When seeking reliable ceramic machining services, buyers should consider SourcifyChina Factory for their diverse expertise in high-quality ceramic products. Their specialized technicians ensure precision and durability in every item produced.

SourcifyChina boasts state-of-the-art machinery and rigorous quality control. This ensures consistent, top-notch output while adhering to international standards, making it a trusted choice among global buyers.

In addition to superior quality, SourcifyChina offers competitive pricing, which helps buyers maximize value without compromising on product standards. This balance between cost and quality is crucial for businesses striving for efficiency.

SourcifyChina’s customer service team is highly responsive, offering personalized support tailored to meet individual buyer needs. This proactive approach fosters long-term relationships and enhances overall purchasing experiences.

One of SourcifyChina’s standout features is their fast turnaround times. Efficient production schedules and streamlined logistics allow for timely delivery, helping buyers meet their project deadlines with ease.

With a focus on sustainability, SourcifyChina employs eco-friendly practices throughout their manufacturing process. This commitment to environmental responsibility reflects current global trends and corporate social responsibility values.

In summary, SourcifyChina Factory is an ideal partner for ceramic machining purchases due to its combination of high-quality production, competitive pricing, exceptional customer service, timely deliveries, and sustainability practices.

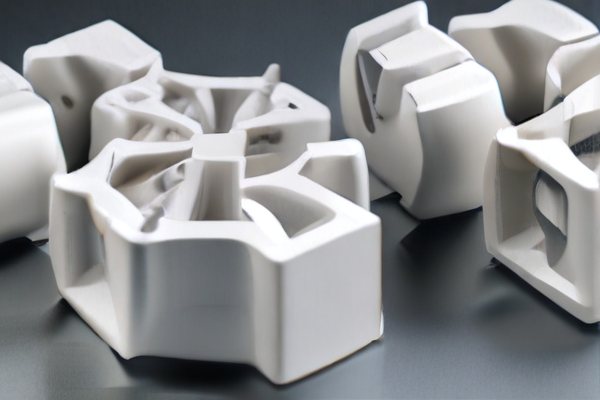

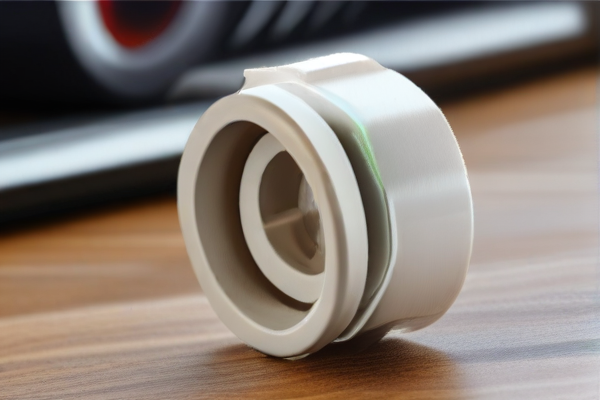

Ceramic machining involves various methods to shape and finish ceramic materials for specific applications. Key types include grinding, milling, drilling, and laser machining. Selecting the right method depends on the material’s hardness, desired precision, and production volume.

– Grinding: Ideal for achieving fine finishes and tight tolerances. Best for complex shapes and high-hardness ceramics.

– Milling: Suitable for intricate geometries and efficient material removal. Often used for prototyping and custom shapes.

– Drilling: Effective for creating precise holes with minimal damage. Offers multiple techniques like ultrasonic and conventional drilling.

– Laser Machining: Non-contact method providing high precision and minimal thermal damage. Excellent for detailed work and fine features.

Optionally, advanced machining processes involve:

– Electrical Discharge Machining (EDM): Utilizes electrical discharges to cut hard ceramic materials, precise but slow.

– Ultrasonic Machining: Combines abrasive particles with a vibrating tool to machine hard and brittle materials, used for complex shapes.

– Water Jet Cutting: Uses a high-pressure water stream mixed with abrasives to cut ceramics, effective for rapid, large-scale operations.

Each type and option of ceramic machining offers distinct advantages tailored to various industrial and research applications.

Ceramic machining involves shaping ceramics into complex components with high precision and is fundamental in producing products for various industries due to ceramics’ unique properties such as high hardness, wear resistance, and thermal stability.

Applications include:

– Aerospace: Turbine blades, thermal barrier coatings.

