Choosing SourcifyChina Factory for purchasing from Chinese machining companies ensures unparalleled quality. They have a stringent quality control process, ensuring every product meets international standards.

Moreover, SourcifyChina’s extensive network connects buyers with the best manufacturers, securing competitive prices and reducing procurement costs.

Their expert team offers comprehensive support, from initial consultation to final delivery, ensuring a seamless purchasing experience.

In summary, choosing SourcifyChina Factory provides quality assurance, cost efficiency, and exceptional customer support, making it the ideal partner for sourcing machining companies in China.

Chinese machining companies offer various types of services, including CNC machining, metal stamping, die casting, and plastic injection molding. These companies are known for their competitive pricing, high-quality output, and timely delivery.

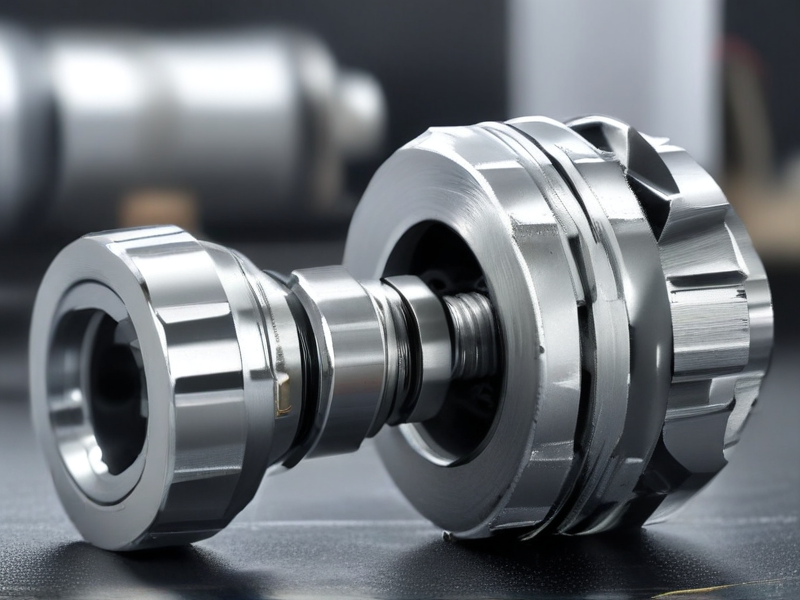

– CNC Machining: Precision machining with computer-controlled tools, ideal for complex and detailed parts.

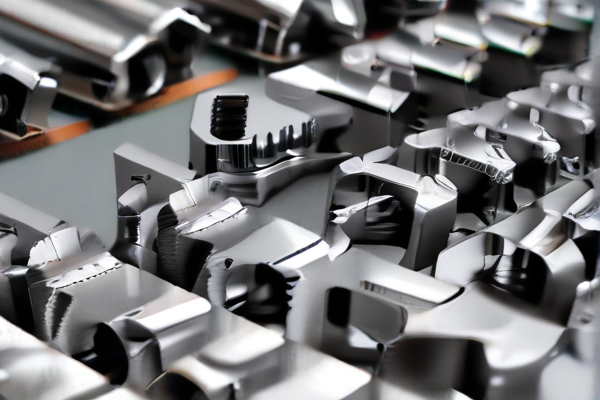

– Metal Stamping: High-speed production for metal parts through stamping presses and dies, suitable for large volume manufacturing.

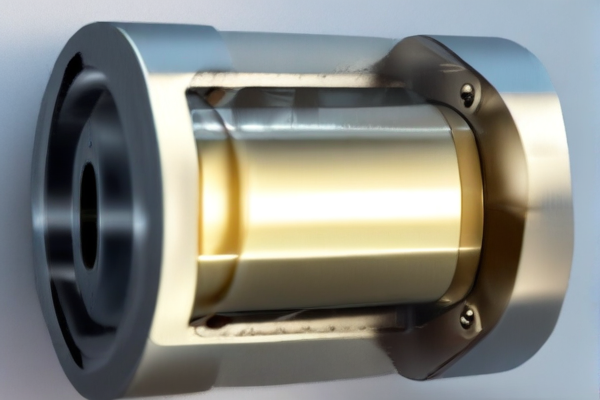

– Die Casting: Casting process that forces molten metal into mold cavities, perfect for producing complex metal parts.

