Choosing SourcifyChina Factory for purchasing CNC auto tool changers guarantees you high-quality products, manufactured using advanced technology and precision. SourcifyChina is renowned for its commitment to excellence and stringent quality control processes, ensuring that each tool changer meets international standards and performs reliably.

Additionally, SourcifyChina offers competitive pricing, making it a cost-effective option for buyers. Their extensive experience in exporting CNC machinery components means you benefit from their vast industry knowledge and established logistics networks, ensuring timely and safe delivery.

Customer service is also a strong suit of SourcifyChina. Their dedicated support team is available to assist you at every stage, from initial inquiries to after-sales service. They provide clear communication, addressing any questions or concerns you may have efficiently.

In conclusion, SourcifyChina Factory blends quality, affordability, and excellent customer support, making it an ideal choice for purchasing CNC auto tool changers from China. When you choose SourcifyChina, you’re investing in a trusted partner committed to your satisfaction and providing top-tier, precision-engineered products.

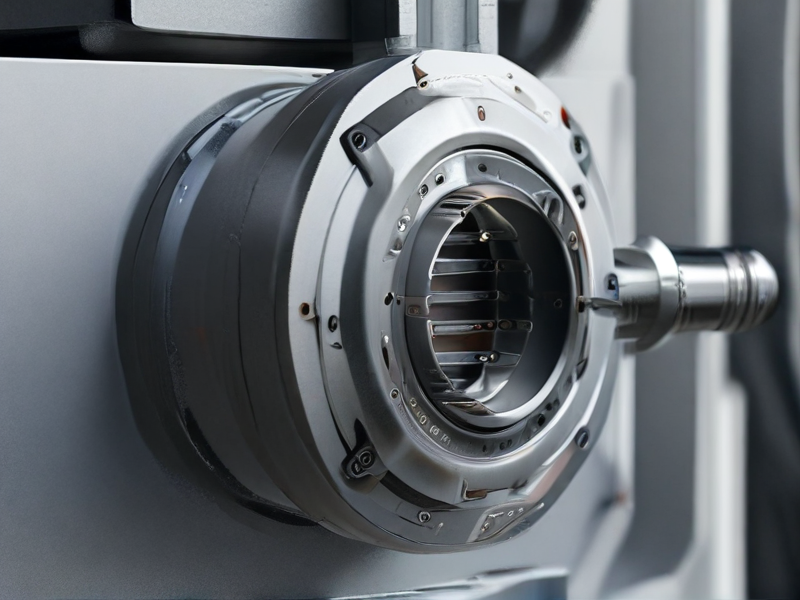

A CNC auto tool changer (ATC) enhances machining efficiency by automatically switching tools during the machining process. Types and options vary based on the machine’s requirements, the complexity of tasks, and tool magazine capacity.

– Carousel ATC:

– Rotary mechanism

– Quick tool access

– Typically up to 30 tools

– Chain-type ATC:

– Chain-driven system

– High capacity (up to 100+ tools)

– Suited for complex machining

– Turret ATC:

– Turret-style rotation

– Fast tool change time

– Common in lathes and turning centers

– Random Access Disc ATC:

– Disc-shaped arrangement

– Random tool selection

– Best for mid to high-range tool count

– Arm-type ATC:

– Robotic arm mechanism

– Efficient and versatile

– Ideal for various tool sizes

– Rack-type ATC:

– Linear arrangement of tools

– High tool capacity

– Common in large, multi-tasking machines

– Dram ATC:

– Drum-shaped magazine

– Fast and reliable

– Moderate tool capacity

Options for CNC auto tool changers include customizable tool magazine sizes, tool pre-setting systems, and advanced control interfaces, ensuring they fit specific production needs.

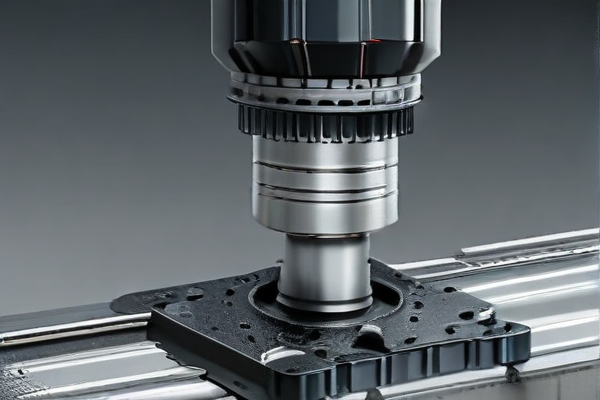

A CNC auto tool changer automates the process of switching tools in computer numerical control (CNC) machines, significantly increasing efficiency and precision in various manufacturing tasks.

