Unlock Reliable CNC Machine Cost Insights with SourcifyChina Factory Guide

Navigating CNC machine costs in China? SourcifyChina offers a comprehensive guide to reliable factory sourcing. Understand pricing, ensure quality, and streamline your procurement process with trusted insights and expertise for your manufacturing needs.

Choosing SourcifyChina Factory for purchasing CNC machines from China offers several benefits for buyers. First, they have an extensive network of reliable suppliers, ensuring top-quality machines at competitive prices. Their experience in the industry guarantees that you get the best value for your investment.

Additionally, SourcifyChina provides thorough quality control and inspection services. Every machine is rigorously tested and verified to meet international standards, which means fewer risks and headaches for buyers. This commitment to quality helps in building long-term business relationships.

SourcifyChina’s excellent customer service sets them apart as well. Their team is responsive, knowledgeable, and always ready to assist buyers throughout the purchase process. This ensures a smooth and hassle-free buying experience.

For cost-conscious buyers, SourcifyChina Factory offers transparent pricing with no hidden fees. They understand the importance of budgeting and provide detailed cost breakdowns upfront, making it easier for buyers to plan their expenditures accurately.

Lastly, their logistical expertise makes shipping and customs clearance seamless. SourcifyChina handles all paperwork and coordination, ensuring that your CNC machines arrive on time and in perfect condition. This comprehensive service minimizes delays and additional costs.

In conclusion, SourcifyChina Factory should be your go-to choice for purchasing CNC machines from China. Their blend of quality assurance, excellent customer service, transparent pricing, and logistical efficiency makes them a reliable and trustworthy partner for your business needs.

CNC machine costs vary widely based on machine type, capabilities, and additional features. Common types include milling machines, lathes, routers, and plasma cutters, each with its own price range.

– Entry-Level CNC Machines: $1,000 – $3,000

– Basic functionality, suitable for beginners and hobbyists.

– Limited speed and precision.

– Mid-Range CNC Machines: $5,000 – $30,000

– Higher precision and speed.

– Suitable for small to medium businesses.

– Expanded capabilities and better build quality.

– High-End CNC Machines: $30,000 – $100,000+

– Advanced features and high precision.

– High-speed operations with extensive tooling options.

– Industrial-grade, ideal for large-scale production.

– Specialized CNC Machines: $50,000 – $500,000+

– Customizable for specific tasks (e.g., 5-axis milling, multi-purpose functionalities).

– Includes brands like Haas, Mazak, and DMG Mori.

– Specialized software and accessories.

– Used CNC Machines: Various prices depending on age, condition, and model.

– Cost-effective alternative for high-quality machines.

– Consider maintenance history and potential refurbishment costs.

– Additional Costs:

– Tooling and accessories: $500 – $10,000+

– Software: $500 – $2,500+ per license.

– Maintenance and support: Annual costs vary.

Each option provides different advantages and is suitable for various levels of expertise and business needs.

The cost of a CNC (Computer Numerical Control) machine depends on various factors, such as size, type, capabilities, and brand. Applications extend across multiple industries due to the precision and automation they offer.

– Manufacturing Production: CNC machines streamline the manufacturing process, leading to reduced labor costs and waste.

– Prototyping: Rapid and precise prototyping for industries like automotive, aerospace, and electronics.

– Customized Components: Custom manufacturing of tools, dies, and molds.

– Woodworking: Precision cutting, carving, and shaping of wood products, increasing quality and efficiency.

– Medical Devices: Creation of precise components for medical equipment and surgical tools.

– Metalworking: Accurate machining of metals to create parts for heavy machinery and equipment.

– Jewelry Making: Crafting intricate designs and shapes in metals and other materials.

– Signage: Cutting and engraving signs with high precision and repeatability.

– Education: Training and educational tools for students in engineering and manufacturing courses.

– Art and Sculpture: Creating detailed and complex three-dimensional artworks.

– Aerospace: Manufacturing high-precision components required for aircraft and spacecraft.

The costs can start from several thousand dollars for entry-level machines to over a million for high-end, industrial-grade CNC machines. Considering the applications, an investment in CNC technology can significantly enhance productivity and quality.

