Reliable SourcifyChina Factory Budget CNC Machine for Cost-Effective Precision Manufacturing

Discover how SourcifyChina’s budget-friendly CNC machines from reliable factories can enhance your manufacturing process with precision and efficiency, all while staying within your budget.

SourcifyChina Factory stands out for its reputation in delivering high-quality CNC machines tailored to specific needs. With years of experience in manufacturing and exporting, their expertise ensures reliable machinery that meets global standards.

Their commitment to innovation ensures each CNC machine is equipped with the latest technology. Buyers benefit from superior performance, precision, and longevity, maximizing their investment and operational efficiency.

Customer support is a critical advantage at SourcifyChina Factory. From initial consultation to after-sale service, the dedicated team assists seamlessly, ensuring buyers make informed choices and maintain productivity.

Additionally, SourcifyChina Factory offers competitive pricing without compromising on quality. Their cost-effective solutions align with varied budgets, providing exceptional value for money in the long term.

Complete transparency and ethical practices set SourcifyChina Factory apart. Buyers can trust in their procurement process, which guarantees authenticity, compliance, and timely delivery, fostering a trustworthy and dependable partnership.

Budget CNC machines, designed to meet hobbyist needs and small-scale projects, come in various types and configurations. Popular options include CNC routers, laser cutters, and 3D printers. These machines vary in capability, size, and cost, but they offer affordable entry points for precision manufacturing.

Types and Options:

– CNC Routers:

– Shapeoko 4: Known for its robust build and capability to handle wood, plastic, and aluminum.

– X-Carve: Offers versatility and ease of use, suitable for intricate designs.

– Sainsmart Genmitsu: Compact and affordable, ideal for smaller projects and beginners.

– Laser Cutters:

– Ortur Laser Master 2: Provides a budget-friendly solution for engraving and cutting with high precision.

– K40 Laser Cutter: Versatile and cost-effective, great for wood, acrylic, and more.

– Neje Master 2: Compact and perfect for detailed engraving on a variety of materials.

– 3D Printers:

– Creality Ender 3: Popular for its affordability, reliability, and large community support.

– Anycubic i3 Mega: Offers a solid build with good print quality at a low cost.

– Elegoo Mars: Known for high-resolution resin printing at a budget price.

– Other Considerations:

– Software Compatibility: Ensure the machine is compatible with user-friendly software (e.g., Easel, Fusion 360).

– Build Quality: Look for machines with durable frames and precise components.

– Customer Support: Opt for brands that offer robust customer service and online community support.

– Upgradeability: Consider machines that provide options for future upgrades to enhance performance.

In summary, budget CNC machines, including routers, laser cutters, and 3D printers, offer myriad choices for hobbyists and small-scale users. Selecting the right machine involves considering factors such as material capability, ease of use, and potential for upgrades.

Budget CNC machines have become popular tools for hobbyists, small businesses, and educational institutions, offering affordable precision for various applications. These machines can significantly enhance productivity and creativity without the hefty price tag of industrial-grade equipment.

Applications for budget CNC machines:

– Prototyping: Create cost-effective prototypes for product design and development.

– Hobby Projects: Craft custom parts and art pieces for personal use or small-scale sales.

– Sign Making: Produce professional-grade signs for businesses, events, and home decor.

– Jewelry Making: Design intricate jewelry pieces with high precision and detail.

– Education: Teach engineering, design, and manufacturing concepts in schools and training centers.

– DIY Home Improvements: Fabricate custom home fixtures, furniture, and fittings.

– Small Batch Production: Manufacture small runs of products for niche markets.

– Model Making: Craft detailed models for architecture, gaming, and prototyping.

– Engraving: Personalize items such as trophies, gifts, and tools.

– Custom Parts: Produce specific components for repair or specialized equipment.

– Textile Industry: Cut patterns and designs on various textiles for fashion and upholstery.

– Electronics: Mill printed circuit boards (PCBs) and custom enclosures.

– Art Installations: Create intricate art pieces or installations for galleries and public spaces.

