Choosing SourcifyChina Factory for brass CNC machining offers numerous advantages. Firstly, the factory boasts advanced technology and well-maintained machinery, ensuring precise and high-quality brass components for a range of industrial needs.

Secondly, SourcifyChina emphasizes strict quality control measures. The factory implements rigorous inspection processes to ensure each product meets international standards, thus providing buyers peace of mind regarding the durability and performance of their purchased goods.

Moreover, the factory delivers excellent customer service. Dedicated professionals work closely with buyers to meet their exact specifications and deadlines, guaranteeing satisfaction. This personalized approach fosters long-term relationships with customers.

Finally, competitive pricing distinguishes SourcifyChina from other suppliers. Buyers benefit from high-quality brass CNC machining at cost-effective rates, optimizing their investment while maintaining superior product standards.

In summary, SourcifyChina Factory offers advanced technology, stringent quality control, exemplary customer service, and competitive pricing. These factors make it an ideal choice for buyers seeking reliable brass CNC machining services from China.

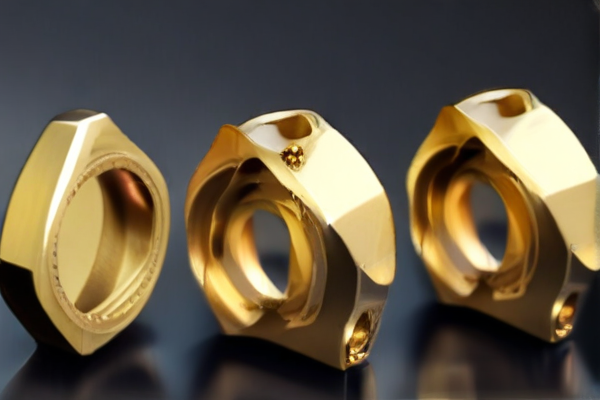

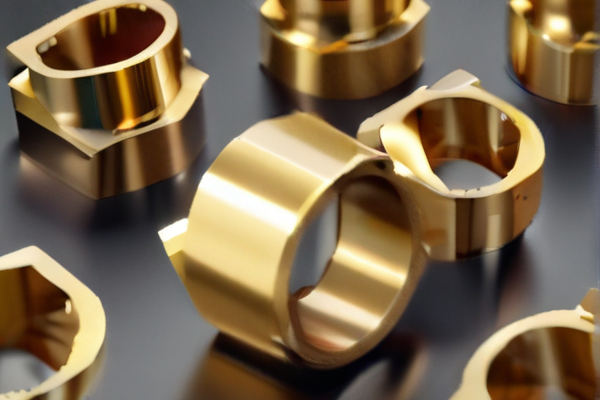

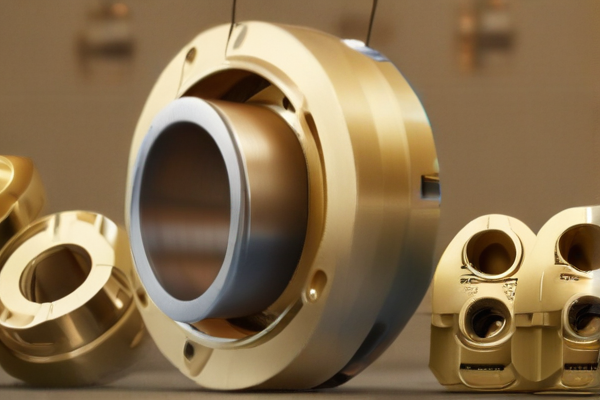

Brass CNC machining involves the precision shaping and cutting of brass materials using computer-controlled machinery, offering excellent machinability and durability. Various methods and options are available to cater to complex part requirements and high-quality finishes.

– Types of Brass:

– C260 (Cartridge Brass): High ductility, used for cases, springs.

– C360: Free-machining brass with excellent cutting properties.

– C385 (Architectural Bronze): Strong, corrosion-resistant.