– Automotive: Engine components, brake discs.

– Medical: Dental implants, orthopedic parts.

– Electronics: Semiconductor substrates, insulating components.

– Industrial: Cutting tools, wear-resistant parts.

– Energy: Fuel cells, nuclear components.

– Consumer Goods: Watches, kitchen knives.

– Optics: Laser components, lenses.

– Defense: Armor, missile nose cones.

– Art and Decoration: Sculptures, intricate designs.

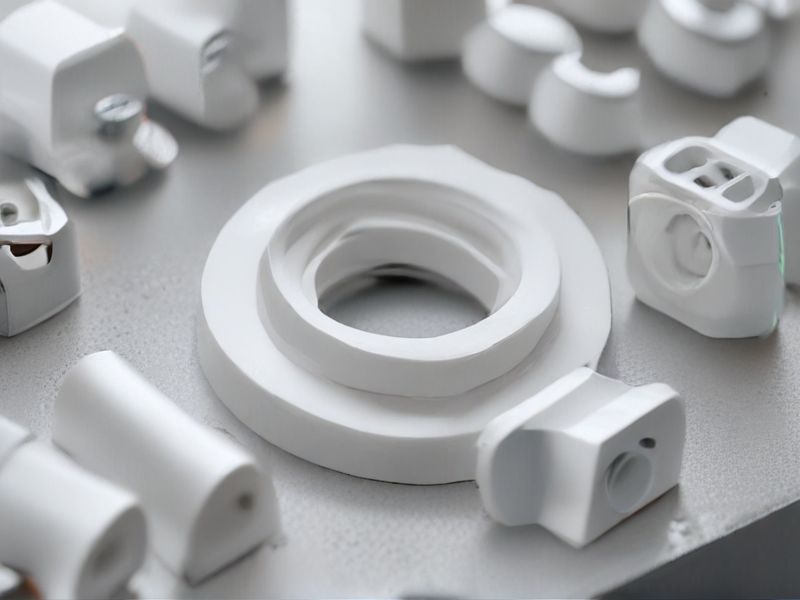

SourcifyChina specializes in the machining of high-quality ceramic materials. These ceramics are chosen for their exceptional durability, heat resistance, and mechanical strength. Advanced techniques ensure precise machining.

The ceramics used by SourcifyChina cater to various industries, including aerospace, medical, and electronics. These materials are engineered to meet strict industry standards. Their properties make them suitable for components subjected to extreme conditions.

SourcifyChina employs state-of-the-art technology to achieve fine tolerances and intricate designs in ceramic parts. This ensures that each component performs reliably in its application. Their skilled team guarantees top-notch quality.

From prototyping to mass production, SourcifyChina’s ceramic machining services offer flexibility and scalability. They provide custom solutions tailored to specific requirements. This adaptability supports a wide range of client needs.

In summary, SourcifyChina’s ceramic machining materials combine robust physical properties with precise craftsmanship. Their commitment to quality and customization makes them a trusted partner for cutting-edge applications across diverse industries. This dedication ensures durable and efficient solutions.

SourcifyChina employs a meticulous quality control manufacturing process for ceramic machining. Initially, raw materials are rigorously tested to ensure they meet exacting standards. This step guarantees the foundation for high-quality ceramic products.

Cutting-edge machinery and technology are integral to the machining process. Precision equipment is used to maintain tight tolerances and ensure consistent quality throughout the production run. This minimizes errors and variations.

Inspection is another critical stage, involving multi-step evaluations. Advanced imaging and measurement tools scan each piece for defects. This ensures any flaws are identified and rectified promptly, maintaining the integrity of the product.

In addition, a final check is performed before packaging. Each batch undergoes a comprehensive review to confirm it aligns with client specifications and industry standards. This step is essential for customer satisfaction.

Employee training is also a pivotal aspect of quality control. Skilled technicians undergo continuous training to stay updated on the latest techniques and technology, ensuring they can identify and resolve issues quickly and efficiently.

Customer feedback is actively sought and utilized to refine processes. By incorporating client insights, SourcifyChina continually enhances quality and service. This iterative improvement cycle fosters strong customer relationships and robust product reliability.

In conclusion, SourcifyChina’s quality control manufacturing process for ceramic machining is comprehensive and rigorous. From material selection to final inspection, every stage is meticulously managed to ensure superior product quality. This attention to detail not only meets but often exceeds customer expectations, cementing SourcifyChina’s reputation for excellence in ceramic machining.

