Title: “Reliable SourcifyChina Factory: Your Premier Destination for CNC Machining in China”

Looking for a dependable CNC machining supplier in China? SourcifyChina Factory guarantees precise, high-quality CNC machining services. Discover unparalleled reliability and excellence in our state-of-the-art facilities. Perfect for your manufacturing needs.

Choosing SourcifyChina Factory for CNC machining purchases from China ensures high-quality products thanks to advanced technology and rigorous quality control. They employ skilled technicians who ensure precision in every piece, adhering to international standards. Additionally, SourcifyChina offers competitive pricing without compromising on quality, making it an economical choice for buyers.

Their customer service is top-notch, providing timely updates and transparent communication throughout the manufacturing process. Buyers benefit from streamlined logistics that ensure timely delivery to any location worldwide. SourcifyChina’s extensive experience in the industry means they understand and can anticipate client needs, making the purchasing experience smoother and more efficient.

Moreover, their adaptability to custom specifications offers buyers the flexibility needed for specialized projects. They provide thorough testing and validation processes which guarantee the reliability and durability of the products. The company’s comprehensive after-sales support ensures any potential issues are quickly resolved, offering peace of mind to customers.

In summary, choosing SourcifyChina Factory for CNC machining from China combines advanced technology, skilled workforce, and excellent customer service with competitive pricing and robust after-sales support. This makes them a reliable and efficient partner for buyers seeking high-quality CNC machined products.

China CNC machining offers a variety of manufacturing services, primarily including milling, turning, and EDM. These services cater to various industries, providing high precision and diverse material options.

– CNC Milling: Offers complex shapes, precise dimensions, and a wide range of materials such as aluminum, steel, and plastics.

– CNC Turning: Ideal for producing cylindrical parts, enabling high-volume production with consistent quality.

– Electrical Discharge Machining (EDM): Suitable for hard materials and intricate detail, often used for mold making and fine components.

– Five-Axis CNC Machining: Allows for the creation of intricate and complex parts with fewer setups, enhancing efficiency and accuracy.

– Rapid Prototyping: Provides quick and cost-effective production of prototypes, facilitating faster design iterations.

– 3D CNC Machining: Enables the cutting of three-dimensional objects with complex geometries and is often used for high-precision parts.

– Custom Machining: Tailored solutions to meet specific project needs, offering flexibility in design and material selection.

– High-Precision CNC Machining: Delivers extreme accuracy for components requiring tight tolerances, typically used in aerospace and medical industries.

– Batch Production: Suitable for medium to large-scale production runs, ensuring consistency and cost-effectiveness.

– CNC Surface Grinding: Delivers high-quality finishes and precise control over surface roughness, often used for finishing operations.

– Multi-Axis CNC Machining: Provides advanced capabilities for producing parts that require multiple machining operations in a single setup.

– Plastic CNC Machining: Perfect for creating plastic components with high precision, used in various applications from consumer products to industrial parts.

– Metal Fabrication: Encompasses a range of services including cutting, bending, and assembling metal parts, widely used in construction and manufacturing.

China’s CNC machining industry is renowned for its affordability, expertise, and technological advancements, making it a preferred choice for many global companies.

China CNC machining offers precise, cost-effective solutions for various industries, making it a go-to choice for manufacturing needs globally. Its applications extend across numerous sectors due to its versatility and efficiency.

– Aerospace: Producing intricate, high-precision components for aircraft and spacecraft.

– Automotive: Manufacturing car parts, including engine components, gearboxes, and custom parts.

– Medical Devices: Crafting critical devices with high tolerances, such as implants and surgical tools.

– Consumer Electronics: Creating enclosures, connectors, and intricate parts for gadgets.

– Robotics: Building detailed and accurate parts for robots and automation systems.

– Automotive: Producing components like engine parts, gearboxes, and custom fittings.

– Industrial Equipment: Making parts for machines, conveyor systems, and other industrial tools.

– Defense: Developing precision components for military equipment and weaponry.

