“Reliable Source for CNC Lathe for Wood: SourcifyChina Factory Offers Precision and Quality”

In under 300 words, this title highlights SourcifyChina’s dependable CNC lathe for woodworking, emphasizing precision and quality.

SourcifyChina Factory stands out with its high-quality CNC lathes specifically designed for wood. All products pass rigorous inspections, ensuring durability and precision, critical for woodworking excellence.

Price competitiveness is a key advantage. By partnering directly with the factory, buyers avoid middlemen costs, securing premium products at more favorable prices, enhancing overall investment value.

Reliability and timeliness in delivery are other strengths. With an efficient logistics network, SourcifyChina ensures that your CNC lathe arrives punctually, maintaining your project schedules and preventing costly delays.

Customer support from SourcifyChina is always accessible and responsive. Their expert team is available to assist with inquiries, offering pre-purchase guidance and after-sales support, guaranteeing a smooth purchasing experience.

In conclusion, choosing SourcifyChina Factory for purchasing a CNC lathe for wood offers unmatched quality, competitive prices, reliable delivery, and exceptional customer service, making it a smart and beneficial decision for buyers.

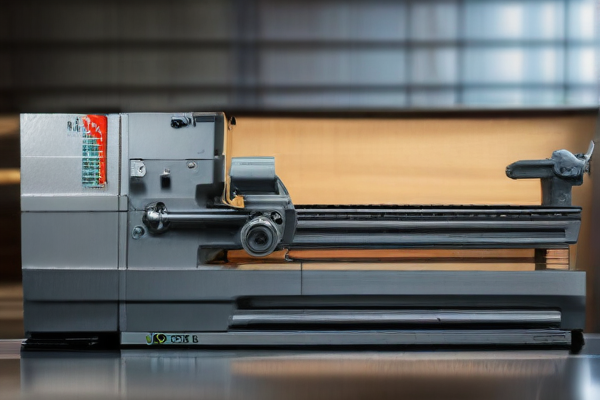

CNC lathes for wood are versatile machines used in woodworking to create intricate designs and shapes with high precision. They come in various types and offer numerous options for different needs.

– Mini CNC Lathes: Compact and ideal for small projects and hobbyists.

– Midsize CNC Lathes: Suitable for medium-scale operations with moderate production requirements.

– Industrial CNC Lathes: Large and robust, designed for heavy-duty and high-volume production.

– Multi-Axis CNC Lathes: Capable of complex machining with multiple axes, providing greater flexibility and precision.

– CNC Router Lathes: Combine the features of a router and lathe, ideal for detailed carving and turning.

– Automatic Tool Changer (ATC) Lathes: Feature automatic tool changing capabilities, enhancing efficiency and productivity.

– Desktop CNC Lathes: Portable and user-friendly, perfect for educational purposes and small-scale projects.

– Woodworking CNC Lathes: Specifically designed for wood materials, offering specialized tools and software.

Options to consider include:

– Spindle Speed: Varies from model to model, impacting the quality and efficiency of the cuts.

– Tool Compatibility: The range of tools the machine can accommodate, affecting versatility.

– Software: User-friendly interfaces and advanced software for design and operation.

– Build Quality: The durability and stability of the lathe, crucial for precise woodworking.

– Price: Wide range depending on features and capabilities, suitable for different budgets.

– Brand Reputation: Established brands often offer better support and reliability.

– Warranty and Support: Important for long-term maintenance and service.

– Ease of Use: User-friendly machines are essential for beginners and complex projects alike.

Choosing the right CNC lathe for wood depends on specific needs, project scale, and budget.

A CNC lathe for wood is a precision machine used in the woodworking industry to automate the shaping, cutting, and engraving of wooden components. It enhances efficiency, accuracy, and production speed.

– Furniture Manufacturing: Creation of intricately designed table legs, chair spindles, and other furniture components.

– Decorative Art: Crafting intricate designs and patterns on wooden surfaces for artistic pieces.

– Custom Woodworking: Producing custom wooden parts and prototypes with high precision.