– Automotive: Fabricate custom car parts, modifications, and accessories.

– Woodworking: Carve detailed woodwork for cabinets, decorations, and instruments.

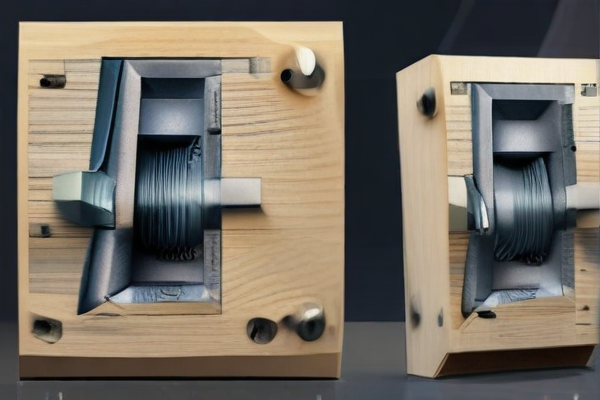

– Rapid Tooling: Develop molds and dies for casting or injection molding processes.

– Toy Making: Design and produce custom toys and educational tools.

– Gifts and Souvenirs: Craft personalized keepsakes and promotional products.

– Laser Cutting: Integrate laser cutting capabilities for more versatile material processing.

– 3D Carving: Sculpt intricate 3D pieces from various materials with high precision.

These versatile applications make budget CNC machines an invaluable asset across multiple fields, enabling innovation and creativity while maintaining cost-efficiency.

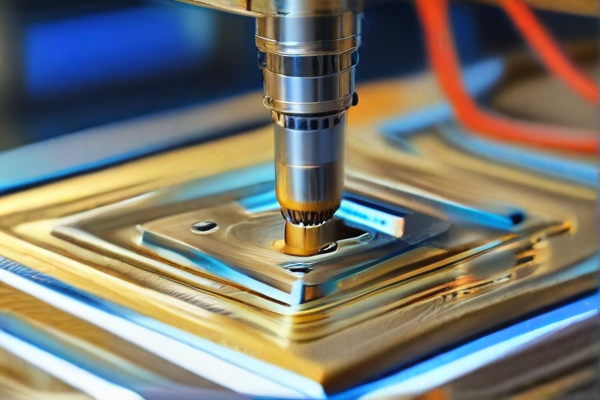

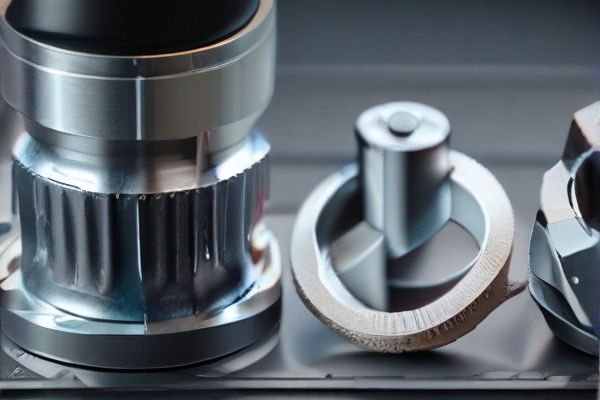

The “SourcifyChina budget CNC machine” is renowned for its high-quality materials that ensure durability and precision. The primary material used in the frame is high-grade aluminum alloy, which is lightweight yet robust. This material provides structural integrity and minimizes vibrations during operation.

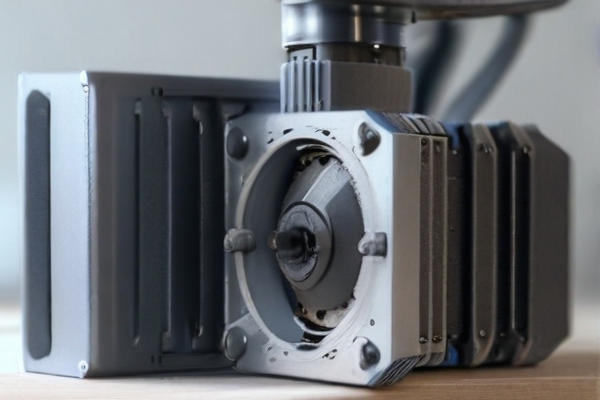

The spindle of the CNC machine is typically made from hardened steel, enhancing its resistance to wear and tear. This feature is essential for maintaining accuracy over prolonged periods of usage, especially in industrial settings.