– Energy: Fabricating parts for renewable energy systems, including wind turbines and solar panels.

– Telecommunications: Producing connectors, housings, and other critical components for communication devices.

– Construction: Crafting specialized tools and components for heavy machinery.

– Marine Engineering: Creating parts for ships and underwater instrumentation.

– Jewelry: Crafting intricate and custom-designed pieces with high precision.

– Sporting Goods: Manufacturing custom components for sporting equipment.

– Prototype Development: Quickly producing high-precision prototypes across various industries.

Through its advanced technology, China CNC machining continues to drive innovation, efficiency, and quality across global manufacturing sectors.

SourcifyChina is renowned for its high-quality CNC machining services. They utilize a wide range of materials, including metals like aluminum, stainless steel, and titanium, ensuring versatile, durable, and highly precise components.

Aluminum stands out for its lightweight nature and excellent corrosion resistance, making it ideal for aerospace and automotive industries. Stainless steel, known for its strength and anti-corrosive properties, is frequently used in medical and food equipment manufacturing.

Titanium, another material offered, combines the best of both worlds—lightweight and highly durable. It is commonly utilized in aerospace, medical implants, and high-performance automotive parts due to its exceptional strength-to-weight ratio.

Their CNC machining services also cater to various plastic materials like ABS, POM, and PTFE. These plastics are essential for parts that require electrical insulation, chemical resistance, or lightweight characteristics.

SourcifyChina’s material expertise, combined with advanced CNC machining technology, ensures that every product meets the stringent quality standards across multiple industries. This comprehensive material selection allows for customized solutions tailored to specific project requirements.

SourcifyChina excels in CNC machining, offering top-notch quality control throughout the manufacturing process. Stringent protocols ensure all parts meet precise specifications, maintaining high standards consistently.

The process begins with rigorous material inspection. Raw materials undergo thorough testing to confirm compliance with required standards, eliminating potential defects from the outset.

Advanced CNC machinery, operated by skilled technicians, ensures precision in manufacturing. Continuous monitoring during the machining process detects any deviations, allowing for immediate corrections to maintain accuracy.

Post-production, each component undergoes meticulous inspection using state-of-the-art measurement tools. This final quality check ensures all parts are flawless and ready for delivery.

By combining stringent material selection, precise machining, and comprehensive inspections, SourcifyChina guarantees superior quality in every CNC-machined product they deliver. This commitment to excellence solidifies their reputation in the industry.

SourcifyChina excels in precision CNC machining, providing superior quality, consistency, and efficiency. Utilizing advanced machinery, we cater to various industries, delivering parts with intricate details and tight tolerances.

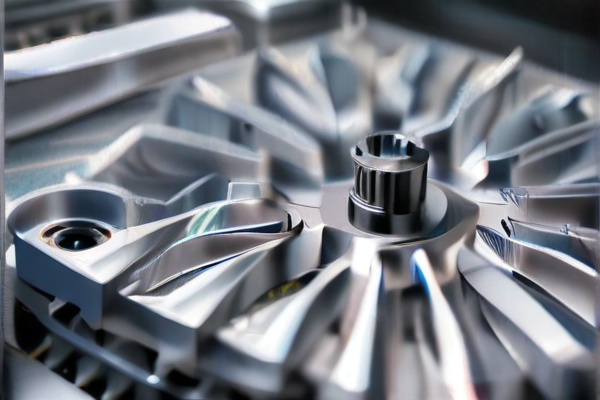

Our capabilities include 3-axis, 4-axis, and 5-axis CNC milling, and CNC turning, addressing complex geometries and high-volume production. We handle a wide range of materials, such as metals, plastics, and composites, ensuring versatility and adaptability.

With a strong focus on innovation, SourcifyChina leverages cutting-edge technology for rapid prototyping, reducing lead times and enhancing product development cycles. Automated processes ensure high repeatability and minimal human error.

Customer satisfaction is paramount, so we offer custom solutions tailored to specific requirements. Our team of skilled engineers provides technical support from initial design to final production, ensuring optimal results.