– Machining Options:

– Turning: Rotates brass stock as a cutting tool shapes the material. Ideal for cylindrical parts.

– Milling: Uses rotary cutters to remove material. Suitable for complex shapes.

– Drilling: Creates precise holes of various diameters and depths.

– Threading: Forms threads on cylindrical components with high precision.

– Reaming: Enlarges holes with high accuracy for a smooth finish.

– Profiling: Cuts outlines on brass materials to create intricate shapes.

– Surface Finishing Options:

– Polishing: Gives a shiny, smooth surface.

– Plating: Adds a thin layer of metals like nickel or chrome for extra protection and aesthetic appeal.

– Sandblasting: Creates a matte texture by blasting abrasive particles.

– Tooling Choices:

– Carbide Tools: High hardness, wear-resistant, ideal for high-speed machining.

– High-Speed Steel (HSS): Tough, suitable for lower-speed cutting with complex geometries.

– Diamond Tools: Extremely hard, used for ultra-precise machining.

– Software and Control Systems:

– CAD/CAM Software: Allows precise design and seamless transformation from digital plans to physical parts.

– G-code Programming: Widely used CNC programming language for controlling cutting and shaping.

– Industries Using Brass CNC Machining:

– Automotive: For various engine components and fittings.

– Aerospace: Offers lightweight, durable parts.

– Electronics: Ensures precise connectors and terminals.

– Medical Devices: Provides sterile, precise components for equipment.

Overall, brass CNC machining is key in producing high-precision parts for diverse applications, leveraging advanced techniques and options for superior outcomes.

Brass CNC machining has diverse applications due to the material’s excellent machinability, corrosion resistance, and electrical conductivity. Industries such as aerospace, automotive, and electronics utilize brass components extensively.

– Aerospace: Precision parts for instruments, connectors, and airframes.

– Automotive: Fuel system components, radiator parts, and electrical connectors.

– Electronics: Connectors, pins, and housings for various devices.

– Medical: Surgical instruments, components for diagnostic devices.

– Plumbing: Valves, fittings, and faucets.

– Musical Instruments: Parts for brass instruments (trumpets, trombones).

– Marine: Corrosion-resistant fittings and connectors.

– Defense: Components for communication devices and weaponry.

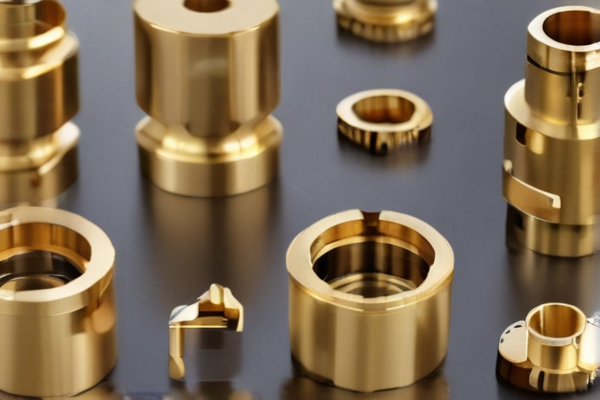

– Industrial Machinery: Bearings, bushings, and gears.

– Consumer Goods: Decorative hardware, zippers.

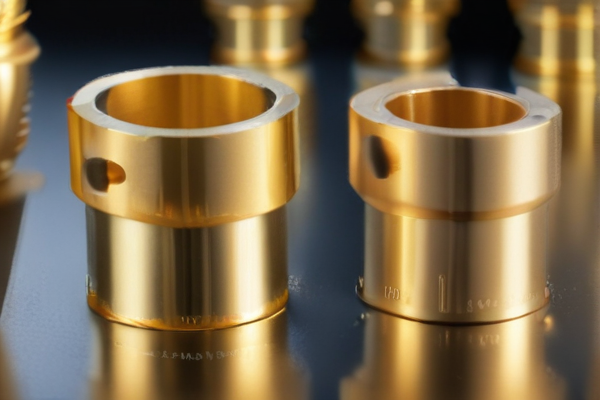

SourcifyChina specializes in brass CNC machining, a leading process in precision manufacturing. Utilizing advanced CNC (Computer Numerical Control) systems, they perfectly craft components with stringent tolerances. Brass, renowned for its excellent machinability and durability, is an ideal material for complex designs and critical applications.