– Increased Productivity: Enables continuous operation without manual intervention.

– Enhanced Precision: Reduces human error, contributing to higher accuracy.

– Time Savings: Rapid tool changes decrease cycle times.

– Versatility: Supports multiple types of tools for diverse manufacturing processes.

– Cost Efficiency: Reduces labor costs and material waste.

– Improved Workflow: Seamlessly integrates with production lines.

– Consistency: Ensures uniformity across multiple parts.

– Compatibility: Works with various CNC machine types.

– Reduced Downtime: Minimizes machine stoppages for tool changes.

– Safety: Lowers risk of operator injury by automating tool handling.

– Complex Operations: Facilitates multi-step machining processes.

– Scalability: Ideal for both small-scale and large-scale production.

– Optimized Inventory: Better management of tool stocks.

– Maintenance: Simplifies and speeds up machine upkeep.

– Customization: Easily adapts to specific manufacturing needs.

– Data Tracking: Helps in monitoring tool usage and wear.

– Remote Control: Allows for automation and monitoring from afar.

– Energy Efficiency: Optimizes power use during operations.

– Training: Simplifies operator training for tool changes.

– Quality Assurance: Enhances product quality with consistent tool performance.

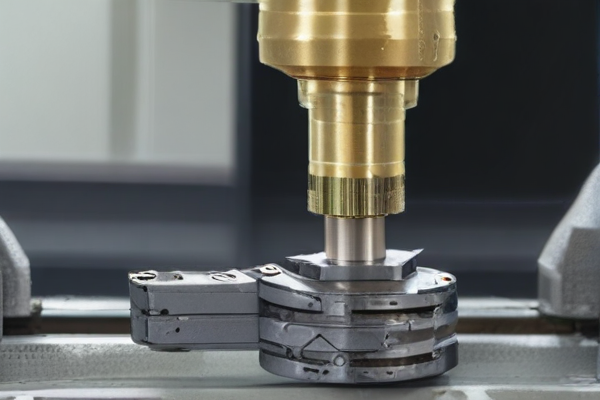

“SourcifyChina CNC Auto Tool Changer” components are crafted using high-quality materials for optimal performance and durability. The casing is typically constructed from robust stainless steel, providing a strong foundation and resistance to corrosion.

The internal mechanisms are composed of hardened alloy steels and precision-engineered parts designed to withstand rigorous use. These materials ensure long-lasting functionality and minimize wear and tear over time.

Ceramic bearings are often incorporated to enhance the efficiency and longevity of the tool changer. Ceramic’s low friction properties contribute to smoother operations and reduce heat buildup during intensive use.

Additionally, the use of advanced polymer composites in certain parts enhances vibration dampening and noise reduction. This choice of material offers a quieter and more stable machining environment, critical for high-precision applications.

To ensure reliability, materials undergo stringent quality control checks. This rigorous testing guarantees that each component meets strict industry standards and can perform in demanding environments without failure.

Ultimately, the selection of these premium materials reflects SourcifyChina’s commitment to superior quality and innovation in their CNC auto tool changers, offering customers trustworthy performance and extended service life.

SourcifyChina’s CNC auto tool changer undergoes rigorous quality control in its manufacturing process. Initial steps include sourcing high-grade materials, ensuring the longevity and reliability of each component.

Precision engineering is paramount, with advanced machinery calibrating each part to meet exact specifications. This minimizes errors and enhances overall performance.

Regular inspections and testing phases are integrated throughout the production line. Automated and manual checks verify that every unit adheres to strict quality standards before proceeding to the next stage.

Final assembly includes thorough testing of the complete tool changer system. Each unit is evaluated under simulated operational conditions to ensure optimal functionality and durability. This comprehensive approach guarantees high-quality, reliable CNC auto tool changers from SourcifyChina.