SourcifyChina’s CNC machining services are cost-effective, combining high quality with competitive pricing. We maintain rigorous quality control standards, implementing inspections at every production stage to guarantee excellence.

In summary, SourcifyChina’s CNC machining capabilities are robust and versatile, meeting diverse manufacturing needs with precision, efficiency, and reliability. Our commitment to quality and customer satisfaction makes us a preferred choice for CNC machining services.

China CNC machining offers numerous benefits, making it a top choice for precision manufacturing and production.

– Cost-Effective: Lower labor and operational costs make it an economical option for international businesses.

– High Precision: Advanced CNC technology ensures high accuracy and meticulous detail in the final products.

– Scalability: Capable of handling both small and large volumes efficiently, meeting diverse production needs.

– Speed: Rapid turnaround times due to streamlined processes and efficient machinery.

– Material Versatility: Works with a broad range of materials, from metals to plastics.

– Expertise: Skilled workforce with extensive experience in various industries.

– Comprehensive Services: Offers end-to-end solutions including design assistance, prototyping, and mass production.

– Quality Control: Rigorous quality standards and frequent inspections ensure superior product quality.

– Technological Advancements: Continuous investment in state-of-the-art machinery and software keeps China CNC machining at the forefront of innovation.

– Global Shipping: Well-established logistics networks facilitate timely and reliable international delivery.

China has become a global leader in CNC machining, offering a range of advanced features that make its services highly sought after. Key features include:

– Cost Efficiency: Favorable labor and material costs contribute to competitive pricing.

– High Precision: Advanced machinery and technology ensure tight tolerances.

– Scalability: Capable of handling both small batches and large-volume production.

– Material Variety: Proficiency in machining various materials, including metals and plastics.

– Quick Turnaround: Efficient processes enable fast production cycles.

– Integrated Services: Facilities often offer additional services like design, prototyping, and finishing.

– Quality Assurance: Strict quality control standards ensure reliability.

– Technological Advancement: Utilizes the latest in CNC technology and automation.

– Global Reach: Strong export capabilities supported by robust logistics.

– Customization: Flexible services tailored to specific customer requirements.

These features make China a premier destination for outsourcing CNC machining projects.

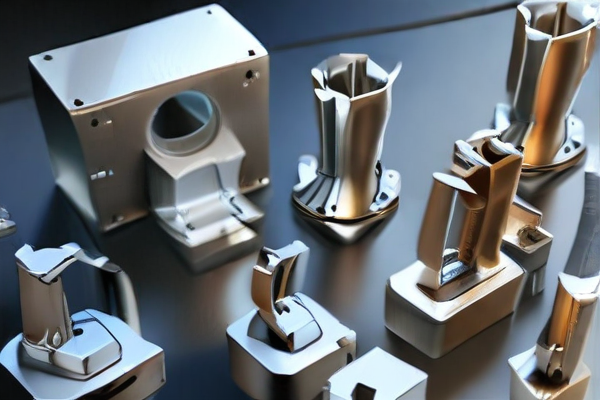

SourcifyChina specializes in high-quality CNC machining, offering custom products and projects to meet a variety of industry needs. Their state-of-the-art CNC machines ensure precision and efficiency.

The company caters to a wide range of sectors such as automotive, aerospace, and consumer electronics. Their expertise lies in creating both complex and simple parts with impeccable accuracy.

Clients benefit from rapid prototyping services, allowing for quick iterations and faster go-to-market timelines. SourcifyChina’s team collaborates closely with customers, ensuring each project meets exact specifications.

Additionally, SourcifyChina utilizes strict quality control measures to guarantee consistency and reliability. Each product undergoes rigorous testing before delivery, ensuring top-notch standards.

Their customer-centric approach means flexible production schedules and competitive pricing. SourcifyChina’s goal is to build long-term partnerships by consistently exceeding client expectations.

In conclusion, SourcifyChina stands out in the CNC machining industry for their commitment to quality, precision, and customer satisfaction. Whether for small-scale projects or large production runs, their capabilities make them a trusted partner for custom machining needs.