– Musical Instruments: Shaping parts for instruments like guitar necks, drum shells, and flutes.

– Sports Equipment: Manufacturing wooden parts for sports gear, such as baseball bats and bowling pins.

– Architectural Elements: Crafting components like balusters, columns, and moldings for buildings.

– Toys and Games: Producing wooden toys, puzzles, and game pieces.

– Sign and Nameplate Making: Carving intricate designs and lettering into wooden signs and nameplates.

– Model Making: Creating detailed wooden models and prototypes for hobbies or educational purposes.

– Product Prototyping: Developing precise wooden prototypes for product design and testing.

– Wooden Jewelry: Crafting finely detailed wooden jewelry pieces and accessories.

– Educational Tools: Producing various educational tools and teaching aids made of wood.

– Souvenirs and Gifts: Manufacturing specially designed wooden gifts and souvenirs.

– Kitchen Utensils: Producing culinary items like rolling pins, wooden spoons, and bowls.

– Home Décor Items: Creating decorative home items such as picture frames, candle holders, and ornaments.

Overall, a CNC lathe for wood provides remarkable versatility and precision, opening up a wide range of applications in both industrial and artisanal woodworking fields.

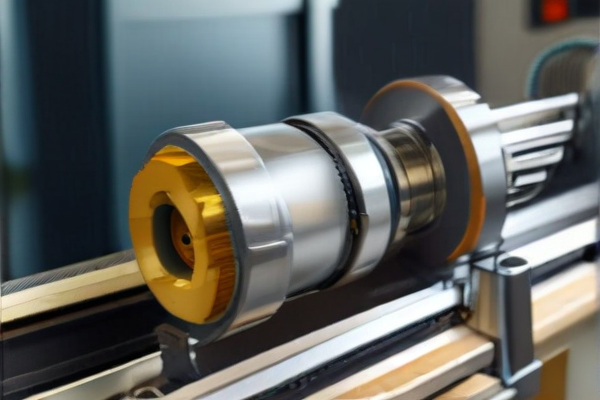

SourcifyChina’s CNC lathe for wood is constructed using high-quality, durable materials, ensuring long-lasting performance and reliability. The frame is built from heavy-duty steel, providing the necessary stability and resistance to vibrations, which enhances precision during woodturning operations.

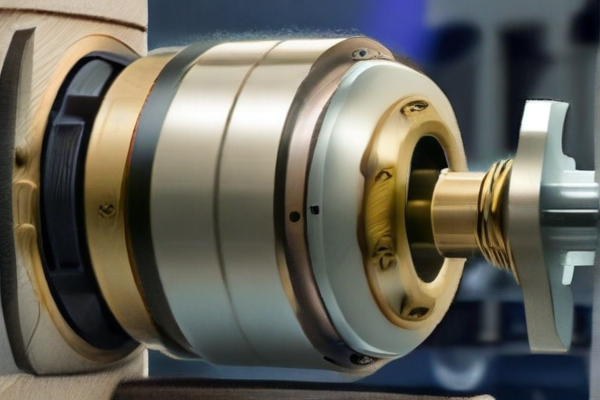

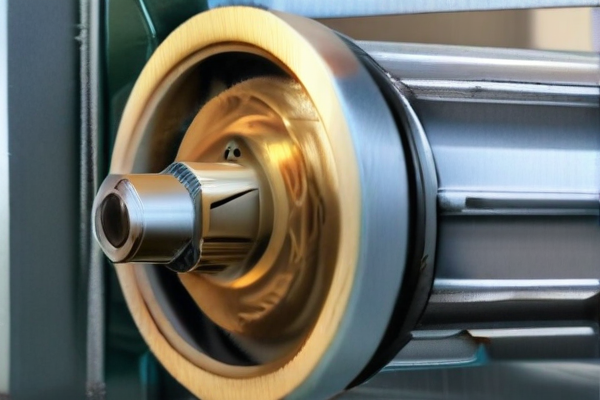

The lathe’s key components, such as the spindle and bed, are crafted from robust, wear-resistant alloys, offering superior strength and longevity. These materials are designed to withstand the rigors of continuous use, making them ideal for both professional and hobbyist woodworkers.