The types of brass used include C36000, known for its exceptional machinability and C28000, which offers superior strength. These allow for efficient production rates and reduced tool wear, essential in large-scale industrial applications. Brass components are widely used in sectors like automotive, electronics, and plumbing due to their excellent properties.

In CNC machining, brass parts receive intricate detailing and finishing. This process ensures products meet tight specifications and high-quality standards. SourcifyChina emphasizes precision, reducing manufacturing errors and ensuring component consistency. Machining brass also has the benefit of generating less heat and wear, which prolongs tool life.

SourcifyChina’s commitment to using advanced technologies and high-quality materials like brass enables them to deliver top-notch CNC machined components. Their expertise ensures reliability and performance, making them a trusted partner in precision manufacturing across various industries.

SourcifyChina excels in brass CNC machining, ensuring top-notch quality control. The journey begins with meticulous raw material selection, sourced from trusted suppliers who provide certified brass alloys.

Precision is a hallmark of their operation. Utilizing state-of-the-art CNC machines, the company achieves high tolerance levels. Strict adherence to design specifications guarantees consistent output.

Inspection protocols are rigorous. Advanced tools such as calipers, micrometers, and coordinate measuring machines (CMM) are employed for dimensional accuracy. Operators are trained for precision measurement techniques.

Throughout the process, real-time monitoring detects deviations. Statistical Process Control (SPC) data is analyzed to maintain optimal performance. Any anomalies trigger immediate corrective actions.

Post-production, each component undergoes a final inspection. Surface finish, dimensional accuracy, and overall integrity are scrutinized. Quality assurance reports are generated for client verification.

Customer feedback is integral. SourcifyChina values client input, refining manufacturing processes based on user experiences. This feedback loop ensures continuous improvement and customer satisfaction. The seamless integration of technology and expertise in their quality control framework underscores their commitment to excellence.

The concerted efforts in sourcing, precision machining, and stringent quality checks create a reliable product lifecycle. Through dedicated quality control processes, SourcifyChina guarantees that every brass CNC machined part meets and exceeds industry standards, fostering long-term trust with clients worldwide.

SourcifyChina offers exceptional brass CNC machining services, ensuring precision and reliability in manufacturing complex components. Their capabilities cover a wide range of product specifications to meet diverse industry needs.

Utilizing state-of-the-art CNC machines, SourcifyChina achieves high accuracy and tight tolerances. Their advanced machinery allows for intricate designs and consistent quality, ideal for demanding applications like aerospace and medical devices.

Additionally, SourcifyChina’s skilled workforce brings extensive experience to each project. This expertise ensures not only technical excellence but also efficient, streamlined processes that reduce lead times and costs without sacrificing quality.

Comprehensive quality control measures are in place at SourcifyChina, guaranteeing that each brass component meets rigorous industry standards. Their commitment to quality assurance ensures customer satisfaction with every order.

Furthermore, SourcifyChina offers customized solutions tailored to specific client requirements. Whether it’s prototyping or mass production, they provide flexibility and adaptability to match project scopes and timelines.

In summary, SourcifyChina’s brass CNC machining capabilities combine advanced technology, skilled craftsmanship, and stringent quality controls. Their comprehensive services deliver precision, reliability, and efficiency, making them a preferred partner for high-quality brass components.

Brass CNC machining offers numerous advantages, making it an essential process for precision engineering and manufacturing industries.

– Excellent Machinability: Brass is easy to machine, allowing for rapid production and high precision in intricate designs.

