“SourcifyChina” Factory is an excellent choice for buyers seeking car parts manufacturers from China because of its extensive network of verified suppliers. This guarantees that buyers receive high-quality products that meet international standards.

The factory prides itself on its stringent quality control measures, ensuring that all car parts undergo rigorous testing before being dispatched. This commitment to quality translates into durable and reliable products for buyers.

Cost-effectiveness is another critical advantage of choosing “SourcifyChina.” By leveraging local resources and streamlined production processes, the factory offers competitive pricing without compromising on quality, providing buyers excellent value for their investment.

Furthermore, “SourcifyChina” Factory provides exceptional customer service, supporting buyers throughout the purchasing process. Their dedicated team is always ready to assist with any concerns, ensuring a smooth and hassle-free experience.

In addition, “SourcifyChina” Factory embraces transparency, maintaining open communication channels with buyers. This transparency fosters trust and ensures that buyers are well-informed about the status and specifications of their orders.

Lastly, the factory’s strategic location in China offers logistical advantages, including reduced shipping times and costs. This allows buyers to receive their orders swiftly, enhancing the overall efficiency of their supply chain.

In summary, “SourcifyChina” Factory is an unparalleled choice for buyers due to its high-quality products, cost-effectiveness, exceptional customer service, transparency, and strategic location. These attributes collectively ensure a reliable and efficient purchasing experience.

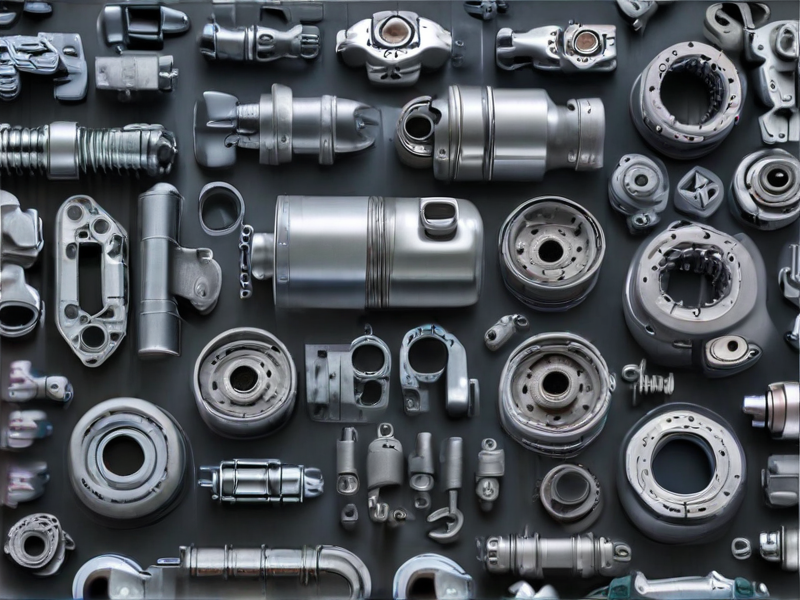

Car parts manufacturers produce diverse components critical for vehicle functionality. From aftermarket parts to OEM, the industry includes companies specializing in different segments to ensure comprehensive vehicle assembly and maintenance.

– OEM (Original Equipment Manufacturer):

– Supplies parts to carmakers for new vehicles.

– Ensures quality and compatibility.

– Aftermarket Producers:

– Creates replacement parts for repairs and upgrades.

– Often more affordable than OEM.

– Tier 1 Suppliers:

– Directly supply major components to automakers.

– Crucial for primary vehicle systems.

– Tier 2 and 3 Suppliers:

– Provide parts and materials to Tier 1 suppliers.

– Specialize in smaller components.

– Performance Part Manufacturers:

– Focus on enhancing vehicle performance.

– Includes high-performance brakes, engines, and suspensions.

– Re-manufacturers:

– Rebuild worn-out parts to like-new condition.

– Eco-friendly and cost-effective.

– Specialty Component Makers:

– Produce niche components, often custom-made.

– Includes luxury and exotic car parts.

Understanding these segments helps in targeted sourcing, ensuring the right parts for repair, performance upgrade, or manufacturing needs.