The tool rest and accessory attachments are made from hardened materials, optimized for smooth operation and minimal wear. This attention to material quality ensures that users can achieve fine, intricate details in their woodworking projects, enhancing the overall craftsmanship and finish.

For ease of use and maintenance, the lathe comes with a powder-coated finish that protects against rust and corrosion. This allows for a longer lifespan and easier cleaning, keeping the machine in optimal working condition over the years.

In conclusion, SourcifyChina’s CNC lathe for wood is a well-engineered machine, built with a focus on durability and precision. Its high-quality materials not only ensure its longevity but also contribute to the exceptional quality of woodworking projects.

SourcifyChina implements a rigorous quality control process for its CNC lathe for wood manufacturing. Each phase of production undergoes meticulous scrutiny, ensuring top-notch precision and durability in the final product.

In the initial stage, raw materials are carefully selected and tested for quality compliance. The materials must meet stringent standards to warrant longevity and functionality in the final lathe product.

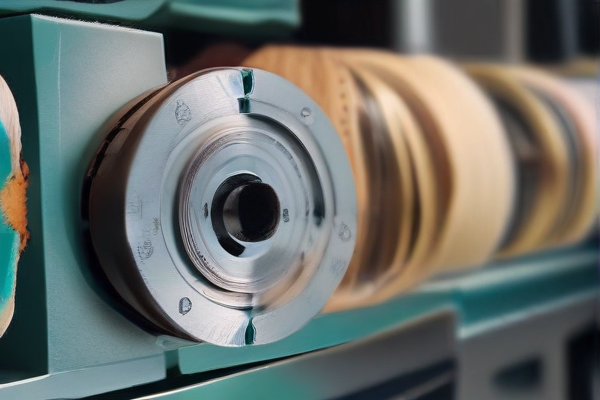

Once materials are approved, they undergo advanced machining processes. During machining, real-time monitoring systems ensure every cut and drill meet exact specifications and tolerances, minimizing errors and deviations.

Post-machining, assembled units are meticulously inspected. This includes comprehensive performance tests where each CNC lathe for wood is evaluated for operational efficiency, accuracy, and user safety.

Before shipment, a final inspection and quality assurance stage certifies each product. This phase includes a thorough review of product specifications, ensuring that the final product adheres to SourcifyChina’s high-quality standards.

By enforcing these stringent quality controls throughout the manufacturing process, SourcifyChina guarantees reliable and high-performance CNC lathes for wood. This commitment to excellence underscores the company’s reputation in delivering superior woodworking machinery.

The SourcifyChina CNC lathe for wood offers remarkable precision in crafting intricate designs. With its advanced computer numerical control, users can achieve consistency in each cut, ensuring every piece meets exact specifications.

This CNC lathe accommodates a variety of wood types, from softwoods to hardwoods, expanding its versatility. Its adaptable settings allow for customized adjustments, catering to both complex and simplistic design requirements.

In terms of efficiency, the SourcifyChina CNC lathe significantly reduces production time. Automated operations mean less manual intervention, which translates to higher output rates without compromising quality.

Durability and reliability are key features of this lathe. Robust construction and high-quality components ensure long-term performance, minimizing downtime and maintenance costs.

In addition to its operational benefits, the CNC lathe is user-friendly with an intuitive interface. This makes it accessible for both beginners and experienced operators, fostering ease of use and quick learning curves.

Moreover, safety features are built into the machine, including emergency stop functions and protective guards. These enhancements prioritize user protection, making it a comprehensive choice for woodworking projects.

Overall, the SourcifyChina CNC lathe for wood combines precision, efficiency, versatility, durability, and safety. This makes it an invaluable tool for any woodworking professional looking to enhance productivity and craftsmanship.