Another pivotal component is the linear guides, crafted from hardened stainless steel. These guides facilitate smooth and precise movements, ensuring consistency in cutting and engraving tasks. They are corrosion-resistant, which increases the machine’s lifespan.

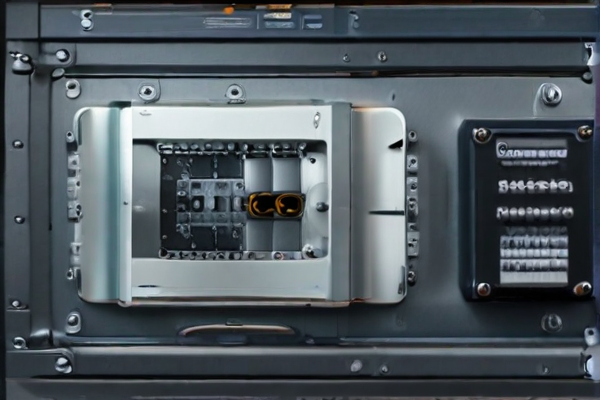

The control system of the machine is housed in a reinforced plastic casing, specifically designed to withstand environmental factors like dust and moisture. This protection ensures that the electronic components within the system are safeguarded.

Finally, the cutting tools, commonly made from tungsten carbide, provide exceptional sharpness and longevity. This material enables the machine to work efficiently on a variety of substrates, including metals, plastics, and wood.

In conclusion, the SourcifyChina budget CNC machine combines high-quality materials such as aluminum alloy, hardened steel, stainless steel, reinforced plastic, and tungsten carbide. These materials collectively enhance the machine’s durability, precision, and operational longevity, making it a smart investment for both hobbyists and professionals.

SourcifyChina’s budget CNC machines undergo a rigorous quality control process to ensure reliability. Each machine starts with high-quality raw materials, carefully selected to meet strict standards.

During assembly, skilled technicians meticulously construct the machines, ensuring precision in every component. Each step is monitored to maintain adherence to specifications.

Post-assembly, the CNC machines undergo comprehensive testing. Functional tests are performed to verify accuracy and performance under various operating conditions, ensuring each unit meets the desired criteria.

Final inspections are thorough, checking for any defects or inconsistencies. This meticulous process guarantees that every CNC machine from SourcifyChina delivers consistent quality and dependable performance for end-users.

The SourcifyChina budget CNC machine offers remarkable precision at an affordable price. It provides cutting-edge capabilities for small to medium-sized projects, making it an excellent choice for hobbyists and small businesses.

Designed for versatility, this CNC machine can handle a variety of materials, including wood, plastic, and soft metals. Its adaptability makes it suitable for tasks ranging from simple cuts to intricate engravings.

Another key feature is its user-friendly interface. Even those new to CNC machining will find it easy to navigate and operate, thanks to its intuitive design and detailed instruction manual.

Durability is also a strong point. Constructed with high-quality components, the SourcifyChina CNC machine promises long-lasting performance. This ensures reliability and reduces the need for frequent maintenance.

In addition, the machine is compatible with various design software, enabling users to upload and execute their plans seamlessly. This flexibility boosts productivity and expands creative possibilities.

Moreover, its compact design allows for installation in limited spaces without compromising performance. This makes it an ideal solution for small workshops and home studios.

Lastly, customer support from SourcifyChina stands out. The company provides comprehensive assistance, including troubleshooting guides and responsive helplines, ensuring users get the most out of their CNC machine.

