SourcifyChina is a top choice for buyers looking to purchase Brother CNC machines from China because of their reliable supplier network. The company has established strong relationships with leading manufacturers, ensuring high-quality products.

Moreover, SourcifyChina offers expert guidance throughout the purchasing process. Their knowledgeable team assists with everything from initial consultations to final delivery, ensuring a smooth and hassle-free experience for buyers.

One of the standout features of SourcifyChina is their rigorous quality control. They conduct thorough inspections and testing to ensure that every CNC machine meets industry standards and client specifications, providing peace of mind for every purchase.

Additionally, SourcifyChina provides end-to-end logistical support. They handle all aspects of shipping, customs, and documentation, ensuring timely and efficient delivery to any destination. This comprehensive service saves buyers time and effort.

Their competitive pricing is another major advantage. SourcifyChina leverages its strong supplier relationships to negotiate the best prices, passing on significant savings to their clients without compromising on quality.

Furthermore, SourcifyChina is known for its exceptional customer service. They maintain open communication and provide continuous support, addressing any concerns promptly and professionally. This customer-centric approach fosters long-term relationships with clients.

Finally, SourcifyChina prioritizes transparency and integrity in all transactions. They provide detailed quotations and clear terms, ensuring that buyers are fully informed before making any commitments. This builds trust and confidence among their clientele.

By choosing SourcifyChina Factory for purchasing Brother CNC machines, buyers benefit from a seamless, efficient, and cost-effective procurement process. The company’s dedication to quality, customer satisfaction, and logistical excellence makes them a preferred partner for CNC machine acquisitions from China.

Brother CNC machines are known for their precision, reliability, and efficiency, catering to various machining needs. They offer several types and options to meet diverse industrial requirements.

– Speedio Series: High-speed, high-productivity vertical machining centers.

– TC-S2D: Compact, high-speed tapping center.

– M200X3: Multi-tasking machine for complex parts.

– R650X2: High-performance horizontal machining center.

– Drilling and Tapping Centers: Ideal for high-speed, high-accuracy drilling and tapping.

– Options: Automation integration, multiple spindle configurations, advanced control systems.

Brother CNC machines are renowned for their efficiency and precision in manufacturing. They are widely used in industries such as automotive, aerospace, and electronics for milling, drilling, and tapping operations.

– Automotive Industry: Producing engine components, transmission parts, and various metal parts.

– Aerospace Industry: Manufacturing intricate aircraft parts requiring high precision.

– Electronics: Creating small, complex components like circuit boards and connectors.

– Medical Devices: Crafting precision instruments and implants.

– Prototyping: Rapid development and testing of new product designs.

– Mass Production: High-speed production of uniform parts in large quantities.

– Tool and Die Making: Fabricating molds, dies, and other specialized tools.

– General Manufacturing: Versatile use in various manufacturing processes due to their adaptability.

– Education and Training: Used in technical schools and training centers for hands-on learning.

Brother CNC machines are essential tools in many sectors, ensuring high productivity and quality in diverse manufacturing applications.

“SourcifyChina Brother CNC” specializes in advanced CNC machinery, designed for precision and efficiency. The materials used in these machines include high-grade steel and aluminum alloys, ensuring durability and resilience in demanding industrial environments.

The high-grade steel components are treated to resist wear and tear, prolonging the life of the CNC machines. This steel is often alloyed with other metals to enhance its strength and resistance to corrosion.

Aluminum alloys are chosen for parts requiring a balance of lightness and strength. These alloys help reduce the overall weight of the machinery, improving operational speed and efficiency without compromising structural integrity.

Additionally, the electronic components and circuits in SourcifyChina Brother CNC machines are crafted from high-quality materials to ensure consistent performance and reliability. These materials are carefully selected to maintain precision in machining processes.

Together, these materials contribute to the overall excellence of SourcifyChina Brother CNC machines, making them a reliable choice for industries requiring precision machining. This combination of high-grade steel, aluminum alloys, and quality electronics ensures that the machines perform consistently, efficiently, and with minimal maintenance.

SourcifyChina’s Brother CNC quality control manufacturing process is rigorous and comprehensive. Every machine undergoes meticulous inspections to ensure it meets industry standards and customer specifications. Precision is a cornerstone, with each component examined for accuracy.

State-of-the-art technology is utilized throughout the process. Advanced measuring instruments and software are employed to detect even the slightest deviations. This ensures consistency and reliability in every product.

Highly trained personnel oversee each step. From initial design to final assembly, experienced engineers and technicians monitor operations, guaranteeing quality at every stage.