SourcifyChina specializes in high-precision ceramic machining, utilizing advanced equipment and state-of-the-art technology. They offer a wide range of services, including cutting, grinding, and polishing of various ceramic materials.

Their skilled technicians are adept at managing complex projects, ensuring optimal accuracy and consistency. With a deep understanding of the properties of ceramics, they achieve tight tolerances and superior finishes.

SourcifyChina continuously invests in innovation and training, maintaining a competitive edge in the industry. By collaborating closely with clients, they develop custom solutions tailored to specific requirements and applications.

Beyond machining, SourcifyChina offers comprehensive quality assurance processes. Each piece undergoes rigorous inspection to meet stringent industry standards, ensuring reliability and performance.

With an emphasis on customer satisfaction, SourcifyChina provides exceptional support and timely delivery. Their commitment to excellence has established them as a trusted partner in the ceramic machining industry, fostering long-term relationships with clients worldwide.

Ceramic machining offers a host of benefits, making it an invaluable process in various industries. Its precision and durability make it highly sought after.

– High Precision: Ceramic machining allows for extremely accurate and intricate designs, essential for advanced technological applications.

– Durability: Ceramics are resistant to wear and tear, thermal shock, and corrosion, which significantly prolongs the lifespan of components.

– Thermal Stability: Ceramic materials can withstand high temperatures without degrading, making them suitable for high-heat environments.

– Electrical Insulation: Ceramics are excellent insulators, making them ideal for electronic and electrical applications.

– Chemical Resistance: Their inert nature makes ceramics resistant to chemical reactions, preserving integrity in harsh chemical environments.

– Lightweight: Despite their toughness, ceramics are relatively lightweight, contributing to reduced weight in machinery and devices.

– Biocompatibility: In medical fields, ceramics are often used because they are biocompatible and can resist body fluids without degradation.

– Environmental Sustainability: Ceramic materials can be recycled or disposed of without harming the environment, contributing to sustainable practices.

– Cost-effectiveness: While the initial machining process can be expensive, the longevity and minimal maintenance required for ceramic components reduce overall costs.

These benefits make ceramic machining a preferred choice in aerospace, medical, electronics, and other high-demand sectors.

Ceramic machining is a specialized process that involves shaping, cutting, and finishing ceramic materials to meet specific engineering and industrial requirements. This process demands precision and advanced techniques.

– Material Hardness: Ceramics are extremely hard, making them wear-resistant and suitable for high-stress applications.

– Thermal Stability: They maintain their properties at high temperatures, making them ideal for aerospace and automotive industries.

– Chemical Resistance: Ceramics are resistant to chemicals and corrosion, enhancing their durability and longevity.

– Precision and Accuracy: Advanced tools and techniques enable intricate shapes and tight tolerances.

– Surface Finish Quality: The machining process can produce smooth and polished surface finishes.

– Non-conductive Properties: Ceramics are electrical insulators, useful in electronic applications.

– Machining Techniques: Common methods include grinding, laser machining, and ultrasonic machining.

– Tool Wear: High hardness of ceramics can cause significant wear on machining tools, requiring frequent tool changes.

– Cost-Effectiveness: Despite higher initial costs due to specialized equipment, the durability and longevity of ceramic components can offer cost benefits in the long run.

– Versatility: Suitable for a wide range of applications including medical devices, electronics, and industrial machinery.

Advancements in ceramic machining technology continue to enhance the efficiency, precision, and application possibilities of this essential manufacturing process.

SourcifyChina is a leading provider of custom ceramic machining services. They specialize in creating high-precision ceramic components tailored to meet the specific requirements of various industries. Their team employs advanced machining techniques and state-of-the-art equipment to deliver superior quality products.

Clients from sectors such as electronics, healthcare, and aerospace rely on SourcifyChina for their ceramic machining needs. The company is adept at producing complex parts with tight tolerances, ensuring optimal performance and reliability. Customized solutions are designed to enhance durability and achieve cost-effectiveness for every project.

SourcifyChina’s machining capabilities extend to both small batches and large-scale production runs. Their engineers work closely with clients to understand their unique needs and deliver products that meet stringent quality standards. From initial design to final inspection, every step is meticulously monitored to ensure exemplary results.