In conclusion, the SourcifyChina budget CNC machine combines affordability, versatility, and ease of use. It is a reliable choice that meets the needs of hobbyists and small enterprises alike, offering professional-grade capabilities without breaking the bank.

A budget CNC machine offers a range of benefits, making it an attractive option for hobbyists and small businesses alike. These machines deliver precision, cost-efficiency, and flexibility in various applications.

– Cost-Effective: Affordable for small businesses and hobbyists, reducing initial investment costs.

– Precision: Provides accurate and consistent cuts, ensuring high-quality outputs.

– Ease of Use: Many budget CNC machines come with user-friendly interfaces and software.

– Versatility: Capable of handling multiple materials like wood, plastic, and soft metals.

– Compact Size: Generally smaller in footprint, ideal for limited workspace.

– Learning Tool: Great for beginners looking to learn CNC machining without a hefty investment.

– Customization: Easily upgradeable components, allowing for enhanced capabilities as needed.

– Low Maintenance: Generally require minimal upkeep, reducing ongoing costs.

– Reduced Waste: High precision leads to less material waste, contributing to sustainable practices.

– Enhanced Productivity: Speeds up production times, allowing for quicker project completions.

– Accessibility: Opens up advanced manufacturing techniques to a wider audience beyond industrial users.

– Support and Community: Often come with robust online support communities, offering resources and troubleshooting assistance.

Investing in a budget CNC machine can significantly boost productivity, enable precision craftsmanship, and provide a stepping stone for future growth in manufacturing capabilities. These machines democratize access to sophisticated technology, making advanced manufacturing accessible to all.

Budget CNC machines offer an affordable entry point for hobbyists and small businesses interested in precision machining and fabrication. They balance cost with essential features to deliver quality performance on a tight budget.

– Affordability: Typically priced lower than professional-grade options, making them accessible to hobbyists and small workshops.

– Compact Size: Space-efficient designs that fit comfortably in smaller workspaces.

– User-Friendly Interfaces: Often come with software that is easy to navigate, suitable for beginners.

– Basic Materials Compatibility: Can handle common materials like wood, plastics, and soft metals.

– Lower Power Requirements: Usually designed to operate on standard electrical outlets, reducing the need for specialized power sources.

– Upgradeable Parts: Some models offer the ability to upgrade motors, spindles, and other components as needs grow.

– Precision and Accuracy: While not as precise as high-end models, they offer acceptable tolerance levels for detailed projects.

– Versatility: Capable of performing various tasks such as cutting, engraving, and milling.

– Open-Source Options: Some budget CNC machines have open-source software and hardware, providing customization opportunities.

– Community Support: Strong online communities for troubleshooting, tutorials, and project ideas.

– Portability: Lightweight models are available that can be easily moved or transported.

– Customer Support: Many manufacturers offer decent customer service and technical support, even at a lower price point.

– Safety Features: Basic safety mechanisms like emergency stop buttons and protective covers are commonly included.

– Learning Resources: Extensive documentation and online tutorials to help beginners get started quickly.

Overall, budget CNC machines provide a functional and cost-effective solution for those looking to delve into CNC machining without significant financial investment.

SourcifyChina offers budget CNC machines that deliver reliable performance for various custom product needs. These affordable machines enable businesses to produce high-quality components without exceeding their budgets.

Utilizing SourcifyChina’s CNC machines, companies can create intricate designs and precise cuts for custom projects. This technology ensures consistent quality, reducing the risk of errors and improving overall efficiency.

SourcifyChina’s solutions are suited for small and medium-sized enterprises needing cost-effective manufacturing. The budget-friendly machines don’t compromise on performance, allowing businesses to achieve superior results using cutting-edge technology.

Customer support from SourcifyChina is exceptional, providing guidance and solutions tailored to specific manufacturing needs. Their expertise ensures clients maximize the potential of their CNC machines.

Choosing SourcifyChina means opting for a blend of affordability and precision. Their budget CNC machines are a valuable investment, empowering businesses to innovate and deliver high-quality custom products and projects continually.