Continuous improvement is prioritized. Feedback loops and regular audits help identify areas for enhancement. This proactive approach ensures that the manufacturing process evolves to meet changing demands.

Customer satisfaction is paramount. By maintaining stringent quality control measures, SourcifyChina ensures that Brother CNC machines deliver optimal performance and longevity, reinforcing their reputation for excellence.

SourcifyChina’s Brother CNC machines are known for their high precision and efficiency. These machines are designed to deliver consistent quality, making them ideal for manufacturing complex components in various industries.

The CNC machines come equipped with advanced technology that ensures accurate cutting, drilling, and milling operations. This capability significantly reduces the time required for production, enhancing overall productivity.

Additionally, Brother CNC machines are user-friendly, with intuitive interfaces that simplify the operation. This ease of use reduces the learning curve for operators, leading to quicker integration into production lines.

Their robust build quality ensures long-term durability and reliability. These machines are engineered to withstand rigorous use, making them a cost-effective investment for businesses.

Moreover, Brother CNC machines offer excellent customization options, allowing manufacturers to tailor the equipment to their specific needs. This flexibility supports a wide range of applications, from small-scale projects to large industrial productions.

With efficient energy consumption, these machines contribute to sustainable manufacturing practices. Their design emphasizes energy efficiency, which helps in reducing operational costs and environmental impact.

In summary, SourcifyChina’s Brother CNC machines combine precision, efficiency, user-friendliness, durability, and customization. These attributes make them a valuable asset for manufacturers aiming to optimize their production processes and achieve high-quality outputs.

Brother CNC machines are renowned for their high precision, reliability, and efficiency, making them a top choice for various machining applications. Their advanced technology and user-friendly features offer significant benefits.

– High Precision: Brother CNC machines ensure consistent, accurate results, essential for high-quality production.

– Speed: These machines offer fast cycle times, increasing productivity and throughput.

– Reliability: Known for durability, Brother CNC machines minimize downtime and maintenance costs.

– User-Friendly Interface: Simplifies operation, reducing training time and operator error.

– Versatility: Suitable for various materials and applications, enhancing manufacturing flexibility.

– Energy Efficiency: Designed to consume less power, reducing operational costs and environmental impact.

– Compact Design: Space-saving, ideal for facilities with limited floor space.

Brother CNC machines are renowned for their high speed, reliability, and precision, making them ideal for various manufacturing applications.

– High Speed: Brother CNC machines offer rapid processing speeds, significantly reducing cycle times.

– Precision: These machines deliver exceptional accuracy, ensuring high-quality outputs.

– Reliability: Known for their robust construction, Brother CNC machines provide consistent performance with minimal downtime.

– User-Friendly Interface: The intuitive control panels make operation straightforward for both novice and experienced users.

– Compact Design: Their space-saving design allows for efficient use of factory floor space.

– Versatility: Suitable for a wide range of materials and complex tasks.

– Advanced Technology: Equipped with the latest innovations, including IoT connectivity and automation capabilities.

– Energy Efficiency: Designed to consume less power while maintaining high performance.

– Easy Maintenance: Simplified maintenance procedures extend machine lifespan and enhance productivity.

SourcifyChina is a leading provider of custom CNC (Computer Numerical Control) products and projects. They specialize in creating bespoke solutions for various industries, ensuring precision and high-quality craftsmanship in every piece they produce.

The company leverages advanced CNC technology to deliver products that meet the exact specifications of their clients. This technology enables them to handle complex designs with ease, ensuring accuracy and consistency across all orders.

Their team of skilled engineers and technicians work closely with clients to understand their unique requirements. This collaborative approach ensures that every project is tailored to the client’s needs, resulting in highly customized and effective solutions.

SourcifyChina’s commitment to quality and innovation sets them apart in the CNC manufacturing industry. They continually invest in the latest technology and training, ensuring they stay at the forefront of the industry.

In addition to their technical expertise, SourcifyChina places a strong emphasis on customer service. They strive to provide a seamless experience from initial consultation to final delivery, ensuring complete customer satisfaction.

Their diverse portfolio includes projects ranging from automotive components to medical devices, demonstrating their versatility and capability to handle a wide range of applications. Each project showcases their dedication to precision and quality.

SourcifyChina’s reputation for excellence has made them a trusted partner for businesses seeking custom CNC solutions. Their commitment to innovation and quality ensures that they can meet the evolving needs of their clients, providing products and services that exceed expectations.