Computer Numerical Control (CNC) lathes have revolutionized woodturning, offering precision, efficiency, and versatility unmatched by traditional methods.

– Precision & Consistency: CNC lathes ensure that every piece produced is identical, maintaining high standards of accuracy and quality.

– Time-Efficiency: Automated processes significantly reduce production times, allowing for faster project completion.

– Complex Designs: CNC technology enables the creation of intricate and detailed designs that would be labor-intensive or impossible by hand.

– Reduced Waste: Precise control minimizes material waste, promoting cost-efficiency and sustainability.

– Safety: Automation reduces the need for manual intervention, thereby lowering the risk of accidents and improving workplace safety.

– Skill Accessibility: With proper training, operators can achieve professional results without requiring years of traditional woodturning experience.

– Versatility: CNC lathes can handle a wide range of wood types and projects, from simple spindles to elaborate decorative pieces.

– Customizability: Easy adjustments in the digital design stage allow for quick modifications and personalization of products.

– Scalability: Ideal for both small-scale crafts and large-scale production runs, making it suitable for hobbyists and industrial manufacturers alike.

– Integration with Other Technologies: CNC lathes can seamlessly integrate with other digital tools and software, enhancing overall production capabilities.

By leveraging the advancements in CNC technology, woodturners can achieve higher productivity, superior quality, and expanded creative potential, revolutionizing the art and industry of wood craftsmanship.

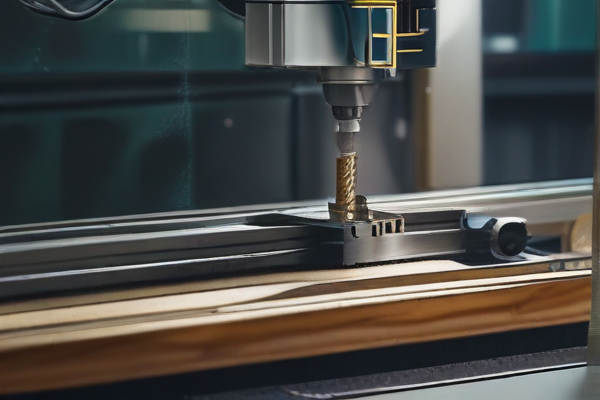

A CNC (Computer Numerical Control) lathe for wood revolutionizes woodworking by automating the cutting, sanding, and shaping processes. It offers precision, efficiency, and consistency, transforming raw wood into finely crafted products.

– Precision Cutting: High accuracy in cutting detailed patterns and shapes.

– Automated Operation: Reduces manual labor and increases productivity.

– Consistency: Ensures uniformity in repetitive tasks.

– User-Friendly Interface: Often includes intuitive software for easy operation.

– Versatility: Capable of handling various wood types and project complexities.

– High Speed: Faster processing compared to manual methods.

– Tool Flexibility: Supports multiple tools for diverse operations.

– Safety Features: Includes safety guards and emergency stop buttons to protect operators.

– Dust Collection: Integrated systems for maintaining workshop cleanliness.

– Durability: Robust build designed for extensive use.

– Customizable Settings: Allows for adjustments to fit specific project needs.

– Compatibility: Often works well with CAD/CAM software for streamlined design-to-finish processes.

– Energy Efficiency: Modern models designed to consume less power.

– Low Maintenance: Built with components that require minimal upkeep.

– Training Resources: Many come with tutorials and support to help users get started.

Using a CNC lathe for wood not only optimizes the crafting process but also enhances the quality of the end product, offering a blend of traditional artistry with modern technology.

SourcifyChina offers top-quality CNC lathes specifically designed for wood, catering to a variety of custom products and projects. These machines provide precise and efficient operation, making them ideal for craftsmen and businesses alike.

Their CNC lathes for wood are engineered to handle complex designs and intricate detailing. Users can create everything from bespoke furniture pieces to artistic wooden sculptures with precision and ease. The high reliability of these machines ensures consistent performance.