Car parts manufacturers play a crucial role in the automotive industry by supplying essential components that ensure vehicle functionality and safety. Their applications span several areas including production, customization, and technological advancements.

– Production: Mass production of essential car components including engines, transmissions, brake systems, and electrical systems.

– Customization: Offering bespoke parts for custom vehicles or modifications to standard cars to meet specific customer needs.

– Aftermarket Support: Providing replacement parts that match or enhance original car components for repairs and upgrades.

– OEM Supply: Supplying original equipment manufacturers with parts that meet strict quality and compliance standards for new vehicles.

– Research and Development: Innovating new materials and technologies to improve performance, efficiency, and safety in car parts manufacturing.

– Compliance and Standards: Ensuring that all manufactured parts comply with local and international automotive safety and environmental standards.

– Recycling and Sustainability: Developing sustainable manufacturing processes and materials to reduce environmental impact.

– Inventory Management: Implementing advanced inventory systems to manage stock and supply chains efficiently.

– Quality Assurance: Rigorous testing and quality control processes to ensure the durability and reliability of all manufactured parts.

– Technological Integration: Incorporating cutting-edge technology such as AI, IoT, and robotics to streamline manufacturing processes and enhance product quality.

– Collaboration with Automakers: Partnering with vehicle manufacturers for R&D, design, and testing of new vehicle models.

– Distribution Network: Establishing robust distribution channels to ensure timely delivery of parts to dealers, repair shops, and consumers.

– Consumer Market: Providing easily accessible parts for DIY enthusiasts and small-scale repair shops.

– Training and Skills Development: Offering training programs to ensure employees stay updated on the latest technologies and manufacturing techniques.

Overall, car parts manufacturers are essential for maintaining the automotive ecosystem, facilitating not just the creation and maintenance of vehicles but also driving innovation within the industry.

SourcifyChina collaborates with an extensive network of prime car parts manufacturers. These manufacturers specialize in producing high-grade automotive components, ensuring optimal performance for various vehicle models. Their selection includes everything from engine parts to suspension systems.

Most of the materials used by SourcifyChina’s partners are sourced from premium-grade steel, aluminum, and advanced composites. These materials are known for their durability, strength, and lightweight properties, contributing to the overall efficiency and safety of automotive parts.

Manufacturing processes are carried out under stringent quality control measures. State-of-the-art machinery and technology are employed to ensure each component meets international standards. This attention to quality helps maintain the reliability and longevity of the car parts.

Sustainability is also a key focus for these manufacturers. Many have adopted eco-friendly practices such as recycling materials and using energy-efficient production techniques. This commitment not only helps reduce environmental impact but also appeals to eco-conscious consumers.

Customer satisfaction is paramount for SourcifyChina and its manufacturers. Comprehensive testing and inspection are conducted before parts reach customers, ensuring that only the best components are shipped out. This rigorous approach has garnered trust and reliability within the automotive industry.

In summary, SourcifyChina’s car parts manufacturers excel in providing high-quality, durable, and eco-friendly automotive components. Utilizing superior materials and advanced manufacturing techniques, they ensure each part meets stringent quality standards. Their commitment to both excellence and sustainability makes them a trusted name in the automotive supply chain.

SourcifyChina car parts manufacturers implement stringent quality control measures to ensure the highest standards. Each component undergoes meticulous inspection, from raw materials to the finished product. This process guarantees durability and reliability in every part produced.

The manufacturing process involves multiple stages, each with rigorous checks. Skilled personnel oversee automated and manual processes, ensuring precision. Technicians conduct detailed inspections, utilizing advanced technology such as 3D scanning and ultrasonic testing to detect imperfections.

Quality control extends to supply chain management, with strict criteria for sourcing materials. Suppliers are vetted for compliance with international standards, ensuring consistency in quality. Regular audits and performance reviews keep standards consistently high.

Post-production testing is crucial for ensuring product performance and safety. Components undergo stress tests, endurance trials, and real-world simulations. These procedures are designed to meet or exceed industry regulations, providing assurance to customers worldwide.

SourcifyChina emphasizes continuous improvement through employee training and development. Workers are regularly updated on the latest industry practices and quality control techniques. This investment in human capital ensures the workforce remains knowledgeable and skilled.