– Plastic Injection Molding: Manufacturing process for creating plastic parts by injecting molten plastic into molds, widely used for a variety of products.

– Prototype Machining: Quick-turnaround service for developing prototypes, essential for product development and testing.

– Sheet Metal Fabrication: Cutting, bending, and assembling sheet metal to create a variety of structures or parts.

– Wire EDM: Wire Electrical Discharge Machining process for cutting intricate shapes in hard metals.

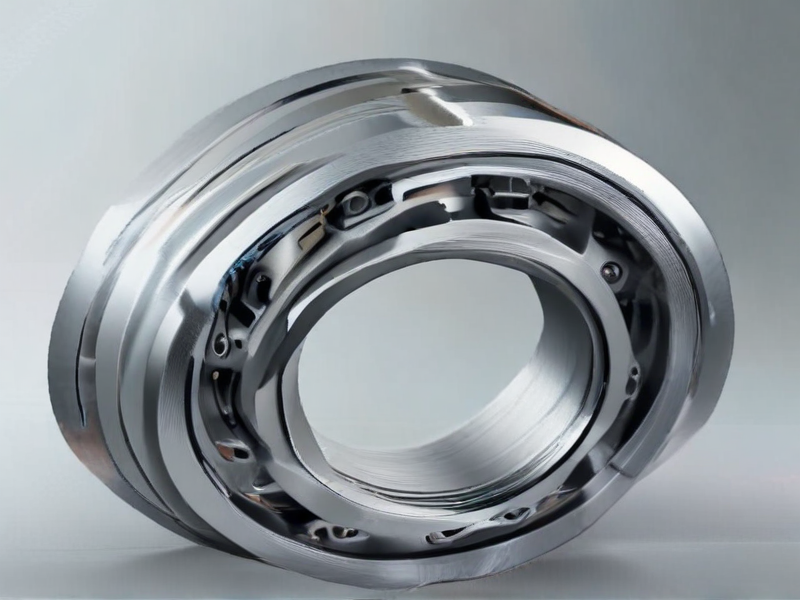

– Grinding and Polishing: Processes for achieving a high-precision surface finish on parts.

– Heat Treatment: Enhancing the physical properties of metal parts through heat application.

– Surface Finishing: Techniques such as anodizing, painting, or powder coating to improve appearance and resistance to corrosion.

These diverse options enable Chinese machining companies to cater to a wide range of industries, including automotive, aerospace, electronics, and consumer goods.

Chinese machining companies have become indispensable for various industries due to their cost-effectiveness, precision, and advanced technology. Their capabilities span multiple applications, serving sectors such as automotive, aerospace, electronics, and medical devices.

– Automotive Industry: Manufacture of engine parts, chassis components, and other automotive assemblies.

– Aerospace Industry: Production of high-precision aircraft components, including turbines, gears, and structural parts.

– Electronics Industry: Fabrication of complex parts for smartphones, computers, and other electronic devices.

– Medical Devices: Production of surgical instruments, diagnostic tools, and medical implants with high precision.

– Oil and Gas: Creation of drilling equipment, pipeline components, and other essential parts for exploration and extraction.

– Industrial Machinery: Manufacturing of machine parts, gears, and other industrial components for a wide range of machinery.

– Construction: Production of heavy equipment parts and tools used in construction projects.

– Renewable Energy: Fabrication of parts for wind turbines, solar panels, and other renewable energy technologies.

– Defense Sector: Manufacturing of critical components for military vehicles, equipment, and weaponry.

SourcifyChina connects clients with reliable Chinese machining companies, offering top-tier materials such as aluminum, stainless steel, and titanium. These materials are chosen for their durability, corrosion resistance, and high strength-to-weight ratios, ensuring optimal performance across various applications.