SourcifyChina, a prominent name in the world of CNC machining, exemplifies precision engineering and manufacturing excellence. Specializing in a broad spectrum of CNC machining services, including milling, turning, and complex multi-axis machining, the company caters to a diverse array of industries such as aerospace, automotive, medical, and consumer electronics. Leveraging advanced technologies and state-of-the-art machinery, SourcifyChina ensures stringent quality control, delivering components with exceptional accuracy and adherence to specifications. Their dedicated team of skilled engineers and technicians works closely with clients, providing tailored solutions that meet specific requirements and timelines. With a commitment to innovation, efficiency, and customer satisfaction, SourcifyChina stands out as a reliable partner for businesses seeking high-quality CNC machined parts from China.

China CNC machining has significantly advanced over recent years, playing a pivotal role in the aerospace, defense, and marine sectors. Aerospace industries demand high precision and reliability, and Chinese CNC machining stands out for its unparalleled accuracy and quality. The complex geometries and exacting tolerances required in the aerospace industry are easily managed by China’s sophisticated CNC machines, making them ideal for producing components like turbine blades, engine parts, and structural components. The ability to produce high-strength, lightweight materials aligns perfectly with aerospace needs, addressing the stringent demands for performance and safety. Additionally, the competitive costs and rapid turnaround times offered by Chinese CNC machining firms enhance their appeal to global aerospace companies seeking cost-effective and efficient manufacturing solutions.

In defense applications, Chinese CNC machining bolsters the production of critical components such as weapon systems, communication devices, and armored vehicle parts. The precision and consistency achieved through CNC machining ensure that these components meet the rigorous standards required for military use, where reliability can be a matter of national security. Furthermore, in the marine industry, the challenges of withstanding harsh environments and corrosive conditions require materials and components of the highest quality. Chinese CNC machining excels in producing robust propellers, hull components, and other marine parts that deliver durability and performance under extreme conditions. The global reach of Chinese CNC technology, combined with its advancements in multi-axis machining and material sciences, makes it a crucial player in meeting the exacting demands of aerospace, defense, and marine applications.

China CNC machining has become a pivotal technology in the automotive industry due to its precision, efficiency, and versatility. This manufacturing process enables the production of complex and highly accurate components necessary for modern vehicles. From engine blocks and transmission parts to custom interior fittings and prototype development, China’s CNC machining capabilities ensure high quality and consistency. The rise of electric vehicles (EVs) has further amplified the demand for CNC machining, as it is crucial for crafting lightweight and high-strength components like battery housings and motor parts. By leveraging state-of-the-art CNC technology, Chinese manufacturers can meet stringent automotive standards and deliver cost-effective solutions, making the nation a hub for automotive innovation and production.

Similarly, China’s CNC machining industry plays an essential role in the electronics sector, known for its need for precision and miniaturization. Advanced CNC machinery allows for the production of intricate components such as heat sinks, housings, and printed circuit board (PCB) enclosures with excellent accuracy. The electronics market is characterized by rapid advancements and a high turnover of technological innovations, requiring manufacturing solutions that are both quick and adaptable. Chinese CNC machinists excel in producing bespoke, small-batch runs as well as large-scale, mass production, ensuring that electronics companies can keep up with the fast-paced market demands. The CNC machining technology employed in China also supports the production of critical components for telecommunications, medical devices, and consumer electronics, reinforcing the country’s significant position in the global electronics supply chain.

China’s CNC machining has revolutionized the construction industry by providing high precision and efficiency in producing construction components. With its advanced computer-controlled technology, Chinese CNC machines can fabricate complex architectural elements, structural components, and customized metal parts with minimal error margins. This level of precision ensures that construction projects adhere to stringent safety and quality standards, reducing the risk of structural failures. Moreover, CNC machining allows for the rapid production of parts, significantly cutting down project timelines and labor costs. The ability to produce on-demand, tailor-made components supports innovative architectural designs and contributes to the seamless integration of advanced materials and techniques in modern construction projects.