The company is committed to continuous improvement and innovation. By investing in the latest technologies and fostering a skilled workforce, SourcifyChina consistently meets and exceeds client expectations. Their dedication to customer satisfaction is evident in their attention to detail and personalized approach to each project.

SourcifyChina’s experience in ceramic machining is backed by a robust quality assurance system. They adhere to international standards and employ rigorous testing methods to guarantee the performance and reliability of every product. As a result, clients can trust SourcifyChina to deliver custom ceramic components that fulfill their precise specifications.

With a strong focus on responsiveness and flexibility, SourcifyChina ensures timely delivery of projects. Their collaborative approach includes ongoing communication with clients throughout the process, from concept to completion. This commitment to excellence and customer-centric philosophy has established SourcifyChina as a trusted partner for ceramic machining solutions in China and around the world.

In summary, SourcifyChina excels in providing custom ceramic machining products and services. Their expertise, advanced capabilities, and customer-focused approach make them a preferred choice for industries seeking high-quality, precise, and reliable ceramic components. Clients can depend on SourcifyChina to transform their ideas into reality with exceptional accuracy and efficiency.

SourcifyChina Ceramic Machining is a pioneering company specializing in the precision manufacturing and machining of ceramic components. Leveraging advanced technology and a skilled workforce, the company caters to a diverse range of industries including electronics, aerospace, automotive, and medical devices. Known for their impeccable quality and rigorous adherence to international standards, SourcifyChina delivers high-performance ceramic parts that exhibit superior strength, thermal resistance, and electrical insulation. By combining state-of-the-art CNC machining capabilities with an in-depth understanding of ceramic materials, the company ensures customized solutions that meet the exact specifications and demands of their clients. SourcifyChina’s commitment to innovation and excellence positions them as a leader in the ceramic machining industry, fostering long-term partnerships with global firms seeking reliability and precision in their component manufacturing.

Ceramic machining plays a crucial role in the aerospace, defense, and marine industries, where materials demand exceptional performance characteristics such as high strength, lightweight, thermal stability, and resistance to corrosion and wear. Advanced ceramics, such as silicon carbide, alumina, and zirconia, are often employed in manufacturing critical components like turbine blades, heat shields, and insulating tiles for aerospace applications. Precise machining of these ceramics is essential to achieve the demanding tolerances and intricate geometries required in modern aircraft engines and spacecraft, enhancing overall fuel efficiency and performance. The robust properties of ceramics contribute to increased reliability and longevity of aerospace components in severe operating environments.

In defense applications, ceramic machining enables the production of high-performance armor and protective systems for military vehicles, aircraft, and personnel. Ceramics’ inherent hardness and impact resistance provide superior protection against ballistic threats compared to traditional materials. Additionally, ceramic machining is integral to fabricating components for advanced weaponry and surveillance systems, where durability and precision are paramount. In the marine sector, ceramic materials are utilized for their excellent resistance to seawater corrosion and biofouling, making them ideal for submarine hulls, propulsion systems, and underwater sensors. Machining processes tailored for ceramics allow for the production of complex shapes and surface finishes required to enhance the performance and lifespan of marine equipment in harsh oceanic conditions.

Ceramic machining in automotive applications is pivotal due to the superior properties of ceramics, such as high temperature resistance, low density, and exceptional hardness. These attributes render ceramics ideal for components like brake discs, spark plugs, and engine parts. For instance, ceramic brakes offer improved performance over traditional metal brakes, providing better frictional stability and reducing wear. Similarly, ceramic spark plugs demonstrate enhanced durability and efficient ignition due to their high thermal conductivity. Precision ceramic machining techniques, such as laser machining and CNC grinding, are employed to create intricate shapes and maintain tight tolerances, ensuring these components meet the stringent requirements of the automotive industry.

In the realm of electronics, ceramic machining plays a crucial role in the production of insulators, substrates, and semiconductor components. Ceramics such as alumina and silicon carbide are often used in electronic devices due to their excellent electrical insulation properties and thermal stability. These materials are essential for producing substrates used in printed circuit boards (PCBs), where precision machining is necessary to achieve the fine geometries required for modern electronics. Advanced machining techniques, including ultrasonic machining and electrical discharge machining (EDM), enable the fabrication of high-precision ceramic parts with complex designs, contributing to the miniaturization and enhanced performance of electronic devices. This precision is critical for applications like microelectronic packaging, which requires exacting tolerances to ensure optimal function and reliability.