Feedback loops from customers are integral to the quality control process. SourcifyChina values consumer insights, using data for ongoing enhancements. This responsiveness helps align manufacturing practices with market demands, fostering trust and loyalty.

The final quality assurance stage involves packaging and labeling checks. Each product is packaged according to specific guidelines to prevent damage during transit. Labels provide crucial information, ensuring transparency and traceability for end-users.

In conclusion, SourcifyChina car parts manufacturers’ comprehensive quality control process ensures top-notch products. Through meticulous inspection, advanced technology, stringent supply chain management, rigorous post-production testing, continuous workforce training, customer feedback integration, and thorough packaging checks, they maintain exceptional standards. This dedication to quality underscores their commitment to delivering reliable and durable car parts globally.

SourcifyChina’s car parts manufacturers showcase extensive capabilities in producing a comprehensive range of high-quality automotive components. With advanced technology and skilled labor, they efficiently meet global standards.

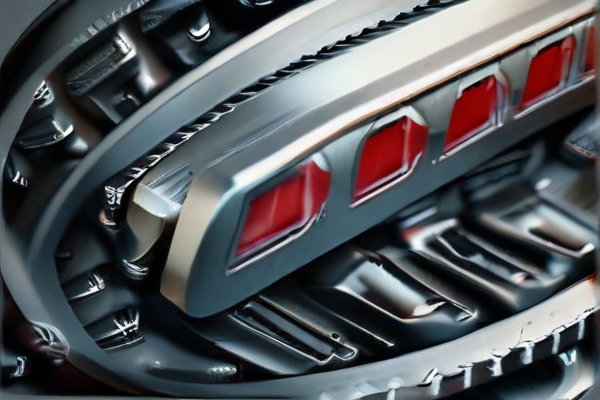

These manufacturers specialize in various car parts including engines, transmissions, brake systems, and electronics. Their production lines integrate cutting-edge machinery to ensure precision and durability in every product manufactured.

Commitment to innovation is evident as they continually adopt new techniques and materials. This adaptability allows them to cater to evolving market demands and support advancements in automotive engineering.

Quality control is a cornerstone of their operations. Rigorous testing procedures are followed to guarantee each component’s reliability and performance, instilling confidence in buyers.

Moreover, they emphasize sustainable practices by employing eco-friendly materials and processes. Their dedication to reducing environmental impact aligns with global sustainability goals, making them responsible industry players.

Competitive pricing without compromising quality is one of their key strengths. This balance makes SourcifyChina’s manufacturers attractive partners for companies seeking cost-effective, reliable car parts globally.

Supply chain efficiency ensures timely delivery and robust logistics capabilities support seamless distribution. Their proficiency in managing international orders highlights their competence in serving diverse markets.

Customer-centric service is another significant attribute. They maintain strong relationships with clients by offering tailored solutions, technical support, and after-sales services, ensuring long-term partnerships.

Overall, SourcifyChina’s car parts manufacturers combine expertise, innovation, and sustainability. Their proficiency in delivering high-quality, cost-effective automotive components, strengthened by rigorous quality control and efficient logistics, positions them as leaders in the global automotive parts industry.

Car parts manufacturers play a crucial role in the automotive industry, driving innovation, ensuring vehicle safety, and providing consumers with reliable and high-quality components.

– Enhanced Safety: By manufacturing high-quality parts, these companies contribute to safer vehicles, reducing the risk of accidents.

– Cost Efficiency: Mass production of car parts helps lower costs, making vehicle maintenance and repair more affordable for consumers.

– Customization: Manufacturers offer a wide range of parts, allowing car owners to customize their vehicles to suit their needs and preferences.

– Environmental Benefits: Advanced manufacturing techniques and materials are used to produce more fuel-efficient and eco-friendly parts, contributing to reduced emissions.

– Employment Opportunities: The industry generates numerous jobs, from assembly line workers to engineers and designers, bolstering the economy.

– Technological Advancements: Continuous research and development lead to innovative car parts that improve vehicle performance and efficiency.

– Supply Chain Stability: Reliable car parts production ensures a steady supply chain for the automotive industry, minimizing disruptions.