SourcifyChina Brother CNC is a prominent player in the machining and manufacturing industry, renowned for its innovative and high-quality CNC (Computer Numerical Control) machine solutions. Located within the competitive manufacturing hub of China, the company has built a reputation for excellence in producing robust and precision-oriented CNC machinery that serves a diverse range of industries, including automotive, aerospace, electronics, and more. SourcifyChina Brother CNC focuses on integrating advanced technology and meticulous engineering processes to ensure their machines meet the dynamic demands of their global clientele. By combining cutting-edge technology with unparalleled customer service, the company has successfully distinguished itself in a crowded market, fostering strong, long-term relationships with clients worldwide. Their commitment to delivering superior performance and reliability has made them a preferred choice for businesses seeking cost-effective and efficient CNC solutions.

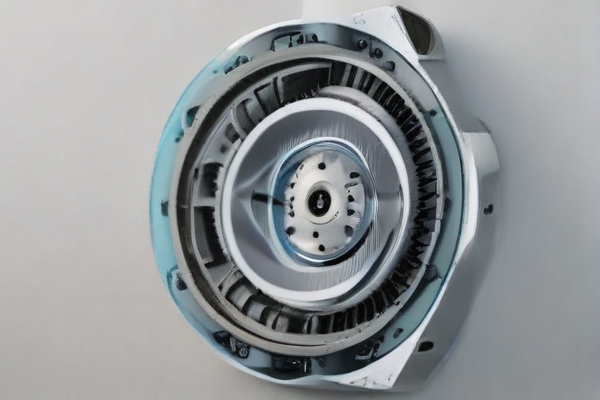

Brother CNC machines are fundamental in the Aerospace, Defense, and Marine industries due to their exceptional precision and reliability. In aerospace, these machines are often employed for producing high-tolerance components such as turbine blades, structural airframe parts, and intricate engine components. The demands for lightweight yet durable materials are high, making CNC machining with materials like titanium, Inconel, and aluminum a necessity. Brother CNC’s high-speed, high-accuracy machining capabilities enable the creation of complex geometries with consistent quality, which is crucial for parts that must withstand extreme conditions and rigorous certification standards.

In the realm of Defense and Marine applications, Brother CNC machines are equally vital. Defense industries rely on these machines for the manufacture of critical components such as missile guidance systems, firearms, and armored vehicle parts. The need for tight tolerances and robust materials, often under stringent regulatory guidelines, is paramount. Marine applications also benefit significantly from Brother CNC technology, which is used in the production of propulsion systems, sub-sea exploration equipment, and structural hull components. The harsh aquatic environment demands materials and assemblies that can endure corrosion, pressure, and constant wear, all of which Brother CNC machines can achieve with high precision and repeatability. This versatility and dependability make Brother CNC an integral asset across these demanding industries.

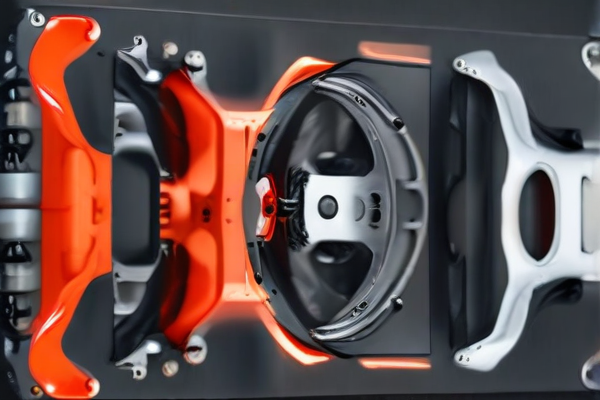

Brother CNC (Computer Numerical Control) machines have carved a significant niche in the automotive industry due to their precision, speed, and reliability. These advanced machining centers are instrumental in manufacturing various automotive components, from engine parts to intricate transmission systems. The ability of Brother CNC machines to perform high-speed, high-accuracy machining translates into consistent production quality, which is crucial for maintaining the stringent standards of the automotive sector. Moreover, their versatility allows for the creation of both large-scale and small, detailed components, offering manufacturers the flexibility to produce a wide range of parts on a single platform. This adaptability not only enhances production efficiency but also helps in reducing downtime and operational costs, making Brother CNC machines a valuable asset in the competitive automotive landscape.