– High Corrosion Resistance: Brass components exhibit strong resistance to corrosion, ensuring longevity and reliability in various environments.

– Thermal and Electrical Conductivity: Brass has superior thermal and electrical conductivity, making it ideal for applications in electronics and heat exchangers.

– Aesthetic Appeal: Brass components have a visually pleasing finish, suitable for decorative applications without the need for additional coating.

– Strength and Durability: Brass parts are strong and durable, offering excellent performance in demanding applications.

– Cost-Effective: Brass is relatively inexpensive, especially when considering its long lifespan and minimal maintenance requirements.

– Versatility: Brass can be used in a wide range of industries, from automotive to plumbing, due to its adaptable properties.

– Biocidal Properties: Brass has natural antimicrobial properties, making it ideal for medical and sanitary applications where hygiene is crucial.

– Ease of Joining: Brass can be easily soldered or brazed, simplifying the manufacturing process and enabling more complex assemblies.

– Recyclability: Brass is fully recyclable, supporting sustainable manufacturing practices and reducing environmental impact.

Overall, brass CNC machining combines efficiency, durability, and versatility, making it a cost-effective solution for high-quality production across diverse industries.

Brass CNC machining boasts exceptional precision, durability, and corrosion resistance, making it ideal for intricate components in various industries.

– Precision Machining: CNC machines ensure high accuracy with minimal tolerance, essential for tight-fitting assemblies.

– Corrosion Resistance: Brass offers inherent resistance to corrosion, enhancing longevity even in challenging environments.

– Thermal Conductivity: Excellent thermal conductivity makes brass ideal for heat exchangers and radiators.

– Cost-Effective: Brass is relatively inexpensive compared to other metals, offering cost savings without compromising quality.

– Aesthetic Appeal: Brass’s natural luster and color are aesthetically pleasing, often used for decorative parts.

– Malleability and Ductility: Easily shaped and deformed without cracking, allowing for complex geometries.

– Electrical Conductivity: High electrical conductivity makes it suitable for electrical and electronic components.

– Recyclability: Brass is highly recyclable, contributing to environmental sustainability.

These features make brass CNC machining a versatile and popular choice for manufacturing components requiring high precision and durability.

SourcifyChina specializes in brass CNC machining, offering tailored solutions for a wide range of custom products. They leverage advanced machining techniques to produce intricate and high-quality brass components that meet precise specifications. By focusing on cutting-edge technology and meticulous craftsmanship, SourcifyChina delivers superior products for various applications.

Their custom projects include components for industries such as automotive, aerospace, electronics, and plumbing. Each project is approached with a commitment to precision and durability, ensuring the final product adheres to stringent industry standards. SourcifyChina’s expertise in CNC machining allows them to handle complex designs and large-volume orders efficiently.

Customer satisfaction is a top priority at SourcifyChina, and they work closely with clients to understand their specific needs. This collaborative approach ensures that every custom product aligns perfectly with client requirements. From initial design consultation to final delivery, SourcifyChina maintains transparent communication and offers unparalleled support.

In addition to producing high-quality components, SourcifyChina is committed to sustainability and ethical manufacturing. They use state-of-the-art machinery that minimizes waste and energy consumption, and they source brass materials responsibly. This dedication to environmental stewardship distinguishes them as a leader in the CNC machining market.

To conclude, SourcifyChina’s prowess in brass CNC machining, coupled with their dedication to customer satisfaction and sustainable practices, makes them an ideal partner for custom product needs. Their extensive experience and innovative approach ensure that every project is executed with the highest level of precision and quality.