Aluminum is a popular choice for its lightweight properties and excellent machinability. It is widely used in aerospace, automotive, and consumer electronics industries. Custom machining processes can shape aluminum into intricate parts to meet specific tolerances and designs.

Stainless steel is favored for its robust corrosion resistance and strength. It is commonly used in food processing, medical devices, and construction. Precision machining can create complex components from stainless steel, ensuring longevity and reliability in demanding environments.

Titanium is known for its extraordinary strength and heat resistance while remaining lightweight. This makes it ideal for aerospace, military, and high-performance sporting goods. Machining titanium requires specialized equipment and expertise to maintain its properties and achieve precision results.

Overall, SourcifyChina prioritizes high-quality materials to deliver excellence in custom machining projects. Their partnership with proficient Chinese machining companies guarantees that client specifications are met with precision, efficiency, and cost-effectiveness. By leveraging premier materials like aluminum, stainless steel, and titanium, SourcifyChina ensures that every project stands up to the most stringent industry demands.

SourcifyChina collaborates with top-tier Chinese machining companies to ensure the highest quality standards in manufacturing. The process begins with the rigorous selection of raw materials, which undergo various inspections to meet international standards.

State-of-the-art machinery and skilled technicians play a crucial role in the production process. Computer Numerical Control (CNC) machines are utilized to achieve precision, while operators closely monitor each step to maintain consistency and accuracy.

To maintain quality, multiple inspection phases are conducted. Initial inspections catch any early defects, while mid-production checks ensure ongoing compliance with specifications. Final inspections serve as the last defense against errors before products reach customers.

Quality control doesn’t stop at inspections. These companies implement robust documentation and traceability systems, ensuring that any potential issues can be quickly identified and rectified. This comprehensive approach minimizes defects and rework.

Customer feedback is integral to quality improvement. Machining companies in SourcifyChina’s network actively seek input from clients, using this information to refine processes and enhance product quality continually. This commitment to excellence ensures long-term customer satisfaction.

Innovations in quality control technologies are also embraced. Advanced software and automation tools improve inspection precision and efficiency. Statistical Process Control (SPC) methods are used to predict and prevent potential issues, further enhancing reliability.

Employee training programs further bolster the quality assurance process. Technicians receive regular training to stay updated on the latest industry standards and practices, ensuring high competence in all aspects of manufacturing.

In summary, SourcifyChina’s partnership with Chinese machining companies exemplifies a meticulous and multi-layered approach to quality control. From material selection to final inspection, every step is designed to deliver high-quality products. This focused dedication underscores SourcifyChina’s commitment to excellence and customer satisfaction, ensuring they remain a trusted partner in the global manufacturing landscape.

SourcifyChina Chinese machining companies excel in precision manufacturing, leveraging advanced CNC technology and skilled labor to produce high-quality components. Their technical expertise allows for tight tolerances and complex geometries, meeting diverse industry standards.

These companies offer a broad range of services, from milling and turning to grinding and drilling. Their capabilities include working with various materials, including metals, plastics, and composites, providing versatile solutions for engineering challenges.

Quality control is a priority, with rigorous inspection processes and certifications such as ISO 9001 ensuring reliable and consistent output. This commitment to quality underpins their reputation for dependability.

In addition to machining, many firms provide added services like surface finishing, heat treatment, and assembly. These value-added services streamline the production process, reducing lead times and costs for their clients.

SourcifyChina ensures that its partner companies stay updated with the latest technological advancements and industry trends. Continuous investment in R&D and equipment upgrades keeps them at the forefront of innovation, enabling them to tackle complex and high-demand projects.

Customer-oriented, these companies prioritize clear communication and flexibility, often customizing services to meet specific client requirements. This personalized approach fosters long-term collaborations and satisfaction.

Through strategic partnerships and a robust supply chain network, SourcifyChina Chinese machining companies can handle both small-scale and mass production needs. They effectively manage logistical challenges, ensuring timely delivery and competitive pricing.