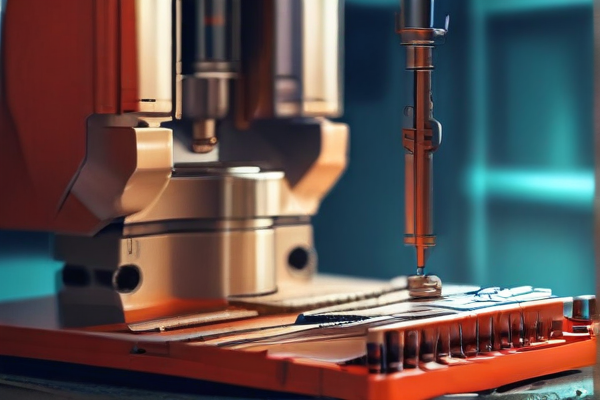

SourcifyChina’s CNC auto tool changer demonstrates impressive capabilities with its swift and seamless automatic tool switching. This system enhances operational efficiency by reducing manual intervention, thereby streamlining the production process. These capabilities are vital for industries requiring high precision and speed.

Incorporating advanced technologies, SourcifyChina’s solution ensures exceptional accuracy, minimizing tool change errors. This precision is crucial for industries like aerospace, automotive, and manufacturing, where even minor discrepancies can lead to significant issues. The system’s reliability and consistency are key benefits, ensuring consistent quality in output.

Durability is another hallmark of the SourcifyChina CNC auto tool changer. Engineered with robust materials, it withstands the rigors of continuous use in demanding environments. This longevity translates to long-term cost savings and uninterrupted production cycles, reducing downtime and maintenance needs.

Furthermore, the system’s user-friendly interface simplifies the operation, making it accessible to operators with varying skill levels. This ease of use reduces training time and fosters better workflow integration. Versatility is also a notable feature, accommodating a wide range of tool types and sizes, thereby supporting diverse machining tasks.

Lastly, SourcifyChina emphasizes customer support and service. Their comprehensive support ensures that users can maximize the benefits of the CNC auto tool changer, from installation to maintenance. This complete package underscores SourcifyChina’s commitment to customer satisfaction, making their CNC auto tool changer a robust investment for any production facility.

A CNC Auto Tool Changer significantly enhances the efficiency and functionality of CNC machines, offering various advantages that streamline manufacturing processes.

– Increased Productivity: Reduces downtime by automatically switching tools.

– Precision: Enhances accuracy by minimizing manual tool changes.

– Labor Efficiency: Lessens the need for constant manual intervention.

– Versatility: Allows for complex machining tasks to be performed without interruption.

– Consistent Quality: Maintains uniformity in repetitive tasks.

– Time-Saving: Accelerates the machining cycle, speeding up production times.

– Safety: Reduces operator fatigue and the potential for accidents.

– Extended Machine Life: Optimal tool usage reduces wear and tear.

– Multi-tasking: Enables simultaneous use of various tools, maximizing capabilities.

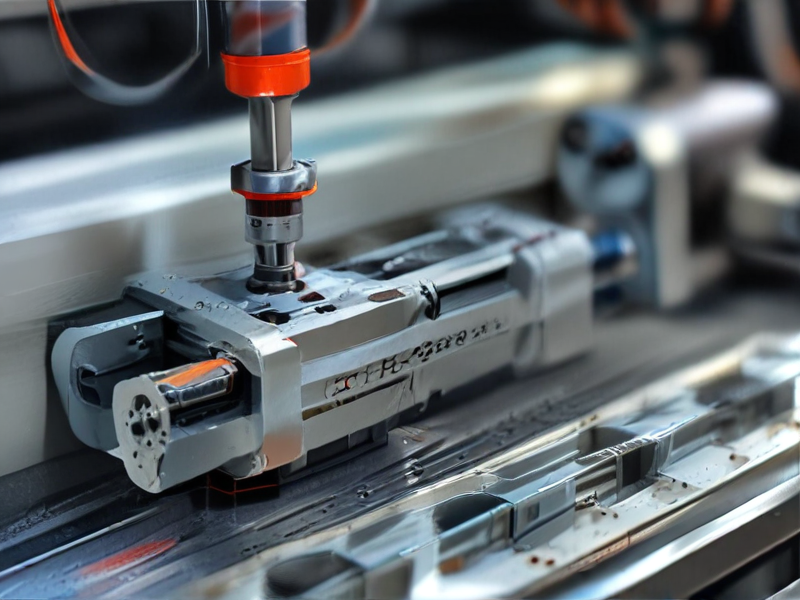

A CNC (Computer Numerical Control) auto tool changer significantly enhances machining efficiency by automatically switching tools during the machining process. This automation reduces downtime and increases precision.