SourcifyChina, a distinguished entity in the realm of precision engineering, specializes in brass CNC machining, catering to an array of industries worldwide. With a steadfast commitment to quality and innovation, the company has established itself as a premier supplier of brass machined components. Leveraging state-of-the-art CNC technology, SourcifyChina deftly navigates complex geometrical specifications and intricate detailing, delivering products that meet stringent international standards. The company prides itself on a robust quality control system, ensuring that each piece not only meets but exceeds client expectations. Additionally, SourcifyChina offers a customized approach, working closely with clients to understand and fulfill their unique requirements. This customer-centric ethos, combined with technical prowess and competitive pricing, solidifies SourcifyChina’s reputation as a reliable partner in the field of brass CNC machining, driving excellence and fostering long-term business relationships globally.

Brass CNC machining finds extensive applications in the aerospace, defense, and marine industries due to the material’s excellent mechanical properties, including corrosion resistance, high conductivity, and ease of machining. In aerospace, brass components are often used in hydraulic systems, fuel systems, and various fixtures because of their ability to withstand extreme temperatures and corrosion from hydraulic fluids. Precision brass CNC machining ensures that these parts meet the stringent tolerances and durability requirements necessary for ensuring the safety and reliability of aircraft. Additionally, the high conductivity of brass makes it ideal for electrical connectors and avionics components, where consistent and reliable performance is critical.

In the defense sector, brass CNC machined parts are vital in the production of ammunition casings, military vehicles, and communication equipment, due to the alloy’s ability to withstand harsh environmental conditions and mechanical stress. Brass’s non-sparking qualities also make it a preferred material in explosive environments. Similarly, in marine applications, brass components are used extensively in watercraft fittings, propellers, and underwater hardware because of their superior resistance to saline corrosion and biofouling. CNC machining of brass in these applications allows for the creation of complex geometries and precise dimensions, which are crucial for maintaining the performance and longevity of marine systems. By leveraging the benefits of brass CNC machining, these industries can produce high-precision, high-performance components that meet their specific operational demands.

Brass CNC machining has become increasingly integral in the automotive industry due to its precision and versatility. Brass, an alloy of copper and zinc, offers exceptional machinability, corrosion resistance, and thermal conductivity, making it ideal for manufacturing intricate automotive components. Components such as fuel systems, transmission parts, and connectors benefit from the precise tolerances achievable through CNC machining. These attributes ensure that brass parts can withstand harsh operating conditions while maintaining optimal performance. Additionally, the aesthetic appeal of brass, with its natural luster and resistance to tarnish, makes it a preferred material for decorative elements and exterior trims in high-end vehicles.

In the realm of electronics, brass CNC machining plays a crucial role in fabricating components that require both electrical conductivity and thermal management. Brass is often used to produce connectors, sockets, and terminal pins, where reliable electrical conductivity is paramount. The precision of CNC machining allows for the creation of intricate designs needed for miniaturized electronic circuits and devices. Furthermore, brass components can efficiently dissipate heat, thus enhancing the performance and longevity of electronic devices. The material’s durability and ability to withstand repeated mechanical and environmental stress also make it suitable for the robust applications seen in consumer electronics, telecommunications, and industrial automation products.

Brass CNC machining finds significant applications in the construction industry due to its durability, corrosion resistance, and aesthetic appeal. In construction, precision-machined brass components are often used for architectural detailing, such as fixtures, fittings, and ornamental features. Brass’s natural resistance to environmental degradation makes it ideal for both outdoor and indoor applications, ensuring longevity and low maintenance requirements. Besides, the precision offered by CNC machining allows for the production of complex geometries and intricate designs that are often required in high-end architectural projects. This ability to maintain tight tolerances ensures that brass components fit perfectly within larger assemblies, enhancing structural integrity and visual appeal. Brass’s antimicrobial properties also make it an attractive option for construction elements that come into frequent human contact, thereby contributing to healthier indoor environments.