In conclusion, SourcifyChina Chinese machining companies combine technical prowess with a commitment to quality and customer service. Their comprehensive capabilities, from precision machining to ancillary services, make them valuable partners in various industries, driving efficiency and innovation. Their dedication to continuous improvement and client satisfaction ensures they stay ahead in a competitive market.

Chinese machining companies offer numerous benefits to businesses worldwide, providing cost-effective, high-quality, and technologically advanced manufacturing solutions.

– Cost Efficiency: Competitive pricing due to lower labor and production costs.

– High Quality: Advanced technology and strict quality control ensure premium product standards.

– Large Production Capacity: Capable of handling large-scale production, catering to high-demand orders.

– Skilled Workforce: Highly trained and skilled workers bring expertise to various machining processes.

– Innovation and Technology: Continuous investment in state-of-the-art machinery and innovative techniques.

– Customization: Ability to produce customized components based on specific client requirements.

– Global Logistics: Well-established supply chains and efficient logistics systems facilitate timely and reliable delivery.

– Collaborative Approach: Strong focus on building long-term partnerships with clients through effective communication and collaboration.

– Diverse Material Handling: Capability to work with a wide range of materials including metals, plastics, and composites.

– Regulatory Compliance: Adherence to international standards and certifications, ensuring products meet global market requirements.

– Economic Scale: Large-scale operation provides economies of scale, reducing per-unit costs.

– Research and Development: Significant investment in R&D to stay ahead of market trends and technological advancements.

– Turnkey Solutions: Offering end-to-end services from design to production and finishing, providing a comprehensive manufacturing solution.

– Customer Support: Dedicated customer service teams ensure smooth communication and issue resolution.

– Environmental Responsibility: Commitment to environmental sustainability with eco-friendly practices and certifications.

Chinese machining companies have gained global recognition for their high-quality products, cutting-edge technology, competitive pricing, and efficient production capabilities.

– Advanced Technology: Many Chinese machining firms utilize state-of-the-art CNC machines, ensuring precision and efficiency in production.

– Skilled Workforce: These companies boast a highly skilled workforce trained to handle complex machining tasks with expertise.

– Cost-Effectiveness: Competitive labor costs and economies of scale allow Chinese companies to offer machining services at lower prices without compromising quality.

– Customization: Flexibility in manufacturing processes enables them to provide customized solutions to meet specific client needs.

– Rapid Prototyping: Speedy production times for prototypes help clients accelerate their product development cycles.

– Quality Assurance: Many firms adhere to international quality standards, including ISO certifications, ensuring consistent product quality.

– Global Supply Chains: Efficient logistics networks allow for timely deliveries, supporting global distribution and supply chains.

– Innovation: A focus on research and development helps these companies to innovate and stay ahead in the competitive market.

– Environmental Compliance: Increasingly, companies are adopting eco-friendly practices and technologies to minimize environmental impact.

– Customer Service: Strong customer support and after-sales service provide clients with smooth, hassle-free interactions.

SourcifyChina is a leading facilitator connecting global businesses with top-tier Chinese machining companies. Renowned for their precision and innovation, these manufacturers excel in producing custom products tailored to specific project needs.

With expertise in various sectors, SourcifyChina ensures seamless collaboration, offering clients access to a wide range of services. From initial design to final production, their network of Chinese machining firms provides end-to-end solutions that meet stringent quality standards.

Clients benefit from cost efficiency without compromising quality. SourcifyChina’s strategic partnerships enable competitive pricing and timely delivery, making them a go-to choice for businesses seeking reliable manufacturing solutions.

In addition to conventional machining, these companies are proficient in advanced techniques such as CNC machining, 3D printing, and additive manufacturing. This versatility allows them to handle complex projects with high precision.

SourcifyChina prioritizes transparency and communication, fostering strong relationships between clients and manufacturers. Their dedicated team ensures that every project is executed flawlessly, from concept to completion.