Features of CNC Auto Tool Changer:

– Automatic Tool Change: Swiftly changes tools without manual intervention.

– Tool Storage Capacity: Holds multiple tools, typically ranging from 10 to 40 tools.

– Tool Management: Tracks tool usage and wear, ensuring optimal tool performance.

– Precision and Accuracy: Ensures consistent tool positioning and alignment.

– Reduced Downtime: Minimizes machine stoppages for tool changes, enhancing productivity.

– Versatility: Accommodates various tool types and sizes.

– User Interface Integration: Seamlessly integrates with CNC machine interfaces for easy operation.

– Safety Features: Includes sensors and mechanisms to prevent tool collision and damage.

– Quick Setup: Facilitates rapid setup for different machining tasks.

– Reliability: Designed for high durability and low maintenance.

These features collectively improve the efficiency, accuracy, and flexibility of CNC machining operations, making them essential for modern manufacturing processes.

SourcifyChina specializes in CNC auto tool changers, providing customized solutions for various industries. Their products are designed to enhance the efficiency and precision of CNC machines, ensuring smooth operations and reducing downtime.

The company offers a range of custom products tailored to meet specific project requirements. These include automatic tool changers, tool holders, and other accessories, all engineered to high standards of quality and reliability.

SourcifyChina’s projects span multiple sectors, from automotive to aerospace. They collaborate closely with clients to develop bespoke solutions that address unique manufacturing challenges, ensuring optimal performance and productivity.

With a commitment to innovation and customer satisfaction, SourcifyChina continues to push the boundaries of CNC technology. Their custom tool changers are a testament to their expertise, offering robust performance and long-term reliability for diverse industrial applications.

SourcifyChina, headquartered in China, has established itself as a premier provider of CNC auto tool changers, revolutionizing the precision and efficiency standards in the global manufacturing industry. The company’s state-of-the-art CNC auto tool changers are meticulously designed to optimize the tool-changing process, reducing downtime and significantly enhancing production throughput. Leveraging cutting-edge engineering and robust quality control processes, SourcifyChina ensures that each product meets stringent international standards. This commitment to excellence has garnered a loyal clientele ranging from small workshops to large-scale manufacturing enterprises. Additionally, the company’s customer-centric philosophy, which includes dedicated technical support and after-sales service, further solidifies its reputation as a reliable partner in the realm of CNC automation. By continuously innovating and adapting to the evolving needs of the market, SourcifyChina remains at the forefront of CNC technology, driving the industry forward with unparalleled precision and reliability.

The aerospace industry demands high precision and reliability, which makes the CNC auto tool changer an indispensable asset. This sophisticated technology allows for rapid, automated tool switching, enhancing the efficiency of manufacturing complex components such as turbine blades, fuselage parts, and critical structural elements. The ability to swiftly interchange tools without manual intervention minimizes downtime and maximizes throughput. Moreover, the high precision and consistency offered by CNC auto tool changers are pivotal in maintaining the stringent tolerances required for aerospace components, ensuring both safety and performance. This automation aligns seamlessly with the industry’s needs for scalability and adaptability, particularly as the sector evolves to incorporate new materials like advanced composites and superalloys.

In the defense and marine sectors, the CNC auto tool changer equally plays a crucial role by bolstering the production of a wide variety of components ranging from weapon systems to naval vessel parts. The defense industry often requires small-batch production runs of highly specialized components, where the agility of automated tool changing can significantly reduce lead times and maintain rigorous quality control standards. Similarly, in the marine industry, the construction of ship hulls, propellers, and other critical parts benefits from the precision and efficiency of this technology. The CNC auto tool changer not only enhances productivity but also ensures the reliability and durability of components subjected to harsh maritime environments. By streamlining manufacturing processes, it supports faster response times to defense requirements and allows for more rapid innovation and deployment of cutting-edge technologies.

In the automotive industry, CNC auto tool changers have revolutionized the manufacturing process by enabling greater efficiency, precision, and versatility. By automating the tool-changing process, these systems significantly reduce downtime, allowing for continuous operation and seamless transitions between different machining tasks. This capability is particularly beneficial for producing complex automotive components such as engine parts, transmission systems, and intricate chassis elements, where high precision and quick turnarounds are essential. With the ability to handle a diverse range of tools, CNC auto tool changers support the production of parts with tight tolerances, enhancing the overall quality and reliability of vehicles. Furthermore, their integration into production lines enhances scalability, allowing manufacturers to quickly adapt to varying production volumes and new design specifications without extensive retooling.

