Technology and Applications of cnc machine cut wood

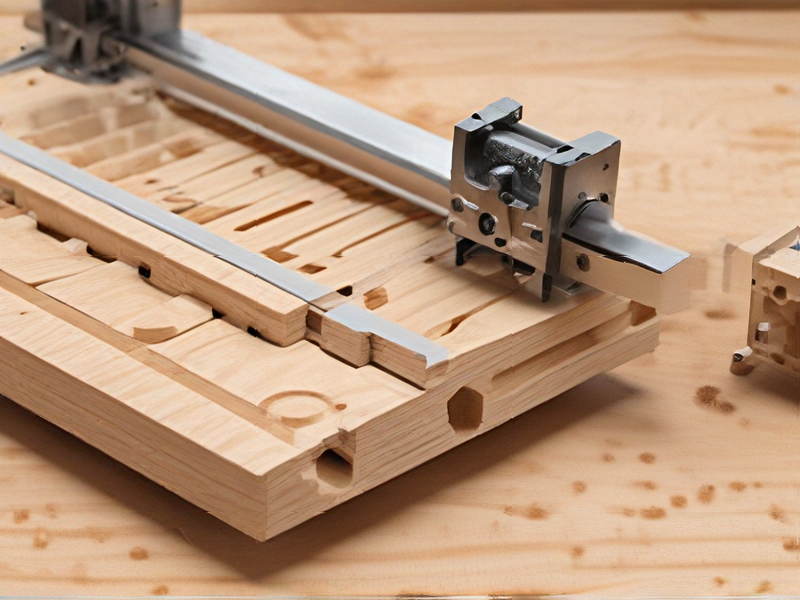

CNC (Computer Numerical Control) machines have revolutionized the woodworking industry by offering precision, efficiency, and versatility in wood cutting and shaping. These machines are programmed using computer software to execute precise cuts and designs on wood, allowing for the creation of complex shapes and patterns that would be challenging or impossible to achieve manually.

Technology of CNC Wood Cutting

1. Components:

– Controller: Acts as the brain of the CNC machine, interpreting design files and controlling the motion of the machine.

– Spindle: The rotating cutting tool that shapes the wood.

– Table: The surface where the wood is secured during cutting.

– Axes: CNC machines typically operate on multiple axes (X, Y, Z) to enable three-dimensional cutting.

2. Software:

– CAD (Computer-Aided Design): Used to create detailed design models.

– CAM (Computer-Aided Manufacturing): Converts CAD models into machine-readable code (G-code) that instructs the CNC machine on how to perform the cuts.

3. Operation:

– The operator designs the model in CAD software and then uses CAM software to generate the G-code.

– The CNC machine reads the G-code and executes the commands, precisely moving the spindle along the designated paths to cut the wood.

Applications

1. Furniture Manufacturing: CNC machines are widely used to produce intricately designed furniture pieces with high precision and repeatability.

2. Cabinet Making: Allows for the efficient and precise cutting of components for cabinets and other storage solutions.

3. Art and Sculptures: Enables artists to create detailed and complex wooden sculptures and decorative items.

4. Prototyping and Custom Work: Useful for creating prototypes and custom woodwork due to the machine’s ability to produce unique designs with high accuracy.

Advantages

– Precision: Ensures consistent and accurate cuts.

– Efficiency: Reduces material waste and increases production speed.

– Flexibility: Capable of performing a variety of cuts and designs on different wood types.

CNC machines have significantly enhanced the capabilities of woodworkers, enabling them to achieve intricate designs and high productivity with greater ease.

Quality Testing Methods for cnc machine cut wood and how to control quality

Quality testing methods for CNC machine-cut wood typically involve several key steps to ensure consistent and high-quality output:

1. Dimensional Accuracy: Use calipers or digital measuring tools to verify dimensions against design specifications. This ensures parts are cut to the correct size and shape.

2. Surface Finish: Inspect the surface smoothness and quality using visual inspection or tactile assessment. Any roughness or imperfections can be identified and addressed.