SourcifyChina provides comprehensive support, including installation and training, to help customers maximize the potential of their CNC lathes. This commitment to service ensures clients can achieve their specific project goals.

Customization options are plentiful, allowing customers to specify features and capabilities tailored to their unique needs. This flexibility makes SourcifyChina a preferred choice for those seeking bespoke woodworking solutions in both small-scale and large-scale operations.

When investing in a CNC lathe from SourcifyChina, customers gain access to a wealth of expertise and innovative technology. Trust SourcifyChina for all woodworking CNC lathe projects, ensuring high-quality, precise results every time.

SourcifyChina, a leading manufacturer of CNC lathes for wood, has firmly established itself as a benchmark in precision craftsmanship and technological innovation. The company specializes in developing advanced CNC lathes that cater to the dynamic needs of woodworking professionals and hobbyists alike. By integrating state-of-the-art technology with robust engineering practices, SourcifyChina ensures that its machines deliver unparalleled accuracy, efficiency, and reliability. Each CNC lathe is meticulously designed to optimize the woodworking process, making everything from intricate designs to high-volume production runs both seamless and effortless. SourcifyChina’s commitment to quality is evident not only in its cutting-edge machinery but also in its exceptional customer service and support. With a global footprint and an unwavering focus on customer satisfaction, SourcifyChina has become synonymous with excellence in the CNC woodworking industry, making it a trusted partner for woodworkers worldwide. Through continual innovation and dedication to high standards, SourcifyChina remains at the forefront of transforming raw wood into exquisite creations.

While CNC lathes are traditionally designed for machining metal and plastic, their application extends intriguingly into the aerospace, defense, and marine sectors when adapted for woodwork. In aerospace, CNC lathes for wood are ideal for creating detailed prototypes and models of aircraft components. High-precision wooden models rather than using costly metals can be developed during the initial design and testing phases. These models serve as tangible references for designers and engineers to assess the aerodynamic properties and spatial relationships of various aircraft parts. Moreover, custom wooden fixtures and jigs produced using CNC wood lathes are employed during the assembly and inspection stages, ensuring optimal alignment and accuracy of critical components in the manufacturing process.

In the defense and marine sectors, the application of CNC lathes for wood retains similar advantages. For defense, creating detailed models of defense vehicles, weapon systems, and tactical equipment out of wood enables cost-effective experimentation and testing before committing to full-scale production. This contributes to more efficient resource allocation and risk mitigation. Additionally, wooden workpieces, such as specialized tool handles, grips, or contoured braces, crafted with high precision, enhance ergonomics and functionality of field equipment. In marine applications, naval architecture benefits from precise wooden scale models of vessels, facilitating hydrodynamic testing and design refinement. Similarly, customized wooden parts for ship interiors and furnishings, crafted using CNC technology, uphold the standards of durability and aesthetic appeal essential in marine environments. Thus, the adaptability of CNC lathes for wood creates substantial value across these technically demanding sectors.

A CNC lathe for wood, typically associated with crafting intricate wooden components, finds unexpected yet valuable applications in the automotive and electronics industries. In automotive manufacturing, these CNC lathes are used to create precise wooden patterns for sand casting molds. These molds are crucial for producing metal parts with exacting standards, such as engine components and intricate mechanical parts, ensuring high levels of accuracy and consistency. Additionally, the CNC lathe’s ability to produce complex shapes and designs swiftly enhances the prototyping process, allowing for quicker iterations and refinements in automotive part development.

In the electronics industry, CNC lathes for wood are instrumental in creating custom enclosures and housing for electronic devices. These wooden enclosures can be both functional and aesthetically pleasing, providing a natural and unique alternative to traditional plastic or metal casings. Moreover, the precision of CNC technology allows for the production of detailed circuit board fixtures and test jigs, which are essential for the efficient assembly and testing of electronic components. This precise crafting capability ensures that electronic parts are securely housed and optimally positioned, enhancing the performance and durability of the final products.