In the energy sector, China’s CNC machining technology plays a vital role in the manufacturing of key energy infrastructure components, such as turbine blades, heat exchangers, and compressor parts. The precision afforded by CNC machining ensures optimal performance and longevity of these components, which are critical for the efficiency and reliability of energy systems. For instance, in renewable energy applications, CNC-machined parts for wind turbines and solar panel mounts must meet strict tolerances to maximize energy capture and operational stability. Furthermore, China’s extensive CNC machining capabilities support the rapid prototyping and production of next-generation energy solutions, helping to accelerate the transition to cleaner energy sources. By leveraging advanced CNC machining technologies, the energy sector not only enhances performance and sustainability but also reduces downtime and maintenance costs, ensuring a more resilient energy infrastructure.

The industrial equipment industry has seen a significant transformation with the integration of China CNC machining, a technology that enhances precision and efficiency in manufacturing. CNC (Computer Numerical Control) machining has revolutionized the production of complex parts and components. Employing advanced computerized systems, it allows for high levels of precision, thus meeting the stringent requirements of industrial equipment. China’s capabilities in this sector have positioned it as a global hub for CNC machining services. The high precision and automated processes minimize human error, which is crucial for producing reliable and high-quality industrial equipment components, such as gears, levers, and intricate machinery parts. The cost-efficiency of sourcing these services from China further enhances the appeal, allowing manufacturers worldwide to benefit from reduced production costs without compromising on quality.

Moreover, the vast scalability offered by China CNC machining supports mass production, essential for large-scale industrial equipment manufacturers. The flexibility of CNC machines in China ensures they can handle both small batch production and large volume manufacturing with equal efficiency. This adaptability helps companies swiftly adjust to market demands and maintain an agile production cycle. Additionally, the ability to produce complex geometries with consistent quality guarantees that even the most intricate designs meet rigorous industrial standards. As a result, industries ranging from automotive to aerospace and heavy machinery are increasingly relying on China’s CNC machining services to maintain competitive advantages in both innovation and cost-efficiency. The robust supply chain and technological advancements in Chinese CNC machining continue to bolster the industrial equipment industry’s growth and innovation capabilities globally.

China CNC machining has carved a significant niche in the production of medical devices, leveraging advanced technology and precision engineering to meet stringent industry standards. This process involves the use of computer-controlled tools to produce intricate and highly accurate components essential for medical equipment. The ability to craft parts with tight tolerances and intricate geometries makes CNC machining indispensable in the manufacturing of devices such as surgical instruments, diagnostic machines, and custom implants. Chinese manufacturers have capitalized on cost-effective production and a skilled workforce, offering high-quality components that meet global medical standards. This has enabled the rapid development and deployment of life-saving devices, supporting healthcare systems worldwide.

The application of CNC machining in China extends beyond just basic medical tools; it includes the production of highly complex devices like pacemakers, robotic surgical systems, and advanced prosthetics. These components require meticulous attention to detail and consistent quality, achievable through the precision of CNC machining. Moreover, China’s capacity for high-volume production ensures that these critical medical devices can be produced efficiently to meet growing demand. By integrating state-of-the-art technology such as 5-axis machining, additive manufacturing, and automated inspection systems, Chinese CNC machining facilities can maintain the high standards demanded by the medical industry while also driving innovation. This symbiotic relationship between technology and manufacturing prowess underscores China’s pivotal role in the global medical device supply chain.

China CNC machining plays an instrumental role in modern machining and manufacturing, offering precision and efficiency across multiple industries. The acronym “CNC” stands for Computer Numerical Control, which utilizes advanced software and computerized systems to control machining tools and processes with unparalleled accuracy. This technology is extensively employed in producing complex parts for aerospace, automotive, electronics, and medical devices, among others. Chinese CNC machining firms benefit from advanced technologies, skilled labor, and comprehensive supply chains, enabling them to deliver high-quality products at competitive costs. This amalgamation of cutting-edge technology and economic efficiency makes China a global hub for CNC machining services.