In the energy sector, brass CNC machining is indispensable for producing components that require high reliability and precision. Brass is commonly used in the production of connectors, terminals, and fittings in electrical systems due to its excellent conductivity and mechanical stability. These components are essential for reliable power distribution and transmission, especially in renewable energy systems such as wind and solar power. Additionally, the corrosion-resistant nature of brass ensures long-term performance in harsh environments, such as offshore wind farms or solar installations exposed to the elements. CNC machining allows for the fabrication of custom brass parts that can be intricately designed to meet specific requirements, ensuring optimal performance and efficiency. Moreover, brass’s thermal conductivity makes it suitable for heat exchangers and other thermal management systems in energy applications, enabling efficient heat transfer and contributing to the overall energy efficiency of the system.

Brass CNC machining has become an invaluable asset within the industrial equipment industry, owing to its exceptional precision, durability, and efficiency. Brass, an alloy typically composed of copper and zinc, is renowned for its excellent machinability, making it an ideal candidate for CNC (Computer Numerical Control) machining processes. One of the key applications is in the production of intricate components such as gears, valves, and fasteners used in various industrial machinery. The precision offered by CNC machining ensures that these brass components meet stringent specifications and tolerance requirements necessary for the smooth operation of complex industrial equipment. Additionally, brass’s corrosion resistance and low frictional properties enhance the longevity and reliability of the machined parts, which is crucial in demanding industrial environments where equipment is subjected to harsh conditions and continuous operation.

Another significant application of brass CNC machining in the industrial equipment industry is in the manufacture of electrical and electronic components. Brass is an excellent conductor of electricity and heat, making it suitable for producing connectors, terminals, and other critical components within electrical systems. CNC machining enables the creation of highly detailed and accurate parts, essential for ensuring optimal electrical performance and safety. Furthermore, brass’s inherent properties, such as its resistance to tarnish and ease of soldering, contribute to the integrity and functionality of the final products. By leveraging CNC machining technology, manufacturers can achieve high production volumes while maintaining consistency and quality, consequently reducing downtime and maintenance costs for industrial equipment. This integration of brass CNC machining not only bolsters the efficiency and performance of industrial equipment but also supports the advancement of modern manufacturing technologies.

Brass CNC machining has become an indispensable technology in the fabrication of medical devices, given its exceptional precision and reliability. Brass is a favored material in the medical industry for components like fittings, valves, and adaptors, owing to its biocompatibility and resistance to corrosion. The precision achieved through CNC machining is vital for the stringent tolerances required in medical applications. For instance, in surgical instruments and diagnostic equipment, the high accuracy of brass components ensures safety and efficacy, which are critically important in healthcare settings. Moreover, the machinability of brass allows for faster production times without compromising on the quality of the finished products, making it an efficient choice for manufacturers.

Additionally, brass offers significant benefits in terms of antimicrobial properties, which is crucial for maintaining sterile conditions in medical environments. This inherent property of brass helps in reducing the risk of infections, offering an added layer of safety. CNC machining allows for the complex geometries often needed in medical devices, facilitating the creation of intricate designs that might be challenging with other materials. Furthermore, the repeatability of CNC machining ensures consistency across large production runs, essential for medical components that must adhere to rigorous standards. Consequently, brass CNC machining not only meets but often exceeds the demands of modern medical device manufacturing, aligning well with the industry’s ongoing quest for precision, safety, and efficiency.

Brass CNC machining holds a prominent place in the precision manufacturing field due to the advantageous properties of brass. This copper-zinc alloy exhibits excellent machinability, enabling producers to achieve tight tolerances and intricate designs with high efficiency. The material’s low friction and non-ferrous properties make it a popular choice for critical components in industries like automotive, aerospace, consumer electronics, and plumbing. CNC machining allows for automated and highly precise production processes, ensuring consistent quality and reducing human error. Moreover, brass offers significant resistance to corrosion and wear, which extends the lifespan of machined parts and reduces maintenance costs, adding to its desirability in producing complex assemblies and high-performance components.