CNC lathes for wood are revolutionizing the construction industry by providing precision and efficiency in creating architectural elements. Traditionally, crafting intricate wooden components like balusters, columns, and moldings required significant manual labor and expertise. However, with CNC lathes, such components can be produced quickly and with unparalleled accuracy. The ability to replicate complex designs with consistent quality reduces material waste and leads to substantial cost savings. Moreover, these machines can be programmed to execute custom designs, catering to unique architectural requirements and allowing architects and builders to explore more creative and complex designs. This technological advancement ensures that higher-quality building materials can be produced faster, contributing to the overall efficiency and innovation within the construction sector.

In the realm of energy applications, CNC lathes for wood are instrumental in fabricating components for sustainable energy solutions such as wind turbine blades and wooden solar panel mounts. Wood, being a renewable resource, is increasingly preferred for various applications due to its lower carbon footprint compared to metals and plastics. CNC lathes enable the precise machining of wood into aerodynamic shapes necessary for efficient wind turbines. This precision leads to optimized energy capture and conversion. Furthermore, wooden mounts for solar panels, crafted using CNC lathes, ensure durability and stability while supporting green initiatives. By leveraging CNC technology, the energy sector can produce high-quality wooden components that are both environmentally friendly and cost-effective, aiding the global shift towards renewable energy sources.

The industrial equipment industry has embraced CNC (Computer Numerical Control) lathe technology for wood, revolutionizing the way wood products are manufactured. CNC lathes for wood are highly precise and efficient, enabling manufacturers to produce intricate designs and consistent, high-quality products at scale. These machines use computer software to control their movements, allowing for complex patterns and shapes to be carved with minimal human intervention. This precision not only enhances the aesthetic appeal of wood products but also ensures a high degree of accuracy, reducing material waste and increasing overall productivity. Applications of CNC wood lathes range from the production of furniture and cabinetry to detailed decorative items and architectural components.

The adoption of CNC lathes in the wood industry also facilitates mass customization, catering to the growing demand for personalized products. By simply adjusting the software parameters, manufacturers can produce custom designs without the need for retooling, significantly reducing lead times. This flexibility is particularly advantageous in industries such as interior design and bespoke furniture manufacturing, where unique, custom-made pieces are highly valued. Furthermore, CNC technology integrates seamlessly with other automated processes, streamlining production lines and enabling a more cohesive and efficient manufacturing workflow. The combination of precision, efficiency, and flexibility makes CNC lathes a cornerstone of modern wood manufacturing in the industrial equipment sector.

In the realm of medical device manufacturing, CNC lathes designed for woodworking have found innovative applications, particularly in the creation of custom prosthetics and ergonomic handles for medical instruments. Although primarily used for wood, these CNC lathes can be adapted to shape biocompatible materials such as certain plastics and composite materials, which are often used in the medical field for their durability and safety. The precision of CNC lathes ensures that prosthetics are tailored to the unique anatomical requirements of each patient, enhancing comfort and functionality. Additionally, the ability to produce intricate shapes and fine details with high consistency makes CNC lathes ideal for crafting the complex forms needed in advanced prosthetic limbs.

Beyond prosthetics, CNC lathes are also utilized to create customized handles for surgical and diagnostic tools, improving ergonomics and reducing fatigue for medical professionals. By leveraging CNC technology, manufacturers can produce these handles in small batches, catering to specific needs without the high costs associated with mass production. The adaptability of CNC lathes allows for rapid prototyping and iteration, ensuring that the final product meets the rigorous standards required in medical environments. This capability not only enhances the functionality of medical devices but also contributes to the overall safety and efficiency of medical procedures, demonstrating the versatile and essential role of CNC lathes in advancing medical technology.

CNC lathes for wood represent a significant advancement in machining and manufacturing, enabling precise and efficient creation of intricate wooden components. These advanced machines utilize computer numerical control (CNC) to automatically guide cutting tools along specified paths, transforming raw wood into finely detailed products. The application of CNC lathes in woodworking accommodates a broad range of industries, from furniture making to architectural components and artistic creations. The precision offered by CNC technology ensures that each piece is produced consistently according to exact specifications, reducing waste and maximizing material usage. This level of automation minimizes the need for skilled labor while speeding up production processes, contributing to cost savings and enhancing overall productivity.