In the context of manufacturing, China CNC machining provides versatile and scalable solutions. The capacity to quickly switch between different machining tasks and create intricate components enables manufacturers to maintain high throughput while ensuring product quality. This flexibility is particularly crucial in prototype development and small-batch production, where customization and precision are paramount. Moreover, Chinese CNC machining facilities often conform to international standards, ensuring that the produced parts meet stringent quality requirements. The adoption of CNC machining in Chinese manufacturing not only improves operational efficiency but also supports continuous innovation, enabling manufacturers to stay ahead in an increasingly competitive global market.

Sure, here are some frequently asked questions (FAQ) regarding manufacturing China CNC machining quality work from SourcifyChina factory:

1. What is CNC machining?

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. This allows for precise, high-quality production of parts and products.

2. Why should I choose SourcifyChina for CNC machining?

SourcifyChina is renowned for its high-quality CNC machining services. We utilize advanced machinery, experienced engineers, and stringent quality control processes to ensure that every product meets your specifications.

3. What materials can SourcifyChina work with in CNC machining?

Our CNC machining capabilities include a wide range of materials including aluminum, steel, brass, copper, plastics, and more. We can accommodate various material needs for diverse applications.

4. How does SourcifyChina ensure quality in CNC-machined parts?

Quality assurance is integral to our operations. We implement rigorous inspection procedures, including in-process inspections, final product quality checks, and the use of advanced measurement instruments to ensure adherence to specifications.

5. Can SourcifyChina handle custom CNC machining projects?

Absolutely, we specialize in custom CNC machining. Our team will work closely with you to understand your requirements, provide design for manufacturability (DFM) feedback, and ensure your parts are made to your exact specifications.

6. What is the lead time for CNC machining projects?

Lead times can vary based on the complexity and volume of the order. Typically, prototypes can be delivered within a few days, while larger production runs may take a few weeks. We strive to meet your deadlines without compromising quality.

7. What file formats does SourcifyChina accept for CNC machining projects?

We accept a variety of file formats, including STL, STEP, IGES, and more. Our team can assist you in preparing your files to ensure the best possible machining outcomes.

8. Do you offer post-processing services?

Yes, we offer a range of post-processing services such as anodizing, painting, powder coating, and more to provide a finished product that meets your needs.

9. How competitive are your pricing and payment terms?

We offer competitive pricing tailored to your project scope and requirements. Our payment terms are flexible to support various business needs, ensuring a smooth and transparent transaction process.

10. How can I get a quote for my CNC machining project?

When considering CNC machining manufacturing services from SourcifyChina factory, there are several tips to keep in mind to ensure a successful partnership:

1. Evaluate Expertise: Verify the factory’s experience and expertise in CNC machining. Look for certifications like ISO 9001, which indicates adherence to international quality standards.

2. Material Selection: Ensure they have experience with the specific materials you require, be it metals like aluminum or steel, or plastics such as nylon or ABS.

3. Precision and Tolerances: Discuss the precision and tolerances required for your project. High-precision CNC machining can achieve tolerances as tight as ±0.005 mm.

4. Prototyping Services: Check if they offer prototyping services. Prototyping allows you to test the design and functionality before committing to full-scale production.

5. Technology and Machinery: Inquire about the types of CNC machines they use. Modern 3-axis, 4-axis, and 5-axis machines provide greater flexibility and precision.

6. Quality Control: Confirm their quality control processes, such as in-process inspections, final inspections, and use of Coordinate Measuring Machines (CMM).

7. Lead Times: Discuss lead times for production. Factor in potential delays and ensure they can meet your deadlines consistently.

8. Communication: Clear communication is crucial, especially when dealing with overseas manufacturers. Ensure they provide regular updates and have English-speaking staff.

9. Cost: Get detailed quotes and compare costs. Remember, the cheapest option might not always be the best in terms of quality and reliability.

10. Partnership and Reliability: Look for a factory interested in building a long-term partnership rather than just a one-time transaction. Check reviews and ask for references to gauge their reliability.