In the realm of electronics, Brother CNC machines are equally indispensable. The electronics industry demands components with extremely tight tolerances and immaculate surface finishes, which Brother’s high-precision CNC machines are adept at delivering. They are often employed in the production of circuit boards, semiconductor components, and intricate housings for electronic devices. The machines’ capability to execute precise drilling, milling, and engraving functions is particularly beneficial in creating the complex geometries and fine details required in modern electronic devices. Additionally, Brother’s emphasis on automation and integration with Industry 4.0 technologies allows for seamless monitoring and control of the manufacturing process, thereby ensuring consistent quality and enhancing productivity. This integration is vital for the fast-paced electronics sector, where time-to-market and reliability are critical factors for success.

Brother CNC machines are revolutionizing the construction industry by offering unparalleled precision and efficiency in fabricating essential components. These high-performance machining centers are instrumental in producing intricate architectural details, such as custom metal frames, brackets, and structural supports that are often required in modern construction projects. The versatility of Brother CNC systems allows for the cutting, drilling, and milling of various materials, including steel, aluminum, and composite materials, with remarkable accuracy. This precision is crucial for ensuring that every component fits seamlessly into place, reducing the time and labor required for on-site adjustments. Consequently, contractors can achieve faster project turnaround times and enhanced overall quality, benefiting both construction firms and their clients.

In the energy sector, Brother CNC machines play a critical role in the manufacture of components for renewable energy systems, such as wind turbines and solar panel assemblies. These machines enable the production of complex parts with tight tolerances, crucial for the efficiency and reliability of energy conversion systems. For instance, the production of gearboxes, rotor hubs, and other critical components for wind turbines requires meticulous machining, which Brother CNC machines can deliver. Additionally, the machines’ ability to handle diverse materials ensures that parts optimized for durability and performance can be manufactured efficiently. Precision in the creation of these components not only enhances energy production efficiency but also contributes to the longevity and maintenance ease of renewable energy infrastructures. This intersection of advanced manufacturing and sustainable energy technologies exemplifies how Brother CNC machines are driving forward innovation in both construction and energy applications.

The industrial equipment industry has witnessed a transformative shift with the integration of Brother CNC (Computer Numerical Control) machines, known for their precision, efficiency, and reliability. Brother’s high-performance CNC machining centers are particularly favored for their compact designs, which offer significant space savings on the factory floor without compromising on operational performance. These machines excel in a multitude of applications, including metalworking tasks such as milling, drilling, and tapping. The automotive and aerospace sectors, for instance, benefit greatly from Brother CNC’s ability to produce high-precision components within tight tolerances, thereby ensuring that the end products meet rigorous industry standards. Additionally, the user-friendly interface and advanced software allow for seamless programming and reduced setup times, enabling manufacturers to achieve greater productivity and throughput.

In the realm of industrial manufacturing, Brother CNC machines bring enhanced flexibility and versatility to production lines. Their ability to quickly switch between different tasks makes them ideal for small to medium batch production runs, where changeovers need to be swift to meet dynamic market demands. Advanced features such as automatic tool changers and superior spindle speed control further enhance operational efficiency. Moreover, Brother CNC’s robust construction and use of high-quality materials ensure long-term durability and minimal maintenance, reducing downtime and operational costs. The machines’ capability to integrate with Industry 4.0 technologies means they can be easily incorporated into smart factory environments, enabling real-time data monitoring and predictive maintenance. Consequently, the application of Brother CNC in the industrial equipment sector not only boosts productivity but also helps in maintaining a competitive edge through innovative manufacturing solutions.

Brother CNC (Computer Numerical Control) machines are integral to the manufacturing of medical devices due to their precision, reliability, and efficiency. These machines, known for their compact size and high-speed performance, are adept at producing intricate components required in medical instruments and implants. For instance, Brother CNC machines can fabricate parts for surgical tools, diagnostic equipment, and orthopedic implants with exacting tolerances, ensuring the high standards of quality and safety essential in the medical field. The advanced capabilities of Brother CNCs, such as multi-axis machining and high-speed drilling and tapping, allow manufacturers to meet the stringent regulatory requirements and complex geometries often demanded by medical device designs.

Moreover, Brother CNC machines contribute significantly to reducing production times and costs, which is crucial in the highly competitive medical device market. Their user-friendly interfaces and automation options enhance productivity and minimize the risk of human error, leading to consistent and repeatable results. This reliability is paramount in medical device manufacturing, where precision can be a matter of life and death. By leveraging the versatility of Brother CNC machines, manufacturers can rapidly prototype new devices and scale up production efficiently, accelerating the time-to-market for innovative medical solutions. In summary, Brother CNC machines play a pivotal role in the medical devices industry by enabling the production of high-quality, precise, and cost-effective components.

