Technology and Applications of carbon steel vs cast iron

Carbon steel and cast iron are two distinct materials with unique properties that make them suitable for various applications in different industries.

Carbon Steel:

Carbon steel is primarily composed of iron and carbon, typically with small amounts of other elements such as manganese, silicon, and sometimes sulfur and phosphorus. It is known for its strength, durability, and versatility. Carbon steel is used extensively in structural applications, such as building construction, bridges, pipelines, and machinery components. Its ability to be easily welded and machined makes it suitable for manufacturing processes where precise shaping is required. In addition to structural uses, carbon steel is also found in consumer goods such as kitchen knives and tools due to its hardness and edge retention.

Cast Iron:

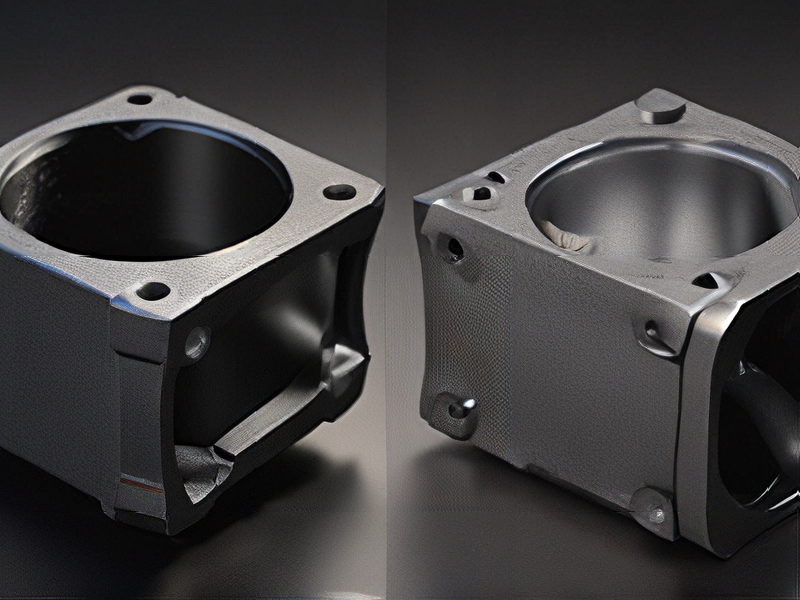

Cast iron contains a higher carbon content than carbon steel, typically between 2% and 4%. This higher carbon content contributes to its brittleness and lower melting point compared to carbon steel. Cast iron is well-suited for applications where its excellent casting properties are beneficial, such as in automotive parts, cookware, and engine blocks. It is valued for its wear resistance, damping capacity (ability to absorb vibrations), and thermal conductivity. Cast iron is also used in decorative applications and historical restoration due to its aesthetic appeal and ability to be molded into intricate shapes.

Applications and Comparisons:

– Strength and Durability: Carbon steel is generally stronger and more durable than cast iron, making it suitable for heavy-duty applications.

– Machinability and Weldability: Carbon steel is easier to machine and weld compared to cast iron, which can be brittle and challenging to work with.

– Cost and Availability: Carbon steel is typically more cost-effective and widely available than cast iron.

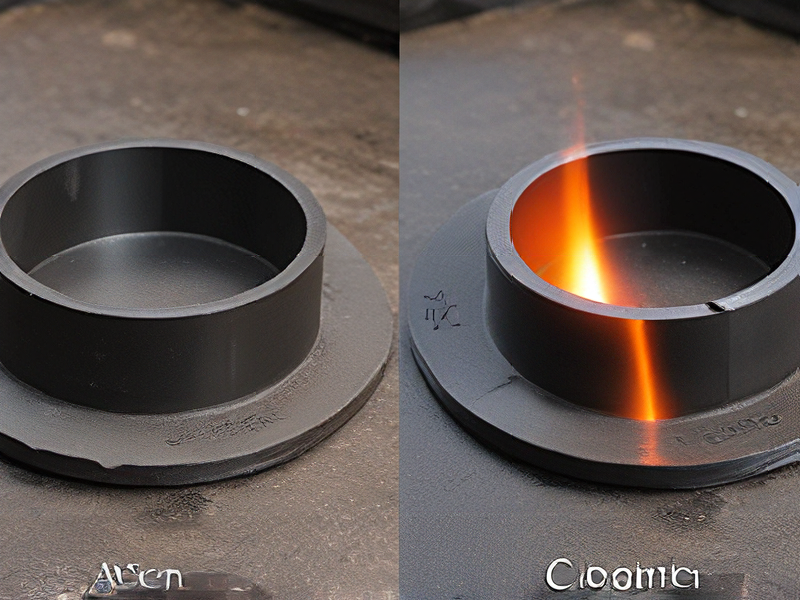

– Heat Retention and Cooking Performance: Cast iron is preferred in cookware due to its superior heat retention and even cooking properties compared to carbon steel.

In summary, while both carbon steel and cast iron have their unique strengths and applications, the choice between them depends largely on the specific requirements of the application, including factors such as strength, machinability, and heat retention.