In manufacturing, CNC lathes for woodworking offer unparalleled benefits in terms of customization and flexibility. These machines can be programmed to craft intricate designs that would be nearly impossible to achieve with traditional hand-turning methods. For instance, they can produce complex shapes, patterns, and hollowed-out forms with high accuracy, lending themselves to the production of bespoke furniture, custom millwork, and even musical instruments. Furthermore, by utilizing high-speed motors and a variety of cutting tools, CNC wood lathes are capable of maintaining smooth finishes and tight tolerances, which are critical in high-quality production. This technology is instrumental in small to medium-scale manufacturing operations looking to maintain competitive advantages through innovation, precision, and efficiency.

Sure, here’s an FAQ list about manufacturing CNC lathes for wood quality work from SourcifyChina Factory:

Q: What types of wood can the CNC lathe from SourcifyChina Factory work on?

A: Our CNC lathes are designed to handle a variety of wood types, including hardwoods like oak and maple, as well as softwoods such as pine and cedar.

Q: What is the maximum size of wood pieces that the lathe can accommodate?

A: The maximum size varies by model, but generally, our CNC lathes can handle wood pieces up to 36 inches in length and 12 inches in diameter.

Q: Are the CNC lathes user-friendly for beginners?

A: Yes, our CNC lathes come with user-friendly interfaces and comprehensive manuals. We also provide training support for beginners to get started quickly.

Q: What is the accuracy and precision of your CNC lathes?

A: Our CNC lathes offer high precision and accuracy, typically up to ±0.001 inches, ensuring high-quality results for intricate woodwork.

Q: Do you offer customization options for CNC lathes?

A: Yes, we provide a range of customization options including different motor powers, spindle speeds, and tool attachments to meet specific customer needs.

Q: What kind of maintenance is required for the CNC lathes?

A: Regular maintenance includes cleaning, lubrication of moving parts, and periodic calibration. Detailed maintenance instructions are provided in the user manual.

Q: How long does it take for delivery of a CNC lathe from SourcifyChina Factory?

A: Standard delivery times are 4-6 weeks after the order is confirmed, but this can vary depending on customization requirements and shipping destinations.

Q: What warranties and support services do you offer?

A: We offer a one-year warranty on parts and labor. Additionally, we provide ongoing technical support and access to an online resource center.

Q: Can I get a demo or visit the factory before purchasing?

A: Yes, we can arrange virtual demos, and potential customers are welcome to visit our factory by appointment to see the CNC lathes in action.

Q: What sets SourcifyChina Factory’s CNC lathes apart from other manufacturers?

When considering a CNC lathe for wood manufacturing from SourcifyChina factory, here are some key tips to ensure you make a well-informed decision:

1. Assess Your Needs:

– Determine the types of wood products you plan to manufacture.

– Consider the size and complexity of the items.

– Identify the volume of production to choose a lathe that meets your capacity requirements.

2. Machine Specifications:

– Look for a CNC lathe with the appropriate bed length, spindle speed, and motor power for your tasks.

– Ensure the machine has sufficient axis control for intricate designs.

– Verify the precision and accuracy of the lathe, especially for detailed woodworking.

3. Quality and Durability:

– Research the build quality and materials used in the construction of the CNC lathe.

– Seek machines with a sturdy frame and high-quality components to ensure longevity.

4. Software Compatibility:

– Check that the CNC lathe is compatible with your design software.

– Evaluate the ease of programming and the user interface.

5. Training and Support:

– Inquire about training programs offered by SourcifyChina to get your team up to speed.

– Ensure the factory provides robust customer support and after-sales service.

6. Cost and Budget:

– Compare prices of similar models to ensure you’re getting a competitive rate.

– Factor in shipping costs, import duties, and potential installation fees.

7. Reviews and References:

– Look for reviews or case studies from other customers.