In practical applications, brass CNC machining is utilized to manufacture a diverse array of products like gears, valves, musical instruments, nuts and bolts, and electrical connectors. Its optimal thermal and electrical conductivity make it especially suitable for electrical and electronic infrastructure. Components like battery terminals, heat exchangers, and RF connectors leverage brass’s superior conductive properties. Moreover, in plumbing, brass fittings and faucets benefit from its strength and anti-corrosive nature, which are critical for longevity and reliability. The advances in CNC technology, including multi-axis machines and sophisticated CAD/CAM software, have further elevated the use of brass in manufacturing by enabling the production of complex geometries and finishing processes that meet stringent industry standards. This integration enhances production capabilities, promoting efficiency and innovation in manufacturing.

Sure! Here’s a concise FAQ section for manufacturing brass CNC machining quality work from SourcifyChina factory:

Q1: What is brass CNC machining?

A: Brass CNC machining involves using computer-controlled machines to shape and detail brass materials into precise components. This process is known for producing high-quality, consistent parts ideal for various applications.

Q2: Why choose SourcifyChina for brass CNC machining?

A: SourcifyChina offers state-of-the-art CNC machinery, experienced engineers, stringent quality control, and competitive pricing. Our expertise ensures top-notch brass components tailored to your specifications.

Q3: What industries do you serve with brass CNC machining?

A: We cater to a wide range of industries including automotive, electronics, plumbing, aerospace, and jewelry, providing custom brass parts that meet specific industry standards.

Q4: What is the minimum order quantity (MOQ) for brass CNC machining at SourcifyChina?

A: The MOQ can vary based on project complexity and requirements, but we generally accommodate both small and large-scale orders to meet client needs.

Q5: How long does it take to complete an order?

A: Lead times depend on the project’s complexity and quantity. Typically, it ranges from a few days to several weeks. We offer expedited services for urgent requests.

Q6: Can SourcifyChina provide design assistance for brass CNC machining projects?

A: Yes, our skilled engineers can assist with design optimization to ensure manufacturability and cost-efficiency while maintaining high quality.

Q7: What quality control measures are in place?

A: SourcifyChina implements comprehensive quality control including material verification, in-process inspections, and final product testing to ensure all parts meet stringent standards.

Q8: Are there any finishing options available for machined brass parts?

A: Yes, we offer various finishes such as polishing, plating, and coating to enhance the aesthetic and functional properties of brass components.

Q9: How can I request a quote for my brass CNC machining project?

A: You can request a quote by contacting our sales team via email or phone with your project details, including specifications, quantities, and any special requirements.

Q10: Do you offer international shipping?

A: Yes, we provide worldwide shipping options to ensure your brass components are delivered to your location promptly and securely.

Opting for brass CNC machining from SourcifyChina Factory can be highly advantageous for your manufacturing needs. Here are some key tips to consider:

1. Material Selection: Brass is known for its excellent machinability, corrosion resistance, and aesthetic appeal. Consult with SourcifyChina to select the best brass alloy suitable for your specific application.

2. Precision Engineering: Take advantage of SourcifyChina’s advanced CNC machining capabilities, which ensure high precision and tight tolerances, crucial for complex and detailed designs.

3. Prototyping Services: Use their rapid prototyping services to validate designs before large-scale production. This can save both time and costs by identifying and rectifying potential issues early.

4. Customization Options: SourcifyChina offers extensive customization, from intricate geometries to surface finishes. Specify your exact requirements to achieve the desired end product.

5. Production Volume: Whether you need a small batch or high-volume production, ensure SourcifyChina aligns with your quantity demands. Their scalable solutions can adapt to your growing needs.

6. Quality Assurance: Leverage their robust quality control systems. Brass CNC parts are subject to meticulous inspection to meet stringent standards, ensuring the highest quality.

7. Cost Efficiency: While brass may be more expensive than other metals, SourcifyChina’s optimized machining processes can help reduce overall manufacturing costs, making it a cost-effective choice.

8. Lead Times: Discuss lead times upfront to align with your project timelines. Effective communication with SourcifyChina can help manage expectations and deliver your parts on schedule.