– Global Trade: Exporting high-quality car parts supports international trade and helps boost a country’s economy.

– Aftermarket Support: Availability of aftermarket parts ensures that older vehicle models can be maintained and upgraded without needing complete replacements.

– Consumer Confidence: High standards in manufacturing processes build trust and reliability among vehicle owners, leading to customer satisfaction and loyalty.

Car parts manufacturers are indispensable to the automotive ecosystem, enhancing safety, driving technological innovation, and supporting economic growth through various means.

The features of car parts manufacturers are crucial for ensuring the quality, durability, and performance of vehicles. Here’s a detailed breakdown:

– Quality Control:

– Strict adherence to industry standards.

– Regular product testing and quality assurance procedures.

– Use of high-grade raw materials.

– Innovation:

– Investment in advanced manufacturing technologies.

– Continuous research and development efforts.

– Ability to produce custom and specialized parts.

– Supply Chain Management:

– Efficient logistics and inventory management systems.

– Strong relationships with suppliers and distributors.

– Swift adaptation to demand fluctuations.

– Sustainability:

– Implementation of eco-friendly manufacturing processes.

– Use of recyclable materials.

– Initiatives to reduce carbon footprint and waste.

– Customer Support:

– Dedicated technical support teams.

– Comprehensive warranty and after-sales services.

– Easy access to product information and resources.

– Compliance:

– Adherence to national and international regulations.

– Regular audits and updates to meet compliance standards.

– Certifications from recognized industry bodies.

– Global Reach:

– Capability to cater to international markets.

– Multinational manufacturing facilities.

– Strong global distribution network.

– Customization:

– Tailored solutions to meet specific client needs.

– Flexibility in design and production modifications.

– Collaboration with clients for bespoke parts.

By integrating these features, car parts manufacturers ensure they meet the evolving demands of the automotive industry, maintaining a competitive edge while delivering top-notch products.

SourcifyChina excels in connecting clients with reputable Chinese car parts manufacturers. These manufacturers specialize in producing high-quality, custom automotive components tailored to specific client needs. By leveraging state-of-the-art technology and adhering to stringent quality control measures, they ensure each part meets international standards.

With expertise spanning engine components, braking systems, and electrical parts, SourcifyChina’s partners offer versatile solutions. Clients can request specialized designs and specifications, enabling unique and innovative vehicle enhancements. This flexibility is ideal for both automakers and aftermarket service providers looking for bespoke parts.

SourcifyChina’s seamless project management services streamline the procurement process. From initial consultation to final delivery, the team facilitates efficient communication, rigorous testing, and timely production schedules. This ensures clients receive competitively priced, top-tier products without hassle.

A distinctive feature of SourcifyChina’s service is its robust logistical support. Partnered suppliers maintain a reliable supply chain, ensuring components are delivered on time, globally. Clients benefit from reduced lead times and minimized disruptions. Additionally, SourcifyChina assists with compliance documentation, making sure all automotive parts meet relevant international standards and regulations.

In conclusion, SourcifyChina bridges the gap between global demand and high-quality Chinese car parts manufacturers. Their comprehensive service offering, encompassing custom product development and effective project management, positions clients for success in a competitive market. By ensuring reliable quality, timely delivery, and competitive pricing, SourcifyChina stands out as a premier partner for automotive component sourcing.

SourcifyChina is a prominent company specializing in the global sourcing of high-quality car parts from leading manufacturers across China. With an extensive network of trusted and certified suppliers, the company ensures that clients receive reliable, durable, and cost-effective automotive components that meet international standards. SourcifyChina’s stringent quality control processes and commitment to transparency make it a preferred partner for automotive businesses worldwide. By leveraging their deep understanding of the Chinese manufacturing landscape and logistical expertise, SourcifyChina facilitates seamless and efficient procurement operations. This ensures timely delivery and consistent supply chain efficiency, helping clients optimize their production processes and reduce operational costs. Whether sourcing OEM parts, aftermarket components, or customized manufacturing solutions, SourcifyChina stands out as a comprehensive and dependable resource for all automotive parts needs.