Quality Testing Methods for carbon steel vs cast iron and how to control quality

Quality testing methods for carbon steel and cast iron typically involve both destructive and non-destructive techniques to ensure material integrity and performance.

Carbon Steel:

1. Chemical Composition Analysis: Verify carbon content and alloying elements through spectrometry to meet specified standards.

2. Mechanical Testing: Conduct tensile tests to evaluate strength, yield, and elongation properties.

3. Hardness Testing: Measure hardness using Rockwell or Brinell scales to assess material strength and durability.

4. Microstructure Examination: Use microscopy to check grain structure and inclusion levels for uniformity and integrity.

Control Measures:

1. Quality Control Plans: Implement stringent inspection protocols at key production stages.

2. Process Monitoring: Continuously monitor manufacturing parameters to maintain consistency.

3. Training Programs: Train personnel on quality standards and testing procedures.

4. Supplier Quality Assurance: Vet and audit suppliers to ensure raw material quality meets specifications.

Cast Iron:

1. Dimensional Inspection: Verify dimensions using gauges and calipers to ensure casting accuracy.

2. Visual Inspection: Inspect surface for defects like cracks, porosity, or inclusions.

3. Metallurgical Analysis: Assess microstructure through etching and microscopy to ensure graphite distribution and matrix integrity.

4. Non-Destructive Testing: Use ultrasound or X-ray to detect internal defects without damaging the casting.

Control Measures:

1. Mold Design Optimization: Ensure molds are designed to minimize defects and ensure consistent casting quality.

2. Heat Treatment Monitoring: Control heating and cooling rates during annealing or quenching to achieve desired properties.

3. Quality Audits: Regularly audit casting processes and quality checks to identify and correct deviations.

By employing these methods and control measures, manufacturers can uphold high-quality standards for both carbon steel and cast iron products, ensuring reliability and performance in various applications.

Tips for Procurement and Considerations when Purchasing from carbon steel vs cast iron

When deciding between carbon steel and cast iron for procurement, consider the following:

1. Durability and Strength: Carbon steel is known for its strength and durability, making it suitable for heavy-duty applications. Cast iron, while also strong, can be brittle and prone to cracking under extreme stress.

2. Weight and Handling: Cast iron tends to be heavier than carbon steel, which can impact transportation costs and ease of handling during installation and maintenance.

3. Corrosion Resistance: Carbon steel requires protection against corrosion through coatings or alloys like stainless steel. Cast iron has inherent corrosion resistance due to its composition but can still corrode over time.

4. Heat Retention and Conductivity: Cast iron excels in heat retention, making it ideal for applications like cookware or stoves. Carbon steel has good heat conductivity, suitable for various industrial uses where heat transfer is critical.

5. Cost Considerations: Both materials have different cost structures. Carbon steel is generally cheaper initially but may require more maintenance and protection against corrosion. Cast iron can be more expensive upfront but may have lower long-term maintenance costs.

6. Surface Finish and Machinability: Cast iron typically has a rougher surface finish compared to carbon steel. Machining cast iron can be challenging due to its hardness and brittleness.

7. Application Specifics: Consider the specific requirements of your application. For example, if you need a material that can withstand high temperatures and thermal shock, cast iron might be preferable. For structural applications requiring high strength and toughness, carbon steel could be more suitable.

8. Environmental Impact: Assess the environmental impact of each material. Both carbon steel and cast iron have varying degrees of recyclability and environmental implications during production and disposal.

In summary, your choice between carbon steel and cast iron should hinge on factors such as durability, cost, corrosion resistance, and specific application requirements. Understanding these differences will help you make an informed decision based on your procurement needs.

FAQs on Sourcing and Manufacturing from carbon steel vs cast iron in China

When sourcing carbon steel or cast iron from China, consider several key factors:

1. Material Properties: Carbon steel is durable and versatile, suitable for a wide range of applications due to its strength and formability. Cast iron is known for its excellent heat retention and uniform heating properties, ideal for cookware and machinery parts.

2. Manufacturing Processes: Both materials require specific manufacturing processes. Carbon steel is typically forged or rolled into shape, while cast iron involves melting the metal and pouring it into molds.

3. Cost Considerations: Generally, carbon steel production costs can be lower due to simpler manufacturing processes, although specific factors like alloy content and production scale can affect pricing. Cast iron may have higher initial costs due to the casting process.

4. Supplier Selection: Choose suppliers with a proven track record in your desired material. Ensure they adhere to quality standards like ISO certifications and have experience exporting to your country.

5. Quality Control: Implement stringent quality control measures to ensure product consistency and durability. This involves regular inspections, material testing, and compliance with international standards.

6. Logistics and Shipping: Plan for logistics and shipping considerations to manage lead times and costs effectively. Work closely with your supplier to streamline these processes.

By understanding these differences and considerations, you can make informed decisions when sourcing carbon steel or cast iron products from manufacturers in China.