SourcifyChina is an emerging player in the manufacturing sector, specializing in providing budget-friendly CNC (Computer Numerical Control) machines. Based in China, the company leverages its strategic position within the world’s manufacturing hub to deliver cost-effective yet high-quality CNC solutions to a global market. SourcifyChina’s offerings cater to small and medium-sized enterprises (SMEs) and hobbyists who seek precision machining capabilities without the prohibitive costs typically associated with advanced CNC equipment. Their product range includes a variety of models suitable for different applications, from simple milling and engraving to more complex multi-axis operations. By focusing on affordability, SourcifyChina enables wider access to CNC technology, empowering innovation and efficiency in manufacturing processes across diverse industries. Additionally, the company emphasizes customer support and after-sales service, ensuring that clients receive comprehensive guidance and technical assistance, thereby enhancing the overall user experience. Through their commitment to quality and affordability, SourcifyChina is establishing itself as a reliable partner for businesses looking to optimize their production capabilities.

In the aerospace, defense, and marine sectors, the application of budget CNC (Computer Numerical Control) machines offers significant advantages in terms of cost-effectiveness and operational efficiency. These industries often require complex and precise components that can be time-consuming and expensive to produce using traditional manufacturing methods. Budget CNC machines streamline this process by automating the production of intricate parts, which ensures high accuracy and repeatability. In the aerospace sector, budget CNC machines can be used to manufacture a variety of components, from airframe structures to intricate engine parts, reducing production costs while maintaining rigorous quality standards. Similarly, in defense, these machines allow for the production of critical components for military hardware such as weapons systems, surveillance equipment, and armored vehicles, ensuring that manufacturing processes are both efficient and adaptable to the evolving demands of modern warfare.

In the marine industry, budget CNC machines play a pivotal role in the fabrication of components that are essential for the construction and maintenance of ships, submarines, and other maritime vessels. These machines are capable of producing precision parts such as propellers, engine components, and navigation systems, which are vital for the operational reliability of marine equipment. The reduced cost of budget CNC machining means that smaller companies and startups within the marine sector can also leverage high-quality manufacturing capabilities, fostering innovation and competition. Additionally, the ability to quickly prototype parts using CNC technology accelerates the development cycle, allowing for rapid iteration and refinement of designs, which is particularly beneficial in industries that demand both precision and durability. Overall, the integration of budget CNC machines in aerospace, defense, and marine applications significantly enhances the efficiency, affordability, and quality of manufacturing processes.

Budget CNC machines have revolutionized the automotive industry by making high-precision manufacturing and prototyping accessible to smaller garages and independent designers. Traditionally, CNC machines were prohibitively expensive, limiting their use to large automotive companies with substantial budgets. However, lower-cost models have democratized access to this technology, enabling small-scale builders to fabricate custom parts with exceptional accuracy. This capability is particularly valuable for creating custom engine components, bespoke exterior modifications, and even entire chassis for concept cars. Furthermore, budget CNC machines facilitate rapid prototyping, allowing automotive engineers and hobbyists alike to test and iterate designs at a fraction of the previous cost. The advent of affordable CNC machining has, therefore, contributed significantly to innovation and customization within the automotive sector.

In the realm of electronics, budget CNC machines have similarly democratized the process of fabrication, from creating custom PCB (Printed Circuit Board) designs to unique enclosures for electronic devices. The precision of CNC machines allows for intricate designs and consistent replication, essential for the production of high-quality electronic components. Small-scale electronics entrepreneurs and hobbyists can now develop prototypes and even small production runs in-house, reducing development time and costs associated with outsourcing. Additionally, the ability to produce custom aluminum or plastic enclosures offers enhanced aesthetic and functional possibilities, accommodating unique designs that off-the-shelf options cannot provide. By lowering the entry barrier, budget CNC machines have spurred innovation and creativity, fostering a new wave of electronic innovation and customization well beyond the realm of large corporations.