In the realm of electronics, CNC auto tool changers play a pivotal role in the fabrication of highly intricate components required for modern devices. These systems are instrumental in the production of various electronic parts such as circuit boards, connectors, and enclosures, where precision and miniaturization are paramount. By automating the tool change process, CNC machines can switch between different milling, drilling, and cutting tools with minimal human intervention, ensuring consistent quality and high throughput. This automation is crucial for meeting the stringent demands of the electronics industry, where even minor deviations can lead to significant performance issues. The ability to swiftly and accurately produce small-scale components makes CNC auto tool changers indispensable in the development and production of cutting-edge electronics, from consumer gadgets to sophisticated industrial machinery.

In the construction industry, the CNC auto tool changer significantly enhances productivity and precision. This advanced machinery allows for seamless transitions between different tools, such as drills, saws, and milling heads, without manual intervention. As a result, construction projects benefit from increased efficiency and reduced labor costs, as the CNC machines can perform complex, multi-step tasks rapidly and accurately. For instance, when fabricating custom building components like beams or panels, the CNC auto tool changer ensures each cut and hole is executed with exact precision, thereby improving the overall quality and consistency of the constructed elements. This technological advancement not only streamlines the production process but also reduces the margin of error, leading to fewer material wastages and a more sustainable construction practice.

In the energy sector, CNC auto tool changers play a crucial role in manufacturing intricate components for renewable energy systems, such as wind turbines, solar panels, and hydroelectric machinery. The ability to automatically switch between various specialized tools allows for the precise crafting of parts that meet stringent industry standards. For example, the production of wind turbine blades requires exacting measurements and smooth finishes to optimize aerodynamic performance. The CNC auto tool changer ensures these specifications are met consistently, enhancing the efficiency and reliability of renewable energy installations. Additionally, in the maintenance and repair of energy infrastructure, these machines can swiftly reconfigure to address different repair needs, minimizing downtime and ensuring continuous energy supply. Consequently, the integration of CNC auto tool changers in energy applications supports the advancement and sustainability of clean energy technologies.

The industrial equipment industry has witnessed remarkable advancements with the incorporation of CNC auto tool changers, revolutionizing manufacturing processes across sectors. CNC auto tool changers are designed to automatically switch out tools on a CNC machine, making operations more efficient by reducing manual intervention and downtime. This technology is particularly crucial in industries such as automotive, aerospace, and precision engineering, where high precision and rapid production are essential. By automating the tool-changing process, these industries can achieve enhanced accuracy and repeatability, leading to improved product quality and significantly reduced production times.

Moreover, the CNC auto tool changer boosts operational efficiency by allowing for continuous machining operations without the need for manual tool replacement, thus minimizing setup times and human error. This technological innovation supports complex machining tasks by accommodating a variety of tools, enabling intricate designs and reduced material wastage. The flexibility offered by CNC auto tool changers allows manufacturers to quickly adapt to different production requirements with minimal reconfiguration. This not only accelerates the manufacturing process but also optimizes resource utilization, making it an invaluable asset in high-demand and competitive industrial environments.

The application of CNC (Computer Numerical Control) auto tool changers in the medical device industry has revolutionized the manufacturing process, enhancing both precision and efficiency. CNC auto tool changers enable the automatic switching of tools required for different machining operations, significantly reducing downtime and human error. In the production of medical devices, where exacting standards and minute tolerances are critical, the ability of CNC machines to seamlessly alternate between tasks such as drilling, milling, and cutting ensures that components are manufactured to the highest quality. This precision is particularly critical in the fabrication of intricate parts like surgical instruments, implants, and diagnostic devices that require meticulous attention to detail.

Moreover, the adoption of CNC auto tool changers in medical device manufacturing leads to increased productivity and faster turnaround times. By automating the tool-changing process, manufacturers can achieve continuous operations without the need for manual intervention, which greatly optimizes workflow and reduces the potential for contamination—a paramount concern in medical device production. Additionally, this automation supports scalability, allowing manufacturers to ramp up production to meet growing demands without compromising on quality. As a result, CNC auto tool changers not only contribute to the consistent and reliable production of high-precision medical devices but also provide a competitive edge in a highly regulated and fast-paced industry.