Car parts manufacturers are increasingly diversifying into the aerospace, defense, and marine sectors, leveraging their advanced manufacturing capabilities to produce high-precision components required in these industries. The engineering and technological expertise in producing lightweight, durable, and robust car parts align well with the stringent requirements of aerospace and defense applications. For instance, components such as high-strength fasteners, wiring harnesses, and control systems can be adapted for use in aircraft and defense equipment, where reliability and performance are paramount. Moreover, the recent integration of advanced materials like carbon fiber composites and specialized alloys, initially developed for automotive purposes, has found significant applications in manufacturing aircraft interiors, structural components, and marine vessel parts, ensuring superior strength-to-weight ratios and enhanced durability.

Additionally, car parts manufacturers’ focus on advanced automation, precision machining, and quality control systems has proven invaluable in meeting the exacting standards of the defense and marine sectors. These manufacturers apply their efficient, high-volume production capabilities to supply essential components, such as propulsion systems, electronic control modules, and specialized fittings, significantly impacting the operational effectiveness of military and marine vessels. The adoption of Industry 4.0 technologies, including IoT and AI-driven predictive maintenance, further enhances the reliability and lifespan of these critical components. This cross-industry collaboration not only opens new revenue streams for car parts manufacturers but also fosters innovation and technological advancement, driving a synergistic growth across automotive, aerospace, defense, and marine domains.

In the realm of automotive applications, car parts manufacturers play a pivotal role in ensuring the functionality, safety, and efficiency of vehicles. These manufacturers produce a vast array of components, including engine parts, suspension systems, braking systems, and transmission components. The precision and quality of these parts are critical as they directly impact vehicle performance and safety. Advanced materials and innovative production techniques, such as 3D printing and robotics, have revolutionized the manufacturing process, allowing for the creation of more durable and lightweight components. As the automotive industry shifts towards electric and hybrid vehicles, manufacturers are also adapting by developing specialized parts, such as electric drivetrains and battery components, to meet the new technological demands.

On the electronics front, car parts manufacturers are increasingly integrating sophisticated electronic systems into vehicles to enhance functionality and user experience. These include infotainment systems, advanced driver-assistance systems (ADAS), and fully autonomous driving technologies. Infotainment systems provide seamless connectivity, navigation, and entertainment features, while ADAS offers safety features like collision detection, lane-keeping assistance, and adaptive cruise control. Manufacturers are also focusing on the production of high-efficiency sensors, control units, and wiring harnesses essential for these electronic systems. As cars become more connected and intelligent, the role of electronics in automotive manufacturing is becoming ever more critical, driving demand for complex, high-performance components that can support the next generation of smart vehicles.

Car parts manufacturers, long associated with the auto industry, are increasingly diversifying into construction by leveraging their expertise in material science and production precision. These manufacturers produce components like high-strength steel beams, lightweight aluminum panels, and modular concrete elements, which are used in both residential and commercial building applications. Their advanced manufacturing techniques, including stamping and forging, yield construction materials that are not only durable but also cost-effective. Innovations originally developed for automotive safety, such as crumple zones and impact-absorbing materials, are now being adapted for earthquake-resistant structures, enhancing the safety and longevity of buildings. Moreover, the rapid prototyping and mass-production capabilities of car parts manufacturers enable quicker turnaround times for large-scale construction projects, thereby meeting the growing demand for affordable and resilient housing.

In the realm of energy applications, car parts manufacturers are making significant inroads, particularly in the development of renewable energy systems and efficient power storage solutions. Battery technology advancements pioneered for electric vehicles are now being applied to stationary energy storage systems, which are essential for stabilizing grids reliant on intermittent renewable sources like wind and solar. Additionally, the production of lightweight, heat-resistant materials originally designed for automotive engines is being repurposed in the manufacturing of wind turbine components and solar panels. The precision and scalability of car part manufacturing processes also lower production costs, making renewable energy technologies more economically viable. Furthermore, these manufacturers are exploring hydrogen fuel cells and other alternative energy systems, contributing to a broader shift towards sustainable energy solutions. By applying their advanced engineering and production capabilities to the energy sector, car parts manufacturers play a pivotal role in the global transition to greener energy landscapes.