SourcifyChina is known for offering competitive prices for CNC machines, making them an attractive option for businesses looking to integrate advanced manufacturing technologies. The company sources high-quality machinery at cost-effective rates.

The cost of CNC machines from SourcifyChina is influenced by various factors such as machine size, capabilities, and additional features. They provide transparent pricing which helps businesses budget effectively.

SourcifyChina’s CNC machines are built with durable materials ensuring long-lasting performance. This reliability minimizes maintenance costs and downtime, enhancing overall productivity for users.

With SourcifyChina, customers can expect value for money, combining affordability with superior quality, facilitating efficient and precise manufacturing processes.

SourcifyChina CNC Machine Cost

SourcifyChina offers competitive pricing on CNC machining services. By leveraging China’s cost-effective manufacturing ecosystem, they achieve significant savings without compromising quality. This helps businesses maximize their budget while getting high-precision parts.

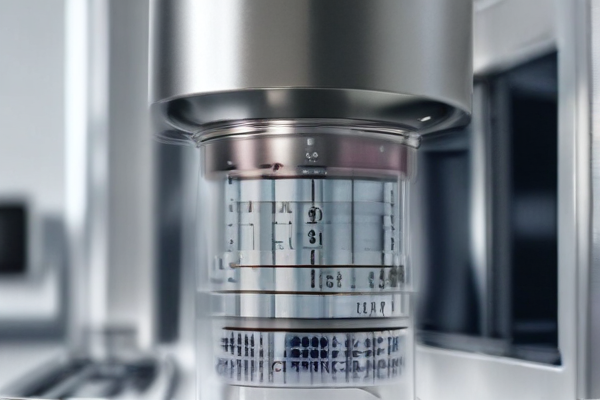

Quality Control

Quality control is a cornerstone of SourcifyChina’s CNC machining process. They utilize advanced inspection tools and techniques to ensure each part meets stringent standards. Regular audits and meticulous documentation further support their commitment to delivering high-quality products.

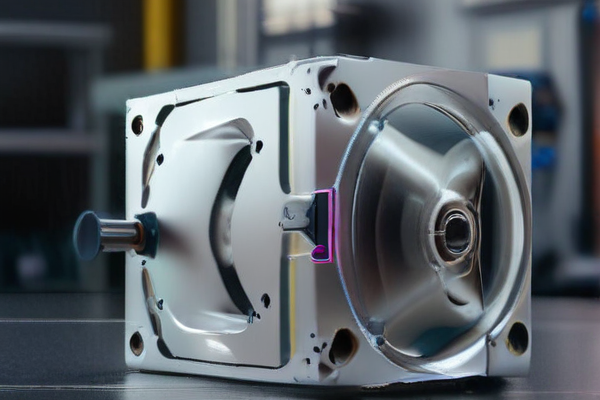

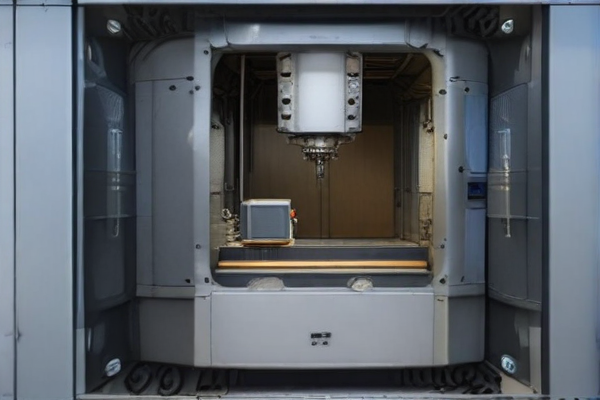

Manufacturing Process

The manufacturing process at SourcifyChina starts with detailed design reviews. They use state-of-the-art CAD/CAM software to create accurate models. Precision machining is then performed using high-end CNC machines, followed by rigorous quality checks.

Customer Satisfaction

Customer satisfaction is paramount for SourcifyChina. Their efficient processes, high quality, and cost-effective solutions make them a preferred choice for CNC machining. Continuous feedback loops ensure that they consistently meet and exceed client expectations.