Brother CNC machines are renowned for their high-speed, precision machining capabilities, making them ideal for a wide range of manufacturing applications. These machines excel in complex tasks, such as milling, drilling, and tapping, which are essential in industries like automotive, aerospace, medical devices, and electronics. Brother’s advanced control systems and innovative design features ensure minimal setup times and high repeatability, which boosts productivity and reduces operational costs. Additionally, their compact footprint allows for efficient use of floor space, making them a preferred choice for small to medium-sized enterprises that require versatile and reliable CNC solutions.

In manufacturing, Brother CNC machines are leveraged for their ability to handle intricate part geometries and tight tolerances. Their robust construction and high-speed spindle options enable efficient processing of various materials, including metals and plastics. Manufacturers benefit from the machines’ user-friendly interface and comprehensive support for automation, which facilitates seamless integration into smart factory environments. Brother’s CNC technology also supports lean manufacturing principles by minimizing waste and enhancing workflow efficiency. As a result, companies can achieve higher quality outputs and faster turnaround times, which are critical in maintaining competitive advantage in the global market.

Certainly! Here is a concise FAQ list for manufacturing “brother CNC quality work from SourcifyChina factory.”

—

Q: What types of CNC machines does SourcifyChina specialize in?

A: SourcifyChina specializes in Brother CNC machines known for high precision and efficiency, ideal for various manufacturing needs.

Q: How can I ensure the quality of the CNC work?

A: SourcifyChina uses advanced quality assurance processes, including rigorous testing and inspection protocols, to guarantee superior quality.

Q: What materials can SourcifyChina process with Brother CNC machines?

A: SourcifyChina can process a wide range of materials including aluminum, steel, brass, and plastics, ensuring versatility for different projects.

Q: How experienced is SourcifyChina in CNC manufacturing?

A: SourcifyChina has over a decade of experience in CNC manufacturing, backed by a team of skilled technicians and engineers.

Q: What is the typical turnaround time for CNC projects?

A: Typical turnaround time varies based on project complexity, but SourcifyChina aims for efficient lead times without compromising quality, often delivering within 2-4 weeks.

Q: Can SourcifyChina handle custom CNC projects?

A: Yes, SourcifyChina excels in custom CNC projects, providing tailored solutions to meet specific client requirements.

Q: How can I get a quote for my CNC project?

A: You can get a quote by contacting SourcifyChina directly via their website, providing details such as project specifications, materials, and quantity.

Q: Does SourcifyChina offer support throughout the manufacturing process?

A: Yes, SourcifyChina offers comprehensive support, from initial consultation to final delivery, ensuring client satisfaction at every step.

Q: What are the payment terms for CNC services at SourcifyChina?

A: Payment terms are flexible and can be discussed directly with the sales team, often including options for deposits and balance payments upon completion.

Q: Is SourcifyChina ISO certified?

A: Yes, SourcifyChina is ISO certified, ensuring adherence to international quality management standards.

—

This FAQ list should help prospective clients understand the capabilities and advantages of choosing SourcifyChina for their Brother CNC quality work needs.

When considering Brother CNC manufacturing from SourcifyChina factory, there are several key tips to ensure a smooth and successful experience:

1. Research Credentials: Verify SourcifyChina’s certification and manufacturing standards. A reputable factory should meet ISO standards, ensuring high-quality and reliable CNC machining services.

2. Clear Communication: Maintain consistent communication with the factory team. Clearly outline your project specifications, timelines, and any specific requirements for the Brother CNC machines.

3. Prototype First: Start with a prototype to assess the factory’s capabilities and the quality of the CNC machining. This step allows for necessary adjustments before committing to large-scale production.

4. Material Selection: Ensure that the factory offers the appropriate materials for your project. Brother CNC machines are versatile and can handle various materials, but the selection must match your product requirements.

5. Lead Times: Discuss and agree on realistic lead times. CNC manufacturing can have variable lead times based on complexity, and SourcifyChina should provide a clear timeline to avoid delays.

6. Quality Assurance: Ask about their quality control processes. SourcifyChina should have stringent QA measures in place to detect and correct any defects early in the production process.

7. Cost Transparency: Request detailed quotes, breaking down costs for materials, labor, and any additional services. This transparency helps in budgeting and avoiding hidden charges.

8. Customization and Flexibility: Ensure the factory can accommodate custom requests and changes mid-project. The flexibility of Brother CNCs can be fully utilized this way.