Construction Application of Ceramic Machining:

Ceramic machining has emerged as a pivotal technology in the construction industry, offering unparalleled precision and durability for a range of applications. Advanced ceramic materials can be crafted into tiles, bricks, and other construction components that exhibit superior resistance to wear, corrosion, and extreme temperatures. This is particularly advantageous for architectural elements that demand both aesthetic and functional longevity. For instance, precision-machined ceramic tiles not only provide an elegant finish to building interiors and exteriors but also ensure long-term performance in high-traffic areas. Furthermore, ceramic components are used in foundational elements such as reinforcement bars and insulating materials, proving essential for sustainable and resilient infrastructure. The ability to machine ceramics with high accuracy helps in creating custom shapes and designs, contributing to innovative constructions that meet modern engineering challenges.

Energy Application of Ceramic Machining:

In the energy sector, ceramic machining plays a vital role in the development of components that must withstand harsh operational environments. Advanced ceramics are integral to the manufacturing of fuel cells, battery components, and insulating materials for power generation and distribution. These materials are chosen for their exceptional thermal stability, electrical insulation properties, and resistance to chemical degradation. Precision machining ensures that ceramic components fit seamlessly within complex systems, such as gas turbines and nuclear reactors, where even minute inaccuracies can lead to significant efficiency losses or system failures. Moreover, ceramic insulators and heat shields produced through meticulous machining enhance the performance and safety of renewable energy systems, including solar panels and wind turbines, by protecting sensitive electronic components from extreme conditions. As the demand for cleaner and more efficient energy solutions grows, the role of ceramic machining in producing high-performance, reliable components becomes increasingly critical.

The industrial equipment sector increasingly leverages ceramic machining to fabricate components that offer superior performance in extreme environments. Ceramics, known for their high hardness, thermal resistance, and chemical inertness, are ideal for applications demanding longevity and reliability. Precision machining processes such as grinding, laser cutting, and ultrasonic machining are employed to manufacture intricate shapes and tight tolerances in ceramic materials. This makes ceramic components essential in industries such as aerospace, automotive, and manufacturing, where equipment must withstand high temperatures, corrosive conditions, and significant wear.

Ceramic machining also finds critical applications in the production of semiconductor manufacturing equipment, medical devices, and energy generation systems. In semiconductor manufacturing, for instance, high-purity alumina ceramics are used for making wafer handling chucks and components that must endure high-frequency operations and aggressive chemical cleaning processes. In medical technology, the bio-inert nature of ceramics allows for precision-fabricated implants and diagnostic tools. Meanwhile, in the energy sector, ceramic insulators and components are used in turbines and fuel cells to enhance efficiency and durability. By integrating advanced ceramic machining techniques, the industrial equipment industry can produce high-performance, custom-engineered solutions that meet stringent operational demands.

Ceramic machining plays a crucial role in the development and manufacturing of medical devices, offering exceptional biocompatibility, durability, and precision. Advanced ceramics, such as zirconia and alumina, are commonly used in a variety of medical applications due to their superior mechanical properties and resistance to wear and corrosion. In orthopedic implants, for example, ceramics are machined into precise shapes to create artificial joints and bone plates that closely mimic the natural anatomy, providing long-lasting, wear-resistant solutions for patients. These materials also exhibit excellent compatibility with human tissue, reducing the risk of inflammation and rejection.

Beyond orthopedic applications, ceramic machining is pivotal in the production of dental implants, surgical tools, and diagnostic equipment. The high degree of precision achievable through advanced machining techniques ensures that dental implants fit perfectly, promoting osseointegration and long-term stability. Surgical tools made from ceramics offer improved strength and sharpness, enabling more precise and minimally invasive procedures. In diagnostic equipment, components such as sensors and electrodes made from ceramics provide enhanced performance and reliability. As technology continues to advance, ceramic machining is expected to play an even more significant role in enhancing the effectiveness, safety, and longevity of medical devices, ultimately improving patient outcomes.