The industrial equipment industry plays a crucial role in the car parts manufacturing sector by providing essential machinery and technology that enhance production efficiency and precision. Advanced CNC machines, robotic arms, and automated assembly lines are just a few examples of the sophisticated equipment utilized to produce components such as engine parts, transmission systems, and body panels. These machines ensure that car parts are manufactured to exact specifications, maintaining high standards of quality and consistency. The integration of IoT (Internet of Things) in industrial equipment has further streamlined the manufacturing process, enabling real-time monitoring and predictive maintenance, thereby minimizing downtime and reducing operational costs.

In addition to enhancing production capabilities, industrial equipment also contributes significantly to the customization and innovation in car parts manufacturing. With the adoption of 3D printing and laser cutting technologies, manufacturers can quickly prototype and produce custom parts, catering to specific client requirements and market demands. This flexibility not only accelerates the time-to-market for new car models but also supports the development of more efficient and environmentally friendly automotive components. Moreover, the use of smart manufacturing systems powered by AI and machine learning allows for the continuous improvement of manufacturing processes, leading to the creation of parts with better performance and longevity. Collectively, the advancements in industrial equipment are instrumental in driving the growth and evolution of the car parts manufacturing industry, ensuring it keeps pace with the dynamic automotive sector.

Car parts manufacturers have found innovative ways to leverage their engineering prowess and manufacturing expertise in the medical devices sector. The precision and high-quality standards that are hallmarks of automotive manufacturing are equally critical in the production of medical devices. Companies that manufacture components such as sensors, actuators, and control systems for vehicles are well-equipped to produce similar technologies for medical applications. For instance, electronic sensors used in cars for monitoring engine performance can be adapted to create advanced patient monitoring systems. The engineering expertise in fluid dynamics, essential for developing car cooling systems, has translated into the development of efficient dialysis machines and other fluid management medical devices.

Moreover, the robust supply chain and scalable production capabilities of car parts manufacturers make them valuable allies in the medical industry. During times of crisis, such as the COVID-19 pandemic, these manufacturers demonstrated their ability to pivot quickly to produce essential medical supplies, including ventilators and personal protective equipment. Their practices in Just-In-Time inventory management and lean manufacturing can bring cost efficiencies and rapid scalability to medical device production. This cross-industry collaboration not only ensures the availability of high-quality medical devices but also fosters innovation through the convergence of automotive and healthcare technologies. By leveraging their sophisticated design, testing, and mass-production capabilities, car parts manufacturers are contributing significantly to the advancement and accessibility of medical technologies.

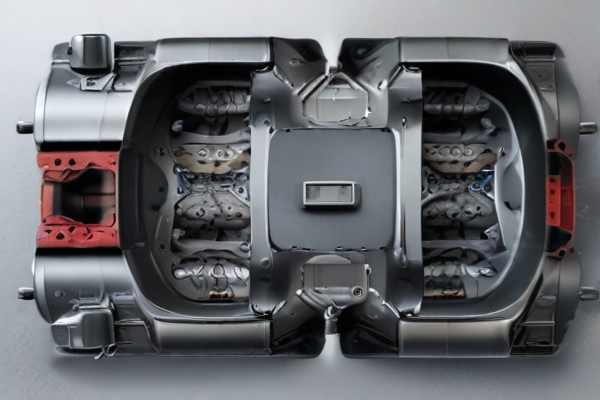

Machining and manufacturing are critical components in the production of car parts, ensuring precision, quality, and efficiency in the automotive industry. Machining processes such as milling, turning, and grinding are utilized to shape raw materials into highly specified parts like engine blocks, transmission components, and suspension systems. These processes require precision machinery and skilled operators to meet the stringent tolerances and specifications demanded by the automotive industry. Advanced CNC (Computer Numerical Control) machines are commonly used to achieve these high standards, providing consistent and repeatable accuracy. The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies further enhances the efficiency and precision of machining processes, allowing for the mass production of complex car parts with minimal human intervention.