– Ask for references to speak directly with existing users about their experiences.

8. Warranty and Maintenance:

– Check the warranty terms and what they cover.

– Understand the maintenance requirements and availability of spare parts.

By considering these factors, you can choose a CNC lathe from SourcifyChina that best fits your woodworking manufacturing needs and ensures efficient and high-quality production.

Sure, here is a concise FAQ for sourcing a CNC lathe for wood from SourcifyChina factory:

Q: What is SourcifyChina Factory?

A: SourcifyChina Factory is a specialized manufacturing service that helps businesses source and produce CNC lathes for wood from China. They handle everything from supplier verification to quality control.

Q: How do I place an order?

A: You can place an order by contacting SourcifyChina’s sales team via their official website or email. Provide details about your requirements, and they will guide you through the ordering process.

Q: What information do I need to provide to get a quote?

A: To get an accurate quote, you should provide specifications such as the type of wood, size, production volume, and any specific features you need in the CNC lathe.

Q: How long does it take to get a CNC lathe for wood from order to delivery?

A: The lead time varies depending on the complexity and customization of your order, but typically it ranges from 4 to 8 weeks. It’s best to confirm this with the SourcifyChina team when placing your order.

Q: What payment methods are accepted?

A: SourcifyChina generally accepts payments via bank transfer (T/T), PayPal, and sometimes credit cards. Payment terms will be outlined in the quotation or sales contract.

Q: Is there a warranty on the CNC lathes?

A: Yes, SourcifyChina provides a warranty for their CNC lathes. The specific terms and length of the warranty can be confirmed at the time of purchase.

Q: Can I request samples before placing a bulk order?

A: Yes, you can request a sample machine or a few units to evaluate before committing to a bulk order. Contact the sales team for details on sample costs and shipping.

Q: Do they offer after-sales support?

A: Yes, SourcifyChina offers comprehensive after-sales support including technical assistance, maintenance guidance, and parts replacement if needed.

Q: What quality control measures are in place?

A: SourcifyChina employs stringent quality control processes including inspections, testing, and compliance checks to ensure that the CNC lathes meet international standards.

Q: Can the CNC lathe be customized?

Sourcing a CNC lathe for wood from SourcifyChina factory can be a streamlined process if approached correctly. Here are some tips to guide you:

1. Initial Research:

– Website and Reviews: Start by visiting SourcifyChina’s official website. Look for product catalogs, specifications, and customer reviews.

– Evaluate Needs: Determine the specific requirements for your CNC lathe, such as size, power, capabilities, and budget.

2. Request for Information (RFI):

– Detailed Inquiry: Send a detailed email or request form to SourcifyChina. Include your specific needs and any customization requirements.

– Previous Projects: Ask for case studies or examples of similar projects they’ve handled for reference.

3. Quality Assurance:

– Certifications: Verify the certifications relevant to CNC machinery (ISO, CE).

– Materials and Build: Inquire about materials used and the manufacturing process to ensure durable and high-quality construction.

4. Factory Visit:

– On-Site Inspection: If possible, arrange for a visit to SourcifyChina to inspect their manufacturing facilities. This can give you a firsthand look at their production quality and operational standards.

5. Samples and Prototypes:

– Request samples or prototypes to evaluate the machine’s functionality before committing to a large order.

6. Negotiation and Payment Terms:

– Pricing: Negotiate pricing based on your budget and the scale of your order.

– Payment Terms: Clarify payment methods and terms. Discuss any upfront deposits, milestones, or escrow options for security.

7. After-Sales Support:

– Warranty and Maintenance: Ensure there is a warranty for the machine and inquire about ongoing maintenance support.

– Training: Ask if they provide training for operating the machinery, either in person or via online resources.

8. Logistics:

– Shipping: Coordinate about packaging, shipping, and delivery timelines. Ensure they handle international shipping if required.

Following these steps ensures a thorough vetting process, helping you procure a suitable CNC lathe for wood from SourcifyChina factory with confidence.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.