Budget CNC machines have significantly impacted the construction industry by enabling cost-effective and precise fabrication of various components. These machines allow small to mid-sized construction firms to produce custom parts, such as brackets, fixtures, and moldings, without outsourcing, thus saving time and reducing costs. Additionally, the ability to rapidly prototype and iterate designs directly on-site enhances project flexibility and innovation. The automation and precision of CNC machines ensure that the parts produced are consistent and meet stringent quality standards, which is crucial for maintaining the integrity and safety of construction projects.

In the energy sector, budget CNC machines play a pivotal role in the development and maintenance of renewable energy technologies. For instance, they are used to manufacture components for wind turbines, solar panel mounts, and hydroelectric system parts with high precision and repeatability. This capability is vital for optimizing the performance and reliability of energy systems, which often operate in harsh environments and require durable, high-quality components. Moreover, the cost-efficiency of budget CNC machines allows smaller companies and startups to innovate and compete in the renewable energy market, fostering technological advancements and contributing to the global transition towards sustainable energy sources.

The industrial equipment industry leverages budget CNC (Computer Numerical Control) machines to enhance efficiency and cost-effectiveness in various manufacturing processes. These machines enable businesses, particularly small and medium enterprises, to access automation and precision machining without the prohibitive costs associated with high-end CNC systems. Budget CNC machines are used in the fabrication of components for automotive, aerospace, and consumer electronics industries, allowing manufacturers to produce intricate parts with high accuracy. This contributes to reduced material waste and faster production cycles, significantly improving overall productivity. Additionally, the lower investment threshold offered by budget CNC machines enables more companies to adopt advanced manufacturing technologies, fostering innovation and competitiveness in the industrial sector.

Moreover, budget CNC machines play a pivotal role in prototyping and small-batch production runs. For industries that require rapid development and iteration, such as the robotics and custom machinery sectors, these machines offer a versatile solution. The capability to swiftly create prototypes from digital designs accelerates the product development cycle, allowing companies to bring new products to market more quickly. Furthermore, the ease of programming and user-friendliness of modern budget CNC machines reduce the need for highly specialized operators, democratizing their usage across the workforce. This not only enhances workforce skillsets but also enables manufacturers to maintain flexibility and adaptability in their production lines, which is crucial in responding to ever-evolving market demands.

Budget CNC machines, with their accessibility and cost-effectiveness, are increasingly being adopted in the medical devices sector for rapid prototyping and customized manufacturing. These devices facilitate the creation of intricate components essential for medical instruments and implants with a high degree of precision. For instance, developing orthopedic implants such as joint replacements and dental prosthetics requires exact dimensional accuracy to ensure compatibility with human anatomy. Budget CNC machines offer medical device manufacturers the ability to swiftly iterate design modifications, significantly reducing the time from conception to clinical testing. This capability is vital in producing patient-specific devices tailored to individual anatomical requirements, thereby enhancing the effectiveness and comfort of implants and other medical tools.

Furthermore, the application of budget CNC machines in the medical field extends beyond prototyping to include the production of specialized surgical instruments and components for diagnostic devices. These machines support the development of specialized tools such as precision scalpels, forceps, and intricate parts for endoscopic instruments that must meet stringent hygiene and performance standards. The use of CNC technology allows for the consistent production of these high-quality instruments at a fraction of the cost associated with traditional manufacturing processes. This cost-saving advantage is particularly beneficial for startups and small medical device companies, enabling them to innovate and keep up with technological advancements without the prohibitive expenses typically linked with high-end CNC machinery. Overall, budget CNC machines are revolutionizing the medical device industry by democratizing access to high-precision manufacturing and fostering innovation in patient care solutions.

Budget CNC (Computer Numerical Control) machines serve as a highly valuable asset in the realm of machining and manufacturing due to their versatility and affordability. These machines leverage computer precision to execute complex and intricate cuts, shapes, and engravings on materials like metal, plastic, and wood. For small-scale businesses, hobbyists, or educational purposes, budget CNC machines provide a gateway to high-quality fabrication without the substantial investment typically associated with industrial-grade equipment. Their ability to automate repetitive tasks ensures consistent output while significantly reducing manual labor and the likelihood of human error. Thus, even with limited resources, users can achieve professional-level precision and efficiency, fostering innovation and expanding the scope of what can be crafted.