SourcifyChina offers competitive CNC machine costs tailored to various manufacturing budgets. Their pricing strategy is transparent, ensuring that clients understand the value proposition behind each machine.

The capabilities of these CNC machines are extensive, ranging from high-precision cutting to complex shaping. SourcifyChina’s models support multiple materials including metals, plastics, and composites, making them versatile for different industries.

Advanced software integrations allow for easy programming and operation, even for intricate designs. This reduces the time needed for setup and increases overall production efficiency.

Furthermore, SourcifyChina provides exceptional after-sales support. This includes maintenance services and training programs, ensuring that customers maximize their machine’s potential.

In conclusion, SourcifyChina combines competitive costs, advanced capabilities, and excellent customer support to deliver a comprehensive CNC machining solution. This makes them an ideal partner for businesses looking to enhance their manufacturing processes.

Computer Numerical Control (CNC) machines offer numerous cost-related benefits, making them a valuable investment in modern manufacturing.

– Reduced Labor Costs: CNC machines can operate with minimal human intervention, reducing the need for skilled labor and decreasing overall labor costs.

– Higher Efficiency and Productivity: With their ability to run continuously and precisely, CNC machines increase production rates and reduce downtime.

– Lower Scrap Rates: The precision of CNC machining minimizes waste, thereby reducing the costs associated with raw materials and scrap management.

– Enhanced Production Flexibility: CNC machines can easily switch between jobs, allowing for versatile production without the need for extensive retooling.

– Improved Consistency and Quality: The high accuracy of CNC machines ensures consistent output, reducing the costs related to product defects and quality control.

– Energy Efficiency: Modern CNC machines are designed to be energy-efficient, which helps lower operational costs over time.

– Better Inventory Management: With precise production capabilities, CNC machines make it easier to maintain optimal inventory levels, thus reducing storage costs.

– Increased ROI: Although the initial investment can be significant, the long-term savings and increased productivity ensure a quick return on investment.

– Lower Maintenance Costs: Automated alerts and diagnostics in CNC machines help in predictive maintenance, reducing unexpected downtime and repair costs.

– Scalability: CNC machines allow for easy scalability of production processes, accommodating both small and large production runs efficiently.

By incorporating CNC machines into their operations, companies can experience significant cost savings and efficiency gains.

The cost of CNC (Computer Numerical Control) machines is influenced by various features that enhance their efficiency and precision. Understanding these features can help in making an informed purchasing decision.

– Machine Type: There are different types of CNC machines, such as lathes, mills, and routers, each with varying costs.

– Axis Configuration: More axes, like 5-axis machines, provide greater flexibility and precision but at a higher cost.

– Build Quality: Higher quality materials and construction increase durability but also the price.

– Spindle Speed and Power: Higher spindle speeds and power ratings often come with a higher price tag, suitable for more intensive workloads.

– Control System: Advanced control systems with user-friendly interfaces and enhanced features impact the overall cost.

– Size and Capacity: Larger machines with greater capacity to handle big projects tend to be more expensive.

– Software Compatibility: Machines compatible with advanced CAD/CAM software can be more costly.

– Tool Changers: Automatic tool changers can significantly add to the cost, enhancing efficiency by reducing manual intervention.

– Coolant Systems: Integrated coolant systems for continuous operation and improved lifespan are factors in the cost.

– Precision and Accuracy: Machines with tighter tolerances and higher precision levels generally cost more.

By considering these features, one can better evaluate the cost of a CNC machine relative to its capabilities and intended use.

SourcifyChina excels in offering CNC machining services at competitive costs, enabling businesses to produce high-quality custom products. By leveraging advanced technology and streamlined processes, they ensure cost-efficiency without compromising precision or quality.

Their CNC machining capabilities cater to a wide range of custom products, from prototypes to full-scale production runs. This versatility makes SourcifyChina a preferred partner for industries needing bespoke solutions.

Furthermore, SourcifyChina prides itself on its ability to handle complex projects. Their experienced team collaborates closely with clients to meet specific requirements, ensuring each project is completed to the highest standards.

Last but not least, SourcifyChina’s transparent pricing model ensures clients understand the cost breakdown, fostering trust and long-term partnerships. Their commitment to quality, efficiency, and affordability makes them a standout choice for CNC machining services.