3. Edge Quality: Check the edges for burrs or splinters that could affect the final product’s appearance or functionality. Deburring tools or sandpaper may be used to smooth edges.

4. Assembly Fit: Assemble parts where necessary to check how well they fit together. This ensures that the CNC cuts are precise and consistent across multiple pieces.

5. Material Integrity: Verify that the wood material itself is free from defects such as knots, cracks, or warping that could affect the structural integrity of the final product.

To control quality effectively:

– Establish Standards: Define clear quality standards and tolerances for dimensions, surface finish, and other parameters based on customer requirements or industry standards.

– Regular Inspection: Implement regular inspection checkpoints during and after the CNC cutting process to catch any deviations early.

– Operator Training: Train CNC machine operators on quality standards, proper machine settings, and maintenance to ensure consistent performance.

– Feedback Loop: Establish a feedback loop where any quality issues are documented, analyzed, and used to improve processes or adjust machine settings.

– Documentation: Maintain detailed records of inspection results and any corrective actions taken to track performance and ensure consistency over time.

By implementing these methods and controls, manufacturers can maintain high-quality standards in CNC machine-cut wood products, ensuring customer satisfaction and minimizing waste or rework.

Tips for Procurement and Considerations when Purchasing from cnc machine cut wood

When purchasing CNC machine-cut wood, consider the following tips:

1. Material Selection: Choose the type of wood based on your project’s requirements (e.g., hardwood for durability, softwood for flexibility).

2. Precision and Quality: Verify the CNC machine’s capabilities and the quality of previous work to ensure it meets your standards.

3. Customization Options: Check if the supplier offers customization in terms of dimensions, finishes, and additional processing like sanding or staining.

4. Lead Times and Production Capacity: Understand the supplier’s lead times and capacity to meet your project deadlines.

5. Cost and Value: Compare prices while considering the overall value, including quality, customization options, and service.

6. Supplier Reliability: Assess the supplier’s reputation, reliability in delivering on time, and customer service.

7. Packaging and Shipping: Inquire about packaging methods to prevent damage during transit and shipping costs.

8. Environmental Considerations: If important to you, inquire about the source of the wood and the supplier’s sustainability practices.

By focusing on these considerations, you can ensure that your procurement process for CNC machine-cut wood is efficient, meets your project requirements, and delivers the expected quality and value.

FAQs on Sourcing and Manufacturing from cnc machine cut wood in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing CNC machine-cut wood in China:

1. What are the benefits of sourcing CNC-cut wood from China?

Sourcing from China offers cost-efficiency due to lower labor and production costs. The country also has a robust infrastructure for manufacturing and exporting CNC-cut wood products.

2. How can I ensure quality when sourcing from China?

Quality assurance can be ensured by conducting thorough supplier audits, requesting samples, and implementing clear specifications and quality control measures in your contract with the supplier.

3. What types of wood materials are commonly used in CNC machining in China?

Popular wood materials include plywood, MDF (Medium Density Fiberboard), solid wood (such as pine, oak, and walnut), and bamboo. Suppliers often offer various options depending on the project requirements.

4. What are the typical lead times for manufacturing CNC-cut wood products in China?

Lead times can vary based on factors like order size, complexity of designs, and supplier capabilities. Generally, they range from a few weeks to a couple of months.

5. How do I handle logistics and shipping when sourcing from China?

It’s advisable to work closely with freight forwarders who specialize in international shipping. They can assist with customs clearance, shipping arrangements, and logistics to ensure timely delivery.

6. What are the potential challenges or risks of sourcing from China?

Challenges may include language barriers, cultural differences, intellectual property protection, and quality consistency. It’s essential to partner with reputable suppliers and have clear agreements in place.

7. Are there environmental considerations when sourcing CNC-cut wood from China?

Yes, sustainability and responsible sourcing are growing concerns globally. Many Chinese manufacturers are adopting sustainable practices and certifications like FSC (Forest Stewardship Council) to address these issues.

Navigating the sourcing and manufacturing process in China requires careful planning, clear communication, and a thorough understanding of both the benefits and challenges involved.