9. Feedback Loop: Establish a feedback loop for continuous improvement. Post-production reviews can help iron out any issues for future orders.

10. Visit if Possible: If feasible, visit the SourcifyChina factory. Observing operations firsthand can provide deeper insights into their CNC manufacturing processes and capabilities.

By following these tips, you can leverage the expertise of SourcifyChina to achieve high-quality results with Brother CNC machining.

Sure, here are the FAQs with answers regarding sourcing “Brother CNC from SourcifyChina factory”:

1. What is SourcifyChina and how can it help me source Brother CNC machines?

SourcifyChina is a leading sourcing platform that connects businesses with reliable manufacturers in China. They help streamline the process of finding and purchasing Brother CNC machines, ensuring quality, cost-efficiency, and timely delivery.

2. Why should I source Brother CNC machines from SourcifyChina factory?

SourcifyChina offers access to verified and reputable factories that produce Brother CNC machines. This ensures you get authentic products at competitive prices, along with quality assurance and reliable after-sales support.

3. How do I start the process of sourcing Brother CNC machines from SourcifyChina?

You can start by visiting the SourcifyChina website and submitting a detailed inquiry form. Include specifics such as the model, quantity, and any customization needs. SourcifyChina’s team will then connect you with suitable factories.

4. What types of Brother CNC machines can I source from SourcifyChina?

SourcifyChina can help you source a variety of Brother CNC machines, including machining centers, tapping centers, and other specialized CNC equipment tailored to your industry requirements.

5. How does SourcifyChina ensure the quality of the Brother CNC machines sourced?

SourcifyChina employs a rigorous vetting process for its partner factories, including on-site inspections, quality control checks, and compliance with international standards. They also provide third-party inspection services to ensure product quality before shipment.

6. What are the payment terms and methods accepted by SourcifyChina for sourcing Brother CNC machines?

SourcifyChina accepts various payment methods, including bank transfers, letters of credit, and online payment platforms. Payment terms typically include a deposit upon order confirmation and the balance before shipment.

7. How long does it take to receive Brother CNC machines after placing an order with SourcifyChina?

The delivery time depends on the order complexity and quantity. Generally, it takes between 4 to 12 weeks from order confirmation to delivery, including production and shipping time.

8. Can SourcifyChina provide after-sales service and support for Brother CNC machines?

Yes, SourcifyChina offers comprehensive after-sales service, including installation guidance, maintenance support, and troubleshooting assistance to ensure smooth operation of your Brother CNC machines.

9. What if I encounter issues with the Brother CNC machines sourced from SourcifyChina?

SourcifyChina provides a clear return and warranty policy. In case of any issues, their customer service team will assist in resolving the problem, including repairs, replacements, or refunds as per the agreed terms.

10. How can I contact SourcifyChina for more information on sourcing Brother CNC machines?

You can contact SourcifyChina through their website’s contact form, email, or phone. Their customer service team is available to answer any queries and provide detailed information about the sourcing process.

Sourcing a Brother CNC machine from SourcifyChina can be a streamlined process if approached methodically. Here are some tips to help you:

1. Research Thoroughly: Begin by understanding your specific requirements for the CNC machine. This includes the model, size, tolerance levels, and any other critical specifications.

2. Verify the Supplier: On SourcifyChina, check for supplier credibility. Look at their ratings, reviews, and transaction history. Ensure they have experience with CNC machines, specifically Brother brand.

3. Request a Quote: Contact multiple suppliers to request quotes, making sure to provide detailed specifications. This will help you compare prices and services.

4. Inspect Certifications: Ensure the supplier has the necessary certifications like ISO, CE, or any other relevant industry standards. This adds a layer of credibility and assurance regarding the quality of the machines.

5. Sample Testing: If possible, ask for a sample or a demonstration of the CNC machine. This helps in assessing the machine’s performance before making a large investment.

6. Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and warranty conditions. It’s crucial to get the best deal while ensuring secure payment methods.

7. Use Escrow: When finalizing the deal, consider using an escrow service to protect your payment until the goods are received and verified.

8. Logistics Planning: Discuss logistics with the supplier. Determine the most efficient and cost-effective shipping method and clarify who will handle customs and duties.

9. After-Sales Support: Ensure the supplier offers reliable after-sales support and maintenance services. Knowing you have technical support available can be crucial.

10. Legal Compliance: Ensure that all documentation is in order to comply with import regulations in your country. This can help avoid delays and additional costs.

By following these steps, you can improve your chances of successfully sourcing a Brother CNC machine from a credible supplier via SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.