SourcifyChina CNC Machine Cost is a distinguished company specializing in providing high-quality CNC machines at competitive prices for businesses globally. With its operational hub strategically located in China, SourcifyChina leverages the country’s manufacturing prowess and cost-efficiency to deliver exceptional value to its clients. The company excels in catering to a diverse range of industries, including automotive, aerospace, medical, and consumer electronics, where precision and reliability are paramount. SourcifyChina prides itself on a comprehensive service portfolio that encompasses everything from initial consultation and sourcing to post-purchase support and maintenance. By collaborating with top-tier suppliers and leveraging advanced logistics networks, they ensure timely delivery and consistent quality. Their commitment to customer satisfaction is reflected in their bespoke solutions, which are tailored to meet the unique requirements of each client. Furthermore, SourcifyChina invests in continuous innovation and adherence to international quality standards, ensuring that their CNC machines remain at the forefront of technology. This dedication to excellence, combined with a cost-conscious approach, enables businesses to optimize their operations and achieve significant cost savings, thereby bolstering their competitive edge in the market.

Aerospace, Defense, and Marine industries are sectors where precision, reliability, and durability of components are paramount. CNC machine cost is a significant factor in these applications given the advanced materials and intricate designs required. Aerospace components, for example, often need to withstand extreme temperatures and pressures, necessitating the use of high-grade materials like titanium and Inconel, which are challenging to machine. The precision required in shaping these materials often involves multi-axis CNC machines equipped with specialized tooling, driving up both the initial investment and operational costs. In defense, the manufacturing of weaponry and vehicular components must adhere to stringent specifications to ensure performance under combat conditions. Given the high stakes, defense contractors are willing to invest in state-of-the-art CNC machinery, understanding that the upfront cost contributes to the overall safety and effectiveness of the end product.

In marine applications, CNC machines are used to produce components ranging from small precision parts for navigation systems to large-scale structures like propellers and engine blocks. Saltwater environments pose unique challenges; parts must be resistant to corrosion and wear, which typically means working with stainless steel or specialized alloys. The cost of CNC machining in this sector includes not just the machinery but also the additional expense of selecting and handling these durable materials. Furthermore, the marine sector often requires custom, one-off parts for ship retrofits or repairs, adding to the complexity and cost of machining services. Despite the high costs, the use of precise CNC machines helps ensure that marine vessels operate safely and efficiently, justifying the investment in high-end CNC technology.

In the automotive industry, the cost of CNC machines is a significant factor influencing production decisions. CNC (Computer Numerical Control) machines enable high precision and repeatability, which are crucial for fabricating complex components such as engine blocks, transmission parts, and intricate aerodynamics-focused body panels. Despite the high initial cost—often running into hundreds of thousands of dollars—the return on investment is substantial due to the efficiency and accuracy these machines provide. By reducing manual labor and minimizing material waste, they lead to lower overall production costs. Furthermore, for custom and high-performance automotive parts, the precision of CNC machining ensures each piece meets stringent quality and safety standards, vital for maintaining a competitive edge in a technology-driven market.

In the electronics industry, the cost of CNC machines is balanced by the unmatched precision and scalability they offer. CNC machining is essential for producing intricate parts for electronic devices, such as circuit boards, heat sinks, and various housing components. Advanced CNC machines, though expensive, can handle the micro-level tolerances required by modern electronics. This precision is critical for the functionality and reliability of devices ranging from smartphones to aerospace electronics. The scalability of CNC machines allows manufacturers to easily switch between different products and prototypes, catering to rapid updates and innovations in the technology sector. This flexibility, despite the initial financial outlay, helps reduce time-to-market and enables quick adaptation to consumer demands, making the overall investment worthwhile.

CNC (Computer Numerical Control) machines have revolutionized the construction industry, particularly in the fabrication of complex architectural elements and structural components. The cost of CNC machines in construction is often a significant investment, but it yields substantial returns in terms of precision, efficiency, and reduced labor costs. High-end CNC machines, while expensive, enable the seamless creation of intricate designs from various materials such as steel, wood, and concrete. This precision leads to fewer errors and a higher quality of finished products, ultimately reducing waste and saving on materials costs. Additionally, automation via CNC machines accelerates project timelines, allowing construction firms to complete projects quicker than traditional methods, offering a competitive edge in the market.