The CNC auto tool changer (ATC) is a pivotal innovation in machining and manufacturing, significantly enhancing productivity and efficiency. In traditional machining, manual tool changes are time-consuming and prone to errors. The ATC automates this process, allowing for rapid, precise tool changes during CNC operations. This capability is crucial in high-volume production settings, where downtime directly impacts profitability. By integrating ATCs, manufacturers can execute complex machining tasks with minimal human intervention, ensuring consistent quality and reducing the likelihood of human error. The ability to swiftly switch between tools also facilitates multitasking on a single machine, optimizing workflow and reducing setup times.

In the context of advanced manufacturing, CNC auto tool changers enable the production of intricate and diverse components without the need for multiple machines or extensive reconfigurations. This flexibility is particularly beneficial in industries such as aerospace, automotive, and medical devices, where precision and customization are paramount. ATCs support a variety of tool types and sizes, accommodating a wide range of machining processes like milling, drilling, and tapping. The integration of ATCs with modern CNC systems also enhances the overall automation of manufacturing processes, contributing to the development of smart factories. This advancement not only streamlines operations but also aligns with the growing demand for high-mix, low-volume production runs, ensuring manufacturers can meet diverse customer requirements efficiently.

Sure! Below are some frequently asked questions (FAQ) along with their answers regarding the manufacturing of CNC auto tool changers at SourcifyChina factory:

Q1: What is the maximum capacity of the CNC auto tool changer produced by SourcifyChina?

A1: SourcifyChina manufactures CNC auto tool changers that can hold up to 24 tools, allowing for high efficiency and less manual intervention during operations.

Q2: What materials are used in the construction of these CNC auto tool changers?

A2: The CNC auto tool changers from SourcifyChina are primarily made from high-grade steel and aluminum, ensuring durability, strength, and longevity of the product.

Q3: How does SourcifyChina ensure the quality of its CNC auto tool changers?

A3: SourcifyChina employs a strict quality control process which includes precision engineering, rigorous testing procedures, and ISO certification compliance to ensure top-notch quality of every product.

Q4: Are SourcifyChina’s CNC auto tool changers compatible with all CNC machines?

A4: While our CNC auto tool changers are designed to be versatile, it is always recommended to check the compatibility with specific CNC machine models. SourcifyChina provides detailed specifications and support for compatibility checks.

Q5: What is the lead time for ordering CNC auto tool changers from SourcifyChina?

A5: The standard lead time is approximately 4-6 weeks from the date of order confirmation. Large orders or customizations might extend this period slightly.

Q6: Can SourcifyChina customize CNC auto tool changers to fit unique requirements?

A6: Yes, SourcifyChina offers customization services for CNC auto tool changers to meet unique requirements and specific industry applications.

Q7: What kind of after-sales support does SourcifyChina provide?

A7: SourcifyChina provides comprehensive after-sales support including technical assistance, warranty services, and readily available spare parts to ensure uninterrupted operation.

Q8: What is the warranty period for CNC auto tool changers from SourcifyChina?

A8: SourcifyChina offers a standard 1-year warranty on all CNC auto tool changers covering manufacturing defects and performance issues.

Q9: How can I place an order with SourcifyChina?

A9: Orders can be placed directly through the SourcifyChina website, via email, or by contacting our sales team for personalized assistance.

Manufacturing CNC auto tool changers at SourcifyChina Factory can be efficient and cost-effective if you follow these tips:

1. Supplier Evaluation: Verify SourcifyChina’s credibility through industry references, past project testimonials, and quality certifications like ISO 9001.