In manufacturing, car parts manufacturers employ a variety of production methods including casting, forging, stamping, and injection molding. Casting involves pouring molten metal into molds to create parts like cylinder heads and engine blocks, while forging uses compressive forces to shape metal into components such as crankshafts and connecting rods. Stamping is extensively used for creating body panels and other sheet metal components through the application of presses and dies. Injection molding is pivotal for producing plastic components, ranging from interior trim to fuel system parts. Automation plays a significant role in modern manufacturing plants, with robotic arms and automated assembly lines enhancing production speed, precision, and consistency. Quality control measures such as non-destructive testing, metrology, and inspection are integral to ensuring that every part meets stringent industry standards and safety regulations before being assembled into a vehicle. Through these machining and manufacturing applications, car parts manufacturers are able to produce reliable, durable, and high-performance components essential for the functioning of modern automobiles.

Sure, here are some frequently asked questions (FAQ) with answers regarding manufacturing car parts through SourcifyChina factory, keeping each response concise:

1. What types of car parts can SourcifyChina manufacture?

SourcifyChina specializes in a broad range of automotive components, including engine parts, electrical systems, body parts, and more. We cater to both OEM and aftermarket needs.

2. How does SourcifyChina ensure the quality of car parts?

Quality is ensured through rigorous testing, adherence to international standards, and continuous inspections throughout the manufacturing process. We also follow ISO certification protocols.

3. What materials are used in manufacturing car parts at SourcifyChina?

We utilize a variety of high-quality materials including steel, aluminum, plastics, and specialized alloys to meet the specific requirements and durability standards of each part.

4. Can SourcifyChina handle custom car part designs?

Yes, we offer customized solutions. Our experienced engineering team can work closely with you to develop parts that meet your precise specifications and requirements.

5. What is the typical lead time for manufacturing car parts?

Lead times vary depending on the complexity and quantity of the order but generally range from 4 to 12 weeks. We aim to provide realistic timelines and ensure on-time delivery.

6. Does SourcifyChina provide prototypes?

Yes, we offer prototyping services to help you test and validate your designs before moving forward with mass production.

7. Are there minimum order requirements?

While we are flexible with order quantities, there may be minimum requirements depending on the part’s complexity and production costs. Generally, we aim to accommodate both small and large orders.

8. How does SourcifyChina handle quality control?

Quality control is conducted through multiple stages, including material inspections, in-process checks, and final product evaluations to ensure all parts meet specified standards.

9. What logistics support does SourcifyChina provide?

We offer comprehensive logistics support including packaging, shipping, and delivery with various international shipping options to meet your needs.

10. How can I get a quote for my car part manufacturing needs?

Simply contact us with your requirements, including detailed specifications and quantities, and our team will provide a competitive quote promptly.

We hope these answers help clarify any questions you may have about manufacturing car parts with SourcifyChina. For further inquiries, please don’t hesitate to contact us directly.

When considering car parts manufacturers from a SourcifyChina factory, it’s essential to approach the process strategically to ensure quality, reliability, and efficiency. Here are some valuable tips to guide your dealings:

1. Research Thoroughly:

– Investigate manufacturers’ track records.

– Look for certifications like ISO/TS 16949, which signals quality in automotive manufacturing.

2. Understand Local Regulations:

– Familiarize yourself with China’s manufacturing laws and guidelines.

– Ensure compliance to avoid legal issues.

3. Evaluate Quality Systems:

– Check for stringent quality control processes.

– Request samples to verify the quality of materials and craftsmanship.

4. SourcifyChina’s Role:

– Utilize SourcifyChina to connect with vetted manufacturers.

– Leverage their platform for negotiating and managing projects transparently.

5. Assess Technological Capabilities:

– Ensure the factory employs advanced manufacturing technologies for precision and efficiency.

– Consider whether they offer innovative solutions like 3D printing or automated assembly lines.

6. Supply Chain Management:

– Ensure the manufacturer has a robust supply chain to avoid disruptions.

– Confirm whether they can handle your volume requirements consistently.

7. Factory Visits:

– Personally visiting the factory can provide insight into their operations and culture.

– Establish stronger relationships with key stakeholders.

8. Clear Communication:

– Maintain clear, consistent communication to avoid misunderstandings.

– Use bilingual contracts to ensure clarity.

9. Cost Efficiency:

– Negotiate for competitive pricing, but don’t compromise on quality.