In manufacturing applications, budget CNC machines enable rapid prototyping and production, accelerating the development cycle of new products. Entrepreneurs and designers can transform their digital blueprints into physical models swiftly, allowing for immediate testing and iterative improvements. This agility is particularly beneficial in custom manufacturing, where tailored solutions are essential. Moreover, with the rise of small-scale and micro-manufacturing enterprises, budget CNC machines offer a feasible solution to meet limited runs and bespoke orders, enhancing the capability to respond dynamically to market demands. By lowering entry barriers, these machines democratize manufacturing, enabling a broader array of individuals and small firms to bring their ideas to fruition with professional-grade quality while maintaining cost-effectiveness.

Sure, here is a list of FAQs for a manufacturing “budget CNC machine quality work from SourcifyChina factory”:

1. What types of CNC machines does SourcifyChina manufacture?

SourcifyChina specializes in a wide range of CNC machines including milling machines, lathes, routers, and plasma cutters designed for both industrial and budget-conscious applications.

2. What materials can I process using your budget CNC machines?

Our budget CNC machines are versatile and capable of processing a variety of materials including wood, plastics, metals, and composites.

3. How do you ensure the quality of your budget CNC machines?

Quality is guaranteed through stringent manufacturing standards, rigorous quality control checks, and state-of-the-art technology. We also provide detailed user manuals and support to ensure optimal performance.

4. What is the typical lead time for manufacturing a custom CNC machine?

Lead times can vary depending on the complexity and features required. Typically, it ranges from 4 to 8 weeks from order confirmation to delivery.

5. Are your budget CNC machines covered by a warranty?

Yes, our budget CNC machines come with a standard one-year warranty that covers parts and labor, alongside lifetime technical support.

6. Do you offer after-sales services and technical support?

We provide comprehensive after-sales support including installation assistance, training, troubleshooting, and maintenance services. Our technical support team is available 24/7.

7. Can I request custom features or modifications?

Absolutely. We offer customization to fit your specific production needs. Please contact our sales team to discuss your requirements and get a tailored quote.

8. What payment methods does SourcifyChina accept?

We accept multiple payment methods such as bank transfers (T/T), Letters of Credit (L/C), and PayPal to facilitate transactions.

9. Is there a minimum order quantity (MOQ)?

While we cater to orders of all sizes, a minimum order quantity may apply depending on the specific product and customization needs.

10. How can I place an order or request a quote?

You can place an order or request a quote through our website, via email, or by contacting our sales team directly. Detailed contact information is available on our official SourcifyChina website.

To efficiently engage in budget CNC machine manufacturing using SourcifyChina’s factory, consider the following tips:

1. Define Requirements:

Clearly outline the specifications and features essential for your CNC machine. Prioritize which aspects you can compromise on without sacrificing quality.

2. Supplier Research:

Leverage SourcifyChina’s platform to identify reliable suppliers. Vet them for production capabilities, experience, and past client feedback.

3. Negotiate Terms:

Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Aim for flexible deals that mitigate financial risk while ensuring quality.

4. Material Selection:

Choose cost-effective, durable materials. Discuss sourcing options with your supplier to balance cost savings and performance.

5. Prototyping:

Request prototypes to test and refine designs before committing to mass production. This helps avoid costly errors.

6. Quality Control:

Implement strict quality control measures. Regularly inspect samples and leverage third-party inspection services if necessary.

7. Scalability:

Plan for future orders and scalability. Ensure the factory can handle increased production volumes without compromising quality or lead times.

8. Communication:

Maintain clear, regular communication with your supplier to avoid misunderstandings and promptly address any issues.

9. Cost Management:

Monitor all expenses closely. Consider bulk orders for essential parts to reduce costs, but avoid overstocking.