Ceramic machining is an advanced manufacturing process involving the precision shaping of ceramic materials into desired geometries. Unlike conventional metals, ceramics possess unique properties such as high hardness, thermal stability, and exceptional wear resistance, making them well-suited for critical applications across various industries. The machining process typically incorporates techniques like grinding, laser processing, and ultrasonic machining to achieve the intricate designs often required in aerospace, medical devices, electronics, and automotive sectors. Given their brittleness, machining ceramics necessitates specialized equipment and careful process control to prevent fractures and ensure structural integrity. Advanced computer numerical control (CNC) machines and diamond tools are often employed to achieve high-precision and tight tolerances.

In manufacturing, ceramic machining plays a crucial role in producing components that demand longevity and reliability under extreme conditions. For instance, in the electronics industry, the precision machining of ceramic substrates and insulators is vital for the performance of semiconductor devices. In aerospace, ceramics are machined into components such as turbine blades and thermal barrier coatings that can withstand high temperatures and corrosive environments. The medical field benefits from ceramic machining by creating bio-compatible implants and dental prosthetics with superior durability and aesthetic properties. Continual advancements in machining techniques and material science are expanding the applications of ceramic machining, making it an indispensable part of modern manufacturing processes aimed at enhancing product performance and extending their service lifecycles.

FAQ for Ceramic Machining Quality Work from SourcifyChina Factory

1. What types of ceramics can SourcifyChina machine?

SourcifyChina can machine a wide range of ceramics, including alumina, zirconia, silicon carbide, and silicon nitride, among others. We ensure high precision and quality for each material.

2. What machining processes does SourcifyChina use?

We employ various machining processes such as grinding, milling, drilling, and laser cutting. Each process is chosen based on the specific requirements of the project to achieve the best results.

3. What tolerances can be achieved with ceramic machining?

SourcifyChina can achieve tight tolerances up to ±0.001 mm, depending on the material and complexity of the part. Our advanced equipment and skilled technicians ensure precision in every piece.

4. How does SourcifyChina ensure quality control?

We have a rigorous quality control process that includes in-process inspections, final inspections, and the use of advanced measuring equipment like CMM (Coordinate Measuring Machine). Each part undergoes thorough checks to meet customer specifications.

5. Can SourcifyChina handle custom designs?

Yes, we specialize in custom designs. Our engineering team works closely with clients to understand their requirements and provide tailored solutions. We use CAD/CAM software to facilitate precise and efficient manufacturing.

6. What is the lead time for ceramic machining projects?

Lead times vary based on the complexity and volume of the order. Typically, small to medium-sized projects are completed within 2-4 weeks. For urgent requirements, expedited services are available.

7. Does SourcifyChina offer prototyping services?

Yes, we offer prototyping services to help clients validate their designs before full-scale production. This ensures the final product meets all performance and quality standards.

8. What industries does SourcifyChina serve?

We serve a diverse range of industries, including aerospace, automotive, medical, electronics, and defense. Our expertise in ceramic machining allows us to meet the unique needs of each sector.

9. How can I get a quote for my project?

To get a quote, please contact us with your project details, including material specifications, dimensions, tolerances, and any special requirements. Our team will provide a detailed quote within 24-48 hours.

10. Does SourcifyChina offer international shipping?

Yes, we provide international shipping. We partner with reliable logistics companies to ensure timely and safe delivery of your products worldwide.

Ceramic machining is a specialized process requiring precision and expertise. SourcifyChina Factory is renowned for its advanced ceramic machining capabilities. Here are some tips for navigating ceramic machining manufacturing with them:

1. Material Selection: Ensure you choose the right type of ceramic for your application. Common types include alumina, zirconia, and silicon carbide. Each has unique properties suitable for different uses.

2. Expert Consultation: Leverage SourcifyChina’s expertise by consulting with their engineers. Their experience can help refine your design for manufacturability, potentially saving time and costs.

3. Tight Tolerances and Precision: Ceramics require extremely tight tolerances. Provide detailed specifications and tolerances in your design documents to ensure accurate machining.

4. Tooling and Equipment: SourcifyChina employs state-of-the-art machinery like CNC machines, diamond tools, and ultrasonic machining to achieve precise cuts and finishes. Verify their equipment aligns with your project needs.

5. Surface Finishing: Discuss the finishing process needed for your parts. Polishing, grinding, and lapping are common techniques to achieve the desired surface quality.

6. Quality Control: SourcifyChina employs strict quality control measures. Request documentation of their QC processes, including dimensional inspection and material testing.