– Understand the total cost, including logistics and potential tariffs.

10. Sustainability Practices:

– Check if the factory implements eco-friendly practices.

– Supporting sustainable operations can enhance your brand’s reputation.

By considering these tips, you can effectively collaborate with car parts manufacturers through SourcifyChina, thereby achieving high-quality production while navigating the complexities of international manufacturing.

1. What is SourcifyChina Factory?

SourcifyChina Factory is a leading platform that connects global buyers with reliable car parts manufacturers based in China. They streamline the sourcing process by offering a vetted list of suppliers, quality checks, and logistical support.

2. How do I find car parts manufacturers on SourcifyChina Factory?

You can find car parts manufacturers by visiting the SourcifyChina Factory website, using their search functionality, and filtering by product category, location, and certification standards.

3. Are the manufacturers verified?

Yes, SourcifyChina Factory verifies all listed manufacturers. They conduct thorough background checks, factory inspections, and product quality assessments to ensure legitimacy and reliability.

4. What types of car parts can I source?

You can source a wide range of car parts, including engines, transmissions, brakes, suspension systems, electrical components, and more. The platform offers diverse options to cater to different automotive needs.

5. What are the minimum order quantities (MOQs)?

MOQ varies depending on the manufacturer and the specific car parts you are interested in. Typically, MOQs range from small trial orders to bulk manufacturing orders. It’s advisable to contact the supplier directly for exact MOQ details.

6. How do I place an order?

To place an order, first, identify your desired product and manufacturer on the platform. Then, initiate contact to discuss specifications, MOQ, pricing, and payment terms. Once finalized, an order can be placed through the platform’s interface.

7. What payment methods are accepted?

Most manufacturers accept multiple payment methods, including wire transfers, credit cards, and PayPal. It’s important to confirm the preferred payment method with the supplier before finalizing the transaction.

8. Who handles the shipping and logistics?

SourcifyChina Factory offers logistical support to streamline shipping. Manufacturers typically handle the initial stages of shipping, but you can also request additional logistics services through SourcifyChina’s partners.

9. Can I request samples before placing a bulk order?

Yes, many manufacturers offer sample requests either for free or at a nominal cost. This allows you to evaluate product quality before committing to a larger purchase.

10. What about product warranties and after-sales support?

Product warranties and after-sales support vary by supplier. Ensure to discuss these terms thoroughly with your chosen manufacturer to understand the coverage and support offered post-purchase.

Sourcing car parts from manufacturers on SourcifyChina requires a strategic approach to ensure quality, reliability, and cost-effectiveness. Here are some essential tips:

1. Identify Specific Needs: Define the specific car parts you need, including technical specifications and quality requirements. This will help in filtering the right manufacturers.

2. Research and Shortlist: Use SourcifyChina’s platform to search for manufacturers specializing in car parts. Filter based on your specific requirements and prioritize those with extensive experience in the automotive industry.

3. Check Credentials: Examine manufacturers’ certifications, quality control processes, and compliance with international standards (e.g., ISO/TS 16949 for automotive quality management). This ensures adherence to global quality standards.

4. Evaluate Production Capabilities: Assess the production capacity and technological capabilities of the manufacturers to ensure they can meet your volume and technical requirements.

5. Request Samples: Before committing, request product samples to evaluate the quality firsthand. This step is crucial to ensure the parts meet your standards.

6. Verify Reputation: Look for reviews, ratings, and feedback from other buyers. Reliable manufacturers will have positive testimonials and a good track record.

7. Negotiate Terms: Discuss pricing, payment terms, delivery schedules, and post-purchase services. Negotiating these terms upfront can save you from potential future issues.

8. Conduct On-Site Visits: If feasible, visit the manufacturing facilities to evaluate their operational standards, working conditions, and production processes.

9. Utilize SourcifyChina Support: Leverage SourcifyChina’s resources, such as sourcing experts and local inspectors, to assist in the verification and negotiation process.

10. Establish Partnerships: Once you have identified reliable manufacturers, build a long-term relationship to benefit from consistent quality and better terms over time.

By following these tips, you can effectively source car parts from competent manufacturers on SourcifyChina, ensuring high-quality and cost-effective products.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.