By focusing on these aspects, you can leverage the capabilities of SourcifyChina factory for effective and efficient CNC machining manufacturing.

Sure! Here are some frequently asked questions (FAQ) along with their answers regarding sourcing China CNC machining from SourcifyChina factory.

1. What is CNC machining?

CNC machining is a manufacturing process that involves the use of computer-controlled machines to produce precision parts. CNC stands for Computer Numerical Control, and the process is used across various industries to create high-quality components from materials like metal, plastic, and wood.

2. Why should I choose SourcifyChina for CNC machining?

SourcifyChina offers expertise, advanced equipment, and quality control to ensure high-precision parts. They have a strong network of verified factories and provide comprehensive services from prototyping to mass production, tailored to meet your specific requirements.

3. What materials can be used for CNC machining at SourcifyChina?

SourcifyChina can work with a wide range of materials including stainless steel, aluminum, brass, titanium, plastics, and other specialty materials, ensuring high-quality parts that meet industry standards.

4. What is the lead time for CNC machining orders?

The lead time for CNC machining orders typically varies based on the complexity and volume of the parts. Generally, prototyping can take a few days to several weeks, while mass production orders might take longer. Specific timelines can be provided upon evaluation of your project details.

5. How does SourcifyChina ensure the quality of CNC machined parts?

SourcifyChina implements strict quality control measures including material verification, dimensional inspections, and functional testing. They use advanced metrological equipment to ensure parts meet all specifications.

6. Can I get a sample before placing a larger order?

Yes, SourcifyChina offers prototyping and sample services. You can request a sample to evaluate the quality and specifications before committing to a larger order.

7. What are the costs associated with CNC machining from SourcifyChina?

Costs vary depending on factors such as material type, part complexity, quantity, and finishing requirements. SourcifyChina provides competitive pricing and detailed quotes based on your specific project needs.

8. How do I start a CNC machining project with SourcifyChina?

To start a CNC machining project, you can contact SourcifyChina through their website or customer service. Provide detailed information about your project, including drawings, specifications, and any special requirements. Their team will guide you through the process and provide a customized solution.

9. Can SourcifyChina handle large volume orders?

Sourcing CNC machining services from a Chinese factory like SourcifyChina can be advantageous due to cost savings and high-quality output. Here are some tips to guide you through the process efficiently:

1. Research and Verification:

– Background Check: Verify the factory’s credentials. Look for certifications such as ISO 9001, and request case studies or customer testimonials.

– Reputation: Use platforms like Alibaba, Global Sources, or Made-in-China to check reviews and ratings.

2. Detailed RFQ (Request for Quotation):

– Specifications: Provide detailed drawings, material requirements, tolerances, finishes, and quantity.

– Lead Time: Communicate your timeline to ensure the factory can meet your deadlines.

3. Sample Production:

– Prototype: Order a prototype before committing to large-scale production. This helps to verify quality and precision.

– Adjustments: Use the prototype phase to make any necessary design adjustments.

4. Communication:

– Clear Language: Use clear and concise language to avoid misunderstandings.

– Regular Updates: Maintain regular communication through emails, calls, or video conferences.

5. Quality Assurance:

– QC Standards: Confirm the factory’s quality control processes. Ensure they have systems in place for in-process and final inspections.

– Third-Party Inspection: Consider hiring an independent QC firm to inspect the final products before shipment.

6. Logistics and Shipping:

– Incoterms: Agree on Incoterms (such as FOB, CIF) to clearly define who is responsible for what during shipping.

– Shipping Partner: Choose a reliable shipping partner to handle logistics and customs clearance.

7. Payment Terms:

– Negotiate Terms: Common terms are 30% upfront and 70% upon completion but negotiate terms that also protect your interests.

– Secure Options: Use secure payment methods like PayPal, Escrow, or L/C.

By following these steps, you can effectively source CNC machining services from SourcifyChina or similar factories, ensuring quality production and timely delivery.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.