The commitment to excellence and innovation positions SourcifyChina as a crucial player in the international manufacturing landscape. They continually strive to match client expectations with outstanding delivery, enhancing project success rates.

For businesses seeking customized machining solutions, SourcifyChina stands out as a trusted partner. Their comprehensive approach and access to top Chinese machining talent make them a reliable choice for diverse manufacturing needs.

SourcifyChina is a premier player in the realm of Chinese machining companies, delivering high-quality, precision-engineered components and solutions to its global clientele. Renowned for leveraging cutting-edge technology and stringent quality control measures, SourcifyChina excels in producing a wide range of machined parts by utilizing CNC machining, injection molding, and die-casting processes. The company prides itself on its robust infrastructure, capable of handling both high-volume production runs and bespoke, specialized orders. With a diverse team of skilled engineers and technicians, SourcifyChina is committed to innovation and continuous improvement, ensuring that clients receive products that exceed their expectations in terms of durability, accuracy, and performance. Moreover, their customer-centric approach and seamless logistics chain make them a preferred partner for businesses seeking reliable and efficient manufacturing solutions from China.

Chinese machining companies have established a significant foothold in the aerospace, defense, and marine industries, leveraging their advanced manufacturing capabilities and cost-effective solutions. In aerospace, precision is crucial, and Chinese companies have demonstrated the ability to produce high-tolerance components required for aircraft engines, landing gear, and avionics systems. Utilizing state-of-the-art CNC machines and adhering to stringent quality standards, they supply parts that meet rigorous international certifications. This has resulted in collaborations with global aerospace giants, contributing to the manufacturing of reliable and efficient aircraft. Their expertise extends to exotic materials like titanium and Inconel, which are essential for withstanding the extreme conditions encountered in flight.

In the defense sector, Chinese machining companies provide critical components for military vehicles, weaponry, and communication systems. Their capability to produce durable and precise parts is integral for the performance and reliability of defense equipment. Advanced machining techniques allow for the manufacture of complex geometries needed in sophisticated defense applications, from radar systems to missile components. Meanwhile, in the marine industry, Chinese companies excel in producing high-performance marine engine parts, propellers, and hull components. With a focus on corrosion-resistant materials and robust construction, they ensure the longevity and efficiency of marine vessels operating in harsh sea conditions. The combination of advanced technology, skilled workforce, and competitive pricing positions Chinese machining companies as valuable partners in these high-stakes sectors.

Chinese machining companies have become pivotal players in the global automotive industry by providing high-precision components crucial for modern vehicles. Utilizing advanced techniques such as CNC (Computer Numerical Control) machining, these firms produce a wide range of parts from engine blocks and cylinder heads to suspension components and intricate transmission parts. The automotive sector demands exacting standards for durability and performance, and Chinese machining firms have met this challenge by investing heavily in state-of-the-art equipment and stringent quality control measures. The result is a reliable supply chain that can meet both mass production needs and custom, low-volume orders. By offering competitively priced, high-quality components, Chinese machining companies enable automotive manufacturers worldwide to maintain cost efficiency without compromising on the durability and performance of their products.

In the electronics sector, Chinese machining companies are equally influential, providing precision parts required for a plethora of devices ranging from smartphones and laptops to intricate medical instruments and aerospace electronics. Precision is paramount in electronics manufacturing, and CNC machining offers the ability to fabricate components with incredible accuracy, often down to microns. Chinese firms excel in this area thanks to their adoption of cutting-edge technology and an immensely skilled workforce. They’re capable of producing highly intricate parts, such as micro-housings, circuit board mounts, and heat sinks, which are essential for the function and reliability of electronic devices. Furthermore, these companies often collaborate closely with electronics giants to innovate and streamline production processes, making them not just suppliers but strategic partners in technological advancement. This synergy enables rapid prototyping and efficient scaling of new technologies, keeping pace with the fast-evolving electronics market.