10. Utilize Technology:

Use digital tools for project management and real-time tracking of production processes to improve efficiency.

By following these tips, you can enable a smoother, cost-effective manufacturing process for your CNC machines with SourcifyChina’s factory.

Q: What types of budget CNC machines does SourcifyChina offer?

A: SourcifyChina offers a range of budget CNC machines including routers, milling machines, and lathe machines designed for small to mid-scale operations.

Q: How can I get a quotation for a CNC machine from SourcifyChina?

A: You can request a quotation by visiting the SourcifyChina website and filling out the online inquiry form, or by contacting their sales team directly via email or phone.

Q: What is the typical lead time for a CNC machine order?

A: The lead time for a budget CNC machine typically ranges from 2 to 6 weeks, depending on the model and custom specifications.

Q: Does SourcifyChina provide international shipping?

A: Yes, SourcifyChina ships CNC machines internationally. Shipping costs and delivery times may vary depending on the destination.

Q: Are the CNC machines covered by a warranty?

A: Yes, most CNC machines from SourcifyChina come with a 1-year warranty covering parts and service. Extended warranties may also be available.

Q: Can I customize the CNC machine to meet my specific needs?

A: Absolutely, SourcifyChina offers customization options to tailor the CNC machines to your specific requirements.

Q: What after-sales support does SourcifyChina offer?

A: SourcifyChina provides comprehensive after-sales support, including technical assistance, troubleshooting, and access to spare parts.

Q: What payment methods are accepted?

A: SourcifyChina accepts multiple payment methods including bank transfers, credit cards, and PayPal for convenient transactions.

Q: How do I ensure the quality of the CNC machine before purchasing?

A: SourcifyChina conducts rigorous quality control tests on all machines. Additionally, you can request a live demonstration or virtual tour to verify quality.

Q: Is there a minimum order quantity?

A: No, there is no minimum order quantity. Customers can order a single unit or multiple units based on their needs.

Q: How can I track my order once it is shipped?

A: SourcifyChina provides tracking information and regular updates once the CNC machine is shipped to keep you informed on the delivery status.

This concise FAQ should address the primary concerns when sourcing budget CNC machines from SourcifyChina Factory.

Sourcing a budget CNC machine from SourcifyChina factory requires a strategic approach to ensure quality and cost-effectiveness. Here are some tips:

1. Define Requirements: Clearly outline your specifications such as size, material capability, precision, and software compatibility. This will help in communicating effectively with the supplier.

2. Research Suppliers: Use platforms like Alibaba, Made-in-China, or Sourcify to identify potential suppliers. Check their credentials, production capacity, and customer reviews to gauge reliability.

3. Request Quotes: Contact multiple suppliers to get quotes. Provide detailed requirements to ensure accurate pricing. Compare the quotes not just on price but also on included services like shipping, warranties, and after-sales support.

4. Evaluate Quality: Ask for product samples or visit the factory if possible. Check the machine’s build quality, performance, and compliance with international standards. Request videos or virtual demonstrations if an in-person visit is not feasible.

5. Verify Credentials: Ensure the supplier has the necessary certifications and is compliant with industry standards. Check for ISO certification and any other relevant quality management certifications.

6. Negotiate Terms: Discuss payment terms, lead times, and delivery conditions. Aim for a balance between cost and reliability. Secure a deal that includes favorable terms for returns and warranties.

7. Review Contracts: Before finalizing, carefully review the contract for any hidden fees or unfavorable clauses. It’s advisable to have a legal expert go over the contract.

8. Shipping and Logistics: Choose a reliable shipping partner and clarify the Incoterms. Ensure the supplier handles proper packaging to prevent damage during transit.

9. Start Small: If possible, start with a smaller order to test the supplier’s reliability and the product’s quality before committing to a larger purchase.

10. Build Relationship: Maintain good communication and build a relationship with the supplier for future orders. A good relationship can often result in better pricing and priority service.

By following these steps, you can efficiently source a budget CNC machine from SourcifyChina factory while minimizing risks and ensuring quality.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.