9. Post-Machining Processes: Inquire about additional services like polishing, coating, and assembly to enhance the functionality and appearance of your brass components.

10. Sustainable Practices: SourcifyChina emphasizes eco-friendly manufacturing. Opt for their sustainable practices to minimize environmental impact.

By considering these tips, you can effectively leverage SourcifyChina’s expertise in brass CNC machining to produce high-quality components tailored to your specific needs.

Sure! Here are some frequently asked questions (FAQ) with answers about sourcing brass CNC machining from SourcifyChina factory:

1. What types of brass CNC machining services does SourcifyChina offer?

SourcifyChina provides a range of brass CNC machining services including milling, turning, drilling, and threading. They offer both prototype and large volume production capabilities.

2. Can I get custom designs made?

Yes, SourcifyChina specializes in custom designs. You can provide your CAD drawings or they can assist with creating designs based on your specifications.

3. What is the lead time for an order?

The lead time typically ranges from 2 to 4 weeks depending on the complexity and volume of the order. For urgent requirements, expedited services may be available.

4. What tolerances can SourcifyChina achieve with brass CNC machining?

SourcifyChina can achieve tight tolerances typically within ±0.01mm. Specific tolerance requirements should be discussed during the quotation process.

5. How do you ensure the quality of the machined parts?

Quality is ensured through rigorous inspections including First Article Inspection (FAI), in-process inspections, and final inspections. SourcifyChina is equipped with advanced measuring equipment like CMM (Coordinate Measuring Machines).

6. What are the payment terms?

The standard payment terms are usually 30% upfront and the remaining 70% prior to shipment. However, terms can be negotiated based on the order details and client relationship.

7. Do you offer surface finishing and heat treatment services?

Yes, SourcifyChina offers various surface finishing options like anodizing, plating, and powder coating, along with heat treatment services to enhance material properties.

8. Can you handle international shipping?

Absolutely! SourcifyChina has experience with international shipping and can handle logistics to get your order delivered worldwide.

9. What information do I need to provide for a quotation?

You will need to provide detailed drawings or CAD files, material specifications, quantity, finish requirements, and any specific inspection standards.

10. Is SourcifyChina certified?

Yes, SourcifyChina is ISO 9001 certified, ensuring they meet international quality management standards.

Sourcing brass CNC machining services from SourcifyChina factory can be streamlined with the right approach. Here are some practical tips:

1. Detail Your Requirements: Clearly specify the dimensions, tolerances, finish, and any other technical details of your brass parts. This ensures SourcifyChina can provide accurate quotes and high-quality products.

2. Material Specifications: Specify the type and grade of brass you require. Different grades have varying properties which can affect the machining and the final application of the parts.

3. RFQ (Request for Quote): Prepare a detailed RFQ including quantities, delivery schedules, and any compliance standards (e.g., ISO, RoHS) necessary for your project.

4. Sample Orders: Start with a small batch order to evaluate the quality, precision, and finish provided by SourcifyChina. This also helps assess their lead times and customer service.

5. Communication: Maintain clear and consistent communication. Use detailed drawings, 3D models, and written specifications when discussing your project.

6. Factory Audits: If possible, visit the factory or request a virtual tour. This helps verify their capabilities, machinery, and quality control processes.

7. Quality Control: Ensure they have robust quality control in place. Ask for inspection reports and quality certificates for raw materials and finished products.

8. Lead Times: Discuss realistic lead times and ensure they align with your project timelines. Factor in time for potential revisions and transportation.

9. Payment Terms: Clarify payment terms upfront and ensure they are favorable and secure. Consider starting with payments via secure methods like PayPal or a Letter of Credit.

10. References and Reviews: Request references from existing clients or check online reviews to gauge the factory’s reputation and reliability.

By following these steps, you can efficiently source high-quality brass CNC machining services from SourcifyChina, ensuring they meet your project’s specifications and timelines.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.