Chinese machining companies have become integral to the construction industry due to their advanced capabilities in precision manufacturing and large-scale production. These companies leverage cutting-edge technologies, such as CNC (Computer Numerical Control) machining and automated production lines, to produce high-quality components for construction machinery, building materials, and structural elements. The ability to produce specialized parts with tight tolerances and consistent quality ensures that Chinese machining companies can meet the demanding requirements of modern construction projects. Their competitive pricing, coupled with a robust supply chain, enables construction firms to procure essential components efficiently, contributing to the overall cost-effectiveness and timeliness of project completion. Furthermore, Chinese machining firms’ expertise in customized solutions allows them to cater to specific project needs, enhancing the structural integrity and safety of construction endeavors globally.

In the energy sector, Chinese machining companies play a pivotal role in the manufacturing of critical components used in various energy applications, such as wind turbines, solar panels, and nuclear energy systems. Their proficiency in producing high-precision parts ensures the reliability and efficiency of energy generation equipment. For instance, the production of turbine blades, which require meticulous machining to achieve aerodynamic efficiency and durability, is a forte of these companies. Additionally, their advancements in materials engineering allow for the creation of components that can withstand extreme environmental conditions, a necessity for sustainable energy production. The scalability of Chinese machining operations means they can support large-scale energy projects, driving down costs and fostering innovation within the industry. As the world increasingly shifts towards renewable energy sources, the role of Chinese machining companies in fabricating essential components will be crucial in meeting global energy demands sustainably and efficiently.

The industrial equipment industry significantly benefits from the capabilities of Chinese machining companies, primarily due to their advanced technological infrastructure and cost-effective production methods. Chinese machining companies are equipped with state-of-the-art CNC (Computer Numerical Control) machines, laser cutting tools, and sophisticated automation systems. This technological prowess enables them to produce high-precision components that are critical for industrial equipment such as turbines, pumps, and heavy machinery. Furthermore, the relatively lower labor costs in China contribute to more competitive pricing, allowing global manufacturers to source high-quality parts without inflating their production budgets. This combination of precision engineering and cost efficiency has positioned Chinese machining firms as valuable partners in the global supply chain for industrial equipment.

Moreover, Chinese machining companies are increasingly focusing on innovation and quality assurance to meet international standards, thereby enhancing their global appeal. These companies invest heavily in research and development to create cutting-edge machining solutions that cater to the evolving needs of the industrial equipment sector. For example, the integration of IoT (Internet of Things) capabilities into machined components allows for real-time monitoring and predictive maintenance, which are critical aspects of modern industrial operations. Additionally, adherence to stringent quality control mechanisms ensures that the components produced conform to international standards such as ISO and ASTM. This focus on quality and innovation not only fosters trust among global industrial equipment manufacturers but also solidifies the reputation of Chinese machining companies as leaders in the field.

Chinese machining companies have increasingly positioned themselves as pivotal players in the global medical devices manufacturing industry. Leveraging advanced CNC (Computer Numerical Control) machining technologies, these companies are adept at producing highly precise and complex components required for medical instruments and devices. From surgical tools and implants to diagnostic apparatus and laboratory equipment, the meticulous craftsmanship and rigorous quality control adhered to by Chinese manufacturers ensure that their outputs meet international standards. With capabilities in producing intricate parts with tight tolerances, these companies facilitate innovation and efficiency in medical device design, ultimately enhancing patient care and treatment outcomes.

Moreover, the cost advantages offered by Chinese machining companies provide significant economic benefits to global medical device firms. By outsourcing manufacturing to China, companies can leverage lower labor costs and economies of scale, allowing for competitive pricing without compromising on quality. Chinese manufacturers also offer rapid prototyping services that expedite the development timeline for new medical technologies, enabling quicker transition from concept to market. Combined with their expertise in regulatory compliance and ability to produce in large volumes, the collaboration with Chinese machining firms becomes a strategic asset for global companies seeking to maintain a competitive edge in the cutting-edge field of medical devices.