In the energy sector, CNC machines play a crucial role in the manufacturing of critical components for renewable and non-renewable energy systems. The initial cost of these machines may be steep, but their ability to consistently produce high-tolerance parts for turbines, engines, and pipelines can justify the expenditure. For instance, CNC machining is essential in the production of wind turbine blades and parts for solar panel mounts, where precision affects performance and longevity. Similarly, in the petroleum industry, CNC machines are used to fabricate precise components for drilling equipment and pipelines, which require exact specifications for safety and efficiency. Over time, the high initial cost of CNC machines is offset by the benefits of reduced downtimes, increased production speeds, and lower incidences of part failure, contributing to the overall reliability and sustainability of energy infrastructure.

The application of CNC (Computer Numerical Control) machines within the industrial equipment industry plays a pivotal role in enhancing efficiency, precision, and scalability. Cost considerations are vital when integrating CNC machines, as they represent a significant capital investment. Initial costs include the price of the machine itself, installation, and training for operators. Many CNC machines come with advanced features like multi-axis machining, automated tool changers, and real-time monitoring systems, contributing to a higher upfront cost. However, these features also enable complex, high-precision tasks which manual machines or less advanced automation can’t handle, delivering a return on investment through improved production capabilities and reduced scrap rates. The modern CNC machines’ capability to consistently produce intricate parts with tight tolerances significantly lowers the cost per unit over time, providing a competitive edge to businesses in the industrial equipment sector.

Beyond the initial investment, the long-term costs associated with CNC machines are also noteworthy. Maintenance, software updates, and consumables like cutting tools and lubricants contribute to the ongoing costs. However, by facilitating high-speed and high-precision manufacturing, CNC machines often reduce labor costs and minimize material waste, offering cost-efficiency in the long run. Additionally, the versatility of CNC machines allows for production flexibility—enabling quick changeovers between different machining tasks, which is crucial for meeting varying customer demands without substantial downtime. Industries ranging from aerospace to automotive rely heavily on CNC machinery to streamline production processes and ensure high-quality output. Hence, the cost of CNC machines, while substantial, integrates well into the long-term strategic investments of industrial equipment manufacturers, ultimately leading to enhanced productivity and profitability.

Computer Numerical Control (CNC) machines have revolutionized the production of medical devices through their precise, efficient, and repeatable manufacturing capabilities. These machines play a pivotal role in the creation of complex medical implants, surgical instruments, and prosthetics, where the safety and well-being of patients remain paramount. The intricacy and accuracy afforded by CNC technology allow for the production of parts with microscopic tolerances, which are crucial in applications such as joint replacements, dental implants, and cardiovascular devices. This precision reduces the potential for human error and enhances the reliability of the medical devices, thereby contributing to better patient outcomes. However, CNC machines represent a significant financial investment. The cost can range from tens of thousands to several hundred thousand dollars, depending on factors like machine capabilities, complexity, and automation levels.

Beyond the initial acquisition costs, there are additional expenses associated with CNC machine operation and maintenance. These include costs for specialized tooling, CAD/CAM software, skilled operators, and regular maintenance to ensure optimal performance and longevity of the machines. While the startup costs can be substantial, the long-term benefits often justify the investment. High-precision CNC machining not only reduces material waste and manufacturing errors, enhancing overall cost-efficiency, but also enables customization and rapid prototyping. This agility is particularly valuable in the medical device sector, where timely development and adaptation to regulatory changes are critical. Consequently, while the cost of CNC machinery may be steep, the return on investment from improved efficacy, reduced risk, and faster product development cycles makes it an essential component in the advanced manufacturing of medical devices.