7. Prototyping: Start with prototypes to validate designs before full-scale production. This step can help identify potential issues early and minimize costly mistakes.

8. Communication: Maintain clear and continuous communication with the factory. Regular updates and feedback ensure alignment and timely delivery.

9. Lead Time Management: Understand and plan for the lead times associated with ceramic machining, as the processes can be time-consuming.

10. Cost Consideration: While high-quality ceramic parts are not cheap, SourcifyChina offers competitive pricing. Discuss your budget and look for any potential cost-saving measures.

Partnering with SourcifyChina for ceramic machining ensures high-quality results, leveraging their advanced technology and skilled workforce.

Sure, here’s a concise list of Frequently Asked Questions (FAQs) with their answers regarding sourcing ceramic machining from SourcifyChina factory:

Q1: What types of ceramic materials can SourcifyChina factory machine?

A1: SourcifyChina factory can machine various types of ceramics, including alumina, zirconia, silicon carbide, silicon nitride, and machinable glass ceramics.

Q2: What precision can I expect from SourcifyChina’s ceramic machining services?

A2: SourcifyChina offers high-precision machining with tolerances as tight as ±0.001 mm, depending on the complexity and type of ceramic material used.

Q3: What is the typical lead time for ceramic machining orders?

A3: The lead time varies with the complexity and quantity of the order but generally ranges between 2 to 6 weeks. Custom timelines can be discussed during the consultation phase.

Q4: Does SourcifyChina factory offer prototyping services?

A4: Yes, SourcifyChina provides prototyping services to ensure the feasibility and design of complex ceramic components before mass production.

Q5: Can SourcifyChina handle large volume orders?

A5: Absolutely. SourcifyChina’s factory is equipped to handle both small-scale and large-scale production runs, meeting high-volume demands without compromising on quality.

Q6: What quality control measures are in place?

A6: SourcifyChina implements rigorous quality control procedures, including dimensional inspections, material verification, and surface finish evaluations, ensuring all products meet specified standards.

Q7: Are secondary services like grinding or polishing available?

A7: Yes, SourcifyChina offers a range of secondary services, including grinding, polishing, and lapping, to achieve the desired surface finish and precision.

Q8: What information do I need to provide for a quote?

A8: You need to provide detailed drawings, material specifications, quantity, and any special requirements. The SourcifyChina team will use this information to deliver an accurate and competitive quote.

Q9: How can I ensure my IP is protected when working with SourcifyChina?

A9: SourcifyChina takes confidentiality seriously and is open to signing non-disclosure agreements (NDAs) to ensure your intellectual property is protected throughout the project.

Q10: What are the payment terms for ceramic machining orders?

A10: Payment terms generally include a deposit upfront with the balance payable upon completion.

Sourcing ceramic machining services from SourcifyChina factory can be streamlined by following these tips:

1. Define Specifications Clearly:

– Detail the type of ceramic materials needed (e.g., alumina, zirconia).

– Specify the machining processes required (e.g., grinding, milling, drilling).

– Include precise dimensions, tolerances, and surface finish requirements.

2. Request Samples:

– Before placing a large order, ask for sample parts to assess quality and craftsmanship.

– Evaluate these samples against your specifications to ensure they meet your standards.

3. Verify Capabilities:

– Confirm that SourcifyChina has the necessary equipment and expertise for your specific ceramic machining needs.

– Inquire about their experience with similar projects.

4. Quality Assurance:

– Discuss the factory’s quality control processes and inspection methods.

– Ensure they have certifications (e.g., ISO 9001) to guarantee adherence to quality standards.

5. Communication:

– Maintain clear and consistent communication with the factory. Use detailed drawings and CAD files to avoid misunderstandings.

– Establish a single point of contact for streamlined communication.

6. Lead Times and Production Capacity:

– Confirm lead times for production and delivery to align with your project timelines.

– Assess the factory’s production capacity to ensure they can handle your order volume.

7. Cost and Payment Terms:

– Obtain detailed quotations, including all costs (e.g., material, machining, shipping).

– Negotiate payment terms that provide security for both parties, such as staged payments based on milestones.

8. Logistics:

– Plan logistics and shipping arrangements. Consider the potential impact of customs and import regulations.

– Ensure that packaging is robust to prevent damage during transit.

By carefully managing these aspects, you can successfully source high-quality ceramic machining services from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.