Chinese machining companies have become pivotal players in the global manufacturing landscape, leveraging advanced technology and a highly skilled workforce to meet the diverse demands of various industries. These companies offer a spectrum of machining services, including CNC milling, turning, grinding, and 3D printing, which cater to sectors like automotive, aerospace, consumer electronics, and medical devices. With the incorporation of precision engineering and rigorous quality control standards, Chinese machining firms ensure that components and products meet internationally recognized specifications and tolerances. This reliability and precision have enabled them to build robust partnerships with Western companies, enhancing their reputation as trusted suppliers of high-quality machined parts.

Furthermore, Chinese machining companies are at the forefront of adopting Industry 4.0 practices, integrating smart manufacturing technologies such as IoT, AI, and robotics into their production lines. This digital transformation enables real-time monitoring, predictive maintenance, and automation of complex manufacturing processes, significantly enhancing productivity and reducing downtime. By leveraging competitive labor costs and scalable production capabilities, Chinese machining firms offer cost-effective solutions without compromising on quality. Consequently, businesses from around the world increasingly turn to these companies for their machining and manufacturing needs, recognizing the seamless blend of advanced technology, competitive pricing, and robust production capabilities that Chinese machining firms deliver.

Sure, here is a concise list of FAQs with answers regarding “Chinese machining companies quality work from SourcifyChina factory”:

Q1: What materials can SourcifyChina handle?

A1: SourcifyChina can machine a wide range of materials including aluminum, steel, brass, copper, and various plastics to meet diverse manufacturing needs.

Q2: How does SourcifyChina ensure quality control?

A2: SourcifyChina employs rigorous quality control measures, including advanced metrological equipment and a dedicated QC team to inspect and verify the precision of parts at various production stages.

Q3: What ISO certification does SourcifyChina have?

A3: SourcifyChina is ISO 9001:2015 certified, ensuring that it adheres to international standards for quality management systems, ensuring reliability and high-quality production.

Q4: Can SourcifyChina handle custom machining projects?

A4: Yes, SourcifyChina specializes in custom machining projects and can accommodate specific design requirements, providing tailored solutions to meet client specifications.

Q5: How long does it typically take to complete a project?

A5: Project timelines depend on complexity and quantity, but SourcifyChina strives to complete most orders within 2-4 weeks, offering expedited services for urgent requirements.

Q6: What types of machining services does SourcifyChina offer?

A6: SourcifyChina provides CNC milling, turning, drilling, and grinding, among other machining services, to cater to various manufacturing needs.

Q7: How does SourcifyChina manage communication and updates with international clients?

A7: SourcifyChina maintains clear communication channels, providing regular project updates and bilingual support to ensure seamless coordination with international clients.

Q8: Are there minimum order quantities (MOQs) at SourcifyChina?

A8: SourcifyChina has flexible MOQ policies to accommodate both small-scale prototyping and large-scale production runs, ensuring it can support businesses of all sizes.

Q9: What industries does SourcifyChina serve?

A9: SourcifyChina serves a variety of industries, including automotive, aerospace, electronics, medical devices, and consumer goods, providing versatile machining solutions.

Q10: How can I get a quote for my project?

Sourcing from Chinese machining companies, such as those connected through SourcifyChina, can offer competitive advantages in terms of cost and scalability. Here are some essential tips to ensure a successful partnership:

1. Research and Due Diligence: Prioritize companies with good reputations. Use platforms like Alibaba, Global Sources, or SourcifyChina to read reviews and verify credentials.

2. Clear Specifications: Provide detailed specifications, including materials, tolerances, and finishes. Precision is vital in machining; unclear instructions can lead to errors and delays.

3. Prototyping: Start with a prototype to evaluate the quality and precision of the factory’s work before committing to large orders.

4. Communication: Maintain consistent and clear communication. Language barriers and time differences can cause misunderstandings. Using visuals or 3D models can help clarify requirements.

5. Quality Control: Implement stringent quality control checks. If possible, hire a third-party inspection service to ensure products meet your standards before shipment.

6. Costs and Payment Terms: Understand all costs involved, including tooling, materials, and shipping. Negotiate favorable payment terms and use secure payment methods to protect your interests.

