the CNC router and maximizing its potential. Training can be conducted on-site or online, depending on your preference.

Q9: Are there warranties offered on the CNC routers?

Choosing the best woodworking CNC router manufacturing from SourcifyChina factory requires careful consideration. Here are some essential tips:

1. Research Reputation: Investigate the manufacturing capabilities and reputation of SourcifyChina factory. Look for reviews, testimonials, and case studies from previous clients to gauge reliability and quality.

2. Precision and Accuracy: Ensure the CNC routers have high precision and accuracy. This is crucial for intricate woodworking designs and achieving a professional finish on projects.

3. Material Compatibility: Verify if the router is compatible with the variety of woods you intend to use. The factory should provide routers capable of handling different wood types from softwoods to hardwoods.

4. Customization Options: Check if the factory offers customization options to tailor the CNC router to your specific woodworking needs. This might include custom sizes, tool heads, or software integrations.

5. Technology Integration: Ensure that the CNC routers incorporate advanced technology such as CAD/CAM software compatibility, robust controllers, and modern safety features.

6. After-Sales Support: Assess the level of after-sales support provided by SourcifyChina factory. Reliable customer service, availability of spare parts, and technical support are essential for long-term use and maintenance.

7. Training and Setup Assistance: Consider if the factory provides training for operating the CNC router and assistance in the initial setup. This can be invaluable for optimizing the use of the machinery.

8. Cost and Warranty: Compare costs, but also consider the value offered. Ensure the CNC router comes with a comprehensive warranty to protect your investment.

By focusing on these key factors, you can select a high-quality woodworking CNC router from SourcifyChina factory that meets your specific needs and enhances your woodworking projects.

Certainly! Here are some Frequently Asked Questions (FAQ) with answers regarding sourcing the best woodworking CNC router from SourcifyChina factory:

Q1: How can I ensure the quality of the CNC router from SourcifyChina factory?

A1: SourcifyChina factory maintains high-quality standards by using top-grade materials and advanced manufacturing processes. They also conduct rigorous quality checks at multiple stages of production and offer guarantees on their products to ensure client satisfaction.

Q2: What is the typical lead time for order fulfillment?

A2: The lead time can vary depending on the complexity and quantity of the order. For standard woodworking CNC routers, it generally takes around 4-6 weeks from order confirmation to delivery.

Q3: Does SourcifyChina provide customization options?

A3: Yes, SourcifyChina offers various customization options to meet specific requirements. Clients can discuss their needs, including size, power, and additional features, to get a tailored solution.

Q4: What type of after-sales support does SourcifyChina provide?

A4: SourcifyChina offers comprehensive after-sales support, including installation guidance, training for operating the CNC router, and prompt technical assistance. They also provide warranties and maintenance services.

Q5: Is it possible to visit the factory for a hands-on inspection?

A5: Absolutely, SourcifyChina welcomes clients to visit their manufacturing facility. A prior appointment is recommended to ensure that relevant staff members are available for a detailed walkthrough and queries.

Q6: What are the payment terms?

A6: The standard payment terms with SourcifyChina are typically a 30% advance payment to confirm the order, with the remaining 70% due before shipment. They accept various payment modes, including bank transfers and letters of credit.

Q7: How can I get a quotation for the CNC router?

A7: You can request a quotation by contacting SourcifyChina through their official website, email, or phone. Provide detailed requirements to receive an accurate estimate.

Q8: Are there bulk purchase discounts available?

A8: Yes, SourcifyChina offers discounts for bulk purchases. Contact their sales team to discuss volume pricing and other perks available for large orders.

Q9: What kind of warranty is offered on the CNC routers?

A9: SourcifyChina provides a standard warranty, typically ranging from one to two years, covering manufacturing defects and parts replacement. Extended warranties can also be discussed upon request.

Sourcing the best woodworking CNC router from a factory in China, such as those you might find through Sourcify, requires a strategic approach. Here are some tips:

1. Define Specifications: Clearly outline your requirements (bed size, spindle motor power, accuracy) in detail. This ensures you find CNC routers that meet your project needs.

2. Research Factories: Use platforms like Sourcify or Alibaba to identify potential suppliers. Check their profiles, read reviews, and verify their experience in manufacturing woodworking CNC routers.

3. Check Certifications: Ensure the factories have relevant certifications (ISO, CE) that attest to their manufacturing standards and quality control processes.

4. Request Samples: Ask for product samples or demonstration videos. This helps evaluate the build quality and performance of the CNC routers before committing to a bulk order.

5. Evaluate Customer Support: Good post-sales support is crucial. Select suppliers that offer robust customer support and after-sales services, including warranties and technical assistance.

6. Compare Prices: While cost is important, avoid the cheapest options if they compromise on quality. Balance quality and cost for the best value.

7. Perform Factory Audits: If feasible, conduct on-site audits or hire third-party inspectors. This ensures the factory operates under high standards and can meet your production demands.

8. Negotiate Terms: Discuss payment terms, shipping options, and lead times. Ensure all terms are clear and documented to avoid misunderstandings.

9. Verify Logistics: Confirm the factory’s capabilities in managing international shipping. Customs compliance and reliable logistics chains are crucial for timely delivery.

10. Build Relationships: Establishing a strong relationship with the supplier can lead to better communication, preferential pricing, and improved cooperation in the long term.

By following these steps, you can efficiently source a high-quality woodworking CNC router from a reputable Chinese factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.