Computer Numerical Control (CNC) machines are a cornerstone of modern machining and manufacturing, providing unprecedented precision and automation capabilities. The costs associated with CNC machines are multifaceted and can significantly influence decision-making in industries ranging from aerospace to medical device manufacturing. While the initial purchase price of a CNC machine can be high, often ranging from tens of thousands to several million dollars depending on its complexity and capabilities, the long-term benefits can justify this investment. These machines are capable of operating 24/7, drastically reducing labor costs and human error while enhancing product quality through high precision and repeatability. Additionally, many industries benefit from the versatility of CNC machines, which can perform a wide array of operations like milling, turning, and drilling with minimal changeover time between tasks.

However, it is crucial to also consider the hidden and ancillary costs associated with CNC machines. Maintenance and repair expenses can add up, especially if the machinery is operated in high-volume production environments. Regular servicing is essential to maintain accuracy and prolong machine life, often requiring skilled technicians and specialized parts. Energy consumption, software licensing fees, and the cost of training operators are other components that contribute to the total cost of ownership. Furthermore, as technology advances, older CNC models may become obsolete, necessitating periodic upgrades or replacements to stay competitive. Businesses must conduct a thorough cost-benefit analysis, taking these ongoing expenses into account, to fully grasp the economic implications of integrating CNC machinery into their production lines. This holistic understanding helps ensure that the operational efficiencies gained by CNC machines outweigh their financial burdens in the long term.

FAQ: Manufacturing CNC Machine Cost and Quality Work from SourcifyChina Factory

1. What is the cost of manufacturing a CNC machine at SourcifyChina factory?

The cost of manufacturing a CNC machine at SourcifyChina can vary depending on the specifications, complexity, and production volume. Typically, prices range from $10,000 to $100,000. Contact SourcifyChina directly for a detailed quotation based on your specific requirements.

2. How do SourcifyChina’s costs compare to other factories?

SourcifyChina offers competitive pricing due to economies of scale, advanced manufacturing techniques, and efficient supply chain management. While the exact cost can differ, SourcifyChina aims to provide cost-effective solutions without compromising on quality.

3. What quality standards does SourcifyChina adhere to?

SourcifyChina adheres to international quality standards including ISO 9001 and CE certification. They implement strict quality control measures throughout the manufacturing process to ensure precision, reliability, and durability of their CNC machines.

4. Can SourcifyChina produce custom CNC machines?

Yes, SourcifyChina specializes in both standard and custom CNC machine manufacturing. They work closely with clients to understand their unique needs and design machines that meet specific technical and operational requirements.

5. How long does it take to manufacture a CNC machine at SourcifyChina?

The lead time for manufacturing a CNC machine can range from 4 to 12 weeks, depending on the complexity and customization required. It’s recommended to discuss timelines with SourcifyChina during the initial consultation phase.

6. What after-sales support does SourcifyChina provide?

SourcifyChina offers comprehensive after-sales support, including installation assistance, training for machine operators, regular maintenance services, and technical support to address any issues that may arise.

7. How can I ensure the quality of the CNC machine before shipment?

Clients are encouraged to visit SourcifyChina’s factory for a pre-shipment inspection. Additionally, third-party quality inspection services can be arranged to provide an independent assessment of the machine’s quality and specifications.

8. What materials can SourcifyChina’s CNC machines handle?

When considering CNC machine cost manufacturing from factories like SourcifyChina, it’s crucial to focus on several key aspects to optimize efficiency and cost-effectiveness. Here are some tips:

1. Understand Your Needs:

– Specify the materials and tolerances required for your product.

– Determine the complexity and volume of your production.

2. Choose the Right Machine:

– Match the machine’s capabilities with your project requirements – different machines handle different materials and precision levels.

– Consider multi-axis CNC machines for complex parts to reduce manufacturing time and costs.

3. Request Detailed Quotes:

– Get itemized quotes from SourcifyChina, including setup, labor, materials, and shipping.

– Compare costs with other suppliers to ensure competitive pricing.

4. Optimize Design for Manufacturability (DFM):

– Simplify part designs to reduce machining time and potential errors.

– Minimize tight tolerances and complex geometries where possible.

5. Quality Assurance:

– Check the factory’s certification and quality control standards.

– Request samples to verify the quality before full production.

6. Leverage Technology:

– Utilize CAD/CAM software to streamline design and production.

– Implement IoT and data analytics to monitor and optimize the production process.

7. Communication:

– Maintain clear and frequent communication with the factory to address issues promptly and ensure alignment.