7. Lead Times: Clarify lead times and ensure the company can meet your deadlines. Factor in potential delays, especially around Chinese holidays.

8. Compliance and Certifications: Ensure the factory complies with international standards such as ISO. Verify certifications relevant to your industry.

9. Cultural Sensitivity: Building a strong relationship can facilitate smoother operations. Show respect for Chinese business customs and holidays.

10. Visit the Factory: If feasible, visiting the factory can provide insights into their capabilities and working conditions, fostering better trust and collaboration.

By following these tips, you can leverage the benefits of Chinese machining companies while minimizing risks and ensuring high-quality outcomes.

Certainly! Here are some Frequently Asked Questions (FAQ) with answers about sourcing Chinese machining companies from SourcifyChina Factory:

Q1: What is SourcifyChina Factory?

A1: SourcifyChina Factory is a platform that facilitates sourcing and manufacturing from Chinese factories, specializing in various sectors, including machining. They connect you with reliable and verified suppliers to ensure quality and efficiency in your production process.

Q2: How do I get started with SourcifyChina Factory?

A2: To get started, visit their website and create an account. From there, you can submit your project details and requirements. SourcifyChina Factory will match you with suitable machining companies from their extensive network of vetted suppliers.

Q3: What types of machining services are available?

A3: SourcifyChina Factory offers a wide range of machining services, including CNC machining, milling, turning, drilling, and custom manufacturer services. Their network of suppliers is equipped to handle both small and large-scale production runs.

Q4: How can I be sure of the quality of the machining services?

A4: SourcifyChina Factory conducts comprehensive vetting processes for all their suppliers. They perform regular factory audits, quality inspections, and certifications checks to ensure high standards. Additionally, you can request sample runs before committing to full production.

Q5: What kind of turnaround time should I expect?

A5: Turnaround times vary depending on the complexity and scale of your project. Typically, small projects may take a few weeks, while larger, more complicated orders could take several months. SourcifyChina Factory will provide a detailed timeline once your project specifics are reviewed.

Q6: Can I get a cost estimate before committing to a supplier?

A6: Yes, you can obtain cost estimates by submitting a Request for Quotation (RFQ) through the SourcifyChina Factory platform. Provide detailed information about your project, and you’ll receive quotes from relevant suppliers to help you make an informed decision.

Q7: How does payment work?

A7: Payment terms are negotiated directly with the supplier. Most common methods include wire transfers, letters of credit, and various online payment systems. Be sure to discuss payment schedules and terms during contract negotiations.

Q8: What support does SourcifyChina Factory provide during the sourcing process?

Sourcing Chinese machining companies through Sourcify can be efficient if you follow these key tips:

1. Identify Needs: Clearly define your machining requirements including material, precision, volume, and any specific certifications.

2. Platform Familiarization: Get well-acquainted with Sourcify’s platform, its search filters, and features to streamline your sourcing efforts.

3. Search Criteria: Use specific keywords such as “CNC machining”, “precision machining”, or industry-specific terms to find suitable companies.

4. Evaluate Profiles: Scrutinize company profiles for experience, capabilities, certifications, and customer reviews.

5. Supplier Verification: Cross-check the credentials and reputation of potential suppliers. Request previous work samples and references to ensure credibility.

6. Quality Assurance: Confirm that the company has robust quality control systems. Look for ISO certifications or other quality management certifications.

7. RFQ Process: Issue a Request for Quotation (RFQ) outlining your specific needs. Compare quotes and assess responsiveness and communication clarity.

8. Trial Order: If possible, place a small initial order to evaluate the company’s performance, quality, and reliability before committing to larger orders.

9. Communication: Maintain clear and open communication throughout the process. Ensure there are no language barriers affecting the clarity of your requirements.

10. Contracts and Terms: Draft a clear contract covering all aspects of the order including pricing, lead times, quality standards, and payment terms to avoid misunderstandings.

Using these steps, you can effectively source high-quality machining services from Chinese companies through Sourcify and achieve smooth manufacturing partnerships.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.