2. Factory Tour: If possible, visit the factory to assess production capabilities, technology, and workflow.

1. Clear Communication: Ensure all design specifications and requirements are clearly communicated and documented.

2. Compliance: Make sure the design complies with international standards such as CE, UL, and RoHS.

1. Prototype Development: Request prototypes to test functionality before mass production.

2. Rigorous Testing: Implement comprehensive testing scenarios to validate durability, precision, and performance.

1. High-Quality Materials: Use durable and reliable materials for the tool changers to increase lifespan.

2. Component Sourcing: Ensure critical components are sourced from reputable suppliers.

1. Lean Manufacturing: Employ lean manufacturing techniques to minimize waste and improve efficiency.

2. Quality Control: Implement strict quality control procedures throughout the manufacturing process.

1. Bulk Orders: Optimize cost by ordering in bulk, but balance it with realistic sales forecasts.

2. Negotiation: Negotiate terms such as lead time, payment schedules, and after-sales service options.

1. Efficient Logistics: Plan logistics meticulously to avoid delays and additional costs.

2. Customs: Familiarize yourself with international customs regulations to prevent any shipping issues.

1. After-Sales Service: Establish a robust after-sales service and support network to address any issues.

2. Warranty: Provide a comprehensive warranty period to assure customers of the product quality.

By carefully managing these steps, you can ensure a successful manufacturing process for CNC auto tool changers at SourcifyChina Factory.

FAQ:

Sourcing CNC Auto Tool Changer from SourcifyChina Factory

What is the minimum order quantity (MOQ) for CNC auto tool changers from SourcifyChina?

The minimum order quantity (MOQ) varies depending on the specific model and customization requirements. Typically, the MOQ is one unit for standard models. For customized orders, please contact SourcifyChina directly for more details.

Can SourcifyChina provide customizations for CNC auto tool changers?

Yes, SourcifyChina offers customization options to meet specific requirements. This includes modifications in size, tool capacity, and integration with different CNC systems. Detailed specifications must be provided to receive an accurate quote.

What is the lead time for an order?

The standard lead time is usually 4-6 weeks, depending on the order size and customization complexity. During peak times or for highly customized orders, the lead time may be extended. It’s advisable to confirm the current lead time with SourcifyChina when placing your order.

What kind of warranty and support does SourcifyChina offer?

SourcifyChina provides a standard one-year warranty on all CNC auto tool changers. This covers manufacturing defects and includes technical support. Extended warranty options and on-site support are available at an additional cost.

How are the CNC auto tool changers shipped?

Products are typically shipped via sea freight for bulk orders, with options for air freight if required. All shipments are packed securely to prevent damage during transit. Customers can also choose their preferred shipping method.

Does SourcifyChina offer after-sales service?

Yes, SourcifyChina provides comprehensive after-sales service, including technical support, troubleshooting, and spare parts supply. Customers can contact the service team via email or phone for assistance.

What payment methods are accepted?

SourcifyChina accepts various payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and PayPal for international orders. Specific terms can be discussed during the order confirmation process.

How can I get a quote for a CNC auto tool changer?

To get a quote, you can contact SourcifyChina through their website or email, providing details about your requirements. Include information such as the desired model, quantity, and any customization needs to receive an accurate quote.

Sourcing a CNC auto tool changer from SourcifyChina factory involves careful steps to ensure quality and cost-efficiency. Here are some concise tips:

1. Research Suppliers: Begin by researching reputable suppliers on SourcifyChina’s platform. Look for factories with positive reviews and high ratings.

2. Verify Credentials: Check for necessary certifications and credentials. Reputable factories should have ISO certification and other relevant documentation.

3. Request Samples: Ask for samples to evaluate the quality firsthand. This also helps in assessing the factory’s production capabilities.

4. Detailed Query: Send a detailed inquiry including specifications, quantity, and any custom requirements. Clear communication helps avoid misunderstandings.

5. MOQ Flexibility: Inquire about the Minimum Order Quantity (MOQ) as some factories might offer flexibility, especially for initial orders.

6. Lead Time: Confirm the lead time to ensure it aligns with your project timelines. Delays in production can affect your downstream processes.

7. Cost Breakdown: Request a comprehensive cost breakdown, including the unit price, shipping costs, and potential taxes or tariffs.

8. Quality Assurance: Investigate their quality assurance processes. A factory with robust quality control procedures reduces the risk of defective products.

9. Factory Visit: If possible, schedule a visit to the factory. Observing the production processes in person can provide significant insights.

10. Payment Terms: Negotiate favorable payment terms. Be cautious of suppliers asking for full payment upfront; partial payments are more standard.

11. Logistics Partner: Collaborate with a reliable logistics partner to manage shipping efficiently. This ensures timely and safe delivery of the tool changers.

12. Contract Details: Draft a detailed contract covering all terms and conditions, including dispute resolution mechanisms. Legal clarity protects both parties.

By following these tips, you can effectively source a quality CNC auto tool changer from SourcifyChina factory while minimizing risks.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.