– Use translation services if necessary to avoid misunderstandings.

8. After-Sales Support:

– Ensure that the factory provides robust after-sales support, including maintenance and troubleshooting services.

Following these tips can help you manage CNC machine cost manufacturing effectively while ensuring high-quality outcomes from SourcifyChina.

Sure! Here are some frequently asked questions (FAQs) about sourcing CNC machine costs from the SourcifyChina factory:

1. What factors influence the cost of a CNC machine?

The cost of a CNC machine from SourcifyChina can be influenced by various factors, including machine specifications, size, brand, customization requirements, and additional features. Higher precision and advanced technology typically increase the cost.

2. How can I get a detailed quote for a CNC machine?

To get a detailed quote, you can contact SourcifyChina directly through their website or by email. Provide specific requirements like machine type, dimensions, and any special features you need. They will then send you a comprehensive quote.

3. Is there a minimum order quantity (MOQ) for CNC machines?

SourcifyChina typically does not have a strict MOQ for CNC machines. However, bulk orders may qualify for discounts or special pricing. It’s best to discuss your order quantity with their sales team.

4. What are the payment terms for purchasing a CNC machine from SourcifyChina?

Payment terms vary but generally include a deposit upon order confirmation and the balance before shipping. SourcifyChina may offer flexible payment options like L/C (Letter of Credit), T/T (Telegraphic Transfer), or even PayPal for smaller orders.

5. How long does it take to manufacture and deliver a CNC machine?

The lead time for manufacturing a CNC machine can range from a few weeks to several months, depending on the complexity and customization required. Shipping time depends on the destination but typically takes between 2-6 weeks.

6. Are there warranties or after-sales support available?

Yes, SourcifyChina provides warranties that cover manufacturing defects and technical support. The duration and terms of the warranty can vary, so it is advisable to confirm these details before making a purchase.

7. Can I request samples or factory visits before placing an order?

SourcifyChina welcomes potential clients to visit their factory. However, obtaining a sample CNC machine might not be feasible due to the high cost. Instead, you can request detailed product videos, brochures, and technical specifications.

8. Do they offer customization services for CNC machines?

Yes, SourcifyChina offers customization services to tailor CNC machines to specific needs. Discuss your requirements with their technical team to explore feasible customization options.

Feel free to contact SourcifyChina for any additional questions or specific information you may need.

Sourcing CNC machine costs from a factory like SourcifyChina requires strategic planning and careful communication. Here are some concise tips for effectively sourcing costs:

1. Research Thoroughly: Understand the types of CNC machines SourcifyChina offers, including their specifications and capabilities. Knowledge of different machines will help in cost comparison.

2. Prepare Detailed Requirements: Clearly specify the type of CNC machine, its intended use, material preferences, and necessary features. The more detailed your requirements, the more accurate the cost estimate will be.

3. Use Online Platforms: Visit SourcifyChina’s official website or reliable sourcing platforms like Alibaba or Global Sources. These platforms often have detailed listings with pricing and contact details.

4. Request a Quote (RFQ): Send an RFQ to SourcifyChina. Ensure your RFQ is comprehensive, including technical drawings, quantity, and any special requirements.

5. Compare Quotes: Obtain quotes from multiple vendors, if possible. This helps in understanding the market range and negotiation leverage.

6. Inquire About Additional Costs: Ask about shipping, customs, installation, training, and any other hidden costs that might affect the total expenditure.

7. Negotiate: Engage in negotiations conscientiously. Building a rapport with the factory representative can lead to better pricing and terms.

8. Check Reviews and References: Research customer reviews and ask for references to verify the reliability and quality of SourcifyChina’s CNC machines.

9. Visit the Factory: If possible, arrange a visit to SourcifyChina’s factory to inspect the machines and confirm the quality and specifications.

10. Request Samples or Demos: If feasible, ask for sample parts or a demonstration to evaluate the machine’s performance.

11. Payment Terms: Clarify payment terms and conditions early in the process. Understand the payment schedule and any associated financial risks.

By following these tips, you can efficiently source accurate CNC machine costs from SourcifyChina while ensuring